The global smart lock market is experiencing robust expansion, driven by rising demand for home automation, enhanced security solutions, and increasing adoption of IoT-enabled devices. According to Mordor Intelligence, the smart lock market was valued at USD 2.16 billion in 2023 and is projected to grow at a CAGR of over 15.8% from 2024 to 2029. Truss locks—engineered for superior structural integrity and often integrated with smart technology—represent a rapidly growing segment within this space. As both residential and commercial sectors prioritize access control and aesthetic design, manufacturers are innovating with advanced materials, cybersecurity features, and seamless smart home integration. Based on market presence, product innovation, and technological advancements, here are the top 7 truss lock manufacturers shaping the future of secure access.

Top 7 Truss Locks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ProX XT

Domain Est. 2013

Website: proxdirect.com

Key Highlights: Our Truss segments are welded and manufactured in our own factory. This top plate also includes four twist-lock connectors that can be mounted securely on the ……

#2 Raising the Roof

Domain Est. 2017

Website: trusslox.com

Key Highlights: Made with a high impact resistant material, TrussLox provides built-in locking technology that safely and easily locks trusses 24” on-center ……

#3 TRUSLOCK, Inc

Domain Est. 1999

Website: truslock.com

Key Highlights: Truslock is a re-usable tool designed to space and brace roof trusses during installation. This tool’s unique design enables it to lock onto the truss as it ……

#4 Contact Us

Domain Est. 2007

Website: lockharttruss.com

Key Highlights: 309 Bee Creek Rd. Red Rock, TX 78662.. Phone. 512-398-5300….

#5 VMB

Website: prolifts.es

Key Highlights: We are specialists in design, manufacture and distribution of Trusses, Rigging, Towers and Stage Systems for the audiovisual sector and events….

#6 Never underestimate the power of Truss

Website: army.mil

Key Highlights: Truss, a chemical, biological, radiological and nuclear specialist deployed in support of US Army Central, placed second in the weightlifting competition and ……

#7 Truss Design & Manufacturing

Domain Est. 1996

Website: doitbest.com

Key Highlights: Our trained staff can design and manufacture quality wood roof trusses for residential, agricultural, and commercial jobs, of any size, large or small. Lumber ……

Expert Sourcing Insights for Truss Locks

H2: Market Trends for Truss Locks in 2026

The global truss lock market is projected to experience significant evolution by 2026, driven by technological innovation, rising security demands, and shifts in construction and industrial practices. Truss locks—specialized mechanical fasteners used primarily in structural and architectural applications—continue to play a critical role in ensuring the stability and safety of truss systems in residential, commercial, and infrastructure projects. The following analysis highlights key market trends shaping the truss lock industry in 2026:

-

Increased Demand from the Construction Sector

The global construction industry is rebounding post-pandemic, with significant investments in housing, smart buildings, and public infrastructure. In emerging economies, urbanization and government-backed housing programs are fueling demand for efficient and reliable structural components, including truss locks. The adoption of modular and prefabricated construction methods—where truss systems are pre-assembled off-site—has amplified the need for high-performance truss locks that ensure rapid, secure assembly. -

Growth of Smart and Connected Building Technologies

By 2026, the integration of Internet of Things (IoT) and Building Information Modeling (BIM) into construction processes is influencing truss lock design. While truss locks are primarily mechanical, developments in smart monitoring systems are leading to “intelligent” structural components. Some manufacturers are exploring embedded sensors within truss connections to monitor stress, corrosion, or displacement, enabling predictive maintenance. Although not yet mainstream, this trend is expected to gradually impact truss lock specifications and performance standards. -

Emphasis on Sustainability and Material Efficiency

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to adopt sustainable materials and reduce carbon footprints. In 2026, truss lock producers are increasingly using recycled steel and aluminum alloys, as well as corrosion-resistant coatings that extend product lifespan and reduce maintenance. Lightweight, high-strength truss lock designs are also gaining favor to reduce transportation emissions and material waste. -

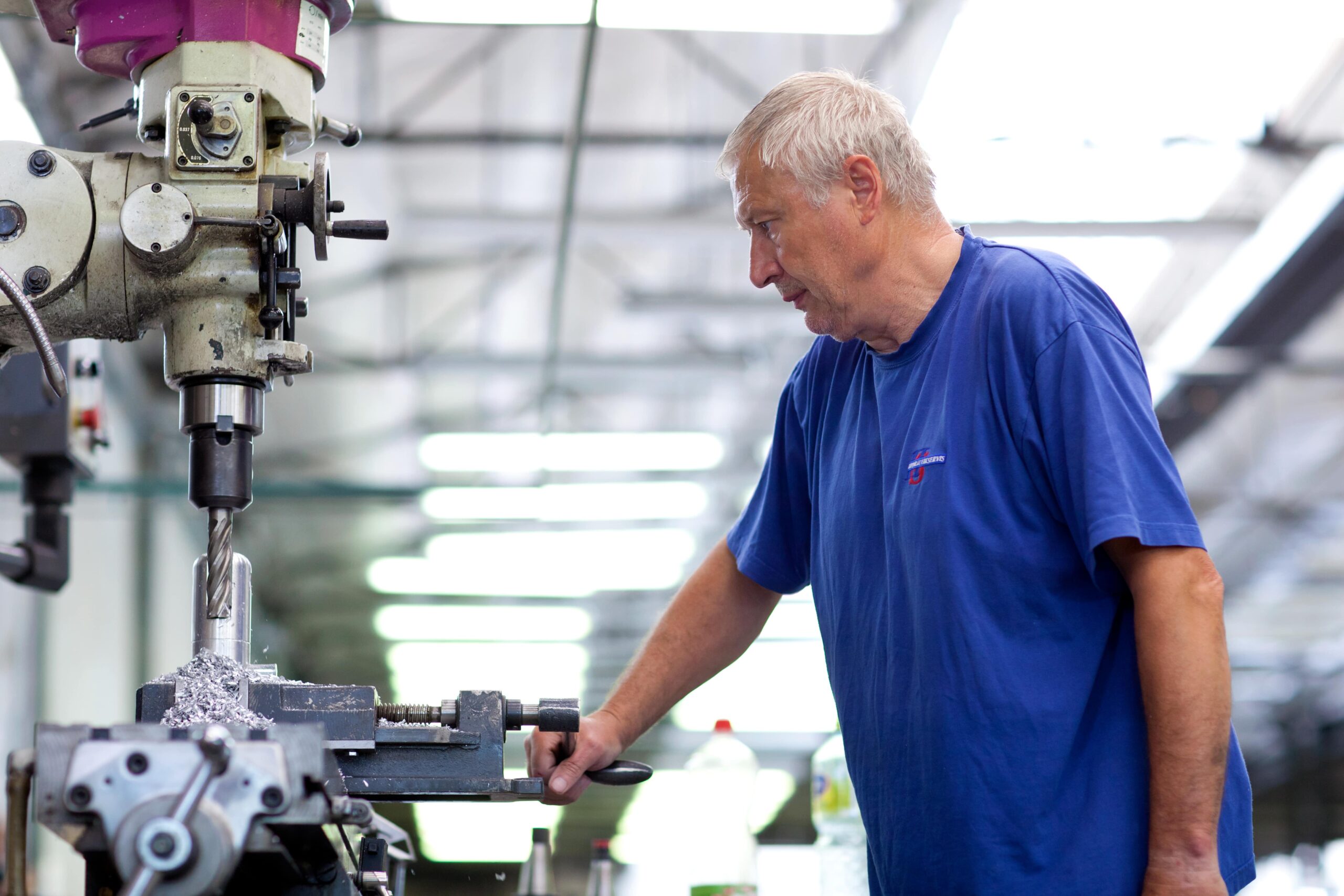

Advancements in Manufacturing and Automation

Precision engineering and automation in manufacturing are improving the consistency, strength, and scalability of truss lock production. CNC machining, robotic assembly, and quality control systems ensure tighter tolerances and compliance with international standards (e.g., ISO, ASTM). This technological shift enables faster production cycles and customization, catering to diverse architectural designs and regional building codes. -

Regional Market Dynamics

- North America remains a leading market due to high adoption of wood truss systems in residential construction, especially in the U.S. and Canada. Building code updates emphasizing structural resilience after natural disasters are increasing demand for certified truss locking systems.

- Asia-Pacific is the fastest-growing region, driven by construction booms in China, India, and Southeast Asia. Local manufacturers are scaling up production to meet demand while improving quality to compete with Western brands.

-

Europe focuses on energy-efficient and modular construction, supporting demand for precision-engineered truss locks compatible with timber and hybrid building systems.

-

Consolidation and Competitive Landscape

The truss lock market in 2026 is witnessing consolidation, with larger manufacturers acquiring niche players to expand product portfolios and geographic reach. Key players are investing in R&D to differentiate through design innovation, corrosion resistance, and ease of installation. Competitive pricing and certification compliance are critical success factors, especially in public infrastructure tenders. -

Regulatory and Safety Standards

Stricter building codes related to seismic resilience, wind loads, and fire safety are influencing truss lock performance requirements. In 2026, third-party certification and traceability of truss lock components are becoming standard, especially in high-risk zones. This drives demand for tested and documented locking systems from reputable suppliers.

In conclusion, the 2026 truss lock market is characterized by technological integration, sustainability imperatives, and robust construction activity. Companies that innovate in materials, digital compatibility, and manufacturing efficiency are best positioned to capture growth in this evolving segment.

Common Pitfalls Sourcing Truss Locks: Quality and Intellectual Property Risks

Poor Manufacturing Quality and Material Deficiencies

One of the most frequent issues when sourcing truss locks—especially from low-cost overseas suppliers—is inconsistent or substandard manufacturing quality. Many budget manufacturers use inferior materials such as low-grade zinc alloys or poorly tempered steel, leading to premature wear, corrosion, or mechanical failure under load. Components like cams, springs, and locking mechanisms may not meet engineering tolerances, resulting in unreliable performance or difficulty in installation. Without rigorous quality control and third-party testing, these defects may go unnoticed until after installation, leading to costly replacements and safety concerns.

Lack of Compliance with Industry Standards

Truss locks used in structural applications must often comply with building codes and industry standards (e.g., ASTM, AISC, or local regulatory requirements). Many off-brand or unverified suppliers fail to provide documentation proving compliance. Sourcing non-compliant truss locks can result in failed inspections, project delays, or liability in the event of structural failure. Always verify that the product meets required performance and safety certifications relevant to your region and application.

Counterfeit or Copycat Products Infringing on IP

Reputable truss lock designs—such as those from established brands like Simpson Strong-Tie or USP—are often protected by patents, trademarks, and trade dress. A major pitfall is sourcing counterfeit or knockoff products that mimic these designs but lack proper licensing. These clones not only violate intellectual property (IP) rights but also typically underperform due to design modifications or inferior engineering. Using such products can expose contractors, distributors, or building owners to legal liability, including fines or injunctions for IP infringement.

Inadequate Testing and Load Performance Data

Genuine truss lock systems undergo extensive load testing and finite element analysis to ensure structural integrity. Imitation products may lack verifiable test data or provide falsified engineering reports. Relying on unverified performance claims can compromise the safety and code compliance of an entire structure. Always demand access to independent test reports, load tables, and engineering certifications from the supplier.

Supply Chain Transparency and Traceability Issues

Many low-cost truss locks originate from opaque supply chains with limited traceability. This makes it difficult to verify the actual manufacturer, material sources, or production conditions. Without transparency, it’s challenging to ensure consistency across batches or respond effectively to quality issues. Establishing relationships with reputable suppliers who provide full chain-of-custody documentation helps mitigate this risk.

Hidden Costs from Rework and Liability

While imitation or low-quality truss locks may offer short-term cost savings, the long-term risks often outweigh the benefits. Failures can lead to expensive rework, project delays, and potential liability in the case of structural incidents. Additionally, using IP-infringing products can result in legal action, recalls, or reputational damage for contractors and developers.

To avoid these pitfalls, prioritize sourcing from authorized distributors, verify certifications, request performance data, and conduct periodic quality audits. Investing in genuine, code-listed products protects both structural integrity and legal compliance.

Logistics & Compliance Guide for Truss Locks

Overview

This guide outlines the essential logistics and compliance considerations for the shipment, handling, and regulatory adherence of truss locks. Truss locks—commonly used in construction to secure modular trusses and scaffolding systems—must be managed in accordance with international and domestic regulations to ensure safety, efficiency, and legal compliance throughout the supply chain.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit and to ensure product integrity. Truss locks should be packaged as follows:

– Secure Bundling: Group truss locks by size and model, secured with rust-inhibitive strapping or shrink-wrapping.

– Corrosion Protection: Apply anti-corrosion coating or vapor corrosion inhibitors (VCI) if shipping to humid or marine environments.

– Palletization: Stack bundles on durable, ISPM-15 compliant wooden or recyclable plastic pallets. Ensure even weight distribution and use edge protectors to avoid load shifting.

– Labeling: Clearly label each package with product type, quantity, part number, batch/lot number, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

Transportation and Shipping

Compliance with transportation standards ensures safe and on-time delivery:

– Domestic Shipping (US/Canada): Follow FMCSA (Federal Motor Carrier Safety Administration) guidelines for load securement. Use DOT-compliant trailers and ensure proper weight distribution.

– International Shipping: Comply with IMDG Code for sea freight, IATA regulations for air freight, and ADR for European road transport as applicable.

– Hazard Classification: Truss locks are typically non-hazardous, but verify material composition (e.g., galvanized steel, zinc plating) for any restricted substances.

– Customs Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin. Include HTS (Harmonized Tariff Schedule) code—typically 7326.90 for forged or stamped steel hardware.

Regulatory Compliance

Ensure truss locks meet all applicable standards and certifications:

– OSHA & ANSI Standards: Confirm compliance with OSHA 1926 and ANSI A10.9 for construction hardware safety. Truss locks must meet required load and shear strength ratings.

– CE Marking (EU): For sales in Europe, truss locks must comply with Construction Products Regulation (CPR) EN 13814 or relevant structural joining standards and bear CE marking.

– RoHS and REACH Compliance: Verify that materials and finishes (e.g., plating, coatings) do not contain restricted substances such as lead, cadmium, or phthalates.

– California Proposition 65: Provide warnings if products contain listed chemicals above safe harbor levels.

Import and Export Controls

- Export Classification: Determine if truss locks require an ECCN (Export Control Classification Number) under the EAR (Export Administration Regulations). Most truss locks fall under EAR99 (low-risk, non-controlled items).

- Sanctioned Destinations: Screen end-users and destinations against OFAC, BIS, and UN sanctions lists. Avoid shipments to embargoed countries (e.g., Iran, North Korea).

- Import Duties and Trade Agreements: Leverage FTAs (e.g., USMCA, CETA) where applicable to reduce or eliminate tariffs.

Quality Assurance and Traceability

- Batch Tracking: Maintain lot traceability from raw material to finished product to support recalls or audits.

- Inspection Protocols: Conduct pre-shipment inspections per ISO 2859-1 (AQL standards) to verify dimensions, strength, and finish.

- Documentation Retention: Archive compliance certificates, test reports, and shipping records for a minimum of 5 years.

Environmental and Sustainability Practices

- Recyclable Materials: Use recyclable packaging and promote returnable/reusable containers where feasible.

- Waste Management: Partner with certified vendors for scrap metal recycling and hazardous waste disposal (e.g., plating sludge).

- Carbon Reporting: Measure and report logistics-related emissions under frameworks such as GHG Protocol.

Conclusion

Adhering to this logistics and compliance guide ensures that truss locks are safely transported, legally compliant, and meet global market requirements. Regular audits, staff training, and supplier collaboration are recommended to maintain continuous compliance and operational excellence.

Conclusion on Sourcing Truss Locks

Sourcing truss locks requires careful consideration of quality, supplier reliability, cost-efficiency, and compatibility with structural requirements. These specialized fasteners play a critical role in ensuring the integrity and stability of truss assemblies in construction and engineering projects. A successful sourcing strategy involves evaluating suppliers based on product certifications, material standards (such as ASTM or ISO), production capabilities, and delivery timelines. Additionally, establishing long-term partnerships with reputable manufacturers can ensure consistency, reduce lead times, and support project scalability. By prioritizing quality assurance and supply chain transparency, stakeholders can secure truss locks that meet both performance demands and safety regulations, ultimately contributing to the success and durability of structural systems.