The global trash compactor market is experiencing steady growth, driven by increasing urbanization, rising waste generation, and growing demand for efficient waste management solutions in both residential and commercial sectors. According to Grand View Research, the global waste management market size was valued at USD 1.4 trillion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. A key segment within this industry is electric trash compactors, which offer energy-efficient, low-maintenance waste volume reduction for homes, restaurants, and healthcare facilities. Mordor Intelligence projects similar momentum, noting that advancements in compacting technology and a rising focus on sustainability are accelerating adoption across North America, Europe, and parts of Asia-Pacific. With demand on the rise, a select group of manufacturers has emerged as leaders in innovation, reliability, and market reach. Here, we present a data-driven overview of the top 10 electric trash compactor manufacturers shaping the industry in 2024.

Top 10 Trash Compactor Electric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

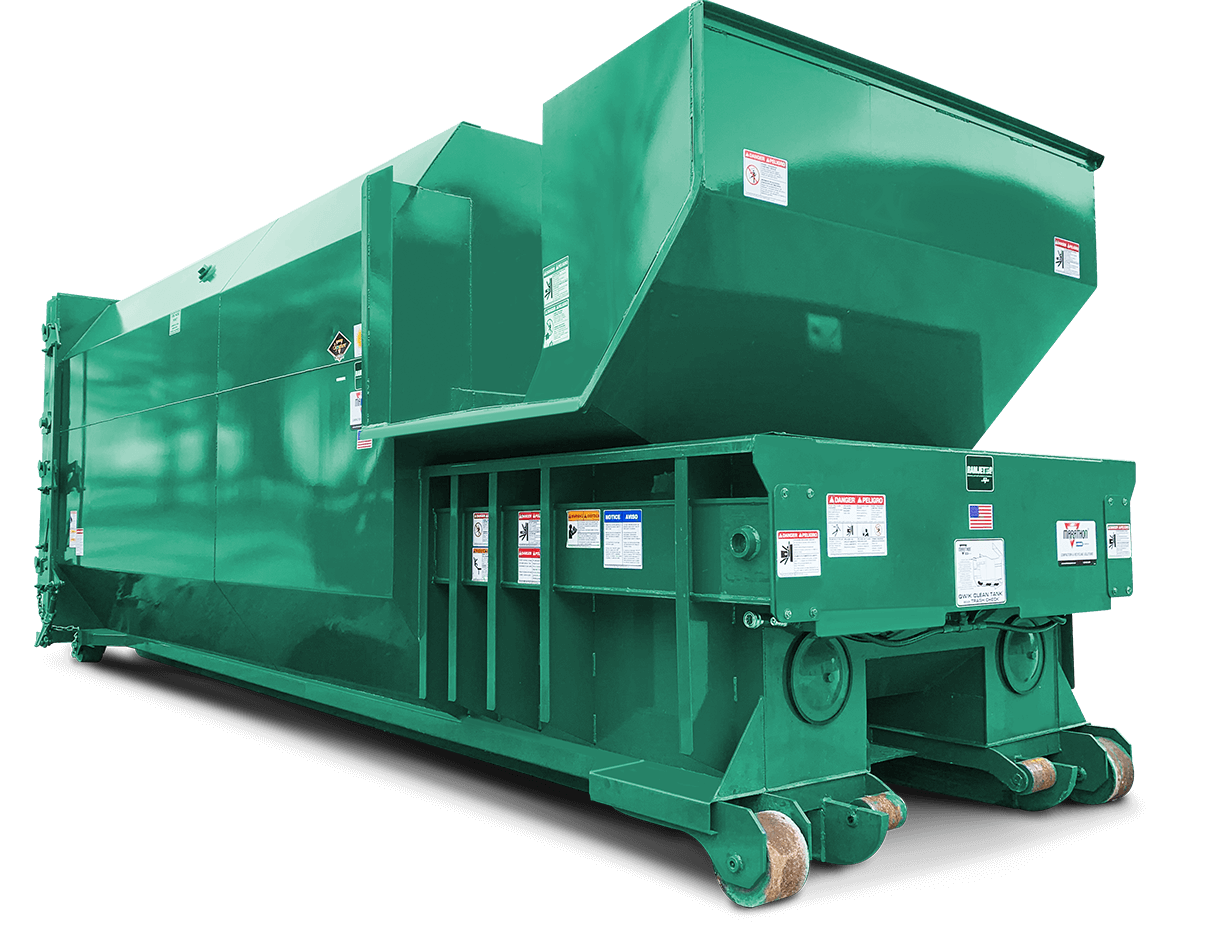

#1 Commercial & Industrial Trash Compactor Services

Domain Est. 1998

Website: wm.com

Key Highlights: WM offers custom commercial & industrial compactor solutions to help your business improve waste efficiency. Sales, rental and maintenance options ……

#2 Commercial Trash Compactors

Domain Est. 1998

Website: sanitech.net

Key Highlights: Sanitech’s commercial trash compactors offer robust, reliable, and energy-efficient solutions tailored to meet the unique needs of your business….

#3 DMH Companies

Domain Est. 2010

Website: dmhcompanies.com

Key Highlights: We partner with the most reliable manufacturers to offer high-quality compactors, balers, and other waste and recycling equipment….

#4 Cardboard balers, trash compactors and other recycling equipment …

Domain Est. 1996

Website: cram-a-lot.com

Key Highlights: Our comprehensive product range includes compactors for wet or dry waste, compactors that can be serviced with roll off, front load, or rear load trucks….

#5 Shop All Trash Compactors

Domain Est. 1996

Website: geappliances.com

Key Highlights: 7-day delivery · 7-day returnsWe design our home trash compactors to maximize your kitchen space. With a toe-pedal opener for hands-free operation, a removable drawer for easy cle…

#6 Heil Garbage Trucks and Trash Trucks

Domain Est. 1997

Website: heil.com

Key Highlights: The future of refuse collection is NOW. Introducing the RevAMP Fully-Electric Automated Side Loader with Auger Compactor & NO HYDRAULICS on-route!…

#7 Learn More About Marathon Equipment Compactor & Baler …

Domain Est. 1998

Website: marathonequipment.com

Key Highlights: We manufacture the highest quality compactors, know throughout the world as the leader in compaction equipment. View Trash Compactors. Balers & Recycling ……

#8 Maximizing Galley Efficiency with Advanced Trash Compaction

Domain Est. 2005

Website: safran-group.com

Key Highlights: T900 Trash Compactor is newly designed with a “trash trolley” for improved functionality. It doubles trash collection capacity and reduces the quantity of ……

#9 Trash Compactors

Domain Est. 2012

Website: dreeselectric.com

Key Highlights: Trash Compactors ; GE® 0.33 HP Stainless Steel Trash Compactor · UCG1520NSS. 3.9 (353) · $1,169.99 ; KitchenAid® 15″ Stainless Steel Built In Trash Compactor….

#10 Refuse Compactor (Garbage Compactor Trucks)

Website: shinmaywa.co.jp

Key Highlights: ShinMaywa’s G-PX is a lineup of garbage compactor trucks for the safe and efficient collection of waste. The advanced level of features for loading, ……

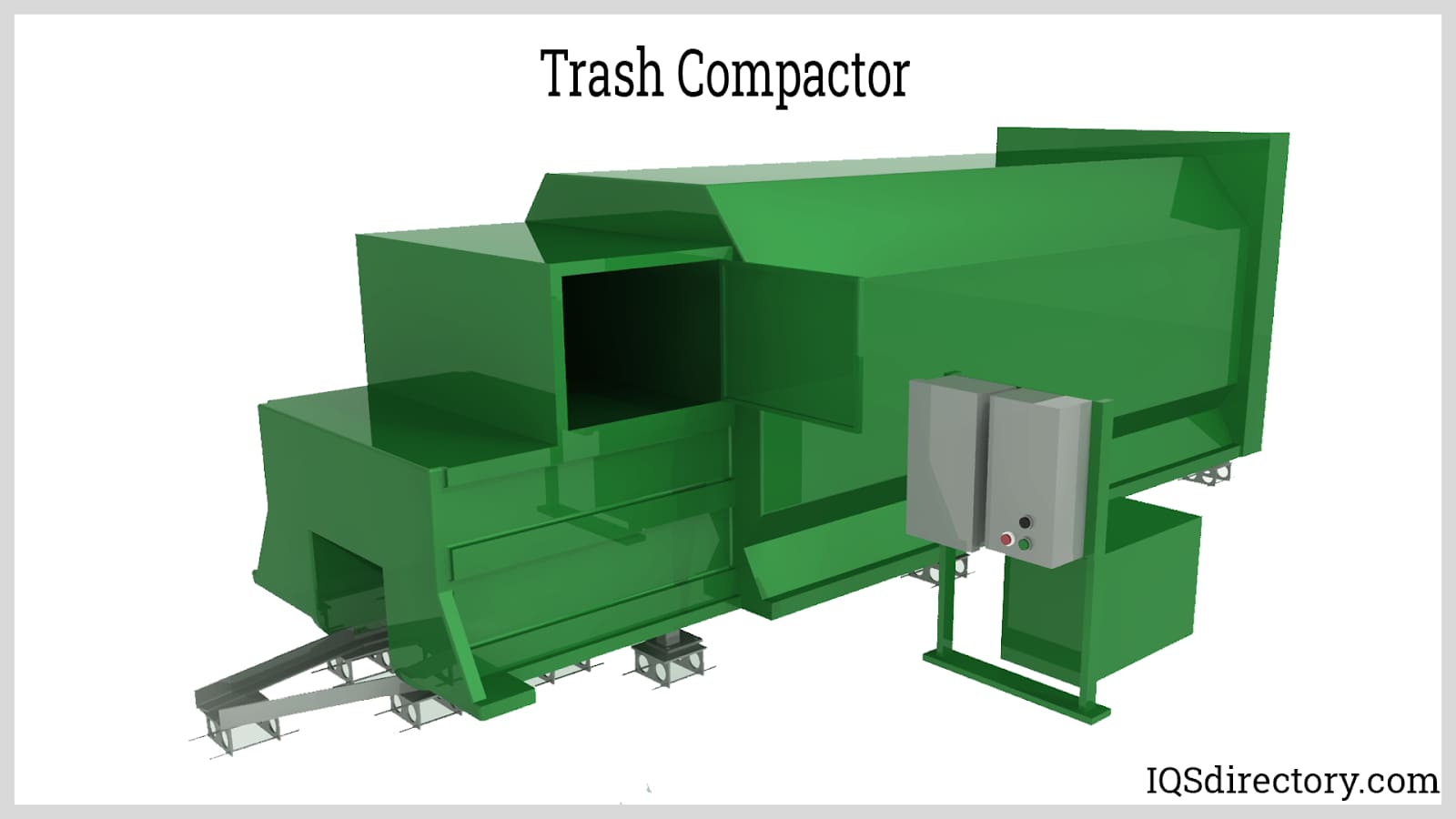

Expert Sourcing Insights for Trash Compactor Electric

H2: 2026 Market Trends for Electric Trash Compactors

The global market for electric trash compactors is projected to experience steady growth by 2026, driven by rising urbanization, increasing waste generation, and growing emphasis on sustainable waste management practices. Key trends shaping the electric trash compactor market in 2026 include technological advancements, expanding applications in residential and commercial sectors, and supportive government regulations.

-

Technological Innovation and Smart Integration

Electric trash compactors are becoming more intelligent and user-friendly. By 2026, manufacturers are increasingly integrating IoT (Internet of Things) capabilities, allowing for remote monitoring, performance tracking, and predictive maintenance. Smart sensors detect fill levels and automatically initiate compaction cycles, improving efficiency and reducing operational costs. Voice-activated controls and compatibility with smart home systems (e.g., Alexa, Google Home) are becoming standard in residential models. -

Growth in Residential Adoption

The residential segment is expected to see significant growth as more households adopt compactors to reduce trash frequency, minimize odor, and support eco-friendly lifestyles. Compact, energy-efficient models designed for under-cabinet or freestanding installation are gaining popularity in urban apartments and single-family homes, especially in North America and Western Europe. -

Commercial and Industrial Demand

Commercial applications—including restaurants, hotels, retail centers, and healthcare facilities—are major drivers of demand. Businesses are investing in heavy-duty electric compactors to lower waste disposal costs and meet sustainability goals. Regulations mandating waste reduction in commercial zones are accelerating adoption, particularly in cities with high population density. -

Sustainability and Environmental Regulations

With increasing focus on circular economies and waste reduction, governments worldwide are implementing stricter waste management policies. In 2026, compliance with environmental standards is pushing municipalities and private entities to adopt electric compactors, which are quieter and produce zero emissions compared to hydraulic or diesel-powered units. -

Energy Efficiency and Green Design

Manufacturers are prioritizing energy-efficient motors and recyclable materials in product design. The use of brushless DC motors reduces power consumption and extends equipment lifespan. These eco-conscious designs appeal to environmentally aware consumers and help companies achieve green building certifications (e.g., LEED). -

Regional Market Expansion

North America and Europe lead the market due to high consumer awareness and established waste infrastructure. However, rapid urbanization in Asia-Pacific—especially in China, India, and Southeast Asia—is creating new opportunities. Emerging markets are adopting electric compactors in smart city projects and large-scale residential developments. -

Competitive Landscape and Product Differentiation

The market is witnessing increased competition, with key players focusing on innovation, brand reputation, and after-sales service. Companies are offering modular designs, enhanced safety features, and noise reduction technologies to differentiate their products. Strategic partnerships with waste management firms and home appliance brands are also on the rise.

In conclusion, the electric trash compactor market in 2026 is defined by smart technology integration, sustainability, and expanding use cases across residential and commercial sectors. As environmental concerns and urban waste challenges grow, electric compactors are poised to become a staple in modern waste management systems worldwide.

Common Pitfalls When Sourcing Electric Trash Compactors (Quality and Intellectual Property)

Sourcing electric trash compactors—especially from international suppliers—can present significant challenges related to product quality and intellectual property (IP) risks. Being aware of these common pitfalls can help businesses avoid costly mistakes and legal complications.

Inadequate Quality Control and Substandard Materials

One of the most frequent issues is receiving compactors built with inferior components. Suppliers may cut costs by using low-grade motors, weak steel frames, or subpar electrical systems that fail prematurely. Without rigorous on-site inspections or third-party testing, such quality lapses may not be evident until after shipment, leading to high return rates and customer dissatisfaction.

Lack of Compliance with Safety and Regulatory Standards

Electric trash compactors must meet safety certifications such as UL, CE, or ETL, depending on the target market. Some suppliers falsely claim compliance or provide forged documentation. Sourcing non-compliant units risks product recalls, regulatory fines, and liability in case of accidents, particularly due to electrical hazards or mechanical failures.

Inconsistent Product Performance and Reliability

Even if a sample unit performs well, mass-produced units may vary significantly in compaction force, noise levels, or cycle time. Inconsistent manufacturing processes can lead to unreliable performance across batches, undermining brand reputation and increasing after-sales service costs.

Intellectual Property Infringement Risks

Many electric trash compactors, especially high-end models, incorporate patented technologies in their drive systems, safety interlocks, or control panels. Sourcing from suppliers who replicate branded designs without authorization exposes buyers to IP litigation. Even unintentional use of patented features can result in cease-and-desist orders, seizures at customs, or costly legal disputes.

Misrepresentation of Design Ownership and OEM Capabilities

Suppliers may claim to be original equipment manufacturers (OEMs) with proprietary designs, when in reality they are copying existing products. This misrepresentation can compromise your ability to secure exclusive rights or differentiate your product in the market. Always verify design ownership through IP searches and request proof of original engineering documentation.

Inadequate After-Sales Support and Spare Parts Availability

Low-cost suppliers may lack the infrastructure to provide spare parts or technical support. If the compactor requires maintenance or repairs, unavailability of replacement components can lead to customer frustration and increased long-term costs.

Failure to Protect Your Own IP When Customizing

When collaborating with a supplier to develop a customized compactor, failing to secure proper legal agreements (e.g., NDAs, IP assignment clauses) can result in the supplier replicating and reselling your design to competitors. Always formalize IP ownership in writing before sharing technical specifications.

Avoiding these pitfalls requires thorough due diligence, including factory audits, independent product testing, IP verification, and strong contractual protections. Investing time upfront can save significant financial and reputational damage down the line.

Logistics & Compliance Guide for Electric Trash Compactors

This guide outlines essential logistics considerations and compliance requirements for the transportation, handling, storage, and operation of electric trash compactors. Adhering to these guidelines ensures safety, regulatory adherence, and efficient supply chain management.

Product Classification & Documentation

Electric trash compactors are classified as industrial or commercial electrical equipment. Accurate product classification is critical for international shipping and customs clearance. Key documentation includes:

- Commercial Invoice with detailed product description, HS (Harmonized System) code (e.g., 8479.89 for other mechanical appliances), model numbers, and declared value.

- Packing List specifying weight, dimensions, and quantity per shipment.

- Bill of Lading or Air Waybill with correct freight classification.

- Certificate of Conformity (CoC) or Declaration of Conformity (DoC) for applicable regulations.

- Safety and user manuals in required local languages.

Packaging & Handling Requirements

Proper packaging ensures the compactor arrives undamaged and meets shipping standards:

- Use robust wooden crates or heavy-duty corrugated containers with internal bracing to protect hydraulic components, electrical panels, and compaction chambers.

- Secure all moving parts (e.g., ram, hopper lid) with transit bolts or straps during shipment.

- Clearly label packages with:

- “Fragile”

- “This Side Up”

- “Do Not Stack”

- Weight and center of gravity indicators

- Include handling instructions for forklift entry points and lifting points.

Shipping & Transportation

Transport electric trash compactors via flatbed trucks, full container load (FCL), or less than container load (LCL), depending on order size:

- Secure units to pallets or flatbeds using ratchet straps or load-locking systems to prevent shifting.

- Comply with carrier-specific freight rules, including weight limits and hazardous material disclosures (if applicable).

- For international shipments, ensure compatibility with Incoterms (e.g., FOB, CIF) and verify import regulations in destination countries.

- Avoid exposure to extreme temperatures, moisture, or corrosive environments during transit.

Storage & Warehouse Management

Store units in a dry, indoor, temperature-controlled environment:

- Elevate units off the floor using pallets to prevent moisture damage.

- Maintain at least 2 feet of clearance around each unit for airflow and access.

- Protect electrical components and control panels with dust covers.

- Rotate stock using FIFO (First In, First Out) principles to prevent prolonged storage.

- Conduct periodic inspections for signs of corrosion, rodent damage, or tampering.

Regulatory Compliance

Ensure compliance with all relevant safety and environmental standards:

- Electrical Safety: Conform to regional standards such as:

- UL 1017 (Standard for Household and Commercial Waste Compactors) in the USA

- CSA C22.2 No. 208 in Canada

- IEC 60335-2-69 for international markets

- EMC (Electromagnetic Compatibility): Comply with FCC Part 15 (USA), CE-EMC Directive (EU), or equivalent standards.

- RoHS & REACH: Confirm that materials used in manufacturing comply with restrictions on hazardous substances (EU and other jurisdictions).

- Energy Efficiency: Meet applicable energy performance standards (e.g., ENERGY STAR where applicable).

- Labeling: Affix required certification marks (e.g., UL, CSA, CE) and technical data plates with voltage, amperage, and model information.

Installation & Site Compliance

Verify site readiness prior to installation:

- Confirm electrical supply matches compactor specifications (voltage, phase, amperage).

- Ensure proper grounding and circuit protection (dedicated circuit recommended).

- Validate ventilation and clearance requirements per manufacturer’s manual.

- Comply with local building codes, fire safety regulations, and waste handling ordinances.

- Provide accessible emergency shut-off switches.

Environmental & Disposal Regulations

Dispose of obsolete or damaged units responsibly:

- Recycle metal components through certified scrap processors.

- Remove and dispose of electrical wiring and control boards in accordance with WEEE (Waste Electrical and Electronic Equipment) directives.

- Handle hydraulic fluid (if applicable) as hazardous waste per EPA or local environmental regulations.

- Maintain documentation of proper disposal for audit purposes.

Training & User Compliance

Provide operators and maintenance personnel with training on:

- Safe operation procedures

- Lockout/Tagout (LOTO) protocols during servicing

- Routine maintenance and inspection schedules

- Emergency response actions

Ensure all users have access to up-to-date manuals and safety warnings.

Summary

Effective logistics and compliance management for electric trash compactors reduces risks, avoids delays, and supports legal and safe operation. Always consult the manufacturer’s specifications and local regulations to ensure full adherence throughout the product lifecycle.

In conclusion, sourcing an electric trash compactor is a smart and sustainable investment for both residential and commercial applications. Electric compactors offer numerous advantages, including energy efficiency, lower operational noise, reduced maintenance needs, and minimal environmental impact compared to hydraulic models. By choosing an electric compactor, organizations can enhance waste management efficiency, reduce waste volume, lower disposal costs, and support environmental sustainability goals.

When sourcing, it is essential to assess specific needs such as compaction force, bin size, duty cycle, space limitations, and ease of integration into existing systems. Partnering with reputable suppliers who provide reliable equipment, strong warranties, and responsive after-sales support ensures long-term performance and operational continuity.

Ultimately, selecting the right electric trash compactor involves balancing cost, functionality, and sustainability. With careful evaluation and strategic sourcing, businesses and institutions can achieve optimal waste management solutions that are efficient, eco-friendly, and cost-effective in the long run.