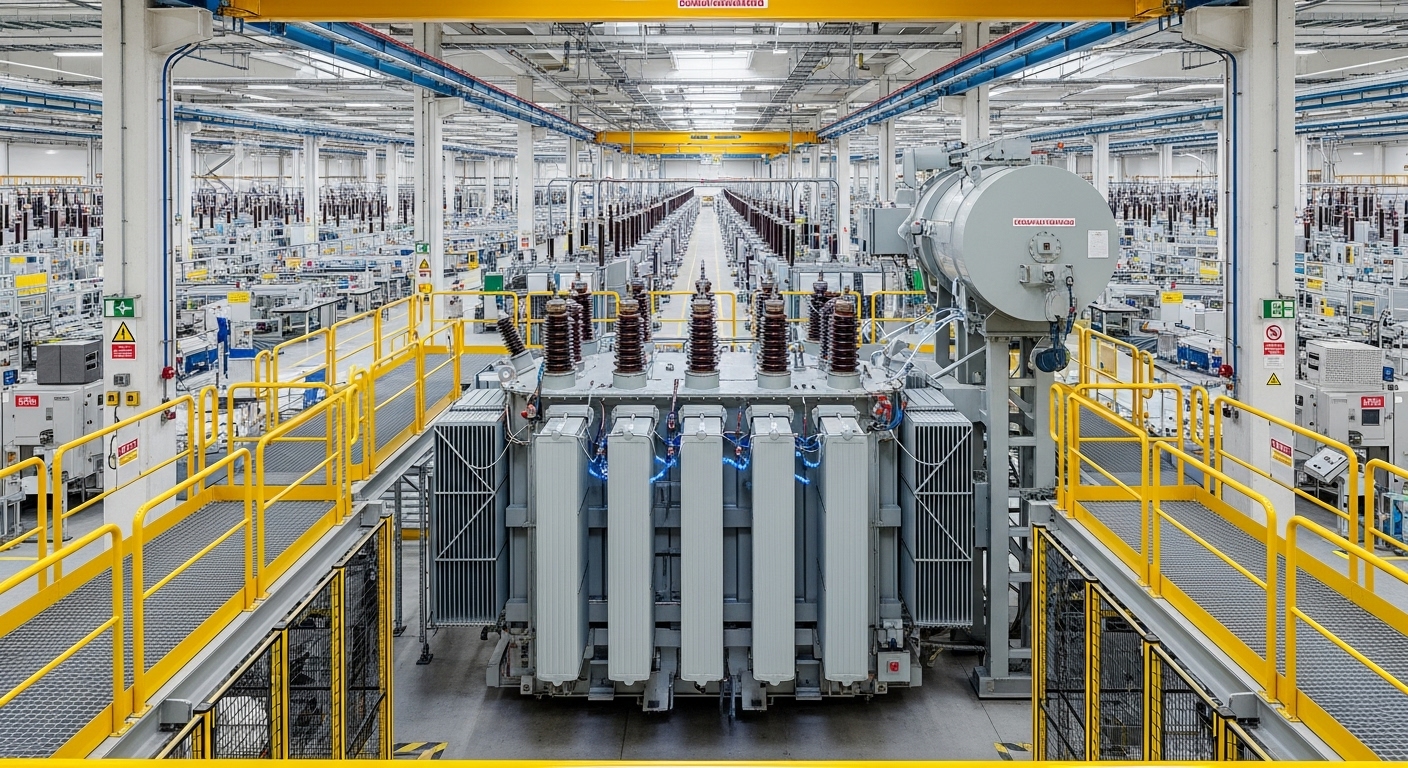

The global transformer market is experiencing robust growth, driven by rising electricity demand, grid modernization initiatives, and the expansion of renewable energy infrastructure. According to Grand View Research, the global power transformer market size was valued at USD 45.6 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2024 to 2030. This growth is further amplified by the increasing deployment of Delta-Wye transformers, which play a critical role in power distribution networks by facilitating voltage transformation and providing neutral grounding for system stability. As industries and utilities prioritize energy efficiency and grid reliability, demand for high-performance Delta-Wye configurations has intensified. In response, leading manufacturers are investing in advanced materials, smart monitoring systems, and scalable production to meet evolving technical standards and regional regulations. This growing market landscape underscores the importance of identifying the top six transformer manufacturers excelling in Delta-Wye technology, innovation, and global reach.

Top 6 Transformer Delta Wye Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Power Transformers

Domain Est. 1995

Website: deltastar.com

Key Highlights: Delta Star’s power transformers are engineered, manufactured, and tested for performance, reliability, and efficiency….

#2

Domain Est. 1997

Website: delta.xfo.com

Key Highlights: Located in Granby, Quebec, Delta Transformers has been designing and manufacturing high-quality dry-type transformers and reactors for more than 40 years. Sign ……

#3 Switchgear Maintenance Procedures

Domain Est. 1998

Website: deltawye.com

Key Highlights: Learn proven switchgear maintenance procedures from 45+ years of field experience. Get step-by-step checklists, testing protocols & NFPA 70B compliance ……

#4 Delta Wye Opens its Doors

Domain Est. 2022

Website: deltawyeeng.com

Key Highlights: Delta Wye Engineering Ltd. is officially open for business! After working in the engineering consulting business for over 15 years with great companies….

#5 The Ultimate Guide to delta wye transformer

Website: daelimtransformer.com

Key Highlights: Delta Wye transformer manufacturer Daelim Transformer has rich experience in the production and sales of transformers. Transformers are exported to many ……

#6 What Is a Delta

Domain Est. 2024

Website: evernewtransformer.com

Key Highlights: A Delta-Wye transformer is a three-phase transformer where the primary winding is connected in a delta (Δ) configuration, and the secondary winding is ……

Expert Sourcing Insights for Transformer Delta Wye

H2: 2026 Market Trends for Transformer Delta Wye

As the global energy landscape evolves toward greater electrification, renewable integration, and grid modernization, Delta-Wye (Δ-Y) transformers are expected to play a pivotal role in power distribution systems by 2026. These transformers, known for their ability to provide voltage transformation, neutral grounding, and phase shifting, are witnessing increased demand driven by several key market trends.

-

Growth in Renewable Energy Integration

The expansion of solar and wind farms—often located in remote areas—requires efficient step-up and step-down voltage transformation. Delta-Wye transformers are frequently used at the interface between renewable generation sites and the main grid due to their reliable neutral grounding capability, which enhances system stability and safety. By 2026, as countries accelerate their transition to clean energy, demand for Delta-Wye transformers in substations and collection systems will rise significantly. -

Smart Grid and Grid Resilience Initiatives

Governments and utilities are investing heavily in modernizing aging infrastructure. Delta-Wye transformers are integral to smart grid deployments, where their configuration supports harmonics mitigation, fault current management, and compatibility with advanced monitoring systems. In North America and Europe, grid resilience programs post-extreme weather events are prioritizing robust transformer installations, favoring Delta-Wye designs for their grounding advantages. -

Electric Vehicle (EV) Charging Infrastructure Expansion

The rapid rollout of high-power EV charging stations—especially DC fast chargers—requires stable, three-phase power distribution. Delta-Wye transformers are commonly used in charging hubs and depot microgrids to ensure balanced loads and provide a neutral reference for single-phase loads. With EV adoption projected to surge by 2026, this application will drive incremental demand for medium-voltage Delta-Wye units. -

Industrial Automation and Data Center Growth

Industrial 4.0 and the proliferation of data centers demand reliable and clean power. Delta-Wye transformers are preferred in these settings for their ability to suppress triplen harmonics and provide a stable neutral for sensitive equipment. The Asia-Pacific region, particularly China, India, and Southeast Asia, is expected to lead installation growth due to rapid data center construction and manufacturing upgrades. -

Regulatory and Efficiency Standards

Stricter energy efficiency regulations (e.g., DOE 2026 standards in the U.S., EU Ecodesign Directive) are pushing manufacturers to produce higher-efficiency Delta-Wye transformers using amorphous metal cores and advanced cooling systems. Compliance with these standards will shape product innovation and procurement decisions across utilities and private sectors. -

Supply Chain Localization and Material Costs

Ongoing geopolitical factors and supply chain disruptions are prompting a shift toward regional transformer manufacturing. Copper and grain-oriented silicon steel prices remain volatile, influencing design optimizations—such as improved winding configurations in Delta-Wye units—to balance cost and performance. By 2026, localized production in regions like India, Mexico, and Eastern Europe is expected to support faster deployment and reduce import dependencies. -

Digitalization and Predictive Maintenance

Delta-Wye transformers are increasingly being equipped with IoT sensors and digital monitoring tools. This trend supports predictive maintenance, reducing downtime and extending asset life. By 2026, digital twin integration and AI-driven diagnostics will become standard in new installations, especially in critical infrastructure.

Conclusion

By 2026, the Delta-Wye transformer market will be shaped by the confluence of energy transition, digital transformation, and infrastructure modernization. Their versatility in grounding, harmonics control, and voltage regulation ensures continued relevance across utility, industrial, and commercial sectors. Manufacturers and utilities that align with efficiency standards, digital integration, and renewable integration will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Transformer Delta Wye (Quality, IP)

Sourcing Delta-Wye (Δ-Y) transformers—especially for industrial or critical infrastructure applications—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to premature failure, safety hazards, and costly downtime. Below are common pitfalls to avoid:

1. Prioritizing Price Over Quality

Many buyers focus on upfront cost, selecting the lowest bidder without evaluating long-term reliability. Low-cost transformers may use substandard materials—such as lower-grade copper windings, inferior insulation, or poor core steel—leading to higher losses, overheating, and reduced lifespan.

Best Practice: Evaluate total cost of ownership (TCO), including efficiency, maintenance, and expected service life. Choose suppliers with certified quality management systems (e.g., ISO 9001) and verifiable test reports (e.g., type tests, routine tests per IEC 60076).

2. Inadequate Ingress Protection (IP) Rating for Environment

Selecting a transformer with an insufficient IP rating for its installation environment is a frequent oversight. For example, using an IP20-rated indoor unit in a dusty warehouse or outdoor setting without proper enclosure exposes internal components to moisture, dust, and vermin.

Best Practice: Match the IP rating to the environment:

– IP20: Suitable only for clean, dry, indoor environments.

– IP54 or higher: Required for outdoor use or harsh indoor conditions (dust, moisture).

– IP65/IP66: Ideal for washdown areas or coastal locations.

Ensure the enclosure design maintains cooling efficiency at higher IP levels.

3. Ignoring Manufacturing and Testing Standards

Some suppliers claim compliance with international standards (e.g., IEC, IEEE, ANSI) without third-party verification. Transformers not properly tested may fail under load or during fault conditions.

Best Practice: Require test certificates (e.g., routine tests: insulation resistance, turns ratio, no-load and load losses) and confirm compliance with applicable standards. Prefer vendors who conduct factory acceptance tests (FAT) with customer witness options.

4. Poor Thermal Design and Cooling Management

Delta-Wye transformers generate heat under load. Units with inadequate thermal design or blocked ventilation (especially in high-IP enclosures) can overheat, degrading insulation and reducing efficiency.

Best Practice: Verify cooling method (e.g., AN, AF), ensure proper clearances for airflow, and confirm temperature rise limits (e.g., 65°C or 115°C rise) are suitable for the application. For sealed high-IP units, ensure forced cooling (fans) is appropriately sized and maintained.

5. Incomplete or Inaccurate Nameplate Data

Missing or incorrect nameplate information (voltage ratios, kVA rating, connection type, impedance, frequency, cooling class) can lead to mismatched installations and operational issues.

Best Practice: Audit nameplate data against specifications before acceptance. Confirm the Δ-Y vector group (e.g., Dyn11, Dyn5) matches system requirements to avoid phase displacement problems.

6. Lack of Supply Chain Transparency

Some suppliers source components or outsource manufacturing without oversight, increasing the risk of counterfeit or non-conforming parts.

Best Practice: Choose suppliers with transparent supply chains, traceable materials, and in-house manufacturing capabilities where possible. Request material certifications (e.g., copper purity, insulating materials).

7. Overlooking Customization and Future-Proofing

Standard transformers may not meet specific site requirements (e.g., harmonic loads, voltage fluctuations). Failure to specify taps, shielding, or K-factor ratings can compromise performance.

Best Practice: Clearly define operational requirements during procurement, including:

– Tap changers (off-load or on-load)

– Harmonic mitigation (K-factor or K-rated design)

– Surge protection and grounding needs

8. Inadequate Documentation and Support

Missing installation manuals, wiring diagrams, or lack of technical support can delay commissioning and troubleshooting.

Best Practice: Ensure the supplier provides complete documentation and offers post-sales support, including spare parts availability and field service.

By addressing these common pitfalls, organizations can ensure they source reliable, safe, and efficient Delta-Wye transformers tailored to their operational and environmental demands.

Logistics & Compliance Guide for Transformer Delta Wye

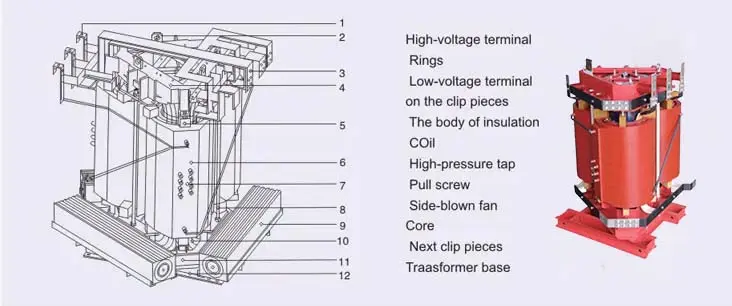

Overview of Delta-Wye Transformers

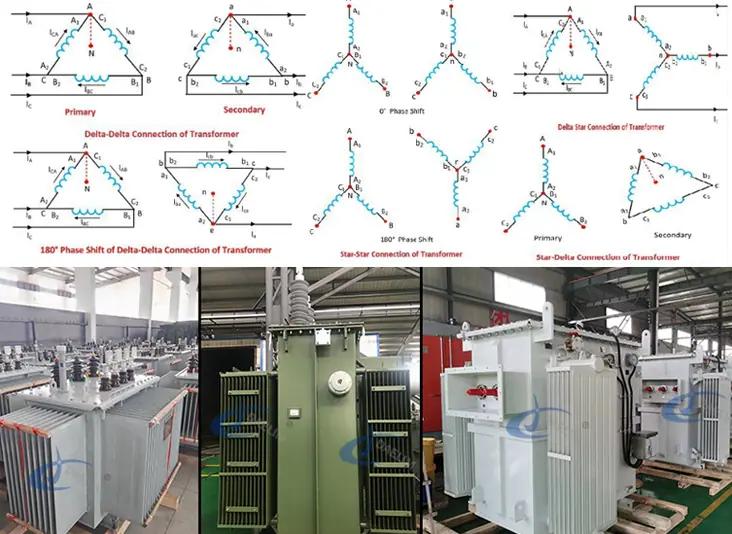

Delta-Wye transformers are three-phase electrical transformers with a delta-connected primary winding and a wye (star)-connected secondary winding. They are widely used in power distribution systems to step down voltage levels, provide neutral grounding, and reduce harmonics. Proper logistics and compliance considerations are essential to ensure safe, efficient, and code-compliant installation and operation.

Transportation and Handling Requirements

- Packaging and Crating: Delta-Wye transformers must be shipped in robust, weather-resistant crates with shock-absorbing materials to prevent damage during transit.

- Weight and Dimensions: Confirm the transformer’s weight, dimensions, and center of gravity before transport. Use lifting lugs only; never lift by tank walls or radiators.

- Transport Vehicles: Use flatbed trucks or specialized trailers with proper securing mechanisms (straps, chains, dunnage). Ensure road clearance and bridge weight limits are observed.

- On-Site Handling: Employ certified riggers and appropriate equipment (cranes, forklifts) to move the unit. Maintain the transformer in an upright position at all times.

- Storage Conditions: If stored before installation, place the unit on a level, dry surface and protect from moisture, dust, and extreme temperatures.

Regulatory and Safety Compliance

- National Electrical Code (NEC): Comply with NEC Article 450 for transformer installation, including clearance, ventilation, and overcurrent protection.

- IEEE Standards: Adhere to IEEE C57.12.00 for general requirements and IEEE C57.12.90 for test codes.

- OSHA Regulations: Follow OSHA 29 CFR 1910.303 for electrical safety in workplace installations.

- Local Jurisdiction Requirements: Verify permits, zoning, and environmental regulations with local authorities.

- Labeling and Nameplate Data: Ensure the transformer bears a permanent nameplate with kVA rating, voltage ratios, impedance, connection type (Δ-Y), and compliance marks (e.g., UL, CSA, CE).

Environmental and Fluid Handling

- Dielectric Fluids: Mineral oil or synthetic ester-filled units require spill containment and secondary containment systems per EPA Spill Prevention, Control, and Countermeasure (SPCC) rules if over threshold volumes.

- PCB-Free Certification: Confirm the transformer is PCB-free (<2 ppm) as per TSCA regulations.

- Disposal and Recycling: Follow EPA and local regulations for end-of-life handling. Recycle oil and metals through certified facilities.

Installation and Grounding Compliance

- Neutral Grounding: The wye secondary must have a properly sized neutral conductor grounded per NEC Article 250. This includes grounding electrode conductors and bonding jumpers.

- Phase Rotation and Polarity: Verify correct phase sequence and polarity during commissioning to prevent equipment damage.

- Clearances and Ventilation: Maintain required air clearances around the unit for cooling and fire safety, especially in indoor installations.

- Seismic Bracing: In seismic zones, comply with IBC and ASCE 7 requirements for anchoring and bracing.

Documentation and Certification

- Test Reports: Request factory test reports including turns ratio, polarity, impedance, and insulation resistance (megger) tests.

- Certificate of Compliance: Obtain documentation proving adherence to NEMA, ANSI, and IEEE standards.

- As-Built Drawings: Maintain updated schematics showing connections, grounding, and protection devices.

- Commissioning Records: Document insulation resistance tests, phasing checks, and protective relay settings upon energization.

Maintenance and Ongoing Compliance

- Routine Inspections: Schedule regular checks for oil levels, leaks, temperature, and corrosion.

- Dissolved Gas Analysis (DGA): Perform periodic DGA for oil-filled units to detect internal faults.

- Infrared Thermography: Use thermal imaging to identify hotspots in connections and windings.

- Regulatory Audits: Prepare for periodic inspections by utilities or regulatory bodies to verify continued compliance.

Emergency Preparedness and Spill Response

- Spill Kits: Keep oil spill kits on-site with absorbents, gloves, and containment booms.

- Emergency Shutdown: Ensure disconnect switches are accessible and labeled.

- Response Plan: Implement a site-specific emergency response plan aligned with EPA and local fire code requirements.

Conclusion

Proper logistics planning and strict compliance with electrical, environmental, and safety regulations are critical for the successful deployment of Delta-Wye transformers. Adhering to this guide ensures operational reliability, regulatory approval, and long-term asset integrity.

Conclusion for Sourcing a Delta-Wye Transformer

Sourcing a Delta-Wye (Δ-Y) transformer requires careful consideration of application requirements, load characteristics, and system compatibility. This transformer configuration is widely preferred in power distribution systems due to its ability to provide a neutral point on the secondary side, support both three-phase and single-phase loads, and reduce harmonics—especially third-order harmonics—through phase cancellation. It also offers voltage transformation between transmission and utilization levels, making it ideal for industrial, commercial, and utility applications.

When sourcing a Delta-Wye transformer, key factors include voltage ratings, kVA capacity, impedance, insulation class, efficiency standards (such as DOE 2016 or equivalent), and environmental conditions (indoor/outdoor, temperature, altitude). Compliance with standards like IEEE C57, NEMA, or IEC ensures reliability and safety. Additionally, considerations such as vector group (e.g., Dyn11 or Dyn1), grounding practices, and harmonic mitigation may influence the selection process.

In conclusion, selecting the right Delta-Wye transformer involves balancing technical performance, regulatory compliance, and lifecycle costs. Proper sourcing ensures efficient, stable, and safe power distribution, minimizing downtime and supporting long-term operational goals. Engaging with reputable manufacturers and qualified engineers during the procurement process is essential to achieving an optimal solution tailored to the specific electrical system needs.