The global traffic cone market is experiencing steady expansion, driven by rising urbanization, infrastructure development, and increased focus on road safety. According to Mordor Intelligence, the traffic cone market was valued at approximately USD 670 million in 2023 and is projected to grow at a CAGR of 4.8% from 2024 to 2029. This growth is fueled by surging investments in transportation infrastructure, stricter road safety regulations, and the need for effective temporary traffic management solutions across construction and maintenance zones. As demand escalates, manufacturers are scaling production and innovating in materials and design to meet diverse regulatory and operational requirements. In this evolving landscape, nine leading manufacturers have emerged as key players, offering a broad range of traffic cone sizes— from 12-inch markers for indoor use to 48-inch high-visibility cones for highways—ensuring compliance and safety in dynamic environments worldwide.

Top 9 Traffic Cone Sizes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 to JBC Safety Plastic

Domain Est. 2017

Website: jbcsafetyplastic.com

Key Highlights: JBC Safety Plastic, Inc. is a leading manufacturer of premium traffic control and highway safety products. Over the past 20 years, JBC™ has created world ……

#2 Traffic Cones

Domain Est. 1998

Website: lakesideplastics.net

Key Highlights: MULTIPLE SIZES. Choose from 7 sizes – 2″, 5″, 6″, 12″, 18″, 28 … Lakeside Plastics is a leading manufacturer of high quality, durable construction cones….

#3 Traffic Cones

Domain Est. 1993

Website: spi.com

Key Highlights: 30-day returnsEnsure your safety on the road with our durable and flexible orange PVC traffic cones. Their base provides exceptional stability and can withstand any weather ……

#4 Traffic Cones (TC)

Domain Est. 1998

Website: vestil.com

Key Highlights: These durable all weather cones are constructed from 100% PVC for long life. Their construction prohibits fading, cracking. Will retain its shape for years ……

#5 JSP

Domain Est. 2003

Website: jspsafety.com

Key Highlights: Manufactured in Oxfordshire England for quick deployment nationwide. Varying sizes are available from 50cm to 1m in height. Add company branding for theft…

#6 Types of Traffic Cones

Domain Est. 2010

Website: trafficsafetywarehouse.com

Key Highlights: Cones range in size as well and come in sizes from 12 inches to 36 inches in height. The size of the cone needed can be determined by the function or placement ……

#7 Florida DOT Approved 36″ Orange Traffic Cone, 12 lb w/6″&4″ 3M …

Domain Est. 2010

Website: trafficconesforless.com

Key Highlights: Rating 5.0 (38) · 6-day deliveryFlorida DOT Approved 36″ Orange Traffic Cone, 12 lb w/ 6″ & 4″ 3M Reflective Collar – Traffic Cones For Less….

#8 Wholesale Traffic Safety Cones

Domain Est. 2011

Website: vipcrowdcontrol.com

Key Highlights: Specification, Traffic Cone ; Size/Height, 12″, 18″ ; Weight, 1.5 lbs, 3 lbs ; Base Height, 1″, 1.25″ ; Base Size, 8.75″ X 8.75″, 10.5″ X 10.5″ ……

#9 Traffic cone price 2026

Domain Est. 2018

Website: mwmgulddalsystems.com

Key Highlights: In this article, we will explain the specifications of standard road cones, where to find plastic cones for sale, and their prices. How do you ……

Expert Sourcing Insights for Traffic Cone Sizes

2026 Market Trends for Traffic Cone Sizes

The global traffic cone market in 2026 is poised for transformation, driven by urbanization, road safety regulations, smart infrastructure development, and sustainability demands. While core product functionality remains essential, size selection is increasingly influenced by evolving infrastructure needs, automation, and regional safety standards. Below is an analysis of key trends shaping the demand and innovation across different traffic cone sizes.

Growth in Demand for Compact Cones (7”–18”)

Smaller traffic cones (7”, 12”, and 18”) are experiencing rising demand, particularly in urban environments and temporary work zones. The 2026 market sees increased adoption of compact cones due to their portability and suitability for indoor and pedestrian-heavy areas. Smart cities are integrating these sizes into automated parking systems, pedestrian guidance zones, and micro-mobility infrastructure (e.g., e-scooter lanes). Furthermore, the growth of indoor construction and warehouse logistics favors lightweight, stackable 12” and 18” cones, especially those made from recycled or biodegradable materials to meet corporate ESG goals.

Dominance and Innovation in Standard Cones (28”–36”)

The 28” and 36” traffic cones continue to dominate the market in 2026, serving as the standard for road construction, lane closures, and highway maintenance. Regulatory frameworks in North America and Europe now mandate enhanced visibility and durability, prompting manufacturers to incorporate advanced reflective collars, UV-resistant additives, and modular designs. A notable trend is the integration of IoT-enabled sensors into 36” cones, allowing real-time monitoring of work zone activity, placement verification, and even vehicle proximity alerts. These “smart cones” are gaining traction in government infrastructure projects aiming to improve worker safety and traffic flow.

Niche Expansion of Oversized Cones (48” and Above)

Oversized cones (48” and 50”) remain a niche segment but are seeing strategic growth in high-speed corridors, airport tarmacs, and rail crossings where superior visibility is critical. In 2026, these larger cones are being redesigned with aerodynamic profiles to reduce wind resistance and improve stability. Some municipalities are adopting 48” cones with integrated solar-powered LED lighting to enhance nighttime visibility without relying on external power sources. Their use in temporary event management (e.g., concerts, marathons) is also increasing, supported by quick-deployment mounting systems.

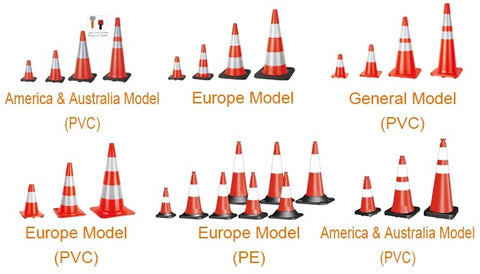

Regional Variations and Standardization Pressures

Regional preferences continue to affect size demand. North America and Europe favor 28”–36” cones due to MUTCD and ECE R104 compliance, respectively. In contrast, Asian markets, particularly India and Southeast Asia, are seeing a shift toward 18”–28” cones due to denser urban layouts and lower-speed zones. However, 2026 brings stronger harmonization efforts through international safety standards, encouraging manufacturers to offer modular cone systems that allow height adjustment—enabling one base to support multiple sleeve sizes and reducing inventory complexity.

Sustainability Driving Material and Design Changes Across Sizes

Environmental regulations are influencing all traffic cone sizes. By 2026, major suppliers are phasing out virgin PVC in favor of recycled rubber, TPE (thermoplastic elastomers), and bio-based plastics. This shift affects durability and weight, particularly in taller cones where structural integrity is paramount. Lightweight, collapsible designs are emerging across sizes to reduce transport emissions and storage space—especially beneficial for 36”+ cones used in large-scale projects.

Conclusion

In 2026, traffic cone size trends reflect a convergence of safety innovation, urban planning, and environmental responsibility. While standard 28”–36” cones remain the market backbone, compact and smart-enabled sizes are growing rapidly, and oversized cones are finding specialized roles. The future lies in adaptable, intelligent, and sustainable designs that meet both regulatory demands and the dynamic needs of modern infrastructure.

Common Pitfalls When Sourcing Traffic Cone Sizes (Quality, IP)

Sourcing traffic cones involves more than just selecting a size—quality, durability, and compliance with safety standards (including Ingress Protection or IP ratings where applicable) are critical. However, many buyers encounter common pitfalls that can compromise safety, performance, and cost-efficiency. Here are the key issues to watch out for:

1. Prioritizing Price Over Quality

One of the most frequent mistakes is choosing the cheapest traffic cones available. Low-cost cones are often made from inferior PVC or recycled materials, which degrade quickly under UV exposure, extreme temperatures, or physical impact. This leads to frequent replacements and higher long-term costs.

- Solution: Look for high-quality, UV-stabilized PVC or polyethylene materials, even if the initial cost is higher. Invest in durability for better ROI.

2. Ignoring Size and Visibility Standards

Traffic cones come in various sizes (e.g., 18″, 28″, 36″, 48″), each suited for different applications. Using undersized cones in high-speed zones or oversized cones in pedestrian areas reduces effectiveness.

- Pitfall: Selecting a size based on convenience rather than application.

- Solution: Match cone height and reflectivity to the environment—taller cones (28″–48″) for highways, smaller (18″) for sidewalks or indoor use.

3. Overlooking Reflective Stripping and Visibility Features

Poor visibility at night or in low-light conditions is a major safety hazard. Some cones lack adequate reflective bands or use low-grade reflective materials that fade quickly.

- Pitfall: Assuming all reflective strips meet regulatory standards.

- Solution: Ensure cones have high-intensity, prismatic reflective bands compliant with local DOT or EN standards (e.g., EN 13422 in Europe).

4. Misunderstanding IP (Ingress Protection) Ratings

While not always applicable to standard traffic cones, IP ratings become relevant for smart traffic cones with embedded electronics (e.g., LED lights, sensors, wireless modules).

- Pitfall: Assuming all “weather-resistant” cones have proper IP ratings.

- Solution: For smart cones, verify IP65 or higher for dust and water resistance to ensure reliability in outdoor conditions.

5. Failing to Check Compliance with Local Regulations

Traffic cones must meet regional safety standards (e.g., MUTCD in the U.S., EN 13422 in the EU). Non-compliant cones may not be legally usable on public roads.

- Pitfall: Importing cones from overseas without verifying local certification.

- Solution: Confirm that cones meet required standards and are tested by accredited labs.

6. Inconsistent Weight and Stability

Lightweight cones may tip over easily in windy conditions, especially on highways. Some suppliers cut corners by reducing base weight or using flimsy designs.

- Pitfall: Not testing stability under real-world conditions.

- Solution: Choose cones with weighted bases or options to add water/sand for improved stability.

7. Poor Supplier Verification

Working with unreliable suppliers can lead to inconsistent quality, delayed deliveries, or counterfeit products.

- Pitfall: Selecting suppliers based solely on online listings or catalogs.

- Solution: Request samples, check certifications, and verify track record through reviews or references.

8. Neglecting Environmental and Recyclability Factors

Some low-quality cones contain harmful additives or aren’t recyclable, leading to environmental and disposal issues.

- Pitfall: Not considering end-of-life impact.

- Solution: Opt for recyclable materials and suppliers with eco-conscious practices.

By avoiding these common pitfalls, organizations can source traffic cones that are safe, compliant, durable, and cost-effective—ensuring optimal performance across diverse traffic management scenarios.

Logistics & Compliance Guide for Traffic Cone Sizes

Understanding traffic cone sizes is essential for ensuring safety, regulatory compliance, and efficient logistics in transportation, construction, and event management. This guide outlines standard sizes, applicable regulations, transportation considerations, and storage best practices.

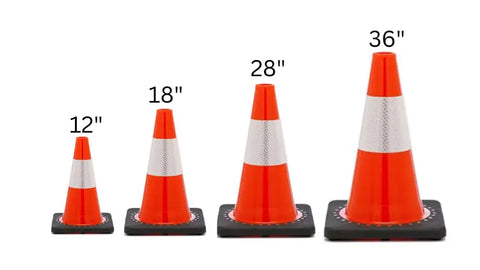

Standard Traffic Cone Sizes

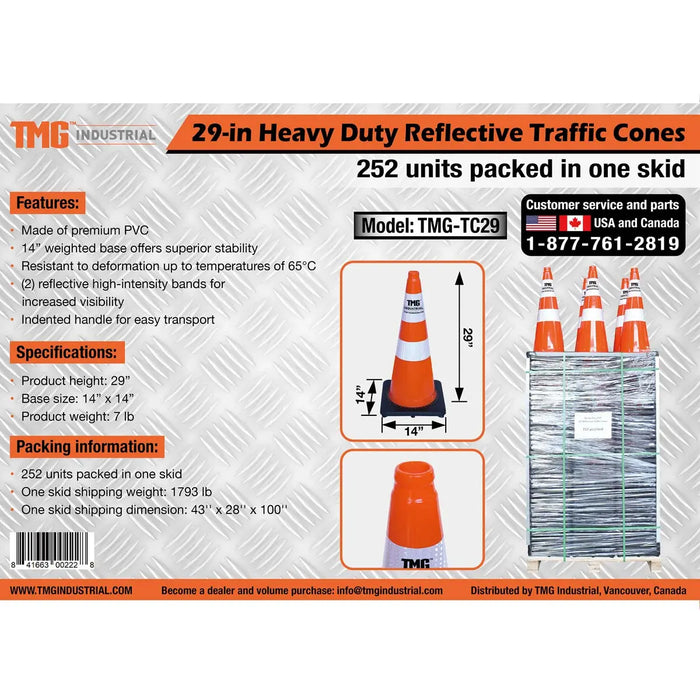

Traffic cones are manufactured in several standardized heights to meet different safety and visibility needs. The most common sizes include:

- 12-inch (30 cm): Used for indoor applications or low-speed areas. Ideal for temporary pedestrian guidance.

- 18-inch (45 cm): Suitable for parking lots and low-traffic zones. Provides moderate visibility.

- 28-inch (70 cm): Commonly used in road construction and lane closures. Offers high visibility for daytime and low-light conditions.

- 36-inch (90 cm): Used in high-speed zones and major roadway work. Meets most federal and state highway requirements.

- 48-inch (120 cm): Typically used for long-term work zones, detours, or areas requiring maximum visibility.

Regulatory Compliance Standards

Traffic cones must comply with local and national regulatory standards to ensure visibility, durability, and safety. Key standards include:

- MUTCD (Manual on Uniform Traffic Control Devices) – USA: Requires cones to be fluorescent orange with retroreflective bands for nighttime visibility. Minimum height is typically 28 inches for roadway use.

- EN 13422 – Europe: Specifies performance requirements for road cones, including color, retroreflectivity, and stability.

- AS/NZS 1906.4 – Australia/New Zealand: Sets standards for materials, dimensions, and performance in various traffic environments.

Ensure purchased cones bear compliance certification marks and are used in accordance with local regulations.

Transportation and Handling

Proper handling and transportation prevent damage and maintain compliance:

- Stacking: Most cones are stackable. Use cone collars or dividers to prevent deformation during transit.

- Vehicle Compatibility: Choose transport containers or racks that secure cones upright. Avoid overloading to prevent crushing.

- Weather Protection: Cover cones during transport to protect from UV exposure, extreme temperatures, and moisture, which can degrade materials.

Storage Best Practices

Efficient storage prolongs cone life and ensures rapid deployment:

- Indoor Storage: Store in a cool, dry place away from direct sunlight to prevent fading and brittleness.

- Vertical Positioning: Keep cones standing upright or nested with supports to maintain shape.

- Inventory Management: Label bins by size and compliance type for quick identification and rotation (FIFO – First In, First Out).

Color and Reflectivity Requirements

Color and reflectivity are critical for compliance and visibility:

- Standard Color: Fluorescent orange is required in most jurisdictions for high visibility.

- Retroreflective Bands: Mandatory on cones used on public roads at night. Typically, one or two white reflective bands are required, depending on cone height and usage environment.

Selection by Application

Choose cone size based on the work environment:

- Low-speed areas (parking lots, sidewalks): 12” to 18”

- Urban roads and construction zones: 28” to 36”

- Highways and high-speed detours: 36” to 48” with reflective collars

Always verify local authority requirements before deployment.

Conclusion

Adhering to standardized traffic cone sizes and compliance guidelines enhances safety, ensures regulatory approval, and optimizes logistics operations. Regular inspection, proper transport, and correct storage are key to maintaining effective traffic control systems.

In conclusion, sourcing traffic cone sizes requires careful consideration of the specific application, regulatory requirements, visibility needs, and environmental conditions. Standard sizes typically range from 12 inches for indoor or low-speed areas to 36 inches or taller for high-speed roads and enhanced visibility. It is essential to select the appropriate height, weight, and durability (e.g., reflective strips, material type) to ensure safety, compliance with local transportation standards (such as MUTCD in the U.S.), and long-term cost-effectiveness. By evaluating these factors and working with reputable suppliers, organizations can source traffic cones that meet operational demands while maximizing safety and visibility in diverse traffic management scenarios.