The global phosphate fertilizer market, which includes key compounds such as trisodium phosphate (TSP), is experiencing steady growth driven by rising agricultural demand and the need for high-efficiency nutrient sources. According to Grand View Research, the global phosphate fertilizer market size was valued at USD 79.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. This growth is fueled by increasing crop intensification, government support for food security, and advancements in fertilizer production technologies. As one of the concentrated phosphorus-based fertilizers, trisodium phosphate plays a vital role in specialized agricultural applications, soil treatment, and pH regulation. With market dynamics shifting toward sustainable and precision farming, leading manufacturers are innovating to enhance product efficiency and reduce environmental impact. Below, we spotlight the top six trisodium phosphate fertilizer manufacturers shaping this evolving landscape, selected based on production capacity, global reach, and technological advancements.

Top 6 Trisodium Phosphate Fertilizer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Top Trisodium Phosphate Manufacturers

Domain Est. 1997

Website: accio.com

Key Highlights: How to Choose trisodium phosphate manufacturer supplier. Prioritize suppliers with verifiable production metrics and compliance documentation….

#2 Trisodium Phosphate

Domain Est. 1997

Website: chemone.com

Key Highlights: Rating 5.0 · Review by astoundzFertilizer (27); Food (8); Industrial (63); Technical (7); Water Treatment (37).. DODECAHYDRATE. Trisodium Phosphate. Categories: Industrial, Wa…

#3 Chemical raw material

Domain Est. 2022

Website: goldenefertilizer.com

Key Highlights: Shop top-quality TSP (Trisodium Phosphate) chemical raw material for various industrial applications. Buy now for reliable and efficient results!…

#4 Products & Applications

Domain Est. 1998

Website: prayon.com

Key Highlights: Extensive range of high-quality phosphate and fluorine solutions that enhance your products from food & beverage, technical to plant nutrition applications….

#5 ICL’s TSP and SSP Phosphate Fertilizers and their Contribution to …

Domain Est. 2002

Website: icl-group.com

Key Highlights: SSP and TSP fertilizers are both proven fertilizers that can enable high yield, high-quality harvests, even on marginal lands….

#6 PhosAgro company is one of the world’s leading phosphate

Domain Est. 2005

Website: phosagro.com

Key Highlights: PhosAgro is a Russian vertically-integrated company that holds one of the leading positions in the world in terms of production of phosphorus-containing ……

Expert Sourcing Insights for Trisodium Phosphate Fertilizer

H2: Projected Market Trends for Trisodium Phosphate Fertilizer in 2026

As of 2026, the global market for trisodium phosphate (TSP) in agricultural applications—particularly as a fertilizer—is expected to experience moderate transformation driven by regulatory, environmental, and technological factors. While trisodium phosphate is more commonly recognized for its industrial and cleaning applications, its role in fertilizer formulations, particularly in niche or specialty agriculture, continues to evolve under shifting market dynamics.

-

Declining Use Due to Environmental Regulations

A significant trend shaping the TSP fertilizer market in 2026 is the continued regulatory scrutiny surrounding phosphate runoff. High phosphate content in fertilizers, including TSP-based products, contributes to eutrophication in water bodies, leading to algal blooms and aquatic ecosystem degradation. In regions such as the European Union and North America, stricter environmental policies are discouraging the use of high-phosphorus fertilizers. As a result, demand for trisodium phosphate in mainstream agriculture is projected to decline, with farmers shifting toward more sustainable alternatives. -

Niche Applications and Hydroponics

Despite declining use in traditional agriculture, trisodium phosphate retains relevance in controlled-environment agriculture, such as hydroponics and greenhouse cultivation. In 2026, the growing adoption of precision farming and soilless cultivation techniques is creating a niche demand for TSP due to its high solubility and ability to deliver readily available phosphorus. These controlled systems minimize environmental leaching, making TSP a more acceptable option in such settings. -

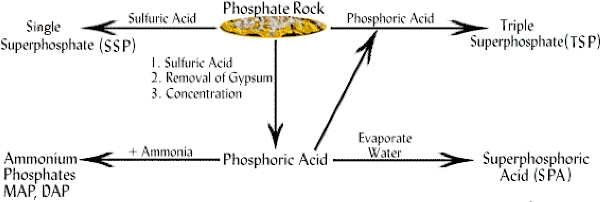

Shift Toward Alternative Phosphate Sources

The fertilizer industry is witnessing a broader shift toward alternative phosphate sources such as monoammonium phosphate (MAP), diammonium phosphate (DAP), and organically derived phosphates. These alternatives offer better nutrient efficiency and lower environmental impact. In 2026, TSP is increasingly viewed as a less optimal choice compared to these modern formulations, especially in large-scale farming operations focused on sustainability and regulatory compliance. -

Emerging Markets with Lagging Regulations

While developed markets are reducing TSP usage, certain developing regions—particularly in parts of Southeast Asia, Africa, and South America—may continue to utilize TSP-based fertilizers due to lower regulatory enforcement and cost-effectiveness. However, even in these regions, awareness of environmental consequences is growing, and international sustainability initiatives are beginning to influence local agricultural practices, potentially curbing long-term TSP adoption. -

Innovation and Reformulation Efforts

Some chemical manufacturers are exploring ways to reformulate trisodium phosphate for agricultural use by combining it with slow-release technologies or blending it with bio-stimulants to reduce runoff potential. While still in early stages, such innovations could carve out a limited but resilient market segment for TSP-based products by 2026, particularly in specialty crop production. -

Price Volatility and Raw Material Constraints

Phosphate rock, the primary raw material for TSP, faces periodic price fluctuations due to geopolitical tensions, supply chain disruptions, and mining restrictions. In 2026, ongoing concerns about phosphate rock availability—especially from key exporters like Morocco and China—are contributing to cost instability, making TSP less economically attractive compared to stabilized or recycled phosphate products.

Conclusion:

By 2026, the trisodium phosphate fertilizer market is expected to occupy a shrinking but specialized role within the broader agricultural sector. Environmental regulations, sustainability trends, and competition from more efficient phosphate fertilizers are the primary forces limiting its growth. However, in controlled agricultural environments and select developing markets, TSP may maintain limited relevance. Long-term viability will depend on innovation in delivery systems and alignment with circular economy principles in nutrient management.

Common Pitfalls in Sourcing Trisodium Phosphate Fertilizer (Quality, IP)

Sourcing Trisodium Phosphate (TSP) fertilizer effectively requires careful attention to both quality specifications and intellectual property (IP) considerations. Overlooking these aspects can lead to significant operational, legal, and financial risks.

Quality-Related Pitfalls

- Inadequate Purity and Grade Verification: Failing to verify that the TSP meets the required agricultural grade (e.g., FCC, technical grade) and minimum phosphate content (typically P₂O₅) can result in ineffective fertilization, crop damage, or soil imbalances. Suppliers may offer industrial-grade TSP unsuitable for agricultural use.

- Contaminant Presence: Sourcing TSP with high levels of heavy metals (e.g., cadmium, lead), arsenic, or other harmful impurities is a major risk. These contaminants can accumulate in soil and crops, posing environmental and food safety hazards, potentially leading to regulatory non-compliance and reputational damage.

- Inconsistent Batch Quality: Relying on suppliers without robust quality control systems can lead to significant variations in particle size, moisture content, solubility, and nutrient concentration between batches. This inconsistency disrupts precise nutrient application and can impact crop performance.

- Misrepresentation of Form: Confusion can arise between different phosphate compounds. Ensuring the product is genuine Trisodium Phosphate (Na₃PO₄) and not mislabeled or substituted with other sodium phosphates (e.g., disodium phosphate) is crucial for achieving the desired agronomic effect.

- Poor Packaging and Handling: TSP is hygroscopic (absorbs moisture). Sourcing from suppliers using inadequate packaging (e.g., non-moisture-proof bags) leads to caking, degradation, handling difficulties, and reduced efficacy upon application.

Intellectual Property (IP)-Related Pitfalls

- Infringement of Patented Formulations or Processes: Some TSP fertilizers may incorporate proprietary additives, coatings, or be produced via patented manufacturing processes. Sourcing such products without proper licensing, especially from unauthorized or grey-market suppliers, exposes the buyer to infringement claims from patent holders, potentially resulting in lawsuits, import seizures, or forced product recalls.

- Unauthorized Use of Brand Names/Trademarks: Purchasing TSP labeled with a well-known brand name from a non-authorized distributor risks acquiring counterfeit or diverted goods. This not only voids warranties and support but also carries legal liability for trademark infringement and risks to product quality and performance.

- Lack of Clear IP Warranties in Contracts: Failing to include explicit warranties in supply agreements where the seller guarantees the product does not infringe third-party IP rights leaves the buyer vulnerable. If infringement occurs, the buyer may have no recourse against the supplier for resulting legal costs or damages.

- Sourcing from Jurisdictions with Weak IP Enforcement: Procuring TSP from regions known for lax IP protection increases the risk of inadvertently obtaining counterfeit or IP-infringing products, even if the supplier appears legitimate. Due diligence on the supplier’s origin and manufacturing practices is essential.

- Neglecting Background IP in Customized Products: If sourcing a customized TSP blend or formulation, failing to clarify ownership of any new IP developed during customization (e.g., specific mixing processes, novel additives) can lead to disputes over rights, usage, and future sourcing flexibility.

H2: Logistics & Compliance Guide for Trisodium Phosphate (TSP) Fertilizer

Trisodium Phosphate (TSP), while historically used as a fertilizer, is now primarily regulated as a cleaning agent and food additive in many jurisdictions. Its use in agriculture is limited and highly regulated due to environmental concerns (eutrophication). This guide focuses on the logistics and compliance aspects of handling TSP in contexts where it is approved or used as a fertilizer component, emphasizing safety, environmental protection, and regulatory adherence.

H2: Regulatory Classification & Key Considerations

- Primary Classification: TSP (Na₃PO₄) is typically classified as an irritant (Skin, Eye, Respiratory). It is not usually classified as acutely toxic, flammable, or explosive under GHS/CLP.

- Fertilizer-Specific Regulations: Regulations vary significantly by country/region (e.g., EU Fertilising Products Regulation (FPR) 2019/1009, US EPA/FIFRA, country-specific fertilizer laws). Crucially, TSP is often restricted or banned as a direct fertilizer due to phosphate runoff concerns. Its use is often limited to specific soil conditions (e.g., highly acidic soils needing phosphorus and sodium adjustment) or as a minor component in specialized formulations.

- GHS Pictograms & Hazard Statements (Typical):

- Pictogram: GHS07 (Exclamation Mark)

- Hazard Statements (H-Phrases):

- H319: Causes serious eye irritation.

- H315: Causes skin irritation.

- H335: May cause respiratory irritation.

- UN Number: UN 3400 (Sodium phosphates, n.o.s. (Trisodium phosphate)) – Class 9 (Miscellaneous dangerous substances and articles). Verify the exact UN number and classification with your specific product’s SDS and competent authority.

- Environmental Regulation: TSP is a significant source of phosphorus. Strict regulations govern its use, storage, and disposal to prevent runoff into waterways, which causes algal blooms and eutrophication. Permits may be required for large-scale storage or application.

H2: Transportation (Land, Sea, Air)

- Classification: Transported as UN 3400, SODIUM PHOSPHATES, N.O.S. (Trisodium phosphate), 9, PG III (Packing Group III – Low danger). Always confirm classification with the Safety Data Sheet (SDS) and regulations.

- Packaging:

- Use strong, leak-proof, moisture-resistant containers (e.g., multi-wall paper bags with polyethylene liners, high-density polyethylene (HDPE) drums, intermediate bulk containers (IBCs)).

- Ensure packaging is suitable for the quantity and mode of transport (e.g., IBCs for bulk, bags/drums for smaller quantities).

- Clearly label packages with:

- Proper Shipping Name: “SODIUM PHOSPHATES, N.O.S. (Trisodium phosphate)”

- UN Number: “UN 3400”

- Hazard Class: “9”

- Packing Group: “III”

- GHS Pictograms (Exclamation Mark)

- Transport Hazard Labels (Class 9 Miscellaneous)

- “Keep Dry” and “Protect from Moisture” markings.

- Documentation:

- Safety Data Sheet (SDS): Mandatory. Must be readily available to all handlers and emergency responders.

- Transport Document (e.g., Waybill, Bill of Lading): Must include UN number, Proper Shipping Name, Hazard Class, Packing Group, and quantity.

- Shipper’s Declaration for Dangerous Goods (Air/Sea): Required for air and sea transport under IATA DGR / IMDG Code. Prepared by trained personnel.

- Modes:

- Road (ADR): Comply with ADR regulations. Vehicle may need Class 9 placards depending on quantity. Segregate from strong acids (risk of toxic fumes – phosphine) and oxidizers.

- Sea (IMDG Code): Comply with IMDG Code. Use appropriate container/hold stowage. Segregation from acids and oxidizers is critical. Proper documentation (Dangerous Goods Manifest).

- Air (IATA DGR): Comply with IATA Dangerous Goods Regulations. Note: Air transport of Class 9 substances often has stricter quantity limits and packaging requirements. Consult IATA DGR thoroughly. May be prohibited on passenger aircraft in certain quantities/forms.

H2: Storage

- Location: Store in a cool, dry, well-ventilated, dedicated, lockable area away from direct sunlight, heat sources, and incompatible materials.

- Conditions:

- Maintain low humidity (<50% RH preferred) to prevent caking and moisture absorption.

- Temperature should be stable and moderate (avoid extremes).

- Segregation: STRICTLY SEGREGATE from:

- Strong Acids (e.g., Sulfuric, Hydrochloric, Nitric acid): Contact can produce highly toxic phosphine (PH₃) gas.

- Oxidizers (e.g., Nitrates, Chlorates, Perchlorates): Risk of fire or violent reaction.

- Foodstuffs, Feed, and Edible Products: Prevent contamination.

- Containers: Keep original, properly labeled containers closed tightly when not in use. Use pallets for stacking stability. Prevent dust generation.

- Secondary Containment: Use bunded (diked) areas or spill pallets capable of holding at least 110% of the largest container’s volume to contain leaks or spills. Prevent access to drains.

- Inventory & Labeling: Maintain accurate inventory. Ensure all containers are clearly labeled with contents, hazards, and GHS pictograms.

H2: Handling & Personal Protective Equipment (PPE)

- General Principles: Minimize dust generation. Use local exhaust ventilation (LEV) where dust is created (e.g., bag tipping, mixing). Practice good hygiene.

- Essential PPE:

- Respiratory Protection: Dust mask (e.g., NIOSH N95 or equivalent) for routine handling with potential dust. Use a powered air-purifying respirator (PAPR) or supplied air in high-dust environments or confined spaces.

- Eye Protection: Chemical splash goggles (ANSI Z87.1). Face shield recommended for tasks generating significant dust or splash risk.

- Skin Protection: Wear chemical-resistant gloves (e.g., nitrile, neoprene). Wear long-sleeved clothing and chemical-resistant apron. Wear safety boots.

- Procedures:

- Avoid breathing dust. Do not eat, drink, or smoke in handling areas.

- Wash hands thoroughly after handling, even when wearing gloves.

- Clean up spills promptly using appropriate methods (see below).

- Use mechanical handling (e.g., pallet jacks) where possible to reduce manual lifting.

H2: Spill & Leak Response

- Immediate Actions:

- Alert: Notify personnel and supervisor. Evacuate non-essential personnel if significant dust or unknown reaction.

- Contain: Prevent material from entering drains, sewers, waterways, or soil. Use absorbent materials (e.g., sand, vermiculite, commercial absorbents) or dikes.

- Ventilate: Increase ventilation in the area.

- Cleanup:

- Small Spills: Wear full PPE. Carefully collect spilled material using non-sparking tools (shovel, brush). Place in a suitable, labeled container for disposal. Wipe area with damp cloth; collect rinse water as hazardous waste.

- Large Spills: Do not handle alone. Contact emergency services or specialized contractor. Keep upwind. Prevent spread.

- Disposal: Collect all contaminated material (spill, absorbents, rinsate, PPE) as Hazardous Waste. Dispose of according to local, state/provincial, and national regulations. Never dispose of down drains or in regular trash. Phosphorus content requires special wastewater treatment.

H2: Waste Disposal

- Classification: Waste TSP and contaminated materials are hazardous waste due to phosphorus content and potential environmental impact.

- Procedure: Collect waste in clearly labeled, compatible, leak-proof containers. Store securely (see Storage section).

- Disposal: Dispose of only through licensed hazardous waste contractors authorized to handle phosphorus-containing waste. Follow all manifesting and tracking requirements. Document disposal meticulously.

H2: Training & Documentation

- Mandatory Training: All personnel involved in handling, storage, transport, or emergency response must receive training on:

- Hazards of TSP (health, safety, environmental).

- Proper use of PPE.

- Safe handling, storage, and transport procedures.

- Spill response and emergency procedures.

- Location and use of SDSs.

- Waste disposal procedures.

- Relevant regulations (GHS, ADR, IMDG, IATA, local).

- Documentation:

- Maintain up-to-date Safety Data Sheets (SDS) for each batch/supplier.

- Keep records of employee training.

- Maintain transport documentation (waybills, declarations).

- Keep waste manifests and disposal records.

- Document spill incidents and corrective actions.

- Maintain inventory logs.

Disclaimer: This guide provides general information. Regulations are complex and subject to change. ALWAYS consult the specific Safety Data Sheet (SDS) provided by your supplier, and comply with all applicable local, national, and international regulations (e.g., EPA, ECHA, DOT, Health Canada, local environmental agencies). Seek expert advice when necessary.

In conclusion, sourcing trisodium phosphate (TSP) as a fertilizer requires careful consideration of its benefits, regulatory constraints, and environmental impact. While TSP can be an effective source of phosphorus for crop nutrition, its use in agriculture is limited and often discouraged due to concerns over phosphate runoff, eutrophication of water bodies, and regulatory restrictions in many regions. Additionally, the industrial and cleaning applications of TSP make its availability and cost for agricultural use less competitive compared to other phosphate fertilizers like diammonium phosphate (DAP) or triple superphosphate (TSP, note similar acronym but different compound).

Sourcing TSP for agricultural purposes should be approached with thorough evaluation of local regulations, environmental guidelines, and the specific nutrient needs of the soil and crops. In most cases, more sustainable and agronomically suitable phosphorus sources are recommended. Therefore, while trisodium phosphate has phosphorus-containing properties, it is generally not a practical or approved choice for modern fertilizer applications, and alternative phosphate fertilizers should be prioritized for responsible and efficient nutrient management.