The global electrical cable market is experiencing robust expansion, driven by increasing urbanization, rising infrastructure investments, and growing demand for reliable power transmission across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the electrical cable market was valued at USD 177.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A significant contributor to this growth is the rising adoption of triplex cables—commonly used in overhead power distribution—particularly in expanding utility grids and rural electrification projects. These bundled conductor cables, known for their cost-efficiency and ease of installation, are increasingly specified in low-voltage distribution networks. As demand intensifies, manufacturers are focusing on improved materials, enhanced insulation technologies, and compliance with regional safety standards to gain competitive advantage. In this evolving landscape, the following nine triplex electrical cable manufacturers stand out for their innovation, production scale, and market reach.

Top 9 Triplex Electrical Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Service Wire Company

Domain Est. 1996 | Founded: 1968

Website: servicewire.com

Key Highlights: Since 1968, we’ve built a reputation for safely manufacturing high-quality wire and cable, delivering industry-leading service levels….

#2 Triplex cable,Triplex wire,Triplex service drop cable

Domain Est. 2011

Website: jytopcable.com

Key Highlights: JYTOP Cable is a professional Triplex cable,Triplex wire (Triplex service drop cable) manufacturer and supplier in China….

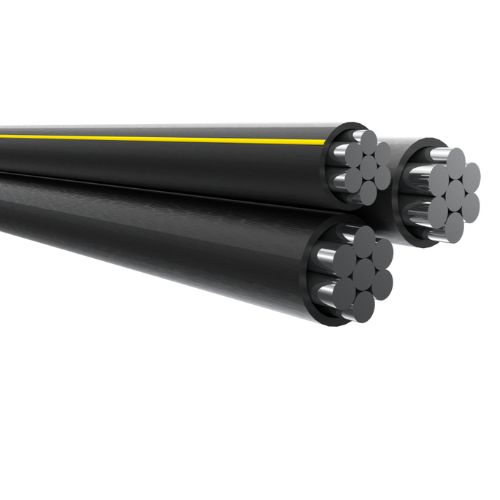

#3 Triplex URD Cable [ 600V Direct Burial Underground Service Cable ]

Domain Est. 2016

Website: 1xtechnologies.com

Key Highlights: We’re a leading United States electrical cable manufacturer headquartered in beautiful Wyoming USA, serving a broad & diverse customer base ……

#4 AL 600V

Domain Est. 1994

Website: southwire.com

Key Highlights: Two phase conductors and one neutral conductor are cabled together to produce the triplex cable configuration. Conductors are also available paralleled. 1350 ……

#5 Triplex Service Drop, Stranded, 2/0 AWG, 3 Conductors, Aluminum …

Domain Est. 1996

Website: stateelectric.com

Key Highlights: In stock $12 deliveryTriplex Service Drop, Stranded, 2/0 AWG, 3 Conductors, Aluminum, Black, 600 Volts, Code Name: Runcina….

#6 SERVICE DROP TRIPLEX

Domain Est. 1996

Website: kingwire.com

Key Highlights: KINGWIRE SERVICE DROP TRIPLEX To supply power from the utility’s lines to the consumer’s weatherhead. For service at 600 volts or less (phase to phase) at a ……

#7 Triplex Service Drop Cable

Domain Est. 1997

Website: houwire.com

Key Highlights: This triplex cable is suited for use as drop cable from a pole mounted transformer to the service entrance of a structure….

#8 Triplex Service Drop Cable #Nassa

Domain Est. 1998

Website: omnicable.com

Key Highlights: OmniCable only sells to electrical and communication distribution companies. Please enter your zip code to find a distributor near you. Enter your zip code ……

#9 Aluminum Triplex

Domain Est. 2014

Expert Sourcing Insights for Triplex Electrical Cable

H2: 2026 Market Trends for Triplex Electrical Cable

The global triplex electrical cable market is poised for steady growth and transformation by 2026, driven by converging infrastructure, energy, and technological demands. Key trends shaping the market include:

1. Accelerated Grid Modernization & Urbanization:

Governments and utilities worldwide are investing heavily in upgrading aging electrical distribution networks to enhance reliability and accommodate growing urban populations. Triplex cables, known for their cost-effective, compact three-phase overhead distribution capabilities, are critical components in these projects. Urban expansion and rural electrification initiatives, especially in Asia-Pacific, Latin America, and Africa, will significantly boost demand.

2. Rising Renewable Energy Integration:

The expansion of distributed energy resources (DERs), such as rooftop solar and small wind farms, necessitates robust local distribution infrastructure. Triplex cables are ideal for connecting these decentralized sources to the grid at the distribution level. As solar adoption grows—fueled by falling costs and policy support—demand for triplex cables in both residential and commercial solar installations will increase.

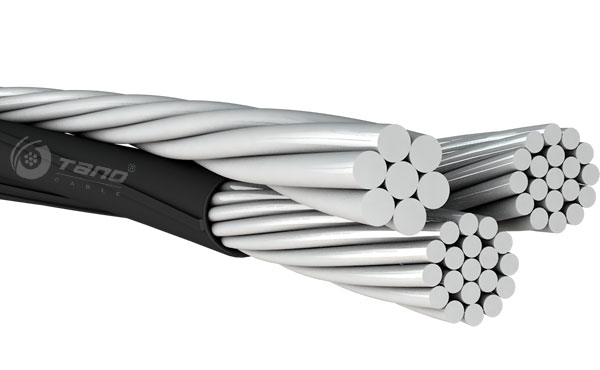

3. Shift Toward All-Aluminum and AAC/AAAC Conductors:

To reduce weight and material costs (particularly avoiding copper), there is a clear industry shift toward aluminum-based conductors in triplex cables. All-Aluminum Alloy Conductor (AAAC) and Aluminum Conductor (AAC) variants offer excellent conductivity-to-weight ratios and corrosion resistance, making them preferred choices for new installations and retrofits, especially in coastal or corrosive environments.

4. Emphasis on Durability and Extreme Weather Resilience:

With increasing frequency of extreme weather events due to climate change, utilities are prioritizing infrastructure resilience. This drives demand for triplex cables with enhanced insulation (e.g., cross-linked polyethylene – XLPE), UV-resistant jackets, and improved mechanical strength to withstand high winds, ice loading, and temperature fluctuations.

5. Regulatory Standards and Safety Compliance:

Stringent electrical safety standards (e.g., NEC in the U.S., IEC globally) are pushing manufacturers to improve product quality and performance. Compliance with fire safety, environmental, and sustainability regulations will influence material choices and production processes, potentially increasing demand for low-smoke zero-halogen (LSZH) jacketing in sensitive areas.

6. Supply Chain Optimization and Regional Manufacturing:

Ongoing supply chain disruptions and geopolitical factors are prompting regionalization of production. Manufacturers are establishing local or near-shore facilities to reduce lead times, mitigate risks, and respond faster to regional demand. This trend supports localized customization and faster deployment in emerging markets.

7. Digitalization and Smart Grid Integration:

While triplex cables themselves are passive components, they are part of broader smart grid deployments. Future-ready installations may incorporate triplex cables with sensors or alongside communication lines, enabling real-time monitoring of load, temperature, and faults—enhancing grid efficiency and predictive maintenance.

Conclusion:

By 2026, the triplex electrical cable market will be characterized by growth driven by infrastructure development, renewable energy expansion, and resilience needs. Innovation in materials, compliance with evolving standards, and strategic supply chain management will be key differentiators for manufacturers. The trend toward aluminum-based, durable, and cost-effective solutions will dominate, positioning triplex cables as essential elements in modern, sustainable power distribution networks.

Common Pitfalls When Sourcing Triplex Electrical Cable (Quality, IP)

Sourcing Triplex Electrical Cable can present several challenges, particularly when ensuring quality standards and verifying intellectual property (IP) protections. Buyers, contractors, and procurement teams must be aware of common pitfalls to avoid performance issues, safety hazards, and legal complications.

Substandard Material Composition

One of the most frequent quality issues involves cables made with inferior materials. Some suppliers may use aluminum conductors with low purity or subpar insulation materials that degrade quickly under environmental stress. These materials can lead to increased resistance, overheating, and premature cable failure, especially in demanding outdoor applications.

Inaccurate Voltage and Current Ratings

Misrepresentation of electrical specifications is a serious concern. Some triplex cables may be marketed with inflated voltage or current ratings that do not comply with international standards such as IEC, ASTM, or NEC. This can result in unsafe installations and compliance violations during inspections.

Poor Weather and UV Resistance

Triplex cables are often used in overhead installations and must withstand prolonged exposure to sunlight, moisture, and temperature fluctuations. Low-quality cables may lack adequate UV-resistant insulation or moisture barriers, leading to cracking, brittleness, and reduced lifespan.

Misleading IP (Ingress Protection) Ratings

The IP rating indicates protection against solid objects and liquids. A common pitfall is suppliers advertising false or unverified IP ratings. For example, a cable might be labeled IP55 without proper certification, giving a false sense of protection against dust and water jets. Always verify IP ratings through independent testing reports or certification bodies.

Lack of Certification and Documentation

Reputable triplex cables should come with certifications such as UL, CSA, CE, or RoHS compliance. Sourcing from suppliers who cannot provide valid documentation increases the risk of receiving counterfeit or non-compliant products. This also exposes buyers to liability in case of system failure or safety incidents.

Intellectual Property Infringement

Some manufacturers may copy patented cable designs, shielding techniques, or connector configurations without authorization. Sourcing such products—even unknowingly—can expose your organization to IP litigation, especially in regulated markets. Always verify that the supplier owns or is licensed to use the technology behind the cable design.

Inconsistent Manufacturing Quality

Cables sourced from unreliable manufacturers may exhibit inconsistencies in strand count, insulation thickness, or jacket uniformity. These variations compromise performance and reliability, particularly in large-scale or mission-critical installations.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request test reports, verify certifications, inspect samples, and work with reputable suppliers who respect both quality standards and intellectual property rights. Proper vetting ensures long-term reliability, safety, and legal compliance in your electrical projects.

Logistics & Compliance Guide for Triplex Electrical Cable

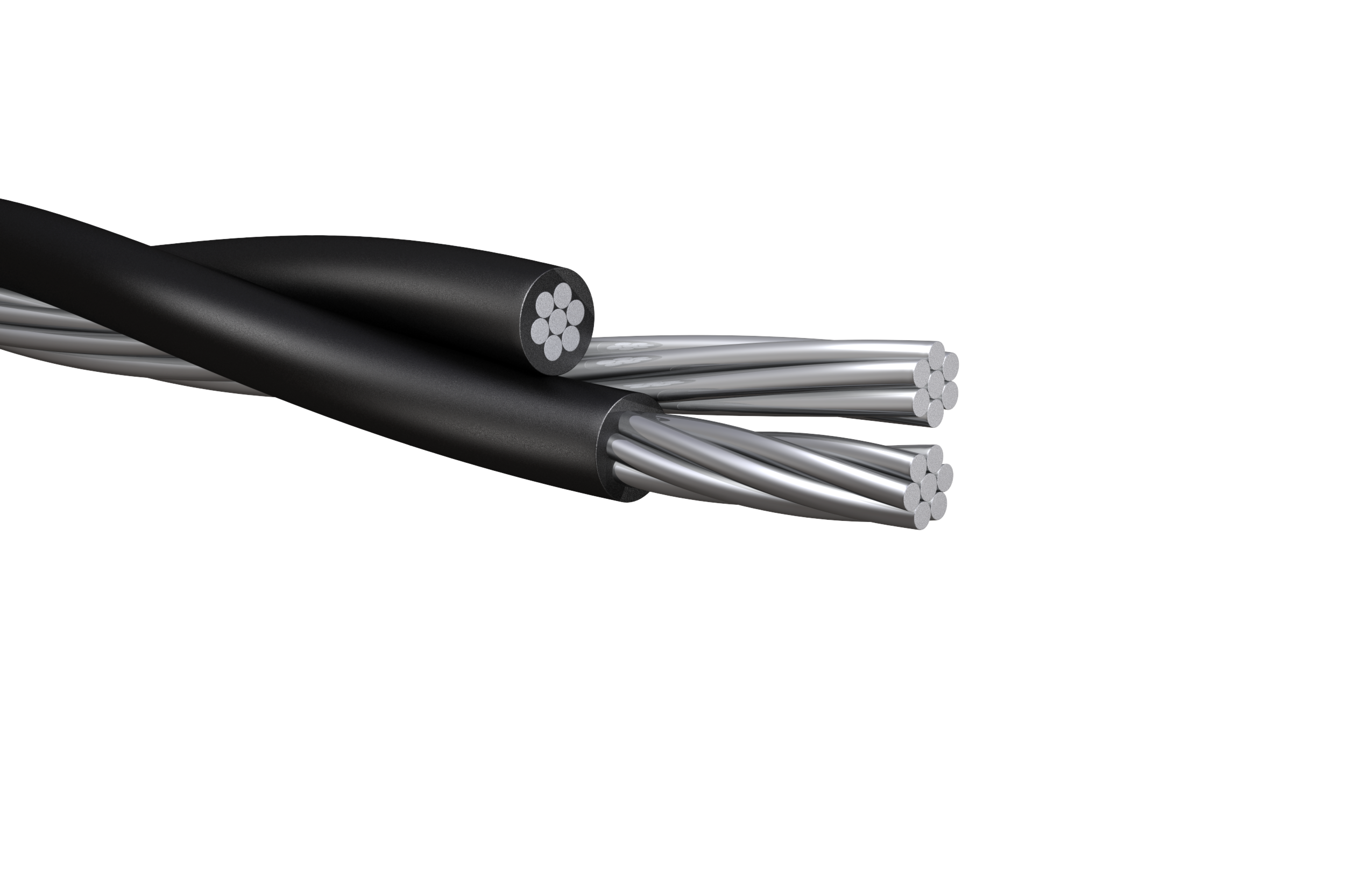

Overview of Triplex Electrical Cable

Triplex electrical cable consists of three insulated conductors—typically two phase conductors and one neutral (often a bare or insulated messenger wire)—twisted or bundled together. Commonly used in overhead secondary distribution systems, triplex cables are essential for delivering power from pole transformers to residential and commercial service entrances. Proper logistics and compliance are critical to ensure safety, performance, and adherence to regulatory standards.

Regulatory Compliance Standards

Triplex cables must comply with national and international electrical and safety standards. Key compliance requirements include:

– National Electrical Code (NEC) – NFPA 70 (USA): Governs installation practices, conductor sizing, insulation types, and ampacity ratings. Relevant articles include NEC Article 338 (Service-Entrance Cable) and Article 310 (Conductors for General Wiring).

– UL Standards: UL 44 (Rubber-Insulated Wire and Cable) and UL 83 (Thermoplastic-Insulated Wire and Cable) certify performance and safety. Look for UL Listed or CSA Listed markings.

– CSA C22.2 (Canada): Equivalent standards for use in Canadian markets, ensuring compatibility with the Canadian Electrical Code (CEC).

– RoHS & REACH (EU): For international shipments, ensure materials are free from restricted hazardous substances.

– DOT & OSHA (USA): Applicable for transportation safety and workplace handling requirements.

Product Specifications & Documentation

Ensure all triplex cable shipments include:

– Manufacturer datasheets detailing voltage rating (typically 600V), conductor size (e.g., 2/0 AWG), insulation type (XHHW, THHN, etc.), temperature rating, and ampacity.

– Certificate of Compliance (CoC) confirming adherence to UL, CSA, or other applicable standards.

– Material Safety Data Sheet (MSDS/SDS) for hazardous material disclosures, if applicable.

– Traceability information, including batch/lot numbers and manufacturing date.

Packaging & Handling Requirements

- Cables must be shipped on reels or spools to prevent kinking, crushing, or insulation damage.

- Reels should be clearly labeled with product type, length, gauge, voltage rating, and compliance markings.

- Protect ends with caps or tape to prevent moisture ingress and contamination.

- Store reels vertically on flat, dry surfaces; avoid exposure to direct sunlight, extreme temperatures, or standing water.

- Use lifting equipment (e.g., forklifts with reel clamps) when moving heavy spools—never roll reels over uneven surfaces.

Transportation & Shipping Considerations

- Secure reels on pallets or in shipping containers to prevent shifting during transit.

- Use weather-resistant covers or enclosed vehicles to protect from rain, snow, and UV exposure.

- Follow Department of Transportation (DOT) regulations for heavy or oversized cargo, including proper vehicle loading and load securement (FMCSA guidelines).

- For international shipments, comply with International Maritime Dangerous Goods (IMDG) Code if applicable, though most triplex cables are non-hazardous.

- Maintain chain-of-custody documentation and shipping manifests.

Import & Export Compliance

- Verify Harmonized System (HS) Code for triplex cables (e.g., 8544.42 or 8544.49 for insulated electrical conductors) for customs declarations.

- Obtain necessary import permits or certifications, especially for markets with stringent electrical safety requirements (e.g., CE marking for EU).

- Comply with U.S. Customs and Border Protection (CBP) and Foreign Trade Regulations (FTR) for export documentation (e.g., Automated Export System filings).

- Be aware of trade restrictions or tariffs on copper or aluminum conductors in certain countries.

On-Site Handling & Installation Compliance

- Only qualified electricians should install triplex cable per NEC/CEC guidelines.

- Maintain proper clearances from buildings, roads, and other utilities during installation.

- Use appropriate tensioning tools to avoid over-stressing the neutral messenger during aerial pulls.

- Inspect cables for damage before installation; do not use if insulation is compromised.

- Ground all metallic components per local code requirements.

Environmental & Disposal Considerations

- Recycle scrap triplex cable through certified e-waste or metal recyclers to recover copper/aluminum.

- Follow EPA and local regulations for disposal of non-recyclable cable components.

- Minimize environmental impact by preventing soil or water contamination during storage or installation.

Audit & Recordkeeping

Maintain records of:

– Certificates of Compliance and test reports for minimum of 5 years.

– Shipping and delivery logs.

– Installation inspection reports.

– Any non-conformance reports or corrective actions taken.

Regular internal audits help ensure ongoing compliance with all logistical and regulatory requirements.

Conclusion

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient handling of triplex electrical cable from manufacturing through installation. Compliance not only mitigates risk but also supports reliable electrical infrastructure and project success.

Conclusion for Sourcing Triplex Electrical Cable:

Sourcing triplex electrical cable requires a comprehensive evaluation of technical specifications, project requirements, supplier reliability, and cost-effectiveness. Triplex cables, commonly used in overhead power distribution for residential and light commercial applications, offer advantages such as durability, flexibility, and efficient phase balancing. When selecting a supplier, it is essential to ensure compliance with industry standards (e.g., ASTM, ICEA, or NEC), verify product certifications, and assess material quality—particularly conductor material (AAC, AAC/AS, or AAAC), insulation type, and weather resistance.

Additionally, lead times, logistical capabilities, and after-sales support play critical roles in maintaining project timelines. A well-balanced sourcing strategy should prioritize long-term reliability and safety over short-term cost savings. By partnering with reputable manufacturers and suppliers, conducting due diligence, and considering total cost of ownership, organizations can ensure the successful integration of triplex electrical cables into their infrastructure projects, supporting efficient and sustainable power distribution.

![Triplex URD Cable [ 600V Direct Burial Underground Service Cable ]](https://www.sohoinchina.com/wp-content/uploads/2026/01/triplex-urd-cable-600v-direct-burial-underground-service-cable-989.jpg)