The global demand for durable, flexible, and high-performance footwear continues to drive innovation in outsole materials, with thermoplastic rubber (TPR) emerging as a preferred choice across athletic, industrial, and casual footwear segments. According to a 2023 report by Grand View Research, the global TPR market was valued at USD 23.6 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by increasing production in the footwear and automotive industries. This growth is further supported by rising consumer preference for lightweight, slip-resistant, and environmentally adaptable soles. As brands prioritize performance and sustainability, manufacturers capable of delivering consistent quality, scalability, and material innovation are gaining strategic importance. Below is a data-informed review of the top nine TPR outsole manufacturers shaping the future of footwear performance and manufacturing efficiency.

Top 9 Tpr Outsole Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

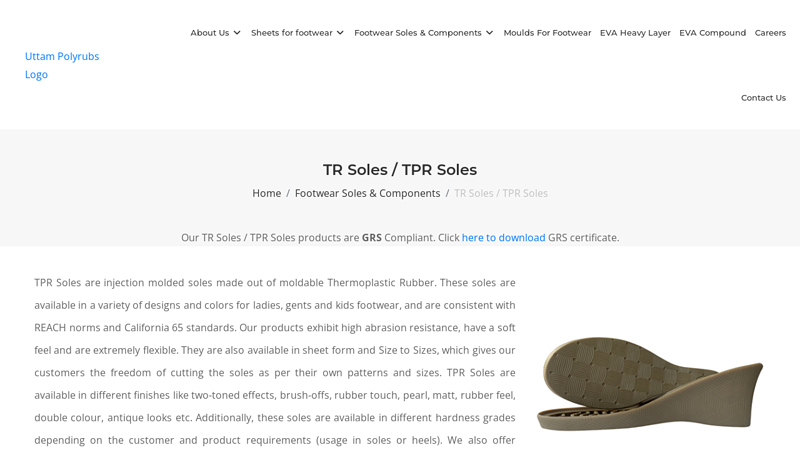

#1 TPR Sole Manufacturers In India

Domain Est. 2006

Website: uttampolyrubs.com

Key Highlights: Rating 5.0 (1,353) TPR Soles are injection molded soles made out of moldable Thermoplastic Rubber. These soles are available in a variety of designs and colors for ladies, gents …

#2 Capstan Rubber India

Domain Est. 2017

Website: capstanrubber.com

Key Highlights: Capstan Rubber India is a leading manufacturer, exporter and supplier of superior quality footwear soles. From prototyping to finished products, we provide ……

#3 What is Thermoplastic Rubber (TPR)?

Domain Est. 1995

Website: ansell.com

Key Highlights: Thermoplastic Rubber a strong rubber-like elastic material that is used in many different products. TPR is what provides impact-resistance to gloves….

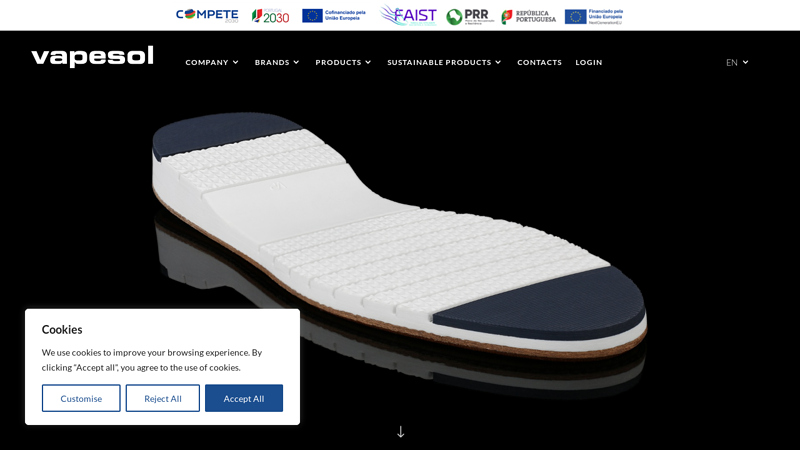

#4 TPR SOLES

Domain Est. 2004

Website: vapesol.com

Key Highlights: TPR has excellent durability and abrasion resistance characteristics. With densities that can vary between 0.60 – 1 g/cm3 and abrasions between 60 and 200 mm3….

#5 Leather, Dainite, Rubber, TPR Shoe Soles

Domain Est. 2019

Website: poyter.com

Key Highlights: Explore Poyter’s range of leather, Dainite, rubber, and TPR soles. Each option offers distinctive comfort, durability, and style to complement your bespoke ……

#6 TPR Shoe Sole

Domain Est. 2019

Website: alertindiapvtltd.com

Key Highlights: It is basically is a heft metal that is utilized as an agent for leather tanning process. These soles are used for making shoes for men, women, and children….

#7 Sole TPR Thermoplastic Rubber Material

Domain Est. 2020

Website: chpolymer.com

Key Highlights: It is a non-toxic, environmentally friendly material, does not contain halogen, nonylphenol, phthalate 16P, PAHS, and meets ROHS, REACH, EN71 ecological test ……

#8 TPR Sole

Domain Est. 2023

Website: maksonsoles.com

Key Highlights: TPR is a fully recyclable material produced through thermal injection molding. It finds extensive use in crafting diverse footwear soles….

#9 EVA + TPR Soles

Domain Est. 2024

Website: flexforcefootwear.com

Key Highlights: Flexforce produces TPR+EVA soles that are both durable and technologically advanced, ensuring long-lasting performance and superior comfort for everyday wear….

Expert Sourcing Insights for Tpr Outsole

2026 Market Trends for TPR Outsoles: A H2 Outlook

As we move through 2024 and look toward the H2 2026 market landscape, Thermoplastic Rubber (TPR) outsoles are poised at a critical juncture, shaped by evolving consumer demands, technological advancements, and sustainability imperatives. Here’s a detailed analysis of the key trends expected to define the TPR outsole market in the latter half of 2026:

1. Sustainability as a Core Driver

By H2 2026, sustainability will no longer be a differentiator but a baseline requirement. TPR manufacturers and footwear brands will face intensified pressure to:

– Increase Recycled Content: Adoption of post-industrial and post-consumer recycled TPR will accelerate, driven by brand ESG commitments and regulations (e.g., EU Green Deal). Expect 20–30% recycled content in mainstream TPR formulations.

– Enhance Recyclability: Closed-loop recycling systems for TPR soles will gain traction, with innovations in mono-material designs that simplify end-of-life processing.

– Reduce Carbon Footprint: Energy-efficient compounding processes and bio-based TPR alternatives (e.g., bio-TPR from renewable feedstocks) will enter commercial scale, appealing to eco-conscious consumers.

2. Performance-Driven Innovation

TPR will continue to compete with EVA, PU, and rubber by enhancing performance characteristics:

– Lightweighting: R&D will focus on high-strength, low-density TPR compounds to meet demand for comfort in athletic and casual footwear.

– Improved Durability & Abrasion Resistance: Advanced polymer blends will extend outsole lifespan, particularly for workwear and outdoor footwear.

– Enhanced Grip & Flexibility: Custom formulations for wet/dry traction and multi-directional flexibility will be critical, especially in safety and outdoor markets.

3. Regional Market Shifts

- Asia-Pacific Dominance: China, India, and Southeast Asia will remain the largest producers and consumers of TPR outsoles due to robust footwear manufacturing and rising domestic demand.

- Nearshoring in Americas & Europe: To reduce supply chain risks and meet sustainability goals, brands may increase regional production using local TPR suppliers, especially in Mexico and Eastern Europe.

4. Cost-Effectiveness in Competitive Markets

Despite sustainability trends, TPR’s cost advantage over PU and rubber will sustain its position in mid-tier and budget footwear segments. In H2 2026:

– Price Stability: Volatility in oil prices will impact TPR costs, but recycling and efficient production will help moderate increases.

– Value Engineering: Brands will demand TPR solutions that balance performance, aesthetics, and cost—driving innovation in compounding and processing.

5. Design & Aesthetic Flexibility

TPR’s moldability and color versatility will support growing demand for customized and fashion-forward designs:

– Complex Geometries: Advancements in injection molding will allow intricate tread patterns and textures.

– Color & Finish Options: Matte, translucent, and metallic TPR finishes will gain popularity in fashion and lifestyle footwear.

6. Regulatory & Compliance Pressures

Stricter chemical regulations (e.g., REACH, California Prop 65) will push suppliers to:

– Eliminate hazardous plasticizers and additives.

– Provide full material disclosure and lifecycle assessments (LCAs).

– Achieve third-party certifications (e.g., OEKO-TEX, Bluesign).

7. Integration with Smart Footwear

While still emerging, TPR outsoles may begin integrating with smart footwear systems by 2026:

– Embedding sensors for gait analysis or impact monitoring.

– Using conductive TPR for data transmission or energy harvesting (long-term prospect).

Conclusion

By H2 2026, the TPR outsole market will be characterized by a dual focus: sustainability transformation and performance optimization. While facing competition from bio-based alternatives and advanced materials, TPR’s versatility, cost-efficiency, and recyclability will secure its role—especially in mid-market and high-volume footwear. Success will depend on suppliers’ ability to innovate sustainably, comply globally, and deliver value across diverse applications—from athletic shoes to industrial safety gear.

Common Pitfalls Sourcing TPR Outsoles: Quality and Intellectual Property (IP) Risks

Sourcing TPR (Thermoplastic Rubber) outsoles from suppliers, especially in competitive manufacturing regions, presents several recurring challenges related to quality control and intellectual property protection. Being aware of these pitfalls is crucial for maintaining product integrity, brand reputation, and legal compliance.

Quality-Related Pitfalls

Inconsistent Material Composition and Formulation

Suppliers may alter TPR formulations to cut costs, substituting cheaper or lower-grade raw materials. This can lead to significant batch-to-batch variations in hardness, flexibility, durability, and resistance to weathering or abrasion. Without strict material specifications and third-party verification, brands risk receiving outsoles that fail performance standards or degrade prematurely.

Poor Manufacturing Processes and Tooling Quality

Low-cost suppliers might use outdated or poorly maintained molds, leading to dimensional inaccuracies, flash (excess material), or surface defects. Inadequate injection molding parameters—such as temperature, pressure, and cooling time—can result in internal stress, warping, or weak structural integrity, increasing the risk of sole delamination or breakage.

Insufficient Quality Control and Testing Procedures

Many suppliers lack rigorous in-house testing capabilities or skip critical performance tests (e.g., flex resistance, slip resistance, compression set). Relying solely on supplier self-certification without independent laboratory validation can result in undetected quality issues that surface only after mass production or during consumer use.

Misrepresentation of Material Grades and Certifications

Suppliers may falsely claim that TPR material meets certain standards (e.g., RoHS, REACH, phthalate-free) without proper documentation or third-party certification. This not only risks non-compliance with regulatory requirements but also exposes brands to potential recalls or reputational damage.

Intellectual Property (IP)-Related Pitfalls

Unauthorized Use of Design Tooling and Mold Duplication

Once a supplier possesses the mold for your TPR outsole design, there’s a risk they will produce identical or similar soles for competing brands—either openly or covertly. Without strong contractual protections and physical control over tooling, your unique design can be easily replicated, eroding your competitive edge.

Lack of IP Ownership Clauses in Contracts

Many sourcing agreements fail to explicitly assign ownership of design molds, CAD files, and product specifications to the buyer. This legal ambiguity allows suppliers to claim partial rights or use the design for other clients, especially in jurisdictions with weak IP enforcement.

Reverse Engineering and Design Leakage

Even without direct mold duplication, suppliers may reverse-engineer your outsole design to create “inspired” versions for other customers. In environments with limited confidentiality culture, design details can leak through subcontractors, former employees, or informal business networks.

Weak Jurisdictional Enforcement

In some manufacturing regions, enforcing IP rights through local legal systems can be slow, costly, or ineffective. This creates a permissive environment for IP violations, making prevention—through legal contracts, audits, and monitoring—far more effective than pursuing remedies after infringement occurs.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Establish detailed technical specifications and material standards.

– Conduct regular on-site audits and request third-party test reports.

– Retain physical and legal ownership of molds and design files.

– Use ironclad contracts with clear IP clauses and penalties for breaches.

– Work with legally vetted, reputable suppliers and consider using escrow for tooling.

– Limit design exposure by sharing only necessary information with suppliers.

Proactive management of both quality and IP risks is essential for ensuring that sourced TPR outsoles meet performance expectations while protecting your brand’s innovation and market position.

Logistics & Compliance Guide for TPR Outsole

Overview of TPR Outsoles

Thermoplastic Rubber (TPR) outsoles are widely used in footwear manufacturing due to their flexibility, durability, and cost-effectiveness. These components must be managed carefully throughout the supply chain to ensure compliance with international standards, environmental regulations, and efficient logistics operations.

Material Specifications & Handling

- Composition: TPR is a blend of polymers, typically including rubber and plastic components, making it recyclable and suitable for injection molding.

- Storage Conditions: Store in a cool, dry environment away from direct sunlight and extreme temperatures (15–30°C recommended).

- Packaging: Use moisture-resistant, durable packaging (e.g., polybags inside woven polypropylene bags) to prevent contamination and damage during transit.

- Shelf Life: Typically 12–24 months; rotate stock using FIFO (First In, First Out) to avoid degradation.

Transportation & Logistics

- Mode of Transport: Suitable for sea, air, and land freight. Sea freight is most common due to cost efficiency for bulk shipments.

- Palletization: Stack on standard pallets (e.g., EUR/EPAL or CHEP), secured with stretch wrap to prevent shifting.

- Load Optimization: Maximize container utilization (e.g., 20ft or 40ft dry containers) while adhering to weight limits and ventilation requirements.

- Labeling: Clearly label each package with product type, batch number, quantity, weight, handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”), and origin/destination details.

Regulatory Compliance

- REACH (EU): Ensure TPR materials are registered under REACH and free from Substances of Very High Concern (SVHC). Provide Safety Data Sheets (SDS) upon request.

- RoHS (EU/UK): Confirm compliance with restrictions on hazardous substances, especially phthalates and heavy metals.

- Proposition 65 (California, USA): Verify that TPR outsoles do not contain chemicals listed under Prop 65 without proper warnings.

- REACH SVHC & PFAS: Monitor for emerging restrictions on PFAS and other regulated compounds in rubber formulations.

- Customs Documentation: Prepare accurate commercial invoices, packing lists, and certificates of origin. HS Code for TPR outsoles is typically 6406.10 (parts of footwear, of rubber or plastics).

Environmental & Sustainability Requirements

- Recyclability: Promote TPR as a recyclable material; encourage end-of-life recycling programs.

- Carbon Footprint: Optimize logistics routes and favor shipping methods with lower emissions.

- Supplier Audits: Require suppliers to comply with ISO 14001 (Environmental Management) and conduct periodic audits.

Quality Assurance & Traceability

- Batch Tracking: Assign unique batch/lot numbers to each production run for full traceability.

- Testing Protocols: Conduct regular quality checks for hardness (Shore A), tensile strength, abrasion resistance, and colorfastness per ISO or ASTM standards.

- Certifications: Maintain valid certificates such as ISO 9001 (Quality Management) and compliance test reports from accredited labs.

Import/Export Considerations

- Tariff Classifications: Confirm correct HS code classification to avoid customs delays or overpayment.

- Duty Rates: Verify applicable duty rates based on trade agreements (e.g., USMCA, ASEAN, EU GSP).

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP) in all contracts.

Risk Management & Contingency Planning

- Supplier Diversification: Maintain multiple qualified suppliers to mitigate disruption risks.

- Insurance: Ensure cargo is insured against loss, damage, or delay during transit.

- Recall Preparedness: Establish a product recall plan in case of compliance or safety issues.

Conclusion

Effective logistics and compliance management for TPR outsoles requires coordinated attention to material handling, regulatory standards, and global trade practices. Adhering to this guide ensures product quality, legal compliance, and supply chain resilience.

Conclusion for Sourcing TPR Outsole:

Sourcing TPR (Thermoplastic Rubber) outsoles presents a cost-effective, durable, and flexible solution for footwear manufacturing. TPR offers excellent grip, moderate cushioning, and resistance to wear and water, making it suitable for a wide range of applications—from casual and safety shoes to children’s footwear. The material’s moldability allows for diverse design options and efficient mass production, reducing tooling and labor costs.

When sourcing TPR outsoles, it is crucial to partner with reliable suppliers who adhere to quality standards, offer consistent material properties, and comply with environmental and safety regulations. Evaluating factors such as formulation (hardness, density), production capacity, lead times, and sustainability practices ensures optimal performance and alignment with brand values.

In summary, TPR outsoles provide a balanced combination of performance and affordability, making them a strategic choice in footwear production—especially for mid-tier and high-volume product lines. Effective sourcing through vetted manufacturers can enhance product quality, reduce costs, and support scalable growth in competitive markets.