The global trailer wiring market is experiencing steady growth, driven by rising demand for commercial vehicles, increasing adoption of trailers in logistics and recreational segments, and stricter safety regulations mandating reliable electrical connections. According to a report by Mordor Intelligence, the global trailer market was valued at USD 50.8 billion in 2022 and is projected to grow at a CAGR of over 5.2% from 2023 to 2028, directly influencing the demand for critical components such as 4-wire trailer wiring systems. These systems, which support essential functions like brake lights, turn signals, and ground connections, are vital for safe towing operations across light-duty trailers used in agriculture, marine, and personal transport applications. As the trailer aftermarket expands and OEMs prioritize durability and compliance, manufacturers of 4-wire wiring harnesses are scaling innovation in weather-resistant materials, corrosion protection, and plug-and-play installation features. With North America and Europe leading in trailer ownership and regulatory standards, competition among wiring manufacturers is intensifying, pushing advancements in product reliability and integration capabilities. In this evolving landscape, identifying the top-performing manufacturers of 4-wire trailer wiring systems becomes essential for distributors, fleet operators, and equipment integrators seeking quality and compliance.

Top 10 Trailer Wiring 4 Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 4 WAY TRAILER WIRING HARNESS

Domain Est. 1996

Website: loadrite.com

Key Highlights: In stock4 WAY TRAILER WIRING HARNESS – 18′ · Manufactured by Vanguard Manufacturing, Inc. · 4 Flat, Wishbone Design · Color Coded, 18 Gauge Bonded Wire ……

#2 Four Star Wire & Cable If you can think it, We can build it!

Domain Est. 1999

Website: fourstarwire.com

Key Highlights: Four Star Wire & Cable – is your trusted U.S. source for industrial, electrical, and pro audio wire and cable solutions….

#3 4 Wire Flat, 48″ Trailer End (13193)

Domain Est. 2007

Website: huskytow.com

Key Highlights: In stock $199 deliveryThis Husky Towing trailer end 4-wire flat Trailer Wiring Connector has 48 inch wire length. Manufacturer part number: 13193…

#4 Trailer Harnesses

Domain Est. 2008

Website: wiring-harness-manufacturer.com

Key Highlights: Ultimate Trailer Versatility Unleashed: Introducing 7-Way, 5-Way Flat, and 4-Way Flat Wishbone Trailer Harnesses for Unmatched Connectivity and Convenience!…

#5 Peterson: A World

Domain Est. 2021

Website: petersonlightsandharness.com

Key Highlights: Peterson Manufacturing innovates vehicle safety lighting and wiring harness systems that improve performance and reduce operational costs….

#6 Vehicle / Trailer Wiring

Domain Est. 1998

Website: wesbar.com

Key Highlights: Wesbar is a Registered Brand of First Brands Group. Address: 3255 West Hamlin Road Rochester Hills, MI, 48309 800-632-3290…

#7 Trailer Wire and Cable

Domain Est. 1998

#8 Trailer Wiring Diagrams

Domain Est. 1999

Website: etrailer.com

Key Highlights: 4-Way Connectors 4-Way connectors are available allowing the basic hookup of the three lighting functions (running, turn, and brake lights) plus ……

#9 Vehicle Specific Wiring Kits

Domain Est. 2005

Website: hopkinstowingsolutions.com

Key Highlights: Hopkins trailer wiring solutions – Vehicle trailer wiring harness kits provide a 4 Wire Flat connector for your trailer and all of the necessary mounting…

#10 The Ultimate Guide to 4

Domain Est. 1997

Website: curtmfg.com

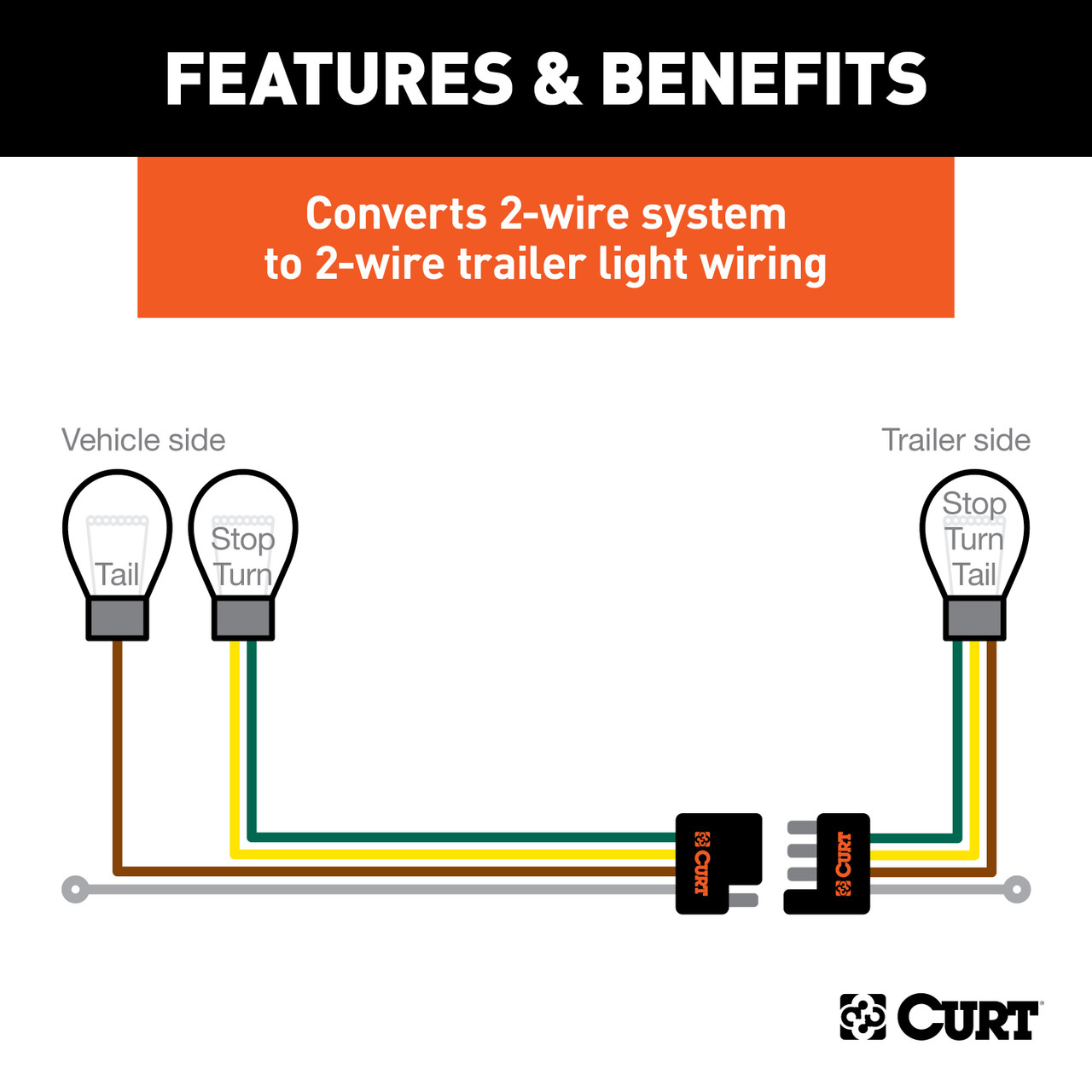

Key Highlights: Learn how to easily install and maintain a 4-wire trailer connector with our comprehensive guide. Perfect for boat, ATV, and utility trailers, this guide ……

Expert Sourcing Insights for Trailer Wiring 4 Wire

H2: Projected Market Trends for 4-Wire Trailer Wiring in 2026

The global market for 4-wire trailer wiring is poised for steady growth through 2026, driven by rising demand in the automotive, recreational vehicle (RV), and light commercial vehicle sectors. As connectivity and safety standards evolve, the 4-wire configuration—commonly used for basic trailer lighting (tail, brake, turn signals, and ground)—remains a cost-effective and reliable solution for light- to medium-duty towing applications. Key trends shaping the 4-wire trailer wiring market in 2026 include:

-

Increased Adoption in Recreational and Light-Duty Vehicle Segments

The continued popularity of SUVs, pickup trucks, and RVs in North America and Europe is fueling demand for aftermarket and OEM trailer wiring solutions. Consumers seeking weekend adventures, boat towing, or small utility trailers are opting for simple, plug-and-play 4-wire systems, supporting market expansion. -

Growth in E-Commerce and DIY Installation

Online retail platforms have made 4-wire trailer wiring harnesses more accessible, with detailed installation guides and compatibility tools enhancing consumer confidence. The do-it-yourself (DIY) trend, especially among younger vehicle owners, is increasing demand for standardized, easy-to-install 4-pin connectors. -

Regulatory and Safety Standards Influence

While advanced systems (e.g., 5-, 6-, or 7-wire setups with auxiliary power or reverse lights) are gaining traction, many regions still mandate minimum lighting compliance that 4-wire systems fulfill. Regulatory frameworks in emerging markets are gradually aligning with international safety norms, creating new opportunities for standardized 4-wire products. -

Competition from Advanced Wiring Systems

Despite steady demand, the 4-wire segment faces pressure from evolving technologies, including integrated trailer braking systems, smart towing modules, and multiplexed wiring. However, due to its simplicity and affordability, the 4-wire system will maintain relevance, particularly in entry-level and retrofit applications. -

Regional Market Dynamics

North America remains the largest market due to high vehicle towing culture and robust RV sales. Europe shows moderate growth, supported by agricultural and leisure vehicle use. In Asia-Pacific, rising vehicle ownership and infrastructure development in countries like India and Southeast Asia are expected to open new avenues for 4-wire trailer wiring adoption. -

Sustainability and Material Innovation

Manufacturers are exploring recyclable insulation materials and corrosion-resistant coatings to extend product lifespan and meet environmental standards. Lightweight, UV-resistant PVC and improved connector sealing are becoming standard features by 2026.

In conclusion, while the 4-wire trailer wiring market may not see the same innovation velocity as higher-pin-count systems, its role as a foundational towing solution ensures sustained demand through 2026. Market players focusing on reliability, compatibility, and user-friendly design will remain competitive in this niche yet essential segment of the automotive electrical ecosystem.

Common Pitfalls When Sourcing Trailer Wiring 4-Wire (Quality, IP Rating)

Sourcing 4-wire trailer wiring seems straightforward, but overlooking key quality and Ingress Protection (IP) factors can lead to premature failures, safety hazards, and costly replacements. Being aware of these common pitfalls ensures reliable and safe trailer operation.

Overlooking IP Rating for Environmental Exposure

One of the most critical mistakes is selecting wiring without an appropriate IP rating for the intended environment. Trailers face rain, mud, road spray, and dust. Wiring with insufficient protection—such as IPX4 (splash-resistant) instead of IP67 (dust-tight and submersible up to 1 meter)—can quickly degrade. Low IP-rated connectors allow moisture ingress, leading to short circuits, corrosion, and blown fuses. Always verify that both the connector and wiring harness meet at least IP67 for outdoor or heavy-duty use.

Prioritizing Cost Over Build Quality

Choosing the cheapest available 4-wire harness often results in thin-gauge wires, poor insulation, and flimsy connectors. Low-quality materials break down under heat, vibration, and UV exposure, increasing the risk of electrical failure. Substandard soldering or crimping in connectors leads to intermittent connections, especially under vibration. Investing in reputable brands with robust construction ensures longevity and reliability, especially for frequent or commercial use.

Ignoring Wire Gauge and Current Load Compatibility

Using undersized wire gauge (e.g., 18 AWG instead of 16 or 14 AWG) for the trailer’s lighting load can cause excessive voltage drop, dim lights, and overheating. This is especially problematic for larger trailers with multiple lights or auxiliary circuits. Always match the wire gauge to the expected current draw and length of the run to maintain performance and prevent fire hazards.

Assuming All Connectors Are Interchangeable

Not all 4-pin flat connectors follow the same pin configuration or quality standards. Some suppliers offer non-standard pinouts or poor contact alignment, leading to incorrect light activation (e.g., brake lights turning on with turn signals). Additionally, low-quality plastics become brittle over time, causing cracks and loose connections. Verify compatibility with your vehicle and ensure the connector design supports secure, weather-resistant mating.

Neglecting UV and Temperature Resistance

Many low-cost harnesses use PVC insulation that degrades quickly under prolonged sun exposure, becoming brittle and prone to cracking. Similarly, poor-quality materials can warp or melt in extreme temperatures. Look for wiring with UV-stabilized jacketing and a wide operating temperature range (e.g., -40°C to +105°C) to ensure durability in diverse climates.

Skipping Corrosion Protection

Even with a good IP rating, internal corrosion can occur over time if connectors lack proper plating (e.g., gold or nickel-plated contacts). Moisture trapped inside a connector will corrode copper terminals, increasing resistance and causing overheating. Sealed grommets, dielectric grease, and corrosion-resistant metals are essential features to look for in high-quality trailer wiring.

By avoiding these pitfalls and focusing on verified IP ratings, material quality, and proper electrical specs, you can source a durable and safe 4-wire trailer wiring solution that performs reliably in real-world conditions.

Logistics & Compliance Guide for 4-Wire Trailer Wiring

Overview

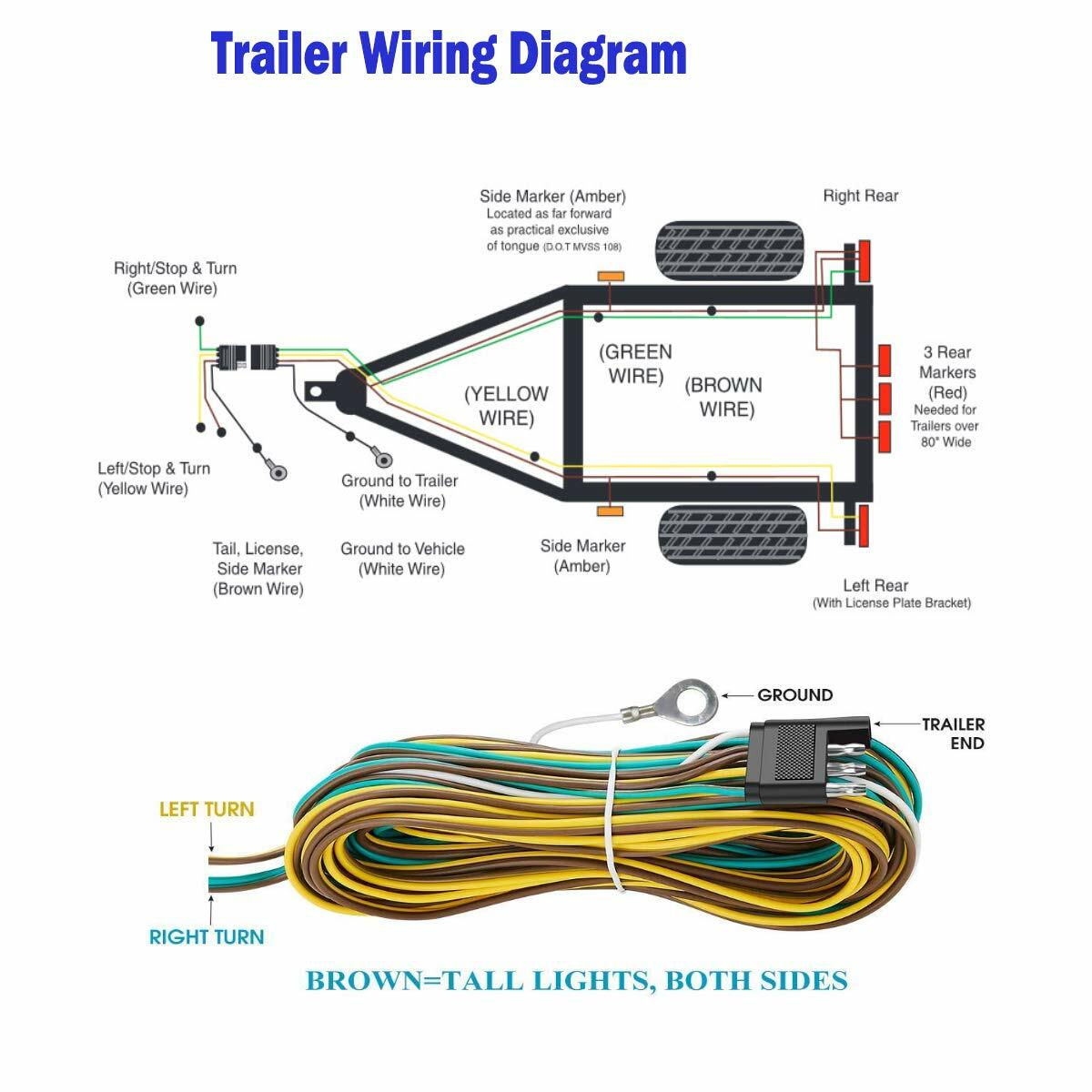

4-wire trailer wiring is a standard electrical connection used to link towing vehicles to trailers, enabling critical lighting functions such as brake lights, turn signals, and tail lights. Ensuring proper logistics and compliance during distribution, installation, and use is essential for safety, regulatory adherence, and operational efficiency. This guide outlines key considerations for logistics and compliance related to 4-wire trailer wiring systems.

1. Regulatory Compliance Standards

DOT and FMVSS (United States)

- The U.S. Department of Transportation (DOT) and Federal Motor Vehicle Safety Standards (FMVSS) require all trailers over 3,000 lbs GVWR to have functional lighting systems connected via standardized wiring.

- FMVSS Standard No. 108 specifies performance requirements for lamps, reflective devices, and associated equipment, including trailer wiring systems.

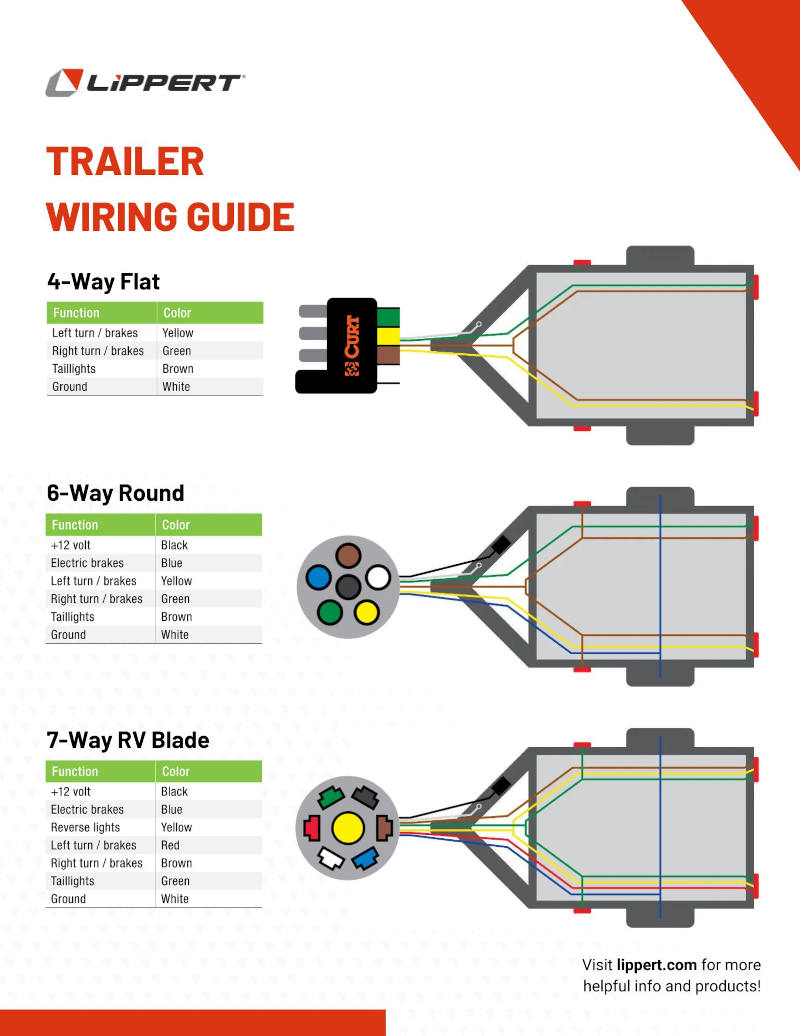

- 4-wire connectors must support:

- Tail Lights (Brown)

- Left Turn/Brake (Yellow)

- Right Turn/Brake (Green)

- Ground (White)

Canadian Regulations (CMVSS)

- Canada follows CMVSS 108, which aligns closely with FMVSS 108.

- Compliance with SAE J560 (for connectors) and CSA C22.2 No. 227.1 (cable standards) is required.

- All 4-wire trailer wiring sold or shipped into Canada must meet these standards.

International Standards (ISO & ECE)

- ISO 1724 defines the 4-pin flat trailer connector used globally.

- ECE Regulation 48 (Europe) mandates uniform provisions for the approval of vehicles regarding installation of lighting and light-signaling devices.

- Exporting 4-wire systems to the EU requires CE marking and conformity with relevant directives.

2. Logistics Handling & Storage

Packaging Requirements

- Wiring harnesses must be coiled and secured to prevent tangling or conductor damage.

- Use moisture-resistant, anti-static packaging to protect against humidity and static discharge.

- Label packages clearly with:

- Product specifications (gauge, length, connector type)

- Compliance marks (DOT, SAE, CE)

- Date of manufacture and batch number

Temperature & Environmental Controls

- Store in dry, temperature-controlled environments (10°C to 30°C / 50°F to 86°F).

- Avoid prolonged exposure to UV light, which can degrade PVC insulation.

- Prevent exposure to oil, gasoline, or solvents that may compromise wire jacketing.

Inventory & Traceability

- Implement a barcode or RFID tracking system for batch-level traceability.

- Maintain records of supplier certifications, material test reports (MTRs), and compliance documentation.

- Use FIFO (First In, First Out) inventory rotation to prevent aging of stock.

3. Transportation & Distribution

Domestic Shipping (U.S. & Canada)

- Comply with FMCSA and Transport Canada regulations for hazardous materials (no hazardous classification for standard 4-wire systems).

- Secure loads to prevent crushing or abrasion during transit.

- Use pallets or containers to minimize movement in trailers.

International Shipping

- Declare goods with correct HS codes:

- 8544.42.00 – Insulated wire, for vehicle use

- Provide certification documentation (e.g., Certificate of Conformity, SAE J560 test report).

- Ensure compatibility with destination country’s electrical standards (e.g., voltage, plug type).

4. Installation & Field Compliance

Proper Wiring Practices

- Use wires rated for at least 16 AWG (commonly 14–16 AWG for 4-wire systems).

- Ensure secure grounding (white wire) directly to clean, unpainted metal on the trailer frame.

- Seal all connections with heat-shrink tubing or waterproof butt connectors to prevent corrosion.

Testing & Verification

- Conduct continuity and insulation resistance tests post-installation.

- Verify all functions:

- Tail lights

- Brake lights

- Left and right turn signals

- Use circuit testers designed for 4-pin connectors.

Documentation & Records

- Provide end users with installation manuals and compliance statements.

- Maintain service logs for commercial fleets and rental operations.

5. Safety & Liability Considerations

Product Liability

- Ensure all 4-wire wiring products are compliant with SAE J560, ISO 1724, and local regulations.

- Retain third-party test reports from accredited labs (e.g., UL, TÜV).

Recalls & Non-Conformance

- Establish a recall protocol in case of defective batches.

- Monitor field performance and respond promptly to failure reports.

6. Environmental & Disposal Compliance

RoHS & REACH (Europe)

- Ensure wiring materials are free from restricted substances (e.g., lead, cadmium).

- Provide SVHC (Substances of Very High Concern) declarations if requested.

End-of-Life Management

- Wire harnesses should be recycled through certified e-waste programs.

- Avoid landfill disposal due to copper and PVC content.

Conclusion

Proper logistics and compliance management for 4-wire trailer wiring ensures safety, legal adherence, and customer satisfaction. Distributors, installers, and manufacturers must follow established standards throughout the supply chain—from production and packaging to installation and disposal. Regular audits, training, and documentation are critical to maintaining compliance across regions.

In conclusion, sourcing a 4-wire trailer wiring harness is a practical and essential step for ensuring safe and reliable electrical connectivity between your vehicle and trailer. It enables proper functioning of critical lighting systems such as brake lights, turn signals, running lights, and license plate illumination. When selecting a 4-wire harness, compatibility with both your vehicle and trailer is crucial—pay attention to connector types, wire gauge, and durability. Opting for weather-resistant, corrosion-proof components enhances longevity and performance, especially in harsh conditions. Whether purchasing from an auto parts store, online retailer, or dealership, choosing a quality harness from a reputable brand ensures compliance with safety standards and reduces the risk of electrical failures on the road. Proper installation and routine maintenance will further contribute to the reliability and safety of your towing setup.