The global market for printer consumables, including transfer rollers—critical components in electrophotographic printing processes—has experienced steady growth driven by rising demand for office automation, sustained use of laser printing technology, and increased adoption in enterprise environments. According to a 2023 report by Mordor Intelligence, the global printer consumables market was valued at USD 54.6 billion and is projected to grow at a CAGR of over 4.2% from 2023 to 2028. This expansion is supported by continuous technological upgrades, an uptick in remote working infrastructure, and the aftermarket demand for replacement parts like transfer rollers. As OEMs and third-party manufacturers compete to deliver high-yield, durable components, innovation in materials and manufacturing precision has become a key differentiator. Against this backdrop, the following list highlights the top 10 transfer roller manufacturers recognized for their technological expertise, production scalability, and global market presence.

Top 10 Transfer Roller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Heat Transfer Rollers for Textile High

Domain Est. 2020

Website: sivarollers.com

Key Highlights: As a leading Heat Transfer Rollers Manufacturer, Siva Roller designs products that are built to withstand the toughest industrial environments ……

#2 Custom Heat Transfer Rollers

Domain Est. 1996

Website: rolltech.com

Key Highlights: Explore heat transfer rolls at Rolltech. Designed for consistent performance and efficiency in thermal applications. Customize your heat transfer rollers ……

#3 Chill rolls

Domain Est. 1998

Website: rollconcept.com

Key Highlights: Roll Concept also offers chill rolls. Based on our Alveotube profiles, our thermal transfer rollers combined low weight, low thermal and rotation inertia….

#4 Vintex Rubber Industries

Domain Est. 2007

Website: vintexrollers.com

Key Highlights: … Transfer Roller / Nip Roller · VMCH Coating Roller – Coating Roller / Applicator … Supplier & Exporter of all kind of rubber rollers in India and globally….

#5 Roller Manufacturer

Domain Est. 2017

Website: r2rengineering.com

Key Highlights: R2R Engineering can manufacture per print, design from-the-ground-up, or tweak a current design for better performance, whatever our customer demands….

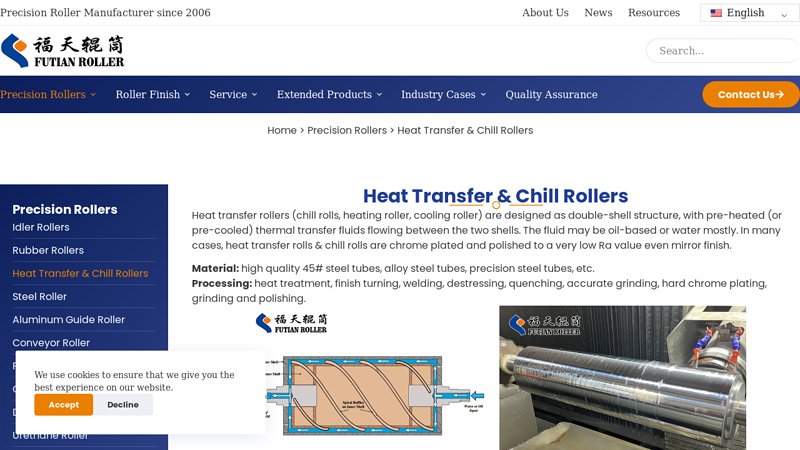

#6 Heat Transfer & Chill Rollers

Domain Est. 2019

Website: rollerft.com

Key Highlights: As a heat transfer and chill roller manufacturer, Futian Roller offers customized heat transfer rollers and chill rolls for many industries….

#7 Heat Transfer & Chill Rollers

Domain Est. 2023

Website: matthews-engineering.com

Key Highlights: Achieve precise temperature control and heat transfer for efficient processes with our advanced industrial heated and chill rollers….

#8 CrossX Easy Transfer Roller

Domain Est. 1996

Website: roachconveyors.com

Key Highlights: The CrossX Easy Transfer Roller converts a standard roller conveyor section into a transverse top push configuration quickly and cost-effectively, ……

#9 Heat Transfer Rollers for Precise Temperature Control

Domain Est. 2019

Website: precisionrollsolutions.com

Key Highlights: Precision Roll Solutions manufactures custom heat transfer rollers designed to maintain stable surface temperatures across high-speed production processes….

#10 Transfer Rollers for Copiers & Printers

Domain Est. 2020

Website: yamauchi-rubber.com

Key Highlights: High-performance transfer rollers for multifunction copiers and printers. Wide-format rollers are available such as A0 and A1 sizes….

Expert Sourcing Insights for Transfer Roller

H2: 2026 Market Trends for Transfer Roller

The global transfer roller market is poised for significant transformation by 2026, driven by advancements in printing technologies, rising demand for high-quality imaging solutions, and increased automation across industries. Transfer rollers—critical components in laser printers, copiers, and multifunction devices—play a vital role in transferring toner images from photoconductors to paper. The following trends are expected to shape the market over the next few years:

-

Growth in Digital Printing and Office Automation

The continued shift toward digital workplaces and automated document processing is fueling demand for reliable and efficient printing systems. As businesses invest in modern office infrastructure, the need for durable and high-performance transfer rollers is increasing. This trend is especially notable in emerging economies where digital adoption is accelerating. -

Expansion of the Aftermarket and Remanufactured Components

Cost-conscious consumers and businesses are increasingly opting for remanufactured or compatible transfer rollers over original equipment manufacturer (OEM) parts. By 2026, the aftermarket segment is projected to capture a larger market share due to sustainability initiatives and cost savings, particularly in regions like Asia-Pacific and Latin America. -

Technological Advancements in Materials and Coatings

Manufacturers are investing in advanced materials such as conductive silicone, EPDM rubber, and nano-coatings to enhance roller durability, conductivity, and resistance to wear. These innovations improve print quality and extend product life, addressing key pain points in high-volume printing environments. -

Sustainability and Environmental Regulations

Environmental concerns are pushing printer OEMs and component suppliers to develop eco-friendly transfer rollers with reduced waste and recyclable materials. Regulatory frameworks in Europe and North America are encouraging the adoption of greener manufacturing practices, influencing product design and lifecycle management. -

Rise of Industrial and Wide-Format Printing

Increasing demand in industrial applications—such as packaging, textiles, and large-format signage—is expanding the use of transfer rollers beyond traditional office equipment. These applications require robust rollers capable of handling diverse substrates and continuous operation, presenting new growth avenues. -

Regional Market Dynamics

Asia-Pacific is expected to dominate the transfer roller market by 2026, driven by strong manufacturing bases in China, India, and South Korea, along with growing domestic printer production. Meanwhile, North America and Europe will focus on innovation and premium aftermarket solutions.

In conclusion, the 2026 transfer roller market will be shaped by technological innovation, sustainability mandates, and shifting consumer preferences. Companies that prioritize R&D, environmental compliance, and cost-effective solutions are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Transfer Rollers (Quality, IP)

Sourcing transfer rollers—critical components in laser printers and copiers—can be fraught with challenges, particularly concerning quality consistency and intellectual property (IP) risks. Understanding these pitfalls is essential to ensure reliable performance, avoid legal complications, and maintain brand reputation.

Inconsistent Quality and Performance

One of the most frequent issues when sourcing transfer rollers is variability in quality. Low-cost suppliers may use substandard materials or inconsistent manufacturing processes, leading to premature wear, poor toner transfer, and increased print defects such as smudging or incomplete image transfer. This results in higher failure rates, customer dissatisfaction, and increased warranty claims. Additionally, rollers that do not meet precise electrical resistance and surface finish specifications can degrade overall printer performance and reliability.

Intellectual Property (IP) Infringement Risks

Many transfer rollers are protected by patents held by OEMs (Original Equipment Manufacturers) covering design, material composition, and electrical properties. Sourcing generic or third-party rollers without proper IP clearance can expose buyers to legal action, including product seizures, fines, or injunctions. Even if a roller functions adequately, using a design that infringes on existing patents—intentionally or not—can lead to significant legal and financial consequences, especially in regulated markets.

Lack of Traceability and Certification

Suppliers may fail to provide adequate documentation regarding material sourcing, manufacturing standards, or compliance certifications (e.g., RoHS, REACH). This lack of traceability makes it difficult to ensure environmental compliance and can hinder root cause analysis during field failures. Without proper certifications, products may fail to meet regulatory requirements in key markets, delaying time-to-market or triggering recalls.

Short-Term Cost Savings vs. Long-Term Costs

While choosing lower-cost rollers may appear economical initially, poor quality often leads to higher total cost of ownership. Increased printer downtime, higher service costs, and damage to associated components (like photoconductor units) can outweigh upfront savings. Additionally, reputational damage from unreliable performance can erode customer trust and brand value over time.

Inadequate Testing and Validation

Some suppliers do not perform rigorous performance testing under real-world conditions. Without proper life cycle testing, environmental stress testing, or compatibility verification with various toners and drum units, rollers may fail prematurely in the field. Buyers may unknowingly integrate components that haven’t been validated for long-term reliability, leading to unexpected product issues after deployment.

To mitigate these risks, it is crucial to partner with reputable suppliers, conduct thorough due diligence on IP status, require detailed quality documentation, and implement robust incoming inspection and validation protocols.

Logistics & Compliance Guide for Transfer Roller

This guide outlines the key logistics and compliance considerations for the safe and efficient handling, transportation, storage, and regulatory adherence of Transfer Rollers—critical components in imaging and printing equipment such as copiers, laser printers, and multifunction devices.

Product Overview

Transfer Rollers are electro-mechanical components used to transfer toner from the photoconductor drum to the paper during the printing process. They are typically made of conductive rubber or polymer materials and are sensitive to static electricity, physical damage, and environmental conditions.

Packaging Requirements

- Use anti-static packaging materials (e.g., pink poly bags or conductive foam) to prevent electrostatic discharge (ESD) damage.

- Individually wrap each roller to avoid surface abrasion or contamination.

- Secure packaging within sturdy, corrugated cardboard boxes with internal cushioning to prevent movement during transit.

- Label all packages with “Fragile,” “Static Sensitive,” and “Do Not Stack” indicators as applicable.

Storage Conditions

- Store in a clean, dry, temperature-controlled environment.

- Ideal storage temperature: 15°C to 25°C (59°F to 77°F).

- Relative humidity: 40% to 60% RH to prevent moisture absorption or static buildup.

- Keep away from direct sunlight, UV exposure, and sources of ozone (e.g., motors, high-voltage equipment).

- Limit shelf life per manufacturer specifications (typically 12–18 months); implement FIFO (First In, First Out) inventory rotation.

Handling Procedures

- Personnel must wear ESD-safe wrist straps and gloves when handling transfer rollers.

- Avoid touching the roller surface directly; handle by the ends or casing only.

- Do not flex, bend, or apply pressure to the roller body.

- Use only approved tools and fixtures during installation or inspection.

Transportation Guidelines

- Use climate-controlled transport when possible, especially for long-distance or international shipments.

- Ensure packages are secured to prevent shifting or impact during transit.

- Avoid extreme temperatures (below 0°C or above 40°C) during shipping.

- Comply with IATA, IMDG, or other relevant transport regulations if shipping by air or sea (note: most transfer rollers are non-hazardous but verify per material composition).

- Provide proper documentation, including packing lists and commercial invoices.

Regulatory Compliance

- RoHS (Restriction of Hazardous Substances): Confirm the transfer roller complies with EU Directive 2011/65/EU (lead, mercury, cadmium, etc. limits).

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Ensure no restricted substances are present above thresholds.

- WEEE (Waste Electrical and Electronic Equipment): Include appropriate labeling and provide take-back or recycling instructions where applicable.

- Country-Specific Regulations: Verify compliance with local environmental and safety standards (e.g., EPA regulations in the U.S., CCC in China).

Import/Export Documentation

- Accurate Harmonized System (HS) Code classification (e.g., 8443.99 for printer parts—verify per country).

- Commercial invoice, packing list, and bill of lading/airway bill.

- Certificate of Origin, if required for tariff preferences.

- Material Safety Data Sheet (MSDS/SDS) upon request, especially for customs clearance.

End-of-Life Management

- Classify transfer rollers as electronic waste (e-waste) at end of life.

- Partner with certified e-waste recyclers compliant with R2, WEEELABEX, or equivalent standards.

- Do not dispose of in regular landfill; follow local hazardous waste disposal rules if applicable.

Quality Assurance & Traceability

- Maintain lot tracking and batch records for traceability.

- Conduct periodic audits of storage and handling practices.

- Train logistics staff on ESD safety and proper handling procedures.

Contact Information

For compliance inquiries, logistics support, or safety data, contact:

[Company Name] Logistics & Compliance Team

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Transfer Roller:

In conclusion, sourcing a transfer roller requires a strategic approach that balances quality, cost, reliability, and compatibility with existing printing or imaging equipment. After evaluating multiple suppliers, assessing technical specifications, and considering factors such as material durability, performance consistency, and after-sales support, it is evident that selecting the right supplier is critical to ensuring optimal equipment functionality and minimizing downtime.

The chosen transfer roller meets the required standards for electrostatic performance, wear resistance, and print transfer efficiency. Additionally, the selected vendor demonstrates a proven track record of quality control, timely delivery, and responsive technical support—key elements in maintaining smooth operations.

Moving forward, establishing a long-term partnership with the preferred supplier, coupled with periodic performance reviews and inventory management, will help ensure continued reliability and cost-effectiveness. This sourcing decision supports operational efficiency, reduces maintenance costs, and contributes to overall printing system performance and output quality.