The global tree planting equipment market is experiencing steady growth, driven by increasing afforestation initiatives, reforestation programs, and rising environmental awareness. According to a report by Grand View Research, the global forestry equipment market was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2030. This growth trajectory underscores the rising demand for specialized tools such as tree planting shovels, which are critical for both small-scale conservation efforts and large government-backed reforestation campaigns. As sustainability becomes a priority across public and private sectors, investment in durable, ergonomic, and efficient planting tools has surged. In response, a select group of manufacturers has emerged as leaders in innovation, quality, and product performance. Based on market presence, manufacturing capabilities, and customer reviews, the following eight companies represent the top producers of tree planting shovels worldwide.

Top 8 Tree Planting Shovel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

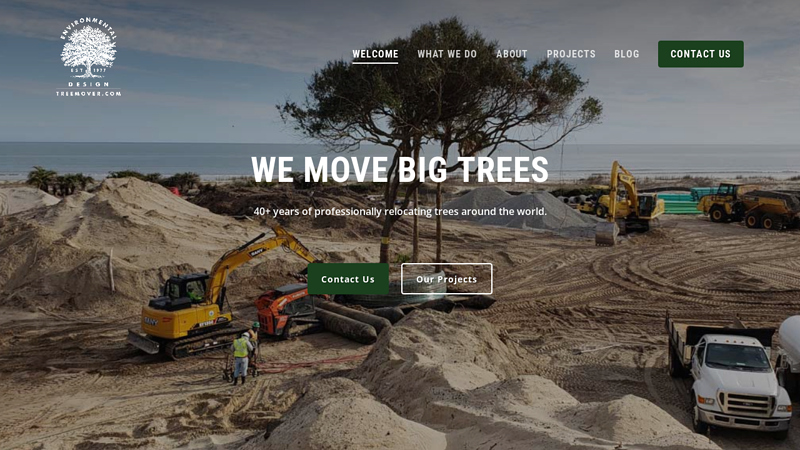

#1 Environmental Design, Inc.

Domain Est. 1999

Website: treemover.com

Key Highlights: We have more experience, over 30 years, and expertise in large tree transplanting than any tree transplanting company in the world. We are the best tree movers….

#2 Dutchman Industries: Tree Spade

Domain Est. 2005

Website: dutchmantreespade.com

Key Highlights: Dutchman Industries is the leading manufacturer of the best tree spade and nursery equipment in the US, Canada and around the world….

#3 Tree Spades and Tree Transplanting Equipment in the US

Domain Est. 1996

Website: big-john.com

Key Highlights: At Big John Manufacturing, we’ve delivered quality tree transplanting equipment for over 40 years, all designed and made in the USA….

#4 Tree Spade Attachment

Domain Est. 1997

Website: bobcat.com

Key Highlights: The rugged, dependable tree spade attachment turns any loader into a transplanting unit, while also speeding up production and cutting labor costs….

#5 Planting Shovels

Domain Est. 1998

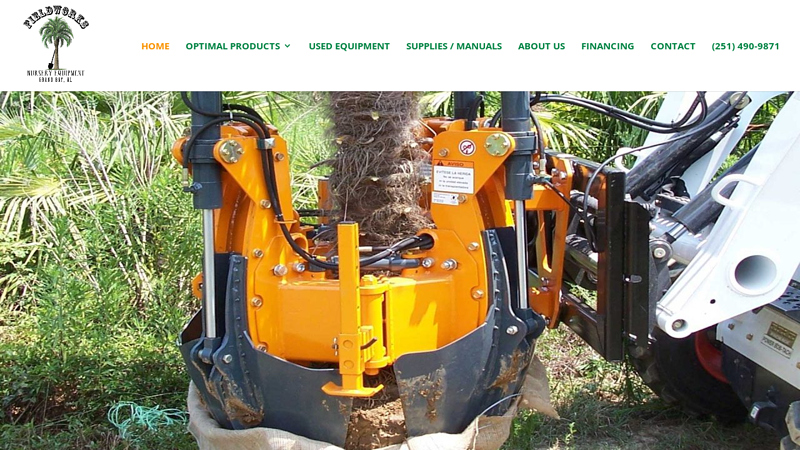

#6 Optimal Tree Spades

Domain Est. 1998

Website: optimaltreespades.com

Key Highlights: We have tree spade models for every size rootball, soil type, and size of machine you could ever need. Call (251) 490-9871….

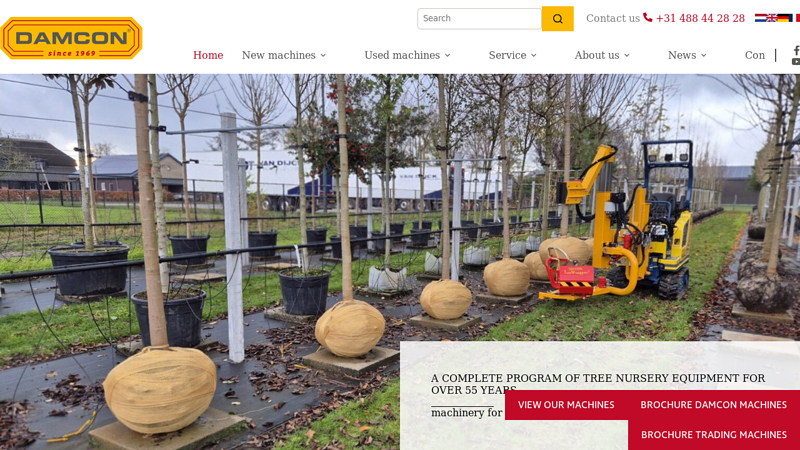

#7 Damcon: Custom

Domain Est. 2000

Website: damcon.com

Key Highlights: Damcon is your reliable partner for custom-made tree nursery machines. We offer innovative solutions for planting, harvesting, pruning, and spraying your ……

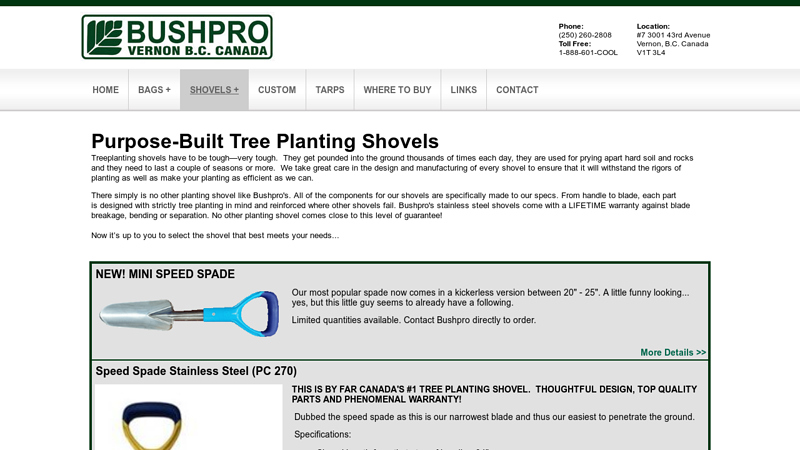

#8 Planting Shovels

Domain Est. 2000

Website: bushpro.ca

Key Highlights: Purpose-Built Tree Planting Shovels We take great care in the design and manufacturing of every shovel to ensure that it will withstand the rigors of planting ……

Expert Sourcing Insights for Tree Planting Shovel

2026 Market Trends for Tree Planting Shovels: Key Drivers and Shifts

The global tree planting shovel market is poised for significant transformation by 2026, driven by escalating environmental concerns, technological advancements, and evolving user demands. Here’s a breakdown of the major trends shaping the landscape:

H2: Surge in Reforestation Initiatives Fuels Demand

Government-mandated reforestation programs, corporate carbon offsetting commitments, and international climate agreements (like the UN Decade on Ecosystem Restoration) will continue to drive large-scale tree planting efforts globally. This directly increases demand for durable, efficient tree planting shovels. National projects in countries like China, India, and across Africa, combined with private-sector afforestation drives, will create sustained procurement opportunities, pushing volume demand and encouraging specialized shovel designs for different terrains.

H2: Demand for Ergonomic and Durable Designs Intensifies

With increased planting volume comes greater focus on worker safety and efficiency. By 2026, ergonomic designs—featuring lightweight composite materials, shock-absorbing handles, and optimized blade angles—will become standard. Users will prioritize shovels that reduce fatigue and injury risk during long planting seasons. Concurrently, durability remains critical; high-carbon steel or reinforced polymer blades will be favored for challenging soil conditions, ensuring longevity and reducing long-term costs.

H2: Technological Integration Begins to Emerge

While still in early stages, smart tools will start influencing the market. Expect prototypes or niche offerings of shovels with embedded sensors to measure planting depth, soil compaction, or moisture levels. These data-enabled tools could appeal to large-scale conservation groups and research institutions seeking to improve planting success rates and gather field data. Additionally, QR codes or digital tags for tool tracking and maintenance logging may become more common among professional forestry teams.

H2: Sustainability in Manufacturing Gains Importance

Environmental consciousness will extend beyond tree planting to the tools themselves. Manufacturers will face growing pressure to use recycled materials (e.g., recycled steel or bioplastics) and adopt low-impact production processes. Brands emphasizing carbon-neutral manufacturing or offering take-back/recycling programs will gain competitive advantage, particularly among eco-conscious NGOs and government buyers.

H2: Regional Market Diversification and Customization

Different regions will demand specialized shovels based on soil type and planting methods. For example, arid regions may require shovels optimized for rocky or compacted soils, while tropical areas may need corrosion-resistant models. This will lead to greater product customization and regional product variants. Additionally, emerging markets in Southeast Asia and Sub-Saharan Africa will see rising demand, encouraging local manufacturing and distribution partnerships.

H2: Rise of Multi-Functional and Compact Tools

Urban forestry and community planting events will drive demand for compact, multi-functional shovels. Tools combining planting, digging, and weeding capabilities in one lightweight unit will appeal to volunteers and city planners. Collapsible or foldable designs will also gain popularity for ease of transport and storage, especially in educational or outreach programs.

In conclusion, by 2026, the tree planting shovel market will be characterized by innovation rooted in sustainability, efficiency, and user well-being. Success will belong to manufacturers who anticipate ecological needs, embrace ergonomic and material advancements, and align their offerings with the global momentum toward reforestation and climate resilience.

Common Pitfalls When Sourcing Tree Planting Shovels (Quality and Intellectual Property)

Sourcing tree planting shovels—especially for large-scale reforestation or agricultural projects—requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to substandard tools, legal risks, and reputational damage. Below are the most common pitfalls to avoid.

Poor Material Quality and Durability

One of the most frequent issues is receiving shovels made from low-grade steel or inferior materials. Thin or soft metal blades wear down quickly, especially in rocky or compacted soil, reducing tool lifespan and increasing replacement costs. Handles made from weak wood or low-impact plastics can splinter or break under stress, posing safety hazards and lowering worker efficiency.

Solution: Specify shovel construction details in procurement contracts—such as high-carbon steel blades, heat-treated edges, and durable hardwood or fiberglass handles. Request material certifications and conduct sample testing before bulk orders.

Inadequate Ergonomic Design

Poorly designed shovels can lead to user fatigue, reduced productivity, and even long-term musculoskeletal injuries. Shovels with incorrect blade angles, poorly balanced weight distribution, or uncomfortable grips compromise efficiency and safety in fieldwork.

Solution: Source shovels designed specifically for tree planting, such as D-handled or rounded-point models with ergonomic features. Look for third-party ergonomics testing or endorsements from occupational health organizations.

Lack of Standardization and Consistency

Suppliers, particularly in low-cost manufacturing regions, may produce shovels with inconsistent dimensions, blade sharpness, or weld quality. This inconsistency affects performance and complicates training and tool maintenance across teams.

Solution: Require detailed technical drawings and quality control checks. Implement factory audits and pre-shipment inspections to ensure batch-to-batch consistency.

Ignoring Intellectual Property (IP) Rights

Using shovel designs that mimic patented or trademarked tools—such as specific blade shapes, handle configurations, or branding—can expose buyers to IP infringement claims. Some suppliers may offer “look-alike” versions of popular branded shovels, which may seem cost-effective but carry legal risks.

Solution: Conduct due diligence on the design origin. Ensure suppliers provide IP indemnification in contracts and avoid replicating protected features. Consider licensing or partnering with original equipment manufacturers (OEMs) if using proprietary designs.

Misrepresentation of Origin or Compliance

Some suppliers falsely claim that shovels meet international standards (e.g., ISO, ANSI) or originate from a certain country to increase perceived value. This misrepresentation can undermine quality assurance and lead to customs or compliance issues.

Solution: Verify certifications with third-party labs and request documentation such as Certificates of Conformity. Use independent inspection services to validate origin and compliance claims.

Overlooking Long-Term Supplier Reliability

Choosing suppliers solely on price can backfire if they lack the capacity for consistent delivery, after-sales support, or scalability. A breakdown in supply can delay planting seasons and disrupt project timelines.

Solution: Assess supplier track records, financial stability, and production capacity. Start with pilot orders and build long-term partnerships with proven vendors.

By addressing these common pitfalls in quality and IP during the sourcing process, organizations can ensure they procure reliable, compliant, and effective tree planting shovels that support sustainable and efficient reforestation efforts.

Logistics & Compliance Guide for Tree Planting Shovel

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for the tree planting shovel to ensure accurate customs clearance and tariff application. Typical classifications fall under HS Code 8201.10 (shovels, spades, and the like, of iron or steel). Confirm with local customs authorities or a licensed customs broker, as variations may exist by country and material composition.

Import/Export Regulations

Understand import and export controls applicable to hand tools in target markets. Most countries do not restrict tree planting shovels, but compliance with general product safety and labeling requirements is mandatory. Check for any environmental or agricultural equipment-specific regulations, especially if the shovel is marketed for reforestation or conservation use.

Packaging and Labeling Requirements

Ensure packaging is durable for transit and complies with international shipping standards. Label packages with:

– Product name (“Tree Planting Shovel”)

– Country of origin

– Manufacturer/importer details

– Safety warnings (if applicable)

– Barcodes and SKU information

Use eco-friendly materials where possible to align with sustainability claims.

Shipping Methods and Freight Options

Choose appropriate shipping modes based on volume and urgency:

– Air freight: Faster but more expensive; ideal for small, time-sensitive orders.

– Ocean freight (FCL/LCL): Cost-effective for bulk shipments; plan for longer lead times.

– Ground transport: Suitable for regional or domestic distribution.

Partner with freight forwarders experienced in handling hardware goods.

Customs Documentation

Prepare accurate and complete documentation to avoid delays:

– Commercial invoice

– Packing list

– Bill of lading (for sea) or air waybill (for air)

– Certificate of origin (if required for preferential tariffs)

– Import declaration forms (as per destination country)

Ensure all documents clearly describe the product and its intended use.

Product Safety and Standards Compliance

Verify that the tree planting shovel meets safety and quality standards in the destination market:

– USA: Complies with OSHA and ASTM standards for hand tools.

– EU: CE marking may be required under the Machinery Directive or General Product Safety Directive.

– Canada: Meets CSA or equivalent safety guidelines.

– Australia/NZ: Complies with AS/NZS standards.

Conduct third-party testing if necessary.

Environmental and Sustainability Considerations

Highlight sustainable features (e.g., recycled materials, long lifespan) in marketing and compliance documentation. Some regions offer import incentives for eco-friendly tools. Ensure packaging and product disposal align with local environmental regulations.

Warranty and After-Sales Compliance

Establish a clear warranty policy that complies with consumer protection laws in each market (e.g., 2-year warranty under EU consumer law). Provide accessible customer support and returns logistics.

Restricted Materials and Substances

Confirm the shovel contains no restricted substances (e.g., lead, cadmium above allowable limits) under regulations such as:

– REACH (EU)

– RoHS (if electric components are involved)

– Prop 65 (California, USA)

Maintain a Substance Compliance Declaration from suppliers.

Final Inspection and Quality Control

Implement pre-shipment inspections to verify product quality, packaging integrity, and documentation accuracy. Use third-party inspection services for large orders to prevent customs rejections or customer complaints.

Recordkeeping and Audit Readiness

Maintain detailed records of all compliance documentation, test reports, supplier certifications, and shipping records for a minimum of 5 years. Be prepared for audits by customs or regulatory bodies.

In conclusion, sourcing a tree planting shovel requires careful consideration of quality, durability, ergonomics, and cost-effectiveness. Selecting the right shovel—such as a transplanter, dibble, or hoedad—depends on the specific planting conditions, soil type, and operational scale. It is essential to source from reputable suppliers who offer reliable materials, such as forged steel and comfortable handles, to ensure long-term performance and user safety. Evaluating warranty, availability, and customer reviews further supports informed decision-making. Ultimately, investing in the appropriate tree planting shovel enhances planting efficiency, reduces labor strain, and contributes to successful reforestation or landscaping initiatives.