The global waste management equipment market is undergoing rapid transformation, driven by increasing urbanization, stricter environmental regulations, and the growing need for efficient waste disposal solutions. According to a report by Mordor Intelligence, the global trash compactor market was valued at USD 2.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 5.3% from 2024 to 2029. This expansion is fueled by rising municipal solid waste generation—estimated by the World Bank to reach 2.01 billion tons annually by 2050—as cities and businesses seek scalable, eco-friendly compaction technologies. With demand surging across commercial, industrial, and municipal sectors, the role of innovative trash compressor manufacturers has become increasingly critical. In this data-driven landscape, identifying the top players—those combining engineering excellence, sustainability, and reliability—is essential for stakeholders aiming to optimize waste handling and reduce environmental impact.

Top 10 Trash Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial Trash Compactors, Balers & Recycling Equipment For …

Domain Est. 1998

Website: marathonequipment.com

Key Highlights: Marathon Equipment Company is known throughout the world as a leading manufacturer of onsite commercial/industrial trash compactors, balers, and recycling ……

#2 Howden

Domain Est. 2001

Website: chartindustries.com

Key Highlights: We own the Howden, HV-TURBO, Turblex, Spencer and Kuehnle, Kopp and Kausch brands. Range encompasses industrial type blowers used in the power, mining and water ……

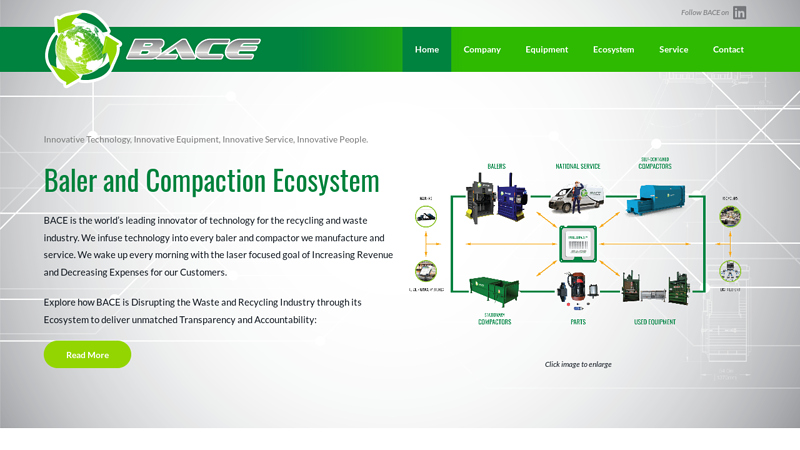

#3 BACE

Domain Est. 2006

Website: bacecorp.com

Key Highlights: The world’s leading innovator of recycling and waste industry technology. We infuse intelligence into every baler and compactor we manufacture and service….

#4 Commercial & Industrial Trash Compactor Services

Website: wm.com

Key Highlights: WM offers custom commercial & industrial compactor solutions to help your business improve waste efficiency. Sales, rental and maintenance options ……

#5 Wastequip

Domain Est. 1997

Website: wastequip.com

Key Highlights: Wastebuilt is your One-Stop Source for waste equipment supplies and replacement parts for refuse trucks, roll-off hoists, compactors, containers, and more….

#6 Heil Garbage Trucks and Trash Trucks

Domain Est. 1997 | Founded: 1901

Website: heil.com

Key Highlights: Heil is the industry leader in garbage truck body design and specialized refuse body manufacturing. Since 1901, we have built a reputation for quality, ……

#7 Orwak

Domain Est. 1998

Website: orwak.com

Key Highlights: Orwak is a world leader in compaction and baling solutions for solid waste materials. We make waste management more efficient and more profitable….

#8 Maximizing Galley Efficiency with Advanced Trash Compaction

Domain Est. 2005

Website: safran-group.com

Key Highlights: T900 Trash Compactor is newly designed with a “trash trolley” for improved functionality. It doubles trash collection capacity and reduces the quantity of ……

#9 U.S. Trash Balers & Compactors

Domain Est. 2008

Website: miltekusa.com

Key Highlights: Mil-tek the U.S. leading provider of Pneumatic trash balers and compactors. Our recycling machines helps companies save space, time and money. Buy or rent….

#10 Smash My Trash: Mobile Waste Compaction Service

Domain Est. 2015

Website: smashmytrash.com

Key Highlights: Transform waste management with our mobile dumpster compaction service. Efficient, eco-friendly solutions that save costs and reduce environmental impact….

Expert Sourcing Insights for Trash Compressor

2026 Market Trends for Trash Compressors

The global trash compressor market is poised for significant transformation by 2026, driven by urbanization, environmental regulations, and technological innovation. Key trends shaping the industry include rising demand for waste volume reduction, integration of smart technologies, and the expansion of recycling infrastructure. Municipalities and private waste management companies are increasingly investing in high-efficiency trash compressors to reduce transportation costs and landfill dependency. Furthermore, the growing emphasis on sustainability is encouraging the adoption of energy-efficient and electric-powered compressors, particularly in Europe and North America. Emerging markets in Asia-Pacific and Latin America are also expected to witness accelerated growth due to rapid urban development and government initiatives promoting waste management modernization. By 2026, the market will likely see increased consolidation among manufacturers, greater customization for commercial and residential applications, and a shift toward IoT-enabled systems for real-time monitoring and predictive maintenance.

Common Pitfalls When Sourcing a Trash Compressor

Sourcing a trash compressor involves several critical considerations, especially regarding quality and intellectual property (IP). Overlooking these aspects can lead to operational inefficiencies, legal risks, and increased long-term costs. Below are common pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost trash compressors use substandard materials or inadequate engineering, leading to frequent breakdowns, reduced lifespan, and safety hazards. Buyers may be tempted by lower upfront prices, but poor-quality components—such as weak hydraulic systems, thin steel frames, or inadequate corrosion protection—can result in high maintenance costs and downtime.

Lack of Safety Certifications and Compliance

A common oversight is failing to verify compliance with regional safety and environmental standards (e.g., CE, UL, OSHA). Compressors lacking proper certifications may not meet operational safety requirements, posing risks to personnel and exposing the buyer to liability or regulatory penalties.

Inadequate After-Sales Support and Spare Parts Availability

Some suppliers, especially overseas or lesser-known manufacturers, offer little to no technical support, training, or spare parts inventory. This can result in extended equipment downtime when repairs are needed, affecting waste management operations and increasing total cost of ownership.

Hidden IP Infringement Risks

Purchasing compressors that replicate patented designs or incorporate proprietary technology without authorization can expose buyers to intellectual property litigation. This is particularly prevalent when sourcing from manufacturers in regions with weaker IP enforcement. Using infringing equipment may lead to legal action, seizure of assets, or forced equipment replacement.

Misrepresentation of Technical Specifications

Some suppliers exaggerate performance metrics such as compression force, cycle time, or throughput capacity. Without independent verification or third-party testing data, buyers may end up with equipment that fails to meet operational demands, reducing efficiency and requiring costly upgrades.

Failure to Verify Manufacturer Authenticity

Counterfeit or rebranded equipment is a growing concern. Some resellers present used or generic compressors as new or from reputable brands. Without proper due diligence—such as site visits, reference checks, or factory audits—buyers risk acquiring unreliable or non-compliant machinery.

Overlooking Customization and Integration Needs

Trash compressors often need to integrate with existing waste handling systems or meet specific site requirements (e.g., footprint, power supply, noise levels). Sourcing a one-size-fits-all unit without assessing compatibility can result in installation challenges or suboptimal performance.

By being aware of these pitfalls and conducting thorough supplier evaluations, quality inspections, and IP due diligence, organizations can make informed sourcing decisions that ensure reliable, compliant, and cost-effective waste compaction solutions.

Logistics & Compliance Guide for Trash Compressor

Overview

This guide provides essential logistics and compliance information for the safe and legal transport, installation, operation, and maintenance of a trash compressor. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and personnel safety.

Regulatory Compliance

Trash compressors are subject to various local, national, and international regulations. Key compliance areas include:

- Environmental Regulations: Ensure compliance with EPA (or equivalent) standards regarding emissions, noise pollution, and waste handling. Verify that the unit does not leak hydraulic fluid or contaminate soil/water.

- Electrical Standards: The compressor must meet electrical safety codes (e.g., NEC in the U.S., IEC internationally). Use certified electricians for all wiring and grounding.

- Workplace Safety: Comply with OSHA (or local equivalent) standards. Install proper guarding, emergency stop buttons, and clear warning labels. Provide operator training and PPE.

- Waste Handling Laws: Follow local regulations for waste collection, transportation, and disposal. Ensure compaction does not violate banned waste material policies (e.g., hazardous waste).

Transportation & Delivery

Proper logistics planning is essential when transporting a trash compressor:

- Pre-Shipment Inspection: Confirm unit dimensions, weight, and mounting requirements. Ensure the unit is securely fastened and protected during transit.

- Delivery Access: Verify site access for delivery trucks and lifting equipment. Check for overhead obstructions, ground stability, and turning radius.

- Lifting & Placement: Use certified rigging and lifting equipment. Follow manufacturer-recommended lifting points. Never lift by hydraulic lines or control panels.

- Documentation: Retain bills of lading, shipping manifests, and inspection reports. Confirm delivery against purchase order specifications.

Installation Requirements

Correct installation is critical for safe and compliant operation:

- Site Preparation: Install on a level, reinforced concrete pad capable of supporting the loaded unit’s weight. Allow adequate clearance for operation, maintenance, and container removal.

- Utility Connections: Connect to appropriate power supply (voltage, phase, amperage) per manufacturer specs. Ensure grounding and surge protection. Confirm hydraulic fluid levels and connections.

- Ventilation & Drainage: Provide proper ventilation if installed indoors. Include drain pans or containment for potential fluid leaks.

- Permits: Obtain necessary building, electrical, and environmental permits before installation.

Operational Compliance

Maintain compliance during daily use:

- Operator Training: Only trained personnel should operate the compressor. Training must cover startup/shutdown procedures, emergency stops, and lockout/tagout (LOTO).

- Maintenance Logs: Keep detailed records of inspections, servicing, and repairs. Follow manufacturer-recommended maintenance schedules.

- Waste Segregation: Do not compress prohibited items (e.g., batteries, gas cylinders, medical waste). Implement clear waste sorting protocols.

- Noise & Emissions Monitoring: Periodically assess noise levels and emissions, especially in urban or sensitive environments.

Disposal & Decommissioning

When retiring a trash compressor:

- Environmental Disposal: Recycle or dispose of hydraulic fluids, metals, and electrical components according to environmental regulations (e.g., RCRA in the U.S.).

- Data & Security: Remove any digital control modules or data storage devices.

- De-registration: Notify relevant authorities if required, especially for units with environmental permits.

Documentation & Recordkeeping

Maintain the following documents on-site or in a central compliance file:

- Equipment manual and safety data sheets (SDS)

- Inspection and maintenance logs

- Training records

- Permits and compliance certifications

- Incident reports (if applicable)

Adhering to this logistics and compliance guide ensures safe, legal, and efficient use of your trash compressor throughout its lifecycle.

Conclusion for Sourcing a Trash Compressor:

Sourcing a trash compressor is a strategic investment that offers significant benefits in terms of waste management efficiency, cost reduction, and environmental sustainability. By compressing waste on-site, organizations can drastically reduce the volume of trash, leading to fewer collection trips, lower disposal fees, and minimized transportation-related emissions. When selecting a trash compressor, it is essential to consider factors such as waste volume and type, available space, power requirements, maintenance needs, and long-term operational costs.

After evaluating various suppliers and models, choosing a reliable, energy-efficient compressor from a reputable manufacturer ensures durability, safety, and compliance with environmental regulations. Additionally, incorporating features like automatic controls, safety guards, and easy serviceability enhances usability and reduces downtime.

In conclusion, sourcing the right trash compressor not only streamlines waste operations but also supports broader sustainability goals. A well-informed procurement decision will deliver long-term savings, improve site cleanliness, and contribute to a greener, more responsible waste management system.