The global truck-mounted crane market is experiencing robust growth, driven by surging demand across construction, infrastructure, and energy sectors. According to a report by Mordor Intelligence, the market was valued at USD 11.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by increasing urbanization, government investments in public infrastructure, and the need for efficient, mobile lifting solutions. Additionally, rising emphasis on safety and operational efficiency is accelerating the adoption of advanced hydraulic and smart crane technologies. As demand intensifies, nine manufacturers have emerged as industry leaders, consistently setting benchmarks in performance, innovation, and global market share—shaping the future of mobile lifting equipment.

Top 9 Truck Mounted Crane Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Liftmoore, Inc. Truck Cranes

Domain Est. 1999 | Founded: 1961

Website: liftmoore.com

Key Highlights: Liftmoore has been manufacturing quality crane products since 1961. Our complete line of cranes ranging from an electric DC-Powered 800 lbs. Capacity….

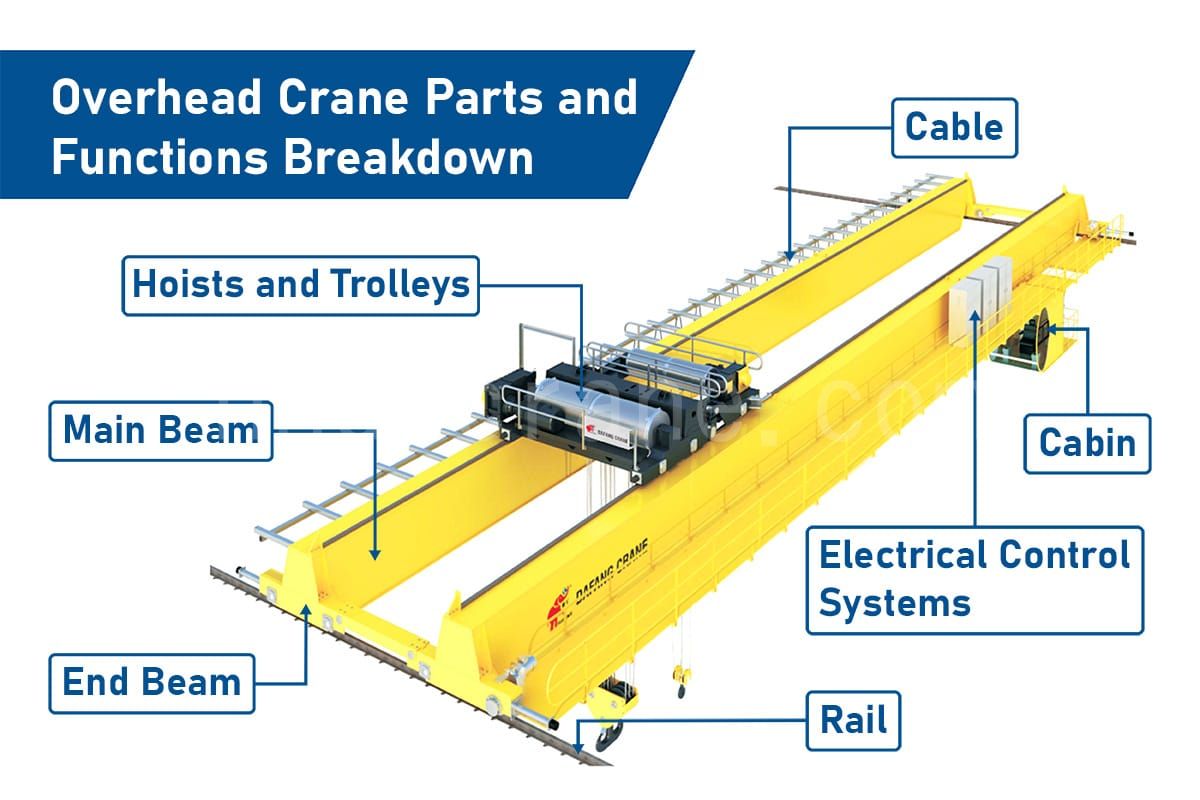

#2 Overhead cranes, parts & reliable service for every …

Domain Est. 1999

Website: konecranes.com

Key Highlights: Discover Konecranes’ overhead cranes, parts, and services designed for industrial reliability, backed by the world’s largest crane service network….

#3 NATIONAL CRANE

Domain Est. 1995

Website: manitowoc.com

Key Highlights: National Crane boom trucks set the global standard for truck-mounted hydraulic cranes. With crane models that offer exceptional reach….

#4 Terex Cranes

Domain Est. 1995

Website: terex.com

Key Highlights: A Terex crane is built to be your tough and ready workhorse. Terex cranes show up day after day almost anywhere to get the job done….

#5 Mobile and crawler cranes

Domain Est. 1996

Website: liebherr.com

Key Highlights: Our range of mobile cranes extends from 2-axle 35 tonne cranes to heavy duty cranes with a lifting capacity of 1200 tonnes and a 9-axle chassis….

#6 Knuckle Boom Cranes

Domain Est. 1997

Website: palfinger.com

Key Highlights: PALFINGER offers some of the most durable knuckle boom cranes in the industry. With a comprehensive range of models covering the entire range of working….

#7 Link

Domain Est. 1999

Website: linkbelt.com

Key Highlights: Link-Belt Cranes is a leader in the design and manufacture of telescopic and lattice boom cranes. Rough terrain cranes · hydraulic truck cranes….

#8 Heavy

Domain Est. 2003

Website: stellarindustries.com

Key Highlights: Stellar offers 10+ hydraulic service truck cranes to meet your company’s needs. Request a quote today or reach out for help in finding the right one….

#9 Ramsey Industries

Domain Est. 2004

Website: ramseyindustries.com

Key Highlights: Ramsey Industries, through our brands Auto Crane®, Eskridge®, and Ramsey Winch®, designs and manufactures products that lift, move, and drive today’s workforce….

Expert Sourcing Insights for Truck Mounted Crane

H2: 2026 Market Trends for Truck Mounted Cranes

The global truck-mounted crane market in 2026 is poised for steady growth, driven by infrastructure development, urbanization, and technological advancements, though tempered by economic volatility and supply chain considerations. Key trends shaping the market include:

H3: Infrastructure Investment as the Primary Growth Engine

Major government-led infrastructure projects—particularly in roads, bridges, renewable energy (wind farm installation), and urban development—are the dominant demand drivers. Initiatives like the U.S. Infrastructure Investment and Jobs Act, India’s National Infrastructure Pipeline, and EU Green Deal projects are creating sustained demand for versatile lifting equipment. Truck-mounted cranes, known for mobility and quick deployment, are favored for these distributed, time-sensitive projects.

H3: Electrification and Sustainability Gaining Momentum

Environmental regulations and corporate ESG goals are accelerating the shift toward cleaner operations. By 2026, hybrid and fully electric truck-mounted cranes are transitioning from niche to mainstream offerings. Major manufacturers (e.g., Tadano, Terex, Palfinger) are expanding electric model portfolios, especially in emission-sensitive urban zones and European markets. Battery technology improvements are extending operational range and lifting capacity, making electrification more viable.

H3: Demand for Higher Capacity and Versatility

Construction complexity is pushing demand for cranes with increased lifting capacity (100+ tons) and longer reach. Simultaneously, there’s strong growth in mid-range cranes (20–70 tons) due to their adaptability across sectors like utilities, logistics, and industrial maintenance. Telescopic boom designs with advanced hydraulics and load-sensing systems are enabling greater precision and safety in confined spaces.

H3: Digital Integration and Smart Crane Technologies

Connectivity is transforming crane operations. By 2026, IoT-enabled telematics for remote monitoring, predictive maintenance, and fleet management are becoming standard. Features like anti-collision systems, load moment indicators (LMI), and automated boom control enhance safety and efficiency. Data analytics are improving utilization rates and reducing downtime, appealing to rental companies and large contractors.

H3: Regional Divergence in Growth and Demand

Asia-Pacific (especially China and India) leads in volume due to rapid urbanization. North America sees steady growth driven by infrastructure renewal and energy projects. Europe emphasizes sustainability and compliance with stringent emissions standards (e.g., Euro VII). Emerging markets in the Middle East and Africa show potential but face funding and political risks.

H3: Supply Chain Resilience and Localization

Ongoing supply chain disruptions have prompted manufacturers to localize production and secure critical components (e.g., steel, electronics). This trend supports regional manufacturing hubs and may influence pricing and delivery timelines. The availability of skilled operators and maintenance personnel remains a constraint, driving investment in training and automation.

Conclusion

In 2026, the truck-mounted crane market will reflect a balance between traditional infrastructure demand and the rise of smart, sustainable technologies. Companies that invest in electrification, digital solutions, and operational efficiency will gain competitive advantage, while global economic conditions and policy support will remain key variables influencing growth trajectories.

Common Pitfalls When Sourcing Truck Mounted Cranes (Quality and Intellectual Property)

Sourcing truck mounted cranes involves significant investment and technical complexity. Buyers often encounter critical pitfalls related to both product quality and intellectual property (IP) risks. Being aware of these challenges is essential to ensure safe, reliable operations and legal compliance.

Poor Manufacturing Quality and Substandard Components

One of the most frequent issues when sourcing truck mounted cranes—especially from less-regulated markets—is substandard manufacturing. This includes the use of low-grade steel, inadequate welding practices, and poorly calibrated hydraulic systems. These deficiencies can lead to structural failures, reduced lifting capacity, and safety hazards. Buyers may receive cranes that appear compliant but fail under operational stress or do not meet international safety standards such as ISO 9001 or EN 13000.

Lack of Certification and Non-Compliance with Safety Standards

Many suppliers, particularly in emerging markets, may provide cranes without valid third-party certifications or with forged documentation. A common pitfall is assuming that a crane meets regional safety regulations (e.g., CE marking in Europe or OSHA compliance in the U.S.) without independent verification. Non-compliant cranes pose serious safety risks and can lead to legal liabilities, project delays, or equipment seizure upon import.

Inadequate After-Sales Support and Spare Parts Availability

Quality concerns extend beyond initial delivery. Sourcing from manufacturers with limited global service networks often results in long downtimes due to unavailable spare parts or lack of trained technicians. This undermines operational efficiency and increases total cost of ownership. Buyers may discover too late that critical components are proprietary or no longer supported, effectively shortening the crane’s service life.

Intellectual Property Infringement and Counterfeit Designs

Truck mounted cranes often incorporate patented technologies—such as telescopic boom mechanisms, load-sensing systems, or control interfaces. Sourcing from unscrupulous suppliers may result in purchasing cranes that infringe on existing IP rights. This exposes the buyer to legal action, import bans, or reputational damage. Counterfeit or reverse-engineered models may mimic leading brands but lack reliability, safety features, and technical support.

Misrepresentation of Origin and Brand Authenticity

Some suppliers falsely represent the origin of cranes or use branding that closely resembles well-known manufacturers (e.g., “Hyundai-style” or “Liebherr-type”). This misrepresentation can mask inferior quality and void warranties. Buyers may unknowingly import products subject to anti-dumping duties or trade restrictions, especially when goods are transshipped through third countries to disguise their true origin.

Insufficient Technical Documentation and Language Barriers

Incomplete or poorly translated manuals, schematics, and maintenance guides hinder safe operation and compliance with local regulations. Missing IP-related documentation, such as patent licenses or design ownership statements, can also create legal vulnerabilities, particularly in industries with strict audit requirements.

Failure to Conduct On-Site Audits and Factory Inspections

Relying solely on brochures, videos, or third-party agents without conducting independent factory audits increases the risk of encountering quality and IP issues. On-site inspections help verify production capabilities, quality control processes, and adherence to original designs—key factors in avoiding counterfeit or substandard equipment.

Avoiding these pitfalls requires thorough due diligence, engagement with reputable suppliers, verification of certifications, and legal review of IP and compliance documentation before purchase.

Logistics & Compliance Guide for Truck Mounted Crane

Overview and Purpose

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient operation of Truck Mounted Cranes (TMCs). It applies to operators, transport planners, site supervisors, and fleet managers involved in the deployment and movement of TMCs across worksites and public roads.

Regulatory Compliance

All operations involving truck mounted cranes must comply with relevant national and local regulations, including but not limited to:

– Occupational Safety and Health Administration (OSHA) standards (e.g., 29 CFR 1926 Subpart CC for crane and derrick safety in construction)

– Department of Transportation (DOT) regulations for vehicle weight, dimensions, and driver licensing (e.g., FMCSA guidelines)

– American National Standards Institute (ANSI) standards such as ANSI/ASME B30.5 for mobile cranes

– State and local permitting requirements for oversize/overweight loads and crane operation on public roads or near infrastructure

Operators must ensure compliance with all applicable rules governing crane certification, operator licensing, load charts, and inspection schedules.

Pre-Operation Inspection and Maintenance

A comprehensive pre-operation inspection must be conducted daily or before each shift, including:

– Structural integrity of the crane and boom

– Hydraulic system functionality and leak checks

– Wire rope, hook, and lifting accessories (no fraying, deformation, or cracks)

– Outrigger condition and stability mechanisms

– Control systems and safety devices (e.g., load moment indicator, anti-two block devices)

Maintenance logs must be kept up to date, with scheduled servicing performed per manufacturer recommendations to ensure operational reliability and regulatory compliance.

Load Handling and Capacity Management

- Always adhere to the crane’s load chart based on boom length, radius, and configuration.

- Never exceed the rated load capacity under any circumstances.

- Use certified rigging gear appropriate for the load weight and type.

- Conduct a lift plan for complex or critical lifts, including risk assessment and signal person coordination.

- Ensure proper load balancing and secure attachment to prevent swinging or shifting during lifts.

Transport and Road Logistics

When transporting the truck mounted crane:

– Confirm compliance with legal road dimensions and weight limits. If exceeded, obtain necessary oversize/overweight permits from relevant transportation authorities.

– Use proper signage, lighting, and escort vehicles when required for wide or heavy loads.

– Secure the crane and boom in transit position using manufacturer-recommended restraints.

– Plan routes to avoid low bridges, weak structures, and restricted access zones.

– Verify driver holds appropriate commercial driver’s license (CDL) with necessary endorsements.

Site Safety and Setup

- Conduct a site assessment prior to crane setup, checking ground conditions, overhead hazards (e.g., power lines), and nearby traffic.

- Fully extend and properly set outriggers on stable, level ground using crane mats or steel plates if needed.

- Establish exclusion zones during lifting operations to protect unauthorized personnel.

- Communicate clearly using standardized hand signals or radios between operator and signal person.

Operator Qualifications and Training

- Crane operators must be certified by an accredited body (e.g., NCCCO) and trained on the specific crane model in use.

- Employers are responsible for ensuring operators are evaluated and documented as competent per OSHA requirements.

- Regular refresher training and safety meetings should be conducted to reinforce best practices and regulatory updates.

Documentation and Recordkeeping

Maintain up-to-date records including:

– Crane inspection reports (daily, monthly, annual)

– Maintenance and repair logs

– Operator certification and training records

– Lift plans for critical lifts

– Permits for transport and site operations

These records must be readily available for audits or regulatory inspections.

Emergency Procedures

- Develop and communicate site-specific emergency response procedures, including crane tip-over, power line contact, or mechanical failure.

- Ensure all personnel know evacuation routes and emergency shutdown procedures.

- Equip the crane with functional fire extinguishers and first aid kits.

- Report all incidents or near-misses promptly and conduct root cause analysis to prevent recurrence.

Environmental and Community Considerations

- Minimize noise, emissions, and disruption during operation, especially in residential or environmentally sensitive areas.

- Follow local regulations for operating hours and environmental protection.

- Use spill containment kits if hydraulic fluid or fuel handling is involved.

Conclusion

Safe and compliant operation of truck mounted cranes requires careful planning, adherence to regulations, qualified personnel, and thorough documentation. By following this guide, organizations can reduce risk, enhance operational efficiency, and ensure the safety of personnel and the public.

Conclusion for Sourcing a Truck-Mounted Crane:

Sourcing a truck-mounted crane is a strategic investment that enhances operational efficiency, mobility, and versatility in industries such as construction, utilities, logistics, and infrastructure maintenance. After evaluating key factors such as lifting capacity, boom length, vehicle compatibility, maintenance requirements, and total cost of ownership, it is evident that selecting the right crane involves a balance between performance needs and budgetary constraints.

Partnering with reputable manufacturers or suppliers ensures reliability, warranty support, and access to spare parts and technical assistance. Additionally, considering customization options, operator safety features, and compliance with regional regulations further optimizes the long-term value of the equipment.

Ultimately, a well-sourced truck-mounted crane not only improves worksite productivity but also provides the flexibility to respond quickly to dynamic job demands, offering a significant return on investment through enhanced service delivery and reduced equipment downtime.