The global treated lumber screws market is experiencing robust growth, driven by rising demand in residential construction, deck building, and outdoor infrastructure projects. According to a 2023 report by Grand View Research, the global construction fasteners market—of which treated lumber screws are a critical segment—was valued at USD 75.8 billion and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This surge is fueled by advancements in corrosion-resistant coatings and the increasing use of pressure-treated wood in moisture-prone environments. As sustainability and durability become key priorities in building practices, manufacturers are investing heavily in innovative screw designs that combine high tensile strength with weather resistance. Against this backdrop, a select group of nine manufacturers have emerged as leaders, leveraging material science, precision engineering, and scalable production to capture significant market share and set industry benchmarks for performance and reliability.

Top 9 Treated Lumber Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Star Drive Wood Screws – Screw Products, Inc.

Domain Est. 1999

Website: screw-products.com

Key Highlights: Screw Products Inc. specializes in star drive stainless steel and heat treated wood screws for decks, log homes, remodeling, kitchen cabinets, docks, ……

#2 Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: The Strong-Drive SDWS Timber screw is designed to provide an easy-to-install, high-strength alternative to through-bolting and traditional lag screws….

#3 Deck Screws

Domain Est. 1996

Website: minerallac.com

Key Highlights: 8 x 2″ Exterior Wood Screw, “Deck Screw”, Flat Head Star Drive, Type 17 point, “War” corrosion coating, 1000/hr salt spray resistance….

#4 Fasteners & Treated Wood

Domain Est. 2000

Website: conradfp.com

Key Highlights: Conrad Forest Products always recommends the use of hot-dipped zinc-coated galvanized steel, stainless steel, silicon bronze or copper fasteners….

#5 Code Approvals

Domain Est. 2001

Website: grkfasteners.com

Key Highlights: GRK fasteners are ICC code approved for exterior use in ACQ pressure treated lumber and have the strength to meet all your general construction needs….

#6 SPAX US

Domain Est. 2004

Website: spax.us

Key Highlights: Our Engineered Screws & Fasteners are manufactured and rigorously tested right here in the heart of America. Rely on us to help you drive the highest quality….

#7 CAMO Fasteners

Domain Est. 2010

Website: camofasteners.com

Key Highlights: Our innovative hidden deck clips, collated screws, and stand-up deck fastening tools work together to make your jobs smarter, faster, easier, and better….

#8 Teks

Domain Est. 2018

Website: teksscrews.com

Key Highlights: Teks Wood-to-Metal Screws are ideal for attaching roof/subfloor decking, trailer beds to frame, and wood headers to steel frame….

#9 Top 10 Treated Wood FAQs

Domain Est. 1997

Website: treatedwood.com

Key Highlights: 1. What type of nails or screws do you recommend? · Use building-code approved, corrosion-resistant fasteners and connectors suitable for use in pressure-treated ……

Expert Sourcing Insights for Treated Lumber Screws

H2: 2026 Market Trends for Treated Lumber Screws

The global market for treated lumber screws is projected to experience steady growth by 2026, driven by expanding construction activities, advancements in fastener technology, and increasing demand for durable building materials. As outdoor construction and residential renovation projects rise—particularly in North America and parts of Europe—the need for corrosion-resistant fasteners compatible with pressure-treated wood is becoming more pronounced. Treated lumber screws, engineered to withstand moisture, chemicals, and temperature fluctuations, are increasingly favored over traditional nails due to their superior holding power and long-term reliability.

One major trend shaping the 2026 outlook is the adoption of high-performance coatings and materials. Manufacturers are investing in advanced galvanization techniques, such as hot-dip galvanizing and proprietary polymer coatings (e.g., ACR—Advanced Composite Resin), to enhance screw longevity and resistance to the alkaline environment of modern treated lumber (like ACQ and copper azole). These innovations are expected to support market growth, particularly in coastal and humid regions where corrosion is a significant concern.

Another key trend is the shift toward code compliance and sustainability. Building codes in many countries are increasingly mandating the use of corrosion-resistant fasteners in treated wood applications. This regulatory push, combined with a growing emphasis on sustainable construction practices, is boosting demand for screws made from recyclable materials and produced through energy-efficient processes.

Additionally, the rise of DIY (do-it-yourself) culture and home improvement retail channels is influencing product design. By 2026, manufacturers are likely to focus on user-friendly features such as better drive types (e.g., square or star drives), pre-drilling capabilities, and color-matching options to blend with decking materials. E-commerce platforms and digital product configurators are also expected to streamline distribution and customization.

In summary, the 2026 treated lumber screw market will be shaped by technological innovation, regulatory standards, and evolving consumer preferences. Companies that prioritize durability, compliance, and ease of use are poised to gain a competitive advantage in this expanding segment.

Common Pitfalls When Sourcing Treated Lumber Screws (Quality & Intellectual Property)

Sourcing treated lumber screws may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to structural failures, compliance issues, or legal liabilities. Below are common pitfalls to avoid:

Inadequate Corrosion Resistance

Many treated lumber screws are exposed to harsh outdoor environments and chemical preservatives like ACQ or copper azole, which accelerate corrosion. A common mistake is selecting screws with insufficient coating thickness or inappropriate plating (e.g., standard zinc instead of hot-dip galvanized or stainless steel). This can lead to premature rusting, joint failure, and costly repairs.

Poor Thread Design or Drive Type

Screws not engineered specifically for treated lumber may split wood or strip during installation. Low-quality screws often feature weak thread patterns or outdated drive types (e.g., slotted or Phillips) prone to cam-out. This reduces holding power and increases labor time, impacting project timelines and structural integrity.

Lack of Third-Party Certification

Reputable treated lumber screws should carry certifications from organizations like ICC-ES, ASTM, or APA. Sourcing from suppliers who cannot provide valid test reports or certification documents increases the risk of using non-compliant products that may fail building code inspections or void warranties.

Counterfeit or Unbranded Products

Bargain-priced screws from unknown manufacturers may be counterfeit versions of patented designs (e.g., imitations of popular structural screws like Simpson Strong-Tie or GRK). These copies often replicate appearance but not performance, leading to under-specification and potential liability. They also infringe on intellectual property rights, exposing buyers to legal risk.

Ignoring Patent Infringement Risks

Some high-performance screw designs are protected by patents covering thread geometry, head design, or coating technology. Sourcing generic screws that mimic these features without licensing can result in IP litigation, product recalls, or supply chain disruptions. Always verify that suppliers have the right to manufacture and sell the product.

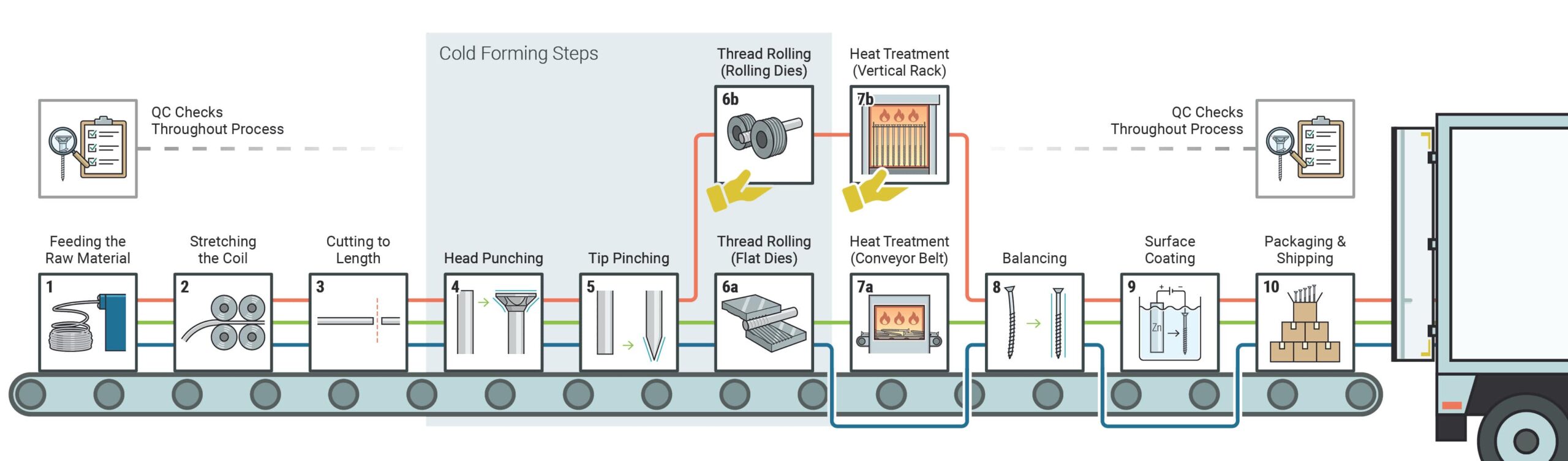

Inconsistent Manufacturing Quality

Low-cost suppliers, especially offshore, may have inconsistent quality control. Variations in steel grade, heat treatment, or coating application can lead to batch-to-batch performance differences. Without proper audits or quality agreements, buyers risk receiving substandard fasteners that compromise safety and durability.

Misrepresentation of Material Specifications

Some suppliers falsely claim screws are “marine-grade” or “316 stainless” when they are actually 304 stainless or lower. This mislabeling can result in inadequate performance in coastal or high-moisture environments. Always request material test reports (MTRs) to verify composition and compliance.

Overlooking Regional Building Code Requirements

Different regions have specific fastener requirements based on climate, load, and treated wood type. Sourcing screws without verifying local code compliance (e.g., IRC, CBC) may result in rejected work or non-compliant installations, especially in high-wind or seismic zones.

By addressing these pitfalls through due diligence, supplier vetting, and specification clarity, buyers can ensure they source treated lumber screws that are both high-performing and legally compliant.

Logistics & Compliance Guide for Treated Lumber Screws

Overview

Treated lumber screws are specialized fasteners designed for use with pressure-treated wood, which contains chemical preservatives to resist rot, decay, and insect infestation. Due to the corrosive nature of these chemicals, treated lumber screws must meet specific material and performance standards. Proper logistics and compliance are essential to ensure product safety, durability, and adherence to regulatory requirements.

Material & Performance Standards

Treated lumber screws must be manufactured from corrosion-resistant materials to withstand the chemicals (e.g., alkaline copper quaternary (ACQ), copper azole (CA), or micronized copper) used in modern pressure-treated wood. Common compliant materials include:

– Type 304 or Type 316 stainless steel

– Hot-dipped galvanized steel (meeting ASTM A153 or ASTM A653)

– Coated carbon steel with heavy-duty corrosion-resistant coatings (e.g., triple-layer coatings approved by ICC-ES or ESR listings)

Screws must comply with building codes such as the International Residential Code (IRC) and be rated for use in treated lumber per manufacturer specifications.

Regulatory Compliance

Ensure all treated lumber screws meet the following standards:

– ASTM A153/A153M: Standard specification for zinc (hot-dip galvanized) coatings on iron and steel hardware

– ASTM A653/A653M: Standard specification for steel sheet, zinc-coated (galvanized)

– ICC-ES Evaluation Reports (ESR): Third-party certification confirming suitability for use with treated lumber

– Local Building Codes: Confirm compliance with regional requirements (e.g., coastal zones may require higher corrosion resistance)

Screws used in exterior or ground-contact applications must be labeled and traceable to approved performance ratings.

Packaging & Labeling Requirements

- Clearly label packaging with:

- Screw type and material (e.g., “Stainless Steel Type 316”)

- Compliance statements (e.g., “Meets ASTM A153 for Use with ACQ-Treated Lumber”)

- ICC-ES report number (if applicable)

- Intended use (e.g., “For Exterior or Ground Contact Applications”)

- Use moisture-resistant packaging to prevent corrosion during storage and transit

- Include safety data sheets (SDS) if required by jurisdiction

Storage & Handling

- Store screws in a dry, climate-controlled environment to prevent moisture exposure and premature corrosion

- Keep packaged units sealed until point of use

- Avoid direct ground contact; use pallets for storage

- Segregate different screw types and finishes to prevent cross-contamination

Transportation & Logistics

- Use enclosed, dry transport vehicles to protect against rain and humidity

- Secure loads to prevent shifting and damage during transit

- Follow carrier requirements for hazardous materials if coatings contain regulated substances (rare, but verify SDS)

- Maintain chain-of-custody documentation for traceability, especially for large construction projects

Documentation & Traceability

- Retain supplier certification, test reports, and compliance documentation

- Maintain batch/lot tracking for quality control and recall readiness

- Provide end-users with installation guidelines and warranty information where applicable

Environmental & Safety Considerations

- Dispose of packaging and damaged product according to local regulations

- Follow OSHA and workplace safety guidelines when handling bulk shipments

- Ensure packaging materials are recyclable where possible to support sustainability goals

Conclusion

Proper logistics and compliance practices for treated lumber screws are critical to ensure long-term structural integrity and code adherence. By following material standards, regulatory requirements, and best practices in storage and transport, distributors and contractors can mitigate risks and deliver reliable, code-compliant fastening solutions. Always verify product suitability with the screw manufacturer and project-specific building codes before use.

Conclusion:

After evaluating various sourcing options for treated lumber screws, it is clear that selecting the right supplier involves balancing quality, cost, availability, and compliance with industry standards. Treated lumber screws must be corrosion-resistant—typically made from materials such as coated steel, stainless steel, or silicon bronze—to withstand the harsh chemicals used in pressure-treated wood. Sourcing from reputable suppliers that certify their products meet building codes (such as ICC-ES or ASTM standards) ensures long-term durability and structural safety.

Purchasing in bulk from specialized construction material suppliers or major home improvement distributors can offer cost efficiencies without compromising quality. Additionally, considering local suppliers can reduce lead times and shipping costs, while supporting regional businesses. Online procurement platforms provide convenience and competitive pricing but require careful vetting to avoid counterfeit or substandard products.

In conclusion, the optimal sourcing strategy involves partnering with trusted suppliers who provide certified, high-performance fasteners suitable for treated lumber applications, ensuring both structural integrity and cost-effectiveness for construction projects. Regular supplier evaluations and staying informed about industry advancements will further support reliable and sustainable sourcing decisions.