The global liftgate market is experiencing robust growth, driven by rising demand for last-mile delivery solutions and increased emphasis on workplace safety in material handling. According to Grand View Research, the global vehicle lift gates market size was valued at USD 667.8 million in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth is fueled by the expansion of e-commerce, growing logistics fleets, and stringent safety regulations across North America and Europe. As demand for efficient, durable, and customizable liftgate systems rises, manufacturers are innovating to meet the evolving needs of truck fleets, delivery services, and industrial operations. In this competitive landscape, nine key players have emerged as leaders, combining engineering excellence, widespread distribution, and data-backed product performance to dominate the market.

Top 9 Truck Liftgates Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

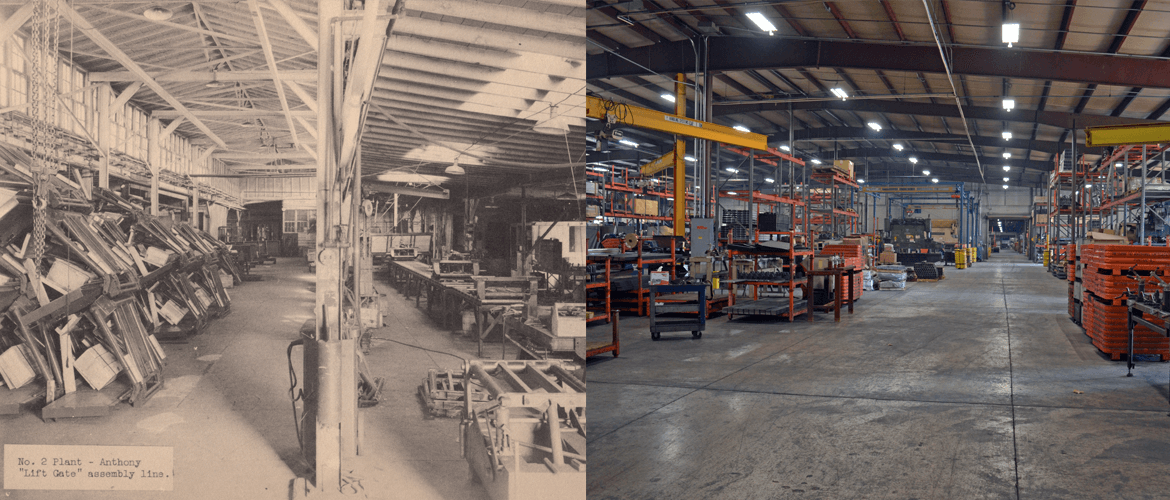

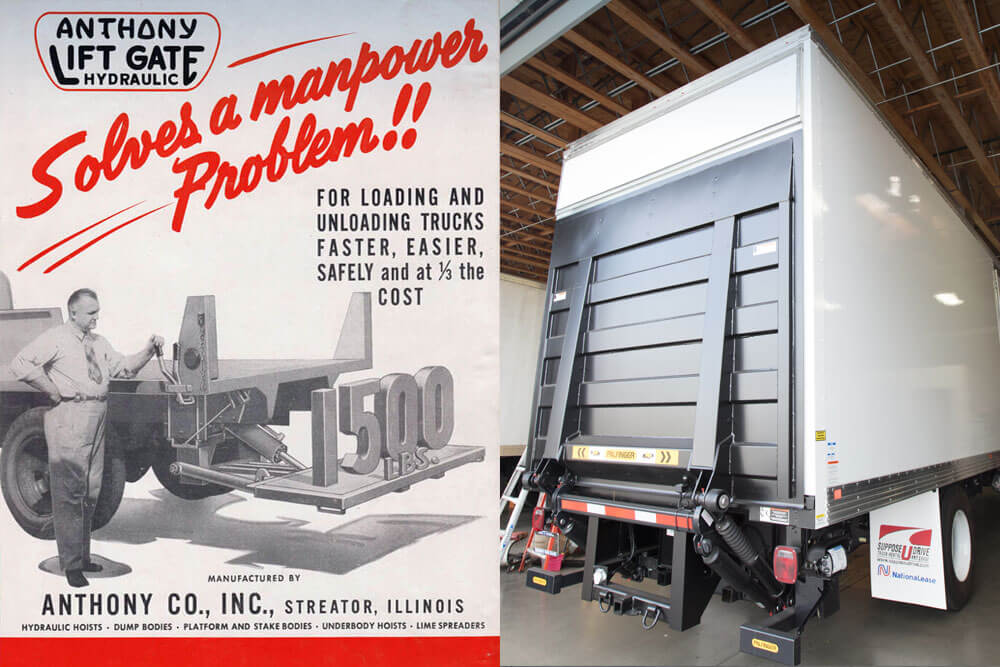

#1 Truck Liftgate

Domain Est. 1998

Website: anthonyliftgates.com

Key Highlights: America’s Toughest LiftgatesTM. Anthony Liftgates is a leading manufacturer of liftgates, producing top-quality products for trucks of all sizes. Contact Us….

#2 LiftGateMe

Domain Est. 2013

Website: liftgateme.com

Key Highlights: Trusted by 18,000+ customers, we’re the only liftgate parts distributor offering 40,000+ online SKUs and full manufacturer support from Maxon, Waltco, Palfinger ……

#3 Maxon Lift

Domain Est. 1996

Website: maxonlift.com

Key Highlights: There’s a Maxon liftgate for every job—find the perfect one for your specific needs right here. If you require further assistance, please contact Customer ……

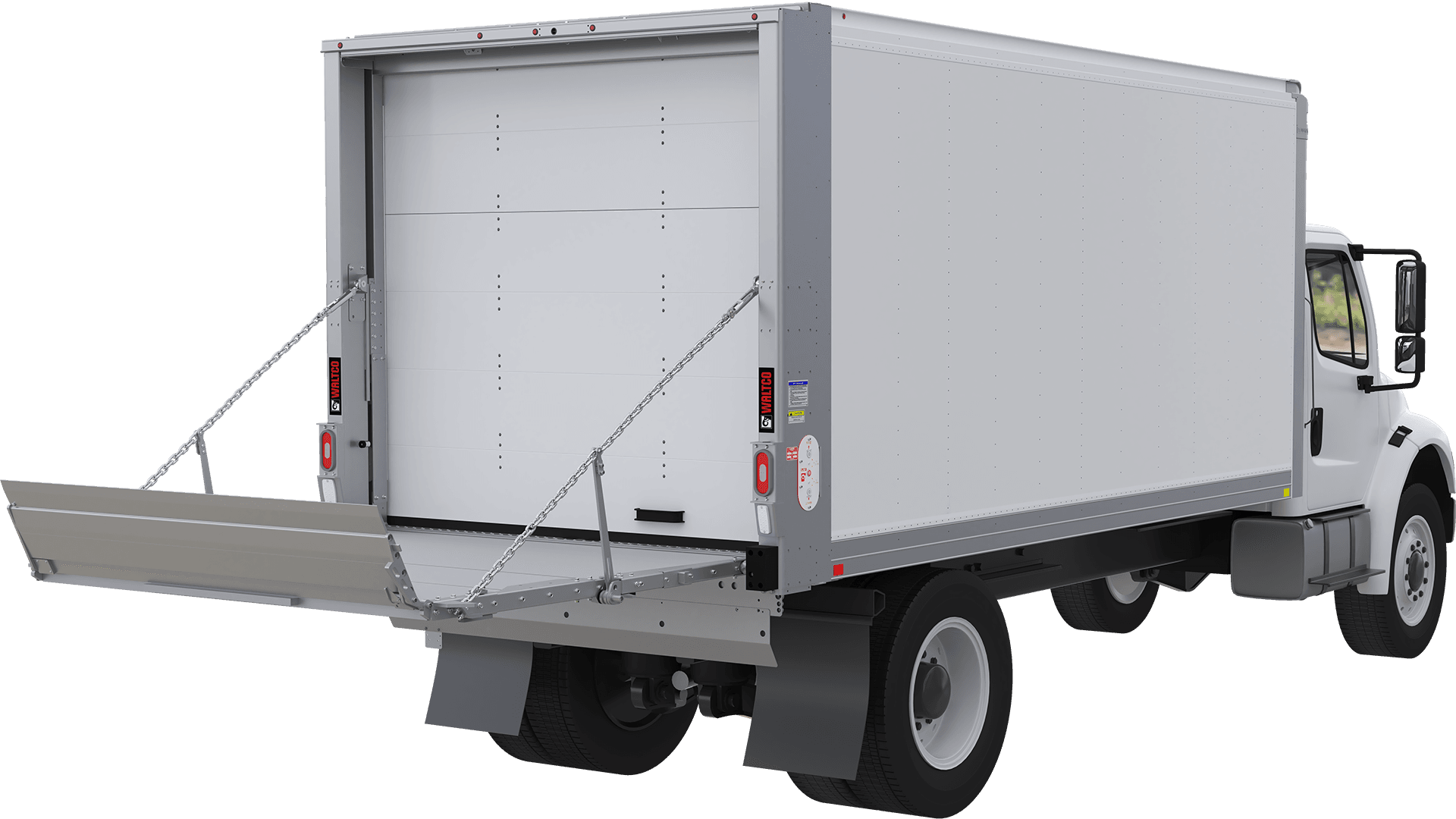

#4 WALTCO Liftgate Trucks Maximizes Your Delivery Uptime

Domain Est. 1996

Website: hiab.com

Key Highlights: WALTCO liftgates are designed for logistics & distribution in urban city use, heavy duty long haul and special applications from coast to coast….

#5 Liftgates

Domain Est. 1996

Website: tommygate.com

Key Highlights: Hydraulic liftgates for pickups, service bodies, flatbeds, box trucks, and cargo vans. Manufactured by Tommy Gate in Woodbine, Iowa….

#6 Optional Liftgates

Domain Est. 1996

Website: morgancorp.com

Key Highlights: We manufacture Class 3 to Class 7 (GVW) box truck/straight truck bodies to serve the dry freight and refrigerated product markets, as well as a wide range of ……

#7 Liftgates

Domain Est. 1997 | Founded: 1993

Website: palfinger.com

Key Highlights: PALFINGER USA is the premier and cost-effective provider for your liftgate needs, offering a full range of products for all applications since 1993….

#8 Leyman Lift Gates

Domain Est. 1998

Website: leymanlift.com

Key Highlights: Known for legendary quality, proven reliability, and customer-first service, every gate we build carries forward a tradition of innovation and craftsmanship….

#9 Liftgates & Hoists

Domain Est. 2003

Website: eagletruckbody.com

Key Highlights: We offer a wide variety of liftgates such as rail lifts, cantilevers, tuck-unders and much more. . Some of our partners include: . Tommy Gate….

Expert Sourcing Insights for Truck Liftgates

H2: Projected 2026 Market Trends for Truck Liftgates

The truck liftgate market is poised for significant evolution by 2026, driven by technological advancements, regulatory changes, and shifting logistics demands. This analysis explores key trends expected to shape the industry in the coming years.

-

Rising E-Commerce and Last-Mile Delivery Demands

The continued expansion of e-commerce is placing increased pressure on last-mile delivery efficiency. As more goods are delivered directly to consumers, urban delivery vehicles—especially box trucks and vans—require greater accessibility and operational speed. Liftgates enable safe and rapid offloading, especially in areas without loading docks. By 2026, demand for liftgates is expected to grow significantly in delivery fleets serving residential and commercial urban zones. -

Adoption of Electric and Hybrid Liftgate Systems

Sustainability initiatives are pushing manufacturers toward electrification. Traditional hydraulic liftgates, while reliable, are often powered by the truck’s engine or auxiliary systems, contributing to fuel consumption and emissions. By 2026, electric liftgates—especially those powered by independent battery packs or integrated with electric vehicle platforms—are expected to gain market share. These systems offer reduced maintenance, quieter operation, and compatibility with zero-emission delivery vehicles. -

Integration with Telematics and Fleet Management Systems

Smart liftgates equipped with sensors and connectivity features are emerging. By 2026, integration with telematics systems will allow fleet managers to monitor liftgate usage, detect maintenance issues, and ensure compliance with safety protocols. Real-time data on lift cycles, load weights, and operational status will enhance fleet efficiency and reduce downtime. -

Focus on Safety and Ergonomics

Workplace safety regulations and rising labor costs are driving demand for ergonomic solutions. Liftgates reduce physical strain on delivery personnel, minimizing injury risk and workers’ compensation claims. By 2026, regulatory bodies and insurance providers may incentivize or mandate liftgate use in certain delivery segments, particularly for heavy or frequent cargo handling. -

Growth in Retrofit and Aftermarket Demand

As existing fleets seek to modernize without full vehicle replacement, the aftermarket for liftgate installations will expand. Retrofitting older trucks with modern, lightweight, and energy-efficient liftgates offers a cost-effective upgrade path. By 2026, specialized installers and modular liftgate designs will support increased adoption across small and medium-sized fleets. -

Regional Market Expansion

While North America currently dominates the liftgate market due to high last-mile delivery volumes and established logistics infrastructure, regions like Europe and Asia-Pacific are catching up. By 2026, urbanization, rising consumer expectations for fast delivery, and evolving commercial vehicle standards in countries such as Germany, Japan, and South Korea will fuel liftgate adoption. -

Innovation in Materials and Design

Manufacturers are focusing on lightweight composite materials and modular designs to improve payload capacity and durability. Aluminum and high-strength polymers are increasingly replacing steel components, reducing overall vehicle weight and improving fuel efficiency. By 2026, advanced composite liftgates could become standard in premium delivery fleets.

Conclusion

By 2026, the truck liftgate market will be shaped by the convergence of e-commerce growth, electrification, digital integration, and sustainability. Companies that invest in innovative, efficient, and smart liftgate solutions will be best positioned to capture market share in an increasingly competitive and regulated environment.

Common Pitfalls When Sourcing Truck Liftgates: Quality and Intellectual Property Risks

Sourcing truck liftgates, especially from overseas or lesser-known suppliers, can expose businesses to significant quality and intellectual property (IP) risks. Understanding these pitfalls is critical to ensuring product reliability, protecting brand reputation, and avoiding legal complications.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

Suppliers may not adhere to consistent manufacturing practices, leading to variability in weld quality, material thickness, and component durability. This inconsistency can result in premature failures, safety hazards, and increased warranty claims.

Substandard Materials and Components

To reduce costs, some manufacturers use inferior steel, hydraulics, or electrical components. This compromises the liftgate’s load capacity, longevity, and performance in harsh environments, increasing maintenance costs and downtime.

Lack of Certification and Testing

Reputable liftgates should meet industry standards such as ANSI/ALI ALCTV or CSA B357. Sourcing from suppliers without proper third-party testing or certifications increases the risk of non-compliance and safety incidents.

Poor After-Sales Support and Warranty Enforcement

Low-cost suppliers may offer inadequate technical support, limited service networks, or ambiguous warranty terms. This can lead to extended downtimes and higher total cost of ownership when repairs or replacements are needed.

Intellectual Property (IP)-Related Pitfalls

Counterfeit or Clone Products

Some suppliers produce liftgates that closely mimic branded models, infringing on design patents or trademarks. Purchasing such products—even unknowingly—can expose buyers to legal liability and damage brand credibility.

Unauthorized Use of Proprietary Designs

Manufacturers may copy patented mechanisms, control systems, or structural designs without licensing. Sourcing these goods can make the buyer complicit in IP violations, especially in regulated markets like the U.S. or EU.

Lack of IP Due Diligence in Contracts

Purchase agreements that fail to include IP warranties or indemnification clauses leave buyers vulnerable. If a third party sues for infringement, the buyer—not the supplier—may bear legal and financial responsibility.

Exposure to Gray Market Risks

Sourcing liftgates through unauthorized distributors or parallel import channels increases the risk of receiving non-genuine parts or rebranded units that violate the original manufacturer’s IP rights.

Mitigating these risks requires thorough supplier vetting, clear contractual protections, and verification of compliance with both quality standards and intellectual property laws.

Logistics & Compliance Guide for Truck Liftgates

Understanding Truck Liftgates: Purpose and Types

Truck liftgates are mechanical devices installed on the rear of delivery trucks to facilitate the loading and unloading of cargo, especially when a loading dock is unavailable. They enhance operational efficiency and reduce the physical strain on drivers. Common types include:

- Rail/Gate Lifts: Mounted externally along the truck’s frame rails.

- Column Lifts: Utilize vertical columns on either side of the gate for support and lifting.

- Cantilever Lifts: Extend outward from the truck, allowing unloading in tight spaces.

- Tuck-Away Lifts: Retract under the truck bed when not in use, saving space.

Choosing the right type depends on payload capacity, vehicle configuration, and delivery conditions.

Regulatory Compliance and Safety Standards

Liftgate systems must comply with national and local safety regulations. Key compliance standards include:

- DOT (Department of Transportation) Regulations: Ensure that the liftgate installation does not compromise vehicle safety or exceed weight limits affecting Gross Vehicle Weight Rating (GVWR).

- OSHA (Occupational Safety and Health Administration): Mandates safe operating procedures to prevent worker injury during liftgate use.

- FMVSS (Federal Motor Vehicle Safety Standards): Applies to modifications affecting vehicle structure or lighting; liftgate installations must not obstruct required lights or reflectors.

Regular inspections and maintenance are required to meet these standards and avoid fines or operational delays.

Installation and Vehicle Certification

Proper installation is critical for safety and compliance. Best practices include:

- Hiring certified technicians familiar with both the liftgate model and the vehicle’s specifications.

- Ensuring the liftgate does not exceed the truck’s rear axle weight capacity.

- Updating the vehicle’s certification label (GVWR, GAWR) if the liftgate significantly increases tare weight.

- Verifying that all electrical connections comply with FMVSS lighting requirements.

Post-installation, maintain documentation of the modification for DOT audits and insurance purposes.

Operational Guidelines for Drivers

To ensure safe and efficient use, drivers should follow these operational practices:

- Conduct a pre-use inspection of the liftgate, checking for hydraulic leaks, structural damage, and proper function.

- Use appropriate safety gear and follow lockout/tagout procedures during maintenance.

- Never exceed the liftgate’s rated capacity (clearly marked on the unit).

- Secure cargo on the platform during lifting and avoid standing under a raised liftgate.

- Use wheel chocks when loading/unloading on inclines.

Proper training reduces accident risks and ensures compliance during roadside inspections.

Maintenance and Inspection Requirements

Regular maintenance extends liftgate lifespan and ensures regulatory compliance. Recommended practices:

- Perform visual inspections before each use.

- Schedule monthly lubrication of pivot points and quarterly hydraulic system checks.

- Replace worn cables, hoses, or structural components immediately.

- Keep a maintenance log accessible for compliance audits.

Many states require documented maintenance as part of commercial vehicle safety programs.

Weight Considerations and Payload Management

Liftgates add significant weight (typically 400–800 lbs), impacting payload capacity. Logistics managers must:

- Recalculate available payload by subtracting the liftgate’s weight and any associated fuel or battery systems.

- Avoid overloading the vehicle, which can lead to DOT violations and safety hazards.

- Factor in liftgate weight when planning routes with weight-restricted bridges or roads.

Accurate payload management ensures legal compliance and vehicle longevity.

Environmental and Accessibility Compliance

In certain regions, environmental and accessibility regulations affect liftgate use:

- Emissions Standards: Electric liftgates powered by the truck’s alternator must not overload the system and increase idling time, potentially violating anti-idling laws.

- ADA Considerations: While not directly governed by ADA for freight, liftgates improve accessibility for delivery personnel and recipients with mobility challenges, supporting inclusive logistics practices.

Documentation and Recordkeeping

Maintain comprehensive records to support compliance efforts:

- Liftgate installation certification

- Maintenance logs and inspection reports

- Operator training records

- Weight certification documents post-modification

These records are essential during DOT inspections, insurance claims, and liability reviews.

Conclusion

Truck liftgates are vital tools in modern logistics, enabling deliveries to locations without loading infrastructure. However, their use demands strict adherence to safety, weight, and regulatory standards. By following this guide—covering installation, operation, maintenance, and compliance—fleets can ensure efficient, legal, and safe use of liftgate-equipped vehicles.

Conclusion for Sourcing Truck Liftgates

Sourcing truck liftgates is a critical decision that significantly impacts operational efficiency, safety, and long-term cost management in logistics and freight operations. After evaluating key factors such as liftgate types (e.g., scissor, telescopic, cantilever), weight capacity, compatibility with vehicle models, durability, power source (hydraulic, electric, or manual), and required maintenance, it becomes evident that selecting the right liftgate requires a strategic approach tailored to specific business needs.

Partnering with reputable suppliers who offer reliable warranties, quality construction, and responsive customer support ensures better performance and reduces downtime. Additionally, considering total cost of ownership—factoring in initial investment, fuel efficiency, maintenance, and expected service life—provides a more accurate assessment of value over time.

Ultimately, investing in high-quality, well-matched liftgates enhances worker safety, improves delivery speed and reliability, and supports scalability as business demands grow. A well-informed sourcing strategy not only optimizes current operations but also positions the organization for long-term success in an increasingly competitive transportation and distribution landscape.