The global apparel trims and embellishments market is experiencing steady expansion, driven by rising consumer demand for customized and fashion-forward clothing. According to a report by Grand View Research, the global apparel accessories market—encompassing trims such as zippers, buttons, labels, and decorative elements—was valued at USD 98.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by the increasing production of premium and ready-to-wear garments, especially in fast-fashion hubs across Asia-Pacific and emerging markets. Additionally, sustainability trends are reshaping sourcing strategies, with leading brands prioritizing eco-friendly trims made from recycled materials. As the fashion industry places greater emphasis on detail and differentiation, manufacturers of trims and embellishments are playing an increasingly strategic role in the supply chain. The following list highlights the top 10 manufacturers leading innovation, scale, and sustainability in this evolving sector.

Top 10 Trims And Embellishments Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TRIMS & NOVELTIES

Domain Est. 1995

Website: fashiondex.com

Key Highlights: A large selection of trims, notions & novelties. Appliques, beaded trims, cords, crochet trims, fringes, frogs, pompoms, ribbons, tassels & more….

#2 Scalamandré

Domain Est. 1997

Website: scalamandre.com

Key Highlights: Discover Scalamandré’s high-end fabrics, wallcoverings, trimming, lighting & furniture. Select from a range of iconic designs created by talented designers….

#3 Craft, Trim & Embellishments

Domain Est. 1999

Website: eeschenck.com

Key Highlights: Shop our curated collection of trims, embellishments, and craft project supplies all sold at wholesale prices. Discover your next endeavor in embroidery, ……

#4 Cheeptrims.com

Domain Est. 2000

#5 Samuel & Sons Passementerie

Domain Est. 2002

Website: samuelandsons.com

Key Highlights: All Trims Collections Sample books · Semi Custom. Back to main menu. Semi Custom … Filter. Type. Borders & Braids; Cords; Fringes; Tassels & Embellishments….

#6 About Vintage Trims

Domain Est. 2002

Website: vintagetrims.com

Key Highlights: VintageTrims.com is a 35 year old company that offers a huge selection of fabric trimmings, lace, braid and sewing products at great discounts….

#7 Joyce Trim

Domain Est. 2005

#8 Trimco Trims

Domain Est. 2015

Website: trimco-group.com

Key Highlights: We deliver trims to some of the biggest fashion brands worldwide, covering everything from hangtags, and woven and printed labels to badges and patches….

#9 Trims by the Yard

Domain Est. 2017

Website: trimsbytheyard.com

Key Highlights: Free delivery over $35 30-day returns…

#10 Schumacher

Domain Est. 2022

Website: schumacher.com

Key Highlights: Shop for fabrics, wallpaper and wallcoverings, trims, pillows, accessories, furniture and more at the official Schumacher website….

Expert Sourcing Insights for Trims And Embellishments

2026 Market Trends for Trims and Embellishments

The trims and embellishments market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and a growing emphasis on sustainability. As fashion and home décor sectors continue to innovate, trims—such as lace, ribbons, zippers, and beads—and decorative embellishments like embroidery, sequins, and appliqués—are becoming more than just aesthetic additions. They are key elements in storytelling, brand differentiation, and product value enhancement.

Rising Demand for Sustainable and Eco-Friendly Trims

Sustainability is at the forefront of the 2026 trims and embellishments market. Consumers and brands alike are demanding eco-conscious materials and production methods. By 2026, biodegradable threads, recycled polyester trims, organic cotton laces, and plant-based sequins are expected to dominate the market. Certifications such as GOTS, OEKO-TEX, and Cradle to Cradle will become standard requirements. Brands are increasingly partnering with suppliers who offer traceable, low-impact embellishment solutions, aligning with circular economy principles.

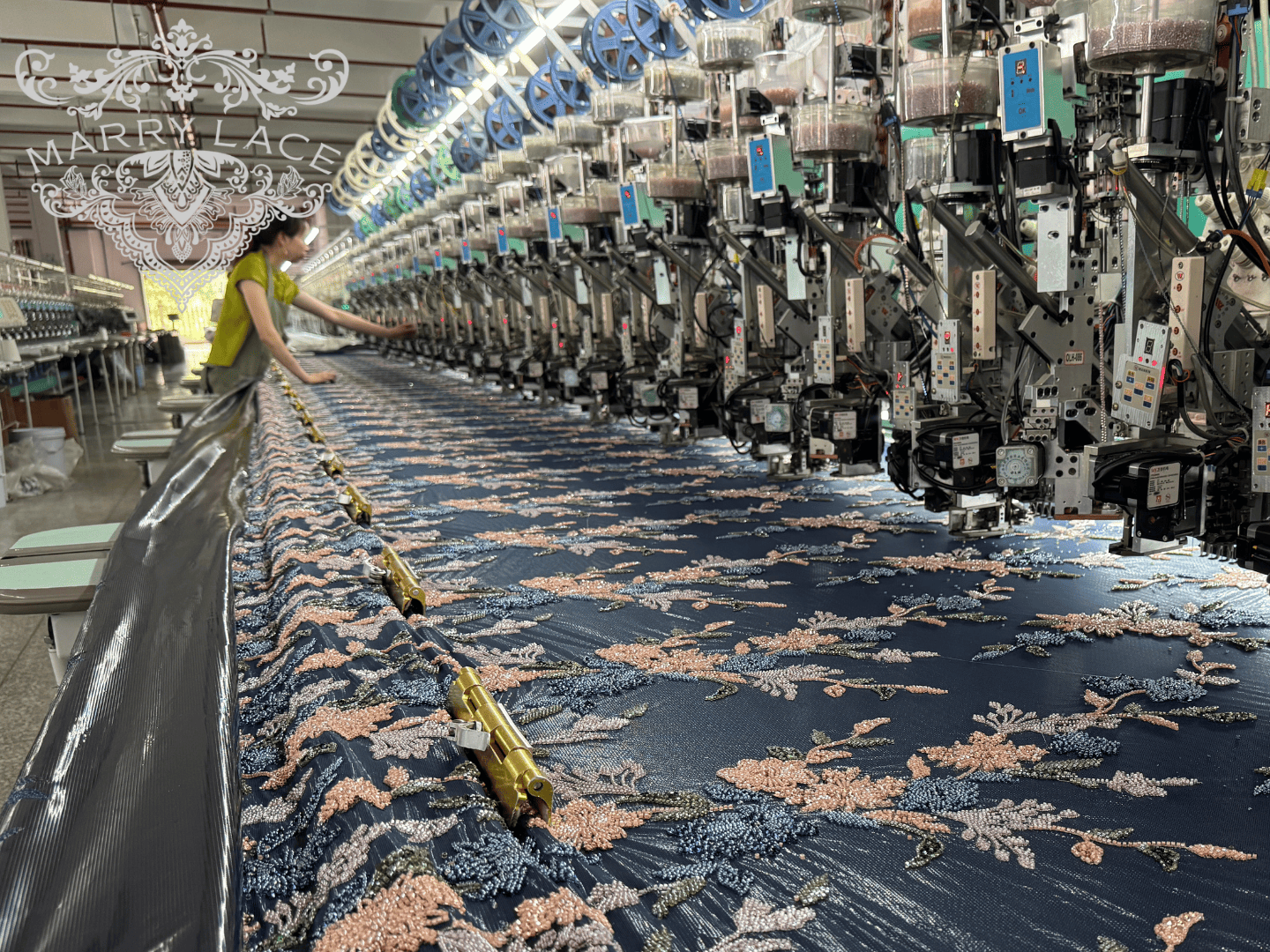

Technological Innovation and Smart Embellishments

Technological integration is reshaping traditional trims. In 2026, smart embellishments embedded with conductive threads, RFID tags, or temperature-responsive materials are gaining traction, especially in activewear and luxury fashion. 3D printing is enabling custom, on-demand trim production, reducing waste and lead times. Digital embroidery and laser-cut detailing offer high precision and design flexibility, appealing to designers seeking unique, limited-edition pieces.

Influence of Fast Fashion and Customization

While fast fashion continues to drive volume demand for affordable trims, there is a parallel shift toward personalization. By 2026, mass customization platforms will allow consumers to choose embellishments for garments and accessories online, fueling demand for modular and interchangeable trim systems. This trend supports both consumer engagement and brand loyalty, particularly among Gen Z and millennial shoppers.

Growth in Emerging Markets and Local Artisanship

Asia-Pacific, particularly India, China, and Southeast Asia, remains a major production hub and growing consumer market for trims. In 2026, there will be increased appreciation for handcrafted embellishments rooted in local traditions—such as Indian zari work, Ukrainian embroidery, or Japanese sashiko. Global brands are collaborating with artisan communities to offer culturally rich, ethically produced embellishments, adding premium value and authenticity to their collections.

Expansion Beyond Apparel into Home and Lifestyle

The application of trims and embellishments is expanding beyond fashion into home textiles, accessories, and lifestyle products. Decorative trims on upholstery, curtains, and bedding are becoming key design elements. In 2026, the interior design sector will increasingly adopt luxury embellishments, driven by the rise of “home as sanctuary” trends and social media-inspired aesthetics.

Conclusion

By 2026, the trims and embellishments market will be characterized by sustainability, innovation, and cultural authenticity. Brands that embrace eco-friendly materials, digital manufacturing, and inclusive design practices will lead the market. As trims evolve from functional components to strategic design assets, their role in defining brand identity and enhancing consumer experience will be more critical than ever.

Common Pitfalls Sourcing Trims And Embellishments: Quality and Intellectual Property Issues

Sourcing trims and embellishments—such as buttons, zippers, sequins, lace, patches, and decorative hardware—can significantly impact the final product’s look, durability, and compliance. However, brands and manufacturers often encounter critical challenges related to quality consistency and intellectual property (IP) infringement. Overlooking these pitfalls can lead to costly delays, product recalls, legal disputes, and reputational damage.

Inconsistent Quality Standards

One of the most frequent issues when sourcing trims and embellishments is inconsistent quality across production batches. Suppliers, particularly in low-cost regions, may use variable raw materials or lack rigorous quality control processes. This can result in mismatches in color, size, durability, or finishing (e.g., plating that tarnishes quickly or embroidery that unravels after minimal wear). Without clear specifications and third-party inspections, these inconsistencies can go unnoticed until after production, leading to rejected shipments or customer complaints.

Lack of Durability and Performance Testing

Many trims are not subjected to adequate performance testing before integration into garments or accessories. For example, buttons may crack under stress, zippers may jam, or adhesive-backed embellishments may peel after washing. Failing to test for factors like wash-fastness, abrasion resistance, and heat stability compromises product integrity and customer satisfaction. Brands often assume trims are “fit for purpose” without validating performance under real-world conditions.

Hidden Minimum Order Quantities (MOQs) and Lead Times

Suppliers may advertise attractive pricing but impose high MOQs for custom trims or embellishments, making small-batch production difficult and costly. Additionally, long lead times—especially for specialty items like custom zippers or embroidered patches—can disrupt production schedules. Delays in trim delivery often bottleneck the entire manufacturing process, resulting in missed delivery deadlines.

Intellectual Property Infringement Risks

Sourcing embellishments such as logos, branded hardware (e.g., designer-inspired buckles or zippers), or licensed characters carries significant IP risks. Many suppliers offer “inspired by” or counterfeit versions of branded trims, which may appear authentic but violate trademarks, copyrights, or design patents. Using these components—even unknowingly—can expose the buyer to legal action, seizure of goods by customs, and reputational harm.

Unauthorized Use of Licensed Designs

When working with licensed properties (e.g., cartoon characters, sports logos), brands must ensure that both the trim supplier and the final product manufacturer are authorized licensees. Sourcing embellishments from a non-licensed vendor, even if the design is purchased legitimately, can invalidate the brand’s license agreement and lead to termination of rights or litigation.

Poor Documentation and Traceability

Lack of proper documentation—such as material certifications, compliance reports (e.g., REACH, CPSIA), or certificates of authenticity for branded trims—can hinder traceability and regulatory compliance. This is especially critical in industries like children’s apparel or eco-conscious fashion, where material origin and safety standards are strictly enforced.

Avoiding these pitfalls requires thorough due diligence, clear communication of specifications, legal vetting of designs, and ongoing quality assurance throughout the supply chain.

Logistics & Compliance Guide for Trims And Embellishments

Overview

Trims and embellishments—such as buttons, zippers, lace, sequins, beads, labels, and embroidery threads—are essential components in apparel and textile manufacturing. While small in size, they significantly impact product quality, safety, sustainability, and compliance. Effective logistics and adherence to regulatory standards are critical to avoid delays, recalls, or legal issues. This guide outlines key considerations for managing the supply chain and compliance of trims and embellishments.

Sourcing and Supplier Selection

Choose suppliers carefully based on reliability, certifications, and ethical practices. Prioritize vendors who comply with international standards and can provide documentation upon request. Conduct regular audits to ensure continued compliance with environmental, labor, and safety regulations. Maintain a diversified supplier base to mitigate risks related to geopolitical issues or disruptions.

Material Compliance and Restrictions

Ensure all trims and embellishments meet relevant chemical and material restrictions, including:

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals—restricts substances like phthalates and heavy metals.

– CPSIA (USA): Consumer Product Safety Improvement Act—limits lead and phthalates in children’s products.

– OEKO-TEX® Standard 100: Certification indicating textiles are free from harmful levels of toxic substances.

– RoHS (EU): Restricts hazardous substances in electrical components (e.g., LED embellishments).

Request test reports and certificates from suppliers for each batch to verify compliance.

Packaging and Labeling Requirements

Proper packaging protects delicate trims during transit and ensures traceability. Use recyclable or sustainable packaging materials where possible. Labels must include:

– Item description and SKU

– Lot/batch number

– Country of origin

– Compliance markings (e.g., CE, UKCA, FCC if applicable)

– Care and handling instructions

Accurate labeling supports customs clearance and consumer safety.

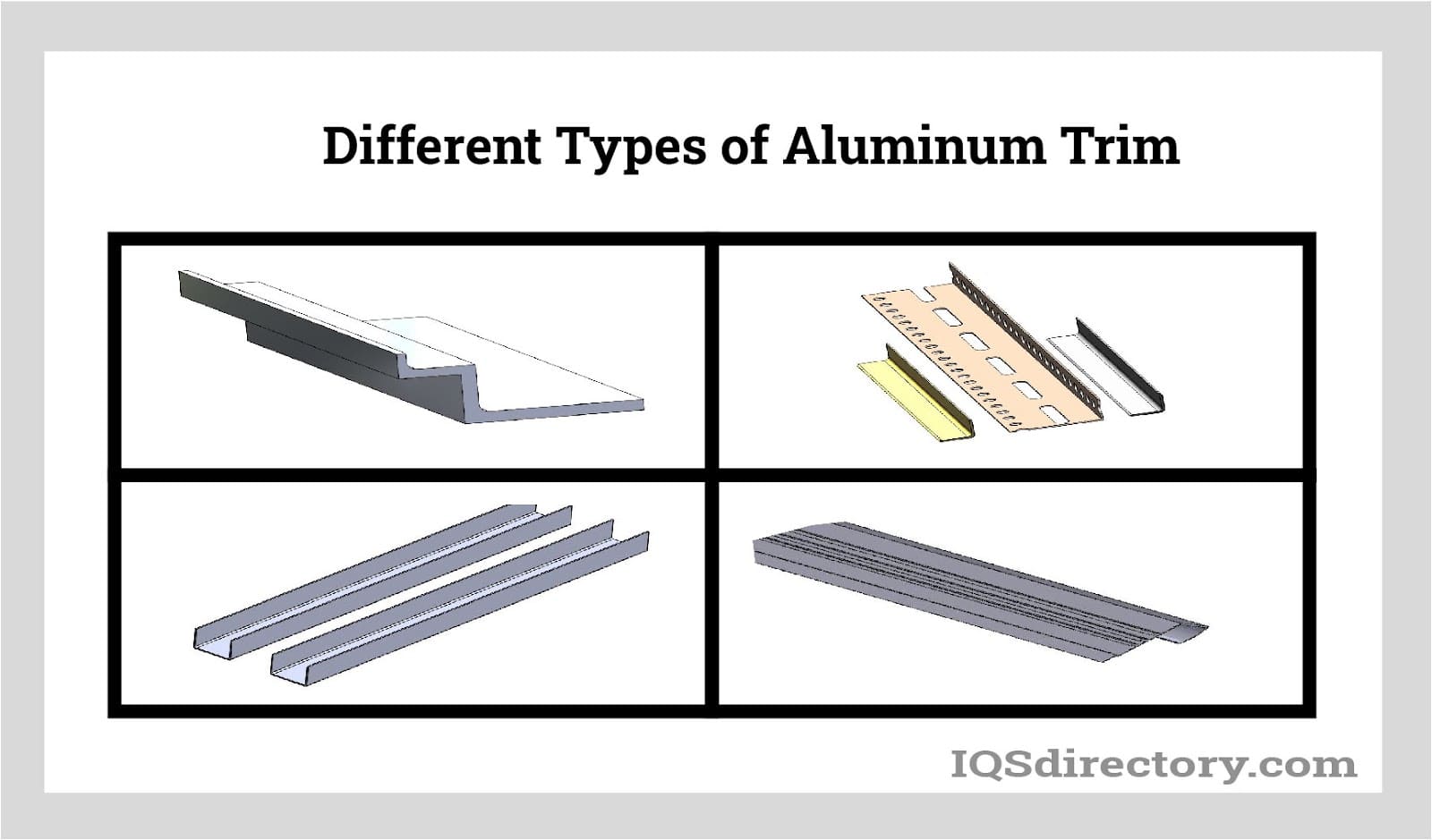

Import and Export Regulations

Understand tariff classifications (HS codes) specific to trims (e.g., 9606 for buttons, 9607 for zippers). Maintain up-to-date knowledge of:

– Import duties and quotas

– Rules of origin (e.g., USMCA, RCEP)

– Customs documentation (commercial invoice, packing list, certificates of origin)

– Prohibited or restricted materials (e.g., certain animal-based products like real pearl or bone)

Work with customs brokers to ensure smooth cross-border movement.

Sustainability and Environmental Compliance

Minimize environmental impact by:

– Selecting recyclable or biodegradable trims (e.g., corozo nuts, recycled polyester thread)

– Avoiding PVC-based embellishments

– Ensuring compliance with Extended Producer Responsibility (EPR) schemes

– Tracking carbon footprint across the supply chain

Adopt circular economy principles by designing for disassembly and recyclability.

Quality Control and Inspection

Implement rigorous quality checks at multiple stages:

– Pre-production sampling

– During production (in-line inspections)

– Pre-shipment audits

Verify colorfastness, durability, attachment strength, and dimensional accuracy. Use AQL (Acceptable Quality Level) standards to assess defect rates.

Traceability and Documentation

Maintain a full audit trail for every trim component, including:

– Supplier invoices and contracts

– Test reports (chemical, physical, flammability)

– Certifications (e.g., GRS, FSC, BSCI)

– Batch tracking logs

Blockchain or digital supply chain platforms can enhance transparency and responsiveness in case of recalls.

Safety and Product Liability

Ensure trims meet safety standards for intended use:

– No sharp edges or small parts that pose choking hazards (especially for children’s wear)

– Flame resistance where required (e.g., sleepwear)

– Secure attachment to prevent detachment during use

Non-compliance can lead to product recalls, fines, or litigation.

Reverse Logistics and Waste Management

Plan for end-of-life handling of trims:

– Partner with recycling programs for metal zippers, plastic buttons, etc.

– Manage defective or excess inventory responsibly

– Avoid landfill through take-back programs or upcycling initiatives

Conclusion

Managing trims and embellishments requires a strategic approach that balances design, cost, logistics, and compliance. Proactive supplier engagement, robust documentation, and adherence to global regulations are essential for mitigating risks and ensuring sustainable, safe, and market-ready products. Regular training and internal audits will help maintain high standards across the supply chain.

Conclusion: Sourcing Trims and Embellishments

Sourcing trims and embellishments is a critical component in the fashion and textile industry, directly influencing the quality, aesthetic appeal, and overall value of a finished garment. A strategic and well-managed sourcing approach ensures access to diverse, high-quality materials while balancing cost, sustainability, and lead times. By building strong relationships with reliable suppliers, leveraging global markets, and staying informed about emerging trends and innovations, brands can maintain a competitive edge.

Moreover, increasing emphasis on ethical and sustainable practices necessitates careful evaluation of sourcing channels, including material origins, labor standards, and environmental impact. Digital tools and supply chain transparency are becoming indispensable in achieving traceability and efficiency. Ultimately, effective sourcing of trims and embellishments not only supports design integrity but also aligns with broader business goals of quality, sustainability, and profitability.