The global fifth wheel coupling market is experiencing steady growth, driven by rising demand for heavy-duty commercial vehicles and expanding logistics networks. According to Mordor Intelligence, the Fifth Wheel Coupling Market was valued at USD 1.2 billion in 2023 and is projected to reach USD 1.65 billion by 2029, growing at a CAGR of approximately 5.3% during the forecast period. This growth is fueled by increased freight transportation activities, stricter safety regulations, and advancements in fifth wheel technology aimed at improving trailer stability and load efficiency. With North America and Europe leading in adoption due to well-established trucking industries, and Asia-Pacific witnessing rapid expansion due to industrialization and e-commerce growth, the competitive landscape among tractor trailer fifth wheel manufacturers is becoming increasingly innovation-driven. In this evolving market, identifying the top manufacturers—those delivering durability, compliance, and performance—is critical for fleet operators and OEMs alike.

Top 10 Tractor Trailer Fifth Wheel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 A True Four-Season Luxury Fifth Wheel

Domain Est. 2017

Website: luxefifthwheel.com

Key Highlights: Luxe is a leading manufacturer of luxury fifth wheel campers and fifth wheel toy haulers, built with the highest-quality materials and superior craftsmanship….

#2 Global Fontaine Fifth Wheel … fifthwheel.com

Domain Est. 1996

Website: fifthwheel.com

Key Highlights: Experience the No-Slack Fifth Wheel Advantage….

#3 SpaceCraft Mfg Custom Trailers

Domain Est. 1998

Website: spacecraftmfg.com

Key Highlights: Work with Space Craft to bring your CUSTOM dream trailer to life. Our knowledge and experience help guide you through your trailer’s entire design process….

#4 JOST International

Domain Est. 1999

Website: jostinternational.com

Key Highlights: JOST International is proud to be a world market leader and international supplier for the commercial trucking industry. As a pioneer for fifth wheel couplings ……

#5 PullRite

Domain Est. 1999

Website: pullrite.com

Key Highlights: PullRite, the leader in fifth wheel hitch innovation for 40 years, makes quality SAE J2638-tested 5th wheel, gooseneck, and sliding trailer hitches in the ……

#6 5th Wheels

Domain Est. 2003

Website: northwoodmfg.com

Key Highlights: Northwood Travel Trailers, 5th-Wheels and Campers and may differ slightly from actual production models. Interior colors may vary….

#7 Fifth Wheels

Domain Est. 2006

Website: safholland.com

Key Highlights: SAF-HOLLAND Fifth Wheels are offered in a full range of durable, long life performance models for hauling applications….

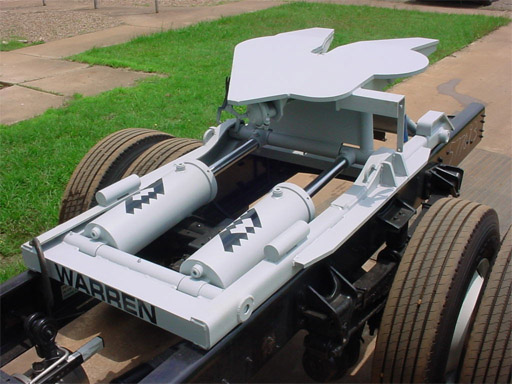

#8 Warren Hydraulic 5th Wheels: Page

Domain Est. 2007

Website: hydraulicfifthwheels.com

Key Highlights: Our upgraded fifth wheels are built to handle the toughest applications and exceed industry standards. We maintain a large inventory of completed fifth wheels ……

#9 Fontaine Fifth Wheel Europe

Domain Est. 2018

Website: fontainefifthwheel.com

Key Highlights: Specialists in truck & trailer coupling. Fit for the long haul, fit for safety, fit for reliability, fit for versatility, fit for efficiency, fit for economy….

#10 List of Fifth Wheel Manufacturers (5th Wheel Brands)

Domain Est. 2019

Website: airskirts.com

Key Highlights: Fifth Wheel Manufacturers ; Keystone RV Company, Travel Trailers, Fifth Wheels, Toy Haulers, Official Site ; K-Z RV, Travel Trailers, Fifth Wheels ……

Expert Sourcing Insights for Tractor Trailer Fifth Wheel

2026 Market Trends for Tractor Trailer Fifth Wheel

The tractor trailer fifth wheel market is poised for significant evolution by 2026, driven by technological innovation, regulatory shifts, and changing fleet demands. Key trends shaping the landscape include:

Advancements in Lightweight and Durable Materials

Manufacturers are increasingly adopting high-strength, low-alloy (HSLA) steels, aluminum alloys, and composite materials to reduce fifth wheel weight without compromising durability. This focus on lightweighting supports fuel efficiency and increases payload capacity—critical factors for cost-conscious fleets. By 2026, lightweight fifth wheels are expected to capture a larger market share, especially in long-haul and regional delivery applications where every pound saved translates into economic and environmental benefits.

Integration with Smart Trailer Technologies

The rise of connected and smart trailers is pushing fifth wheels to evolve beyond mechanical coupling. By 2026, expect greater integration with telematics systems for real-time monitoring of hitch status, load distribution, wear diagnostics, and maintenance alerts. Smart fifth wheels equipped with sensors will enhance safety by detecting improper coupling, excess lateral movement, or structural stress, feeding data directly into fleet management platforms to prevent breakdowns and improve operational efficiency.

Emphasis on Safety and Automation

As autonomous and semi-autonomous trucking technologies advance, fifth wheels must adapt to support automated coupling and uncoupling processes. By 2026, OEMs are likely to introduce standardized interfaces and alignment-assist features that facilitate seamless integration with automated trailer handling systems. Enhanced locking mechanisms, improved visibility designs, and fail-safe systems will also be prioritized to meet growing safety regulations and reduce driver risk during manual coupling operations.

Growth in Aftermarket and Retrofit Solutions

With rising demand for improved performance and compliance, the aftermarket for fifth wheels will expand significantly by 2026. Fleets will increasingly adopt retrofit kits that enhance durability, reduce maintenance, or add smart features to existing equipment. Modular designs and quick-swap platforms will gain traction, allowing operators to switch between different trailer types (e.g., dry van, flatbed, tanker) more efficiently and reduce downtime.

Sustainability and Circular Economy Practices

Environmental concerns are influencing manufacturing processes and end-of-life strategies. By 2026, leading fifth wheel producers will emphasize recyclable materials, energy-efficient production methods, and remanufacturing programs. Closed-loop recycling and refurbishment services will become more common, aligning with broader industry sustainability goals and reducing the total cost of ownership for fleets.

In summary, the 2026 fifth wheel market will be defined by innovation in materials, connectivity, automation, and sustainability—transforming a traditionally mechanical component into a smarter, safer, and more efficient part of the modern freight ecosystem.

Common Pitfalls Sourcing Tractor Trailer Fifth Wheels: Quality and Intellectual Property Risks

Sourcing tractor trailer fifth wheels—critical components that connect trailers to tractors—requires careful due diligence to avoid significant operational, safety, and legal risks. Two major areas of concern are quality inconsistencies and intellectual property (IP) violations, both of which can lead to costly recalls, liability claims, and reputational damage.

Quality-Related Pitfalls

Sourcing low-cost fifth wheels without verifying manufacturing standards can compromise safety and durability. Common quality pitfalls include:

- Inferior Materials and Workmanship: Some suppliers use substandard steel or poor welding techniques, leading to premature wear, cracking, or catastrophic failure under load.

- Lack of Certification and Testing: Reputable fifth wheels meet rigorous standards (e.g., SAE J71, ISO 5210). Sourcing from non-certified manufacturers risks non-compliance and reduced performance in real-world conditions.

- Inconsistent Tolerances and Fitment: Poor manufacturing control results in misaligned kingpin engagement, causing difficult coupling, excessive wear, or disengagement during transit.

- Inadequate Corrosion Protection: Exposure to road salts and weather demands robust coatings. Low-quality finishes lead to rust, jamming, and shortened service life.

- Insufficient Load Testing and Validation: Suppliers may not conduct real-world load cycle tests, risking failure under dynamic conditions such as heavy braking or rough terrain.

To mitigate these risks, buyers should insist on third-party inspection reports, factory audits, and sample testing under load conditions before placing bulk orders.

Intellectual Property (IP) Risks

The fifth wheel market includes several patented designs and proprietary technologies. Sourcing from unauthorized manufacturers can expose buyers to serious IP infringement issues:

- Counterfeit or Clone Products: Some suppliers replicate patented designs (e.g., specific locking mechanisms or pivot systems) without licensing, selling them under generic branding.

- Use of Protected Trademarks and Logos: Imitation fifth wheels may bear logos resembling those of established brands (e.g., Jost, Jost Rutter, Holland), misleading customers and inviting legal action.

- Design and Utility Patent Infringement: Even subtle design elements—such as jaw configuration or greaseless bushing systems—may be protected, and unauthorized replication constitutes infringement.

- Supply Chain Liability: Buyers may be held liable for importing or distributing infringing goods, even if unaware of the violation, leading to seizures, fines, or lawsuits.

To avoid IP pitfalls, conduct thorough due diligence on supplier legitimacy, request IP indemnification clauses in contracts, and verify that designs do not closely mimic patented features of major OEMs. Engaging legal counsel to perform freedom-to-operate analyses can further reduce risk.

In conclusion, sourcing fifth wheels demands a balance of cost-efficiency and rigorous quality and legal oversight. Prioritizing certified, reputable suppliers with transparent manufacturing and IP compliance is essential for safety, reliability, and legal protection.

Logistics & Compliance Guide for Tractor Trailer Fifth Wheels

Understanding the logistics and compliance requirements for tractor trailer fifth wheels is essential for safe, efficient, and legal operations in the freight transportation industry. The fifth wheel is a critical coupling device that connects the tractor (truck) to the semi-trailer and plays a key role in vehicle stability, load distribution, and overall safety. This guide outlines key considerations for logistics planning and regulatory compliance.

Understanding the Fifth Wheel System

The fifth wheel is a horseshoe-shaped coupling mounted on the chassis of the tractor. It connects with the trailer’s kingpin to form a secure pivot point. Key components include the locking jaws, release lever, grease plate, and height adjustment mechanisms. Proper operation and maintenance of the fifth wheel are vital for preventing trailer separation, ensuring even weight distribution, and maintaining control during transit.

Weight Distribution and Load Compliance

Correct weight distribution across the tractor-trailer combination is crucial for safety and legal compliance. The fifth wheel position can be adjusted fore and aft on the tractor to manage weight on the drive axles and steer axle.

- The fifth wheel position affects how much weight is transferred to the tractor’s drive axles vs. the trailer tandems.

- Federal and state regulations govern gross vehicle weight (GVW), axle weight limits, and bridge formulas.

- Carriers must ensure that the loaded combination does not exceed:

- 80,000 lbs gross weight on interstate highways (federally regulated).

- Individual axle limits: 12,000 lbs (steer), 34,000 lbs (drive tandem), 34,000 lbs (trailer tandem).

- Use certified scales to verify weights before departure.

Height and Clearance Standards

- The fifth wheel height must be compatible with the trailer’s kingpin and landing gear to ensure a level ride.

- A misaligned fifth wheel can cause trailer sag or tilt, leading to poor weight distribution, steering issues, and increased wear.

- Industry standard height from the ground to the top of the fifth wheel is typically 48 to 52 inches.

- Ensure sufficient ground clearance, especially when turning or driving over uneven terrain.

Inspection and Maintenance Requirements

Regular inspection and maintenance of the fifth wheel are required under the Federal Motor Carrier Safety Administration (FMCSA) regulations.

Key inspection points include:

– Locking Jaws: Must close securely around the kingpin with no excessive wear or damage.

– Greasing: The fifth wheel plate and kingpin must be properly lubricated to reduce friction and wear.

– Wear Indicators: Check for excessive wear on jaw faces, pivot pins, and the skid plate.

– Release Mechanism: Ensure the locking handle operates smoothly and clearly indicates locked/unlocked status.

– Mounting Bolts: Inspect for tightness and signs of fatigue or cracking.

FMCSA mandates that all commercial motor vehicles undergo a post-trip inspection, with any defects documented and repaired before the next use.

Safety Protocols During Coupling and Uncoupling

Improper coupling is a leading cause of accidents involving fifth wheels. Follow these safety protocols:

- Positioning: Back the tractor under the trailer slowly, ensuring the fifth wheel is centered under the kingpin.

- Alignment: Confirm the fifth wheel jaws are open and the release lever is in the unlocked position.

- Engagement: Raise the trailer landing gear slightly after coupling to ensure the kingpin is fully seated.

- Verification: Perform a “tug test” — gently pull forward to confirm the locking jaws have securely engaged the kingpin.

- Safety Check: Always chock the trailer wheels before uncoupling and lower the landing gear fully before disconnecting.

Regulatory Compliance (FMCSA & State Requirements)

Carriers and drivers must comply with FMCSA regulations, including:

- 49 CFR Part 393.70: Specifies requirements for fifth wheel assemblies, including strength, locking mechanisms, and maintenance.

- Annual Inspections: All commercial vehicles must pass an annual inspection; fifth wheel condition is a key component.

- Driver Responsibility: Drivers are required to perform pre-trip and post-trip vehicle inspections (DVIRs) and report defects.

- Documentation: Maintenance records for fifth wheel repairs or replacements must be retained for at least 1 year.

Training and Driver Certification

Proper training for drivers and maintenance personnel is essential:

- Drivers must understand how to safely couple/uncouple, perform inspections, and adjust fifth wheel position when needed.

- Training should include:

- Recognizing signs of wear or damage.

- Correct greasing procedures.

- Compliance with weight and safety regulations.

- Employers should maintain training records to demonstrate compliance.

Technological Advancements and Best Practices

Modern fifth wheels may include:

- Sliding fifth wheels: Allow for on-the-go adjustment of weight distribution.

- Lubrication-free models: Use self-lubricating materials to reduce maintenance.

- Sensors and monitoring systems: Some fleets use telematics to monitor coupling status and wear.

Best practices:

– Standardize fifth wheel maintenance schedules.

– Use only manufacturer-approved replacement parts.

– Conduct periodic audits of coupling procedures and equipment condition.

Conclusion

The fifth wheel is a critical component in the safe and compliant operation of tractor-trailer combinations. Adhering to weight regulations, performing regular inspections, following proper coupling procedures, and ensuring driver training are essential to logistics efficiency and regulatory compliance. By maintaining fifth wheel systems to the highest standards, fleets can enhance safety, reduce downtime, and avoid costly violations.

Conclusion:

After a thorough evaluation of the market, specifications, and supplier options, sourcing a tractor trailer fifth wheel requires a strategic approach focused on quality, compatibility, durability, and total cost of ownership. It is crucial to select a fifth wheel that meets industry standards (such as those set by the Society of Automotive Engineers – SAE) and is compatible with both the tractor and trailer configurations in use.

Key considerations include load capacity, ease of maintenance, safety features (e.g., double locking jaws, self-lubricating components), and resistance to wear in demanding operating conditions. Sourcing from reputable manufacturers with proven track records ensures reliability and long-term performance, while supplier support, warranty terms, and after-sales service further enhance value.

In conclusion, a well-informed sourcing decision—based on technical requirements, supplier credibility, and lifecycle costs—will contribute to improved safety, operational efficiency, and reduced downtime in over-the-road hauling operations. Prioritizing these factors ensures that the selected fifth wheel supports the overall reliability and productivity of the transportation fleet.