The global truck rims market is experiencing steady expansion, driven by rising commercial vehicle production, increasing demand for fuel-efficient and lightweight components, and growing e-commerce logistics networks. According to a report by Mordor Intelligence, the global automotive wheel market—encompassing steel and aluminum rims for trucks, buses, and other heavy-duty vehicles—is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Similarly, Grand View Research valued the global automotive wheels market at USD 68.3 billion in 2022 and forecasts a CAGR of 4.8% from 2023 to 2030, citing robust demand from emerging economies and advancements in rim materials as key growth accelerators. Within this competitive landscape, manufacturers are prioritizing innovation in durability, weight reduction, and corrosion resistance to meet evolving regulatory and performance standards. As the industry adapts to stricter emissions norms and the rise of electric trucks, the top suppliers are scaling advanced manufacturing techniques and sustainable practices. Based on market presence, production capacity, technological innovation, and global reach, the following analysis presents the top 10 truck rim manufacturers shaping the future of heavy-duty transportation.

Top 10 Truck Rims 20 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 U.S. Wheel Corp.

Domain Est. 1998

Website: uswheel.com

Key Highlights: US Wheel Corp – Steel and Aluminum Wheel manufacturer for Hot Rod, Muscle Car, Truck, Off-Road, VW, Trailer, OEM Replacement, and Import Performance….

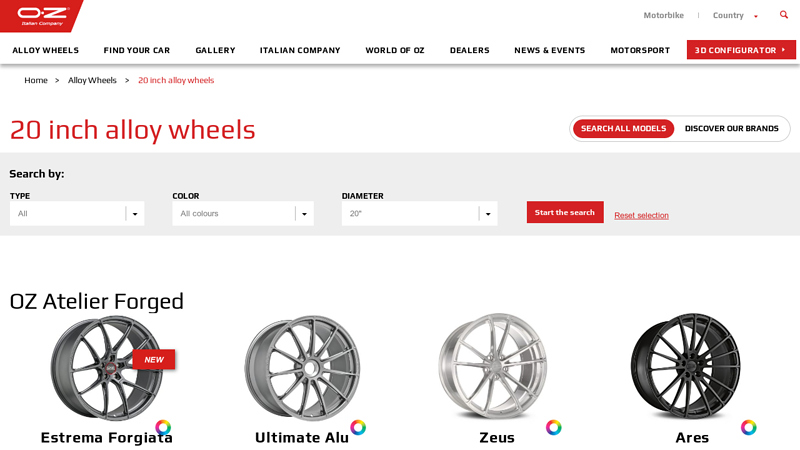

#2 20 inch alloy wheels

Domain Est. 1996

Website: ozracing.com

Key Highlights: Discover all OZ Racing and MSW alloy wheels 20 inch made in Italy and MSW. Discover the new models of OZ and its brands with NAD approval and TUV …Missing: truck manufacturer…

#3 WELD Racing Wheels: Forged & Flow

Domain Est. 2000

Website: weldwheels.com

Key Highlights: Free delivery 30-day returnsWELD Racing Wheels is a manufacturer of advanced, street & strip, drag racing, oval racing and heavy duty truck high-performance, professional forged……

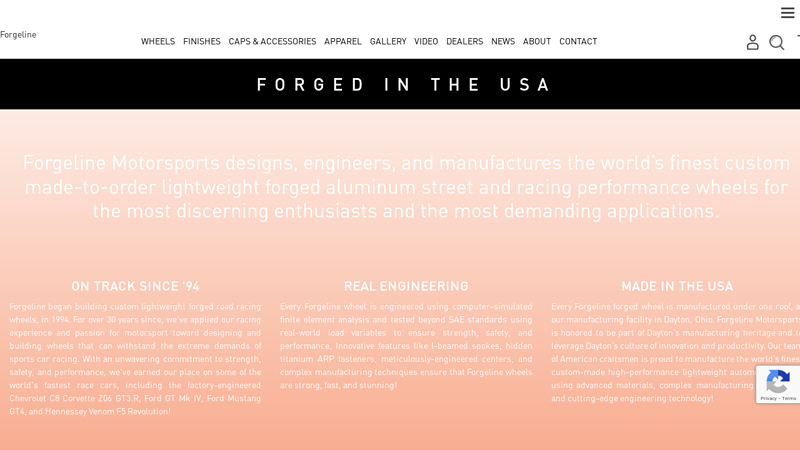

#4 Forgeline

Domain Est. 1996

Website: forgeline.com

Key Highlights: Forgeline Motorsports designs, engineers, and manufactures the world’s finest custom made-to-order lightweight forged aluminum street and racing performance ……

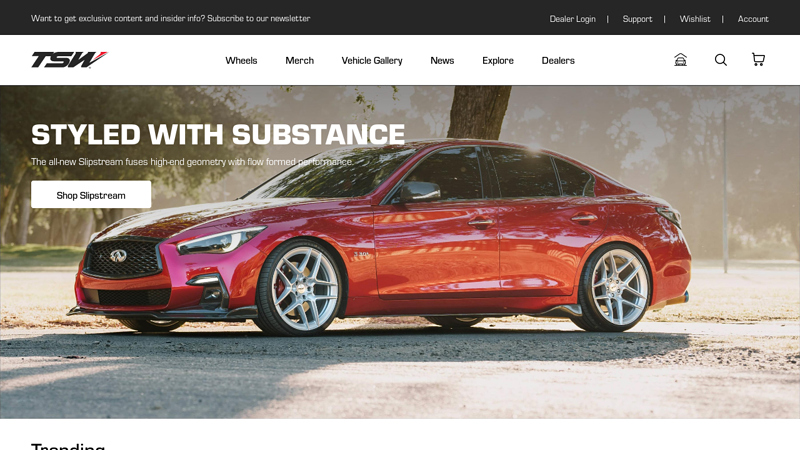

#5 TSW Alloy Wheels

Domain Est. 1999

Website: tsw.com

Key Highlights: TSW Alloy Wheels engineers custom wheels to precisely fit your car or SUV. With 35 breathtaking designs, from 17″ to 22″, our selection is only surpassed by ……

#6 Raceline Wheels

Domain Est. 2000

Website: racelinewheels.com

Key Highlights: 7-day delivery 60-day returnsRaceline Wheels offers performance wheels for off-road, street, and track use so you can Go Everywhere. Find your wheels now!…

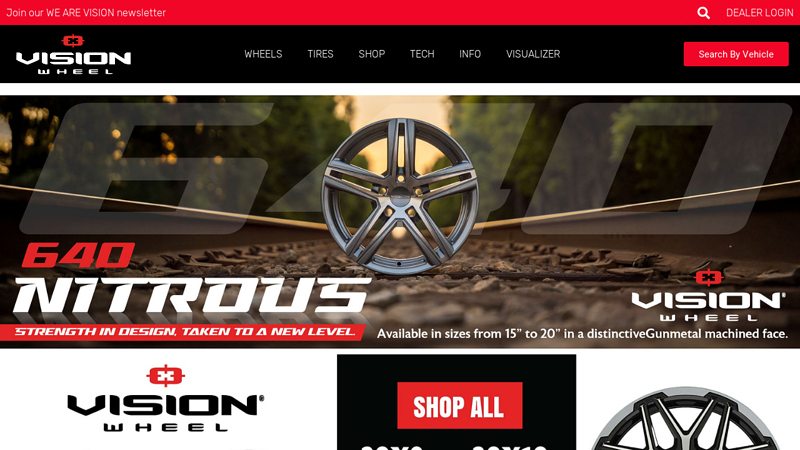

#7 Vision Wheel

Domain Est. 2002

Website: visionwheel.com

Key Highlights: WHEELS · NEW · OFF ROAD · UTV · STREET · RACE/BEADLOCK · TIRE-LOCK · TRAILER · HD/VAN · AMERICAN MUSCLE · ATV/GOLF….

#8 Shop Wheels

Domain Est. 2003

#9 Shop Wheels

Domain Est. 2005

#10 Moto Metal: Off

Domain Est. 2008

Website: motometal.com

Key Highlights: 20″. Starting at $309.00. WARLOCK. Cast Aluminum. 1 finish available. 20″. 22″. Starting at $264.00. TURBINE. Cast Aluminum. 3 finishes available. 20″….

Expert Sourcing Insights for Truck Rims 20

H2: 2026 Market Trends for 20-Inch Truck Rims

The global market for 20-inch truck rims is poised for significant evolution by 2026, driven by advancements in materials, growing demand for fuel efficiency, and the rise of electric and connected commercial vehicles. As fleet operators and individual truck owners increasingly prioritize performance, durability, and aesthetics, 20-inch rims—particularly aluminum and lightweight alloy variants—are gaining traction across key markets.

-

Shift Toward Lightweight Materials

By 2026, aluminum and high-strength alloy rims are expected to dominate the 20-inch truck rim segment. These materials offer substantial weight reductions compared to traditional steel rims, contributing to improved fuel economy and lower emissions—critical factors under tightening global emissions regulations (e.g., EPA and Euro VII standards). The adoption of lightweight rims is especially prominent in long-haul and regional freight fleets aiming to maximize payload capacity and reduce operating costs. -

Increased Demand in North America and Europe

North America remains the largest market for 20-inch truck rims due to high trucking activity and consumer preference for larger rim sizes in Class 6–8 trucks. Europe follows closely, with growing demand driven by sustainability initiatives and the modernization of aging commercial fleets. In both regions, the aftermarket segment is expanding as fleets seek cost-effective upgrades for performance and longevity. -

Integration with Electric and Hybrid Trucks

The rise of electric trucks from manufacturers such as Tesla, Rivian, and Volvo is reshaping rim design requirements. Electric vehicles (EVs) demand rims that support higher torque and vehicle weight due to battery packs. As a result, 20-inch rims engineered for enhanced heat dissipation, strength, and aerodynamics are becoming standard in new EV truck models. By 2026, it’s projected that over 15% of newly sold Class 8 electric trucks in the U.S. will be equipped with optimized 20-inch rims. -

Focus on Aerodynamics and Fuel Efficiency

Aerodynamic rim designs, including fully or partially covered wheels and streamlined spoke patterns, are gaining popularity as part of overall vehicle efficiency strategies. These designs reduce drag, contributing to fuel savings of up to 2–3%—a compelling incentive for large fleets. OEMs and aftermarket suppliers are increasingly offering aerodynamic 20-inch rims as standard or optional features. -

Growth in Smart Rim Technologies

Emerging technologies such as integrated TPMS (Tire Pressure Monitoring Systems) and impact-sensing rims are expected to enter mainstream adoption by 2026. These “smart” rims offer real-time monitoring of tire and rim health, improving safety and reducing maintenance downtime. While currently more prevalent in premium segments, falling sensor costs will make these features accessible across broader market tiers. -

Sustainability and Recycling Initiatives

Environmental concerns are pushing manufacturers toward recyclable rim materials and sustainable production processes. Aluminum rims, which are 100% recyclable without quality loss, align well with circular economy goals. By 2026, leading rim producers are expected to emphasize carbon-neutral manufacturing and recycled content in product marketing. -

Aftermarket Expansion and Customization

The aftermarket for 20-inch truck rims is growing, fueled by owner-operators seeking personalized styling, enhanced performance, and extended product life. Chrome, black finish, and custom-designed rims are increasingly popular, supported by e-commerce platforms that simplify access to niche products.

In conclusion, the 2026 market for 20-inch truck rims will be defined by innovation in materials, integration with next-generation vehicles, and a strong focus on efficiency and sustainability. As the commercial transportation sector evolves, 20-inch rims will play a critical role in balancing performance, compliance, and profitability.

Common Pitfalls When Sourcing Truck Rims 20 Inches (Quality and Intellectual Property)

Sourcing 20-inch truck rims can be a complex process, especially when balancing cost, quality, and legal compliance. Buyers often face several challenges that, if overlooked, can lead to compromised safety, financial loss, or legal issues. Below are key pitfalls related to quality and intellectual property (IP) that procurement professionals should be aware of.

1. Compromised Material Quality

One of the most frequent issues when sourcing truck rims—particularly from low-cost suppliers—is substandard material composition. Some manufacturers may use inferior-grade aluminum or steel alloys to cut costs. This can result in rims that are more prone to cracking, warping, or failing under heavy loads or extreme conditions.

- Pitfall: Assuming all 20-inch rims meeting basic specs are equal in durability.

- Solution: Request material certifications (e.g., ISO, SAE standards) and conduct third-party lab testing for metallurgical analysis.

2. Inconsistent Manufacturing Tolerances

Poorly manufactured rims often suffer from inconsistent machining, leading to imbalances, improper fitment, and premature wear. Variations in bolt patterns, center bores, or offset dimensions can make rims incompatible with certain truck models.

- Pitfall: Relying solely on supplier-provided CAD drawings without physical sample validation.

- Solution: Enforce strict tolerance checks during quality inspections and require first-article testing (FAT) before mass production.

3. Lack of Load and Safety Certification

Not all 20-inch truck rims are rated for heavy-duty applications. Some suppliers may falsely claim compliance with load ratings (e.g., J2530 by SAE) or DOT (Department of Transportation) standards without proper certification.

- Pitfall: Accepting self-declared certifications without verification.

- Solution: Require valid, third-party test reports and verify certification bodies (e.g., TÜV, DEKRA) are accredited.

4. Counterfeit or IP-Infringing Products

A significant risk in the aftermarket rim industry is the sale of counterfeit products that mimic well-known brands (e.g., Alcoa, Lexani, Fuel Off-Road). These replicas often copy logos, designs, and patented features without authorization, leading to intellectual property violations.

- Pitfall: Sourcing from suppliers offering “designer look-alike” rims at suspiciously low prices.

- Solution: Conduct IP due diligence—verify design patents and trademarks with agencies like the USPTO or EUIPO. Include IP indemnification clauses in supplier contracts.

5. Unlicensed Use of Brand Designs

Some manufacturers produce rims that closely replicate the design of branded models, violating design patents or trade dress rights. Even if the product functions well, importing or selling such rims can result in customs seizures, legal action, or reputational damage.

- Pitfall: Assuming that minor design modifications avoid IP infringement.

- Solution: Work with legal counsel to perform design freedom-to-operate (FTO) analyses before finalizing product designs.

6. Inadequate Finish and Corrosion Resistance

Poor surface treatment—such as subpar powder coating, chrome plating, or clear coat application—can lead to rapid corrosion, especially in harsh climates or off-road environments.

- Pitfall: Evaluating finish quality only by visual inspection without environmental testing.

- Solution: Specify salt spray test requirements (e.g., ASTM B117) and conduct batch sampling for coating adhesion and thickness.

7. Misrepresentation of OEM Compatibility

Some suppliers claim their rims are “OEM compatible” without proper testing or engineering validation. This can lead to fitment issues, improper lug engagement, or hub-centric alignment problems.

- Pitfall: Trusting compatibility charts without cross-referencing with vehicle OEM specifications.

- Solution: Validate fitment data with OEM service manuals or use fitment databases like TPMS Direct or Tread.

By proactively addressing these quality and IP-related pitfalls, buyers can mitigate risks, ensure regulatory compliance, and maintain the safety and reliability of their truck fleets or aftermarket offerings.

Logistics & Compliance Guide for Truck Rims 20

Product Overview

Truck Rims 20 (20-inch truck rims) are critical components used in commercial vehicles, heavy-duty trucks, and trailers. These rims must meet strict performance, safety, and dimensional standards to ensure compatibility with tires, proper load distribution, and road safety. Given their size and weight, logistics and compliance requirements are essential for safe transportation and regulatory adherence.

Packaging & Handling Requirements

Proper packaging is vital to prevent damage during shipping and storage.

– Stacking & Palletization: Rims should be stacked vertically on wooden or durable plastic pallets with edge protectors to prevent deformation. Maximum stack height should not exceed 1.8 meters (6 feet) unless secured with straps.

– Protective Covering: Use plastic shrink wrap or corrugated cardboard dividers between layers to reduce surface scratches and corrosion.

– Labeling: Each pallet must be labeled with product ID, size (20”), load rating, material type (e.g., steel or aluminum), batch number, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

– Forklift Accessibility: Pallets must be designed for standard forklift entry on all four sides.

Transportation & Shipping

Transporting 20-inch truck rims requires adherence to freight best practices.

– Weight Considerations: Individual 20” steel rims weigh between 25–45 kg (55–100 lbs). Full pallet loads can exceed 1,000 kg (2,200 lbs), necessitating proper freight classification (typically NMFC 382200, LTL Class 70).

– Load Securement: Use steel or polyester straps to secure pallets to the trailer floor. Avoid overhangs and ensure even weight distribution.

– Container Shipping: For international transport, use 20’ or 40’ dry containers. Maximize space using interlocking stacking patterns. Include desiccants to prevent moisture damage.

– Temperature & Humidity: Avoid exposure to extreme temperatures or high humidity, especially for aluminum rims prone to corrosion.

Regulatory Compliance

Truck rims must comply with regional and international standards.

– DOT Certification (USA): Rims sold in the U.S. must meet Department of Transportation (DOT) safety standards. Look for DOT markings indicating compliance.

– ECE Regulations (Europe): Rims must be certified under UNECE Regulation No. 124 for wheel-rim assemblies. The “E-mark” (e.g., E1 for Germany) is mandatory.

– SAE & ISO Standards: Compliance with SAE J261 (wheel load ratings) and ISO 4003 (dimensions) ensures interchangeability and safety.

– REACH & RoHS (EU): Ensure materials used (e.g., coatings, alloys) comply with chemical restrictions under REACH and RoHS directives.

Import & Export Documentation

Accurate documentation ensures smooth customs clearance.

– Commercial Invoice: Must include product description (“20-inch Truck Rims”), HTS code (e.g., 8708.70.60 for wheel rims in the U.S.), quantity, unit price, total value, and country of origin.

– Packing List: Details per-pallet weight, dimensions, and total number of units.

– Certificate of Origin: Required for preferential tariffs under trade agreements (e.g., USMCA, EU-Canada).

– Bill of Lading/Air Waybill: Specifies carrier, consignee, and routing details.

– Material Compliance Certificates: Include supplier declarations confirming adherence to REACH, RoHS, or other environmental standards.

Quality Inspection & Traceability

Maintain quality and accountability throughout the supply chain.

– Pre-Shipment Inspection: Conduct visual and dimensional checks for cracks, warping, or surface defects. Verify labeling accuracy.

– Batch Traceability: Each batch should have a unique identifier linking to manufacturing date, plant, and quality test results.

– Non-Conformance Handling: Establish procedures for quarantining and returning defective rims. Document root cause and corrective actions.

Environmental & Safety Considerations

- Hazardous Materials: Most rims are non-hazardous, but protective coatings or lubricants may require SDS (Safety Data Sheets) if flammable or toxic.

- Recycling & Disposal: Steel and aluminum rims are recyclable. Partner with certified metal recyclers. Avoid landfill disposal where regulations prohibit it.

- Workplace Safety: Train staff in manual handling techniques to prevent injuries. Use mechanical aids for lifting heavy pallets.

Conclusion

Efficient logistics and compliance for 20-inch truck rims require attention to packaging, secure transport, regulatory standards, and accurate documentation. By following this guide, manufacturers, distributors, and logistics providers can ensure product integrity, legal compliance, and timely delivery across domestic and international markets.

In conclusion, sourcing 20-inch truck rims requires careful consideration of several key factors including material quality (aluminum alloy or steel), load capacity, bolt pattern, offset, and finish, all of which must align with your vehicle specifications and intended use—whether for heavy-duty performance, off-road capability, or aesthetic enhancement. It is essential to purchase from reputable suppliers or manufacturers to ensure durability, safety, and compliance with industry standards. Additionally, comparing prices, reading customer reviews, and verifying warranty options can lead to a cost-effective and reliable purchase. By conducting thorough research and prioritizing compatibility and quality, you can successfully source 20-inch truck rims that enhance both the performance and appearance of your vehicle.