The global demand for reliable audio connectivity solutions continues to rise, driven by increasing adoption of consumer electronics, automotive infotainment systems, and professional audio equipment. According to a 2023 report by Mordor Intelligence, the global audio connectors market was valued at USD 2.8 billion in 2022 and is projected to grow at a CAGR of 5.4% from 2023 to 2028. This expansion is fueled by advancements in audio technology, heightened demand for high-fidelity sound, and the proliferation of smart devices. Within this landscape, TRRS (Tip-Ring-Ring-Sleeve) phone connectors—widely used for headsets with microphone functionality in smartphones, laptops, and two-way radios—remain a critical component. As original equipment manufacturers (OEMs) prioritize durability, miniaturization, and signal integrity, strategic partnerships with specialized connector manufacturers have become essential. Based on market presence, product innovation, and technical capabilities, here are the top seven TRRS phone connector manufacturers shaping the industry’s future.

Top 7 Trrs Phone Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

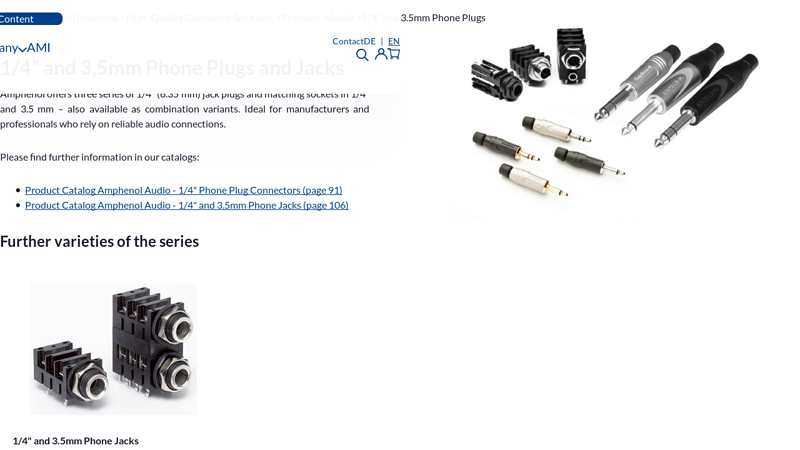

#1 1/4” and 3.5mm Phone Plugs

Website: amphenol-industrial.de

Key Highlights: The Amphenol series offers 1/4″ and 3.5mm jack plugs and sockets in various versions, ideal for manufacturers and end users of phone jacks and plugs….

#2 Phone Connectors

Domain Est. 1995

Website: mouser.com

Key Highlights: $4.99 deliveryMouser is an authorized distributor for many phone connector manufacturers including Amphenol, CUI Devices, Kobiconn, Kycon, Neutrik, Switchcraft & more….

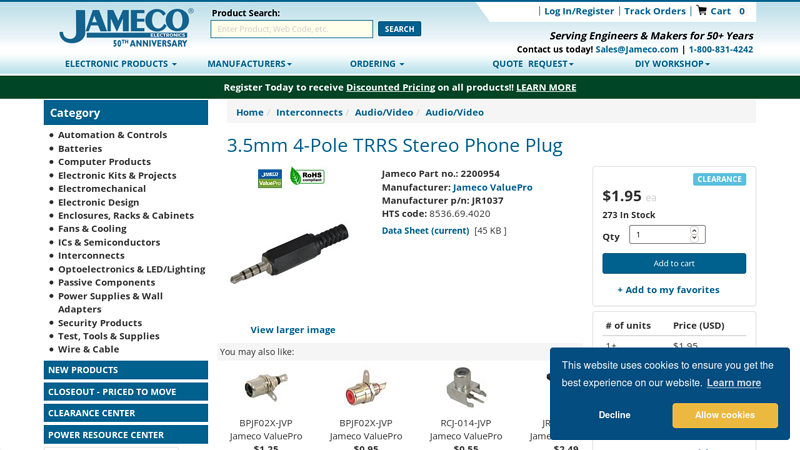

#3 3.5mm 4

Domain Est. 1998

Website: jameco.com

Key Highlights: In stock Free delivery over $503.5mm 4-Pole TRRS Stereo Phone Plug · Jameco Part no.: 2200954 · Manufacturer: Jameco ValuePro · Manufacturer p/n: JR1037 · HTS code: 8536.69.4020….

#4 TRRS audio cable

Domain Est. 1997

Website: ikmultimedia.com

Key Highlights: Free deliveryTRRS audio cable 3.5mm / 1/8″. TRRS audio cable for: 200cm / 78.7″. See all cables here. *Legal detail | Warranty….

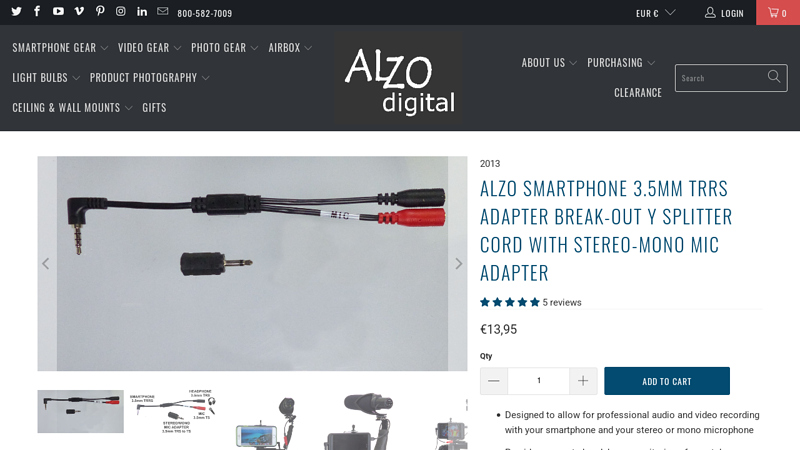

#5 ALZO Smartphone 3.5mm TRRS Adapter Break

Domain Est. 2003

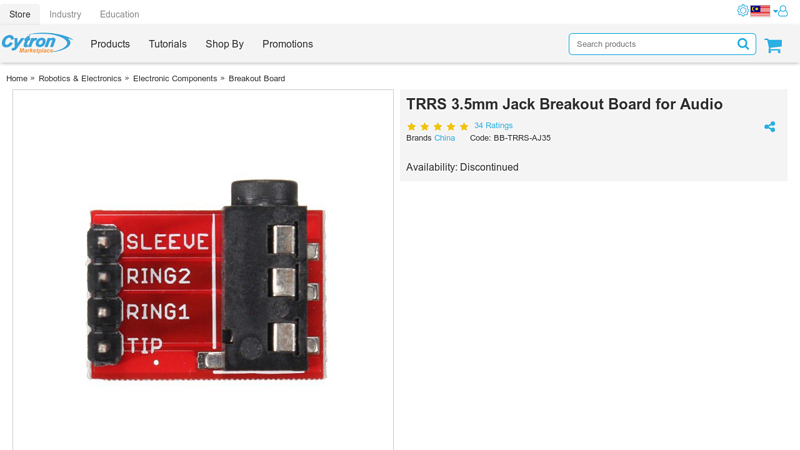

#6 TRRS 3.5mm Jack Breakout Board for Audio

Domain Est. 2017

Website: my.cytron.io

Key Highlights: Rating 5.0 (34) · 3–6 day delivery · 30-day returnsA TRRS or Tip Ring Ring Sleeve plug has four conductors and is very popular with 3.5mm, and can be used with stereo unbalanc…

#7 TRS Connectors: A Comprehensive Guide

Domain Est. 2024

Website: rasantekaudio.com

Key Highlights: A TRS connector, short for Tip, Ring, and Sleeve, is a standardized electrical connector commonly used in audio equipment. It’s designed to transmit audio ……

Expert Sourcing Insights for Trrs Phone Connector

H2: 2026 Market Trends for TRRS Phone Connector

The TRRS (Tip-Ring-Ring-Sleeve) phone connector market is poised for notable evolution by 2026, influenced by technological advancements, shifting consumer preferences, and the broader transition toward digital audio solutions. While the traditional 3.5mm TRRS connector faces declining adoption in mainstream smartphones, niche demand and specialized applications are expected to sustain and even grow its relevance in select sectors.

-

Decline in Consumer Smartphone Integration

By 2026, the majority of flagship smartphones from leading manufacturers (e.g., Apple, Samsung, Xiaomi) will continue to omit the 3.5mm TRRS jack in favor of USB-C or wireless audio solutions. This shift reduces direct consumer demand for TRRS connectors in mobile devices, limiting their use primarily to mid-range and budget phones, particularly in emerging markets where cost-sensitive consumers still value analog audio convenience. -

Growth in Specialized and Industrial Applications

Despite reduced use in consumer smartphones, TRRS connectors are expected to see increased adoption in professional audio equipment, medical devices, aviation headsets, and two-way radio communications. The standardized four-pole configuration (left, right, ground, microphone) remains valuable in environments requiring reliable, low-latency analog audio transmission with microphone support. -

Expansion in Audio Accessories and Adapters

The demand for TRRS-compatible accessories—such as headset adapters, audio interface dongles, and multi-function cables—will rise. Consumers using modern USB-C or Lightning devices will continue to rely on TRRS adapters for legacy headphones and professional headsets. This accessory-driven market will support steady TRRS component manufacturing. -

Regional Market Disparities

In regions like India, Southeast Asia, and parts of Africa, the 3.5mm TRRS jack will persist in popular smartphone models. Local brands and affordable devices are likely to retain the port to meet consumer expectations for headphone compatibility without additional costs, ensuring ongoing regional demand. -

Integration with Hybrid Audio Solutions

By 2026, hybrid devices combining analog TRRS with digital interfaces (e.g., combo jacks supporting both audio and data) may gain traction in laptops, tablets, and communication devices. This dual-functionality appeals to users needing both headset connectivity and accessory power/signaling through a single port. -

Impact of Audio Standardization Efforts

Industry efforts to standardize pin configurations (OMTP vs. CTIA) have largely converged on CTIA, reducing compatibility issues. Continued adherence to CTIA standards will streamline TRRS connector usage across global markets, supporting interoperability and reducing consumer friction. -

Sustainability and Repairability Trends

Growing emphasis on device repairability and sustainability may renew interest in modular designs that include replaceable TRRS jacks. Regulatory developments, such as the EU’s push for longer device lifespans, could indirectly support the retention of standardized analog connectors in certain electronics.

Conclusion:

While the TRRS phone connector is no longer at the forefront of consumer smartphone innovation, its utility in professional, industrial, and regional markets ensures it will remain relevant through 2026. The market will shift from mass consumer integration to targeted applications, supported by accessory ecosystems and standardization. Manufacturers focusing on durability, compatibility, and hybrid solutions will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing TRRS Phone Connectors (Quality, IP Rating)

Sourcing TRRS (Tip-Ring-Ring-Sleeve) phone connectors—commonly used in headsets, audio devices, and communication equipment—requires careful attention to both quality and ingress protection (IP) ratings. Overlooking key factors can lead to product failure, customer dissatisfaction, or increased return rates. Below are common pitfalls to avoid:

Inadequate Quality Control and Material Selection

Many suppliers offer low-cost TRRS connectors made from substandard materials such as zinc alloy with thin plating or low-grade plastics. These materials wear quickly, leading to poor electrical contact, intermittent signals, or mechanical failure. Always verify plating thickness (e.g., gold or nickel), use of phosphor bronze or beryllium copper for spring contacts, and durability through mating cycle testing (e.g., 5,000+ insertions).

Misunderstanding or Falsifying IP Ratings

IP (Ingress Protection) ratings indicate resistance to dust and moisture, but some suppliers exaggerate or misapply ratings. A connector advertised as IP54 may not have been independently tested. Ensure certifications are backed by third-party test reports and confirm that the rating applies to the mated (connected) state, not just the standalone connector. Real-world sealing depends on proper design integration, including gaskets and housing.

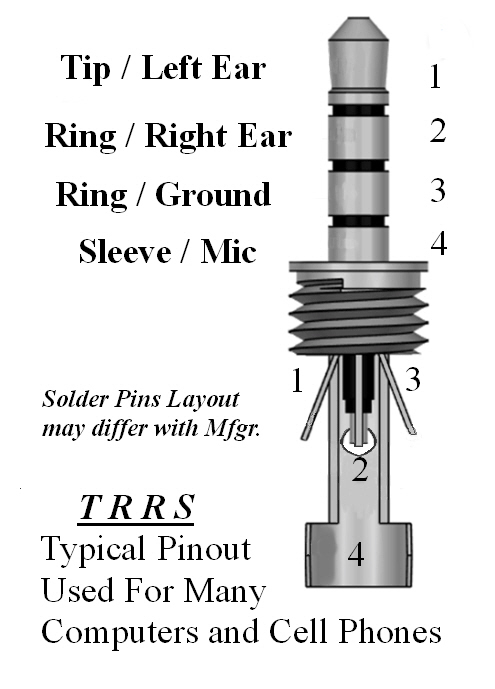

Inconsistent Pin Configuration and Compatibility

TRRS connectors come in various configurations (e.g., CTIA vs. OMTP), and sourcing the wrong type leads to audio or control function failures. Always confirm the pinout (Tip: Left, Ring1: Right, Ring2: Ground, Sleeve: Mic) matches your device standard. Mixed batches from unreliable suppliers can result in mismarked or reversed wiring.

Poor Mechanical Design Leading to Durability Issues

Cheap connectors often lack strain relief, robust housing, or proper keying, making them prone to damage from frequent use or cable stress. This is especially critical in industrial or outdoor applications. Evaluate the connector’s retention force, shroud strength, and cable exit design during sourcing.

Insufficient Environmental and Electrical Testing

Many low-tier suppliers do not perform essential tests such as thermal cycling, humidity exposure, or contact resistance measurements. Without proper testing, connectors may fail in real-world conditions. Require evidence of compliance with relevant standards (e.g., IEC 60603, MIL-STD for rugged applications).

Lack of Traceability and Supplier Reliability

OEMs may face supply chain disruptions or inconsistent quality when sourcing from multiple unverified vendors. Prioritize suppliers with consistent manufacturing processes, quality certifications (e.g., ISO 9001), and traceable lot numbering to support recalls or root cause analysis.

By addressing these pitfalls early in the sourcing process—through rigorous qualification, sample testing, and clear specifications—you can ensure reliable, high-performance TRRS connectors that meet both quality and environmental requirements.

Logistics & Compliance Guide for Trrs Phone Connector

This guide outlines the key logistics and compliance considerations for the distribution, handling, and use of the Trrs Phone Connector. Adherence to these guidelines ensures regulatory compliance, safe transport, and product integrity across the supply chain.

Product Classification & Documentation

Ensure the Trrs Phone Connector is accurately classified under the appropriate Harmonized System (HS) code for international trade (e.g., 8536.69 for electrical connectors). Maintain up-to-date technical specifications, Safety Data Sheets (SDS) if applicable, and product conformity declarations. All shipments must include a commercial invoice, packing list, and bill of lading or air waybill with precise product descriptions.

Packaging & Labeling Requirements

Package connectors in static-dissipative or anti-static materials to prevent electrostatic discharge (ESD) damage. Use sealed, durable packaging to protect against moisture, dust, and physical impact during transit. Label each package with the product name, model number, quantity, batch/lot number, and handling symbols (e.g., “Fragile,” “Do Not Stack,” “This Side Up”). Include any required compliance marks such as RoHS, REACH, or CE directly on the product or packaging.

Regulatory Compliance

The Trrs Phone Connector must comply with relevant regional regulations:

– RoHS (EU): Ensure restricted substances (e.g., lead, cadmium, mercury) are below permissible limits.

– REACH (EU): Confirm no substances of very high concern (SVHC) are present above threshold levels.

– FCC (USA): Comply with electromagnetic compatibility (EMC) standards if applicable.

– IEC Standards: Meet IEC 60603 for dimensional and electrical performance standards for connectors.

Provide Declaration of Conformity (DoC) for applicable markets.

Import/Export Controls

Verify export regulations based on destination country. The Trrs Phone Connector may be subject to export control classifications under the Export Administration Regulations (EAR) in the U.S. Determine if an export license is required, particularly for shipments to sanctioned or restricted regions. Use Electronic Export Information (EEI) filings via the Automated Export System (AES) when required.

Shipping & Handling

Use certified logistics partners experienced in handling electronic components. Maintain a temperature-controlled environment (typically 10°C to 30°C) and relative humidity below 60% during storage and transport. Avoid exposure to extreme conditions or corrosive atmospheres. Follow warehouse best practices for stock rotation (FIFO) and secure storage.

End-of-Life & Environmental Responsibility

Support compliance with WEEE (Waste Electrical and Electronic Equipment) directives by providing take-back or recycling information where applicable. Design packaging to be recyclable and minimize environmental impact. Encourage end-users to dispose of connectors through certified e-waste channels.

Audit & Record Retention

Maintain records of compliance certifications, test reports, shipping documents, and supplier declarations for a minimum of five years. Conduct periodic internal audits to verify adherence to logistics and compliance protocols and prepare for potential third-party or regulatory inspections.

In conclusion, sourcing TRRS phone connectors requires careful consideration of several key factors to ensure compatibility, reliability, and performance. It is essential to identify the correct configuration (e.g., CTIA vs. OMTP) and size (typically 3.5mm or 2.5mm) to match the intended audio device and application. Quality should be prioritized by selecting connectors from reputable suppliers or manufacturers that adhere to international standards and offer consistent electrical performance and durable construction.

Environmental resistance, such as shielding and plating (e.g., gold-plated contacts for corrosion resistance), plays a significant role in long-term reliability, especially in demanding applications. Additionally, evaluating supplier lead times, minimum order quantities (MOQs), and cost efficiency is crucial for seamless integration into production workflows.

Ultimately, a strategic sourcing approach—balancing specifications, quality, cost, and supply chain considerations—will ensure the successful integration of TRRS connectors into audio and communication devices, supporting optimal functionality and customer satisfaction.