The global automotive engine market, valued at approximately $87.5 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2030, according to Grand View Research. A key driver behind this expansion is the rising demand for performance-enhanced, reliable powertrains, particularly within the aftermarket and vehicle restoration sectors—segments where crate motors have become increasingly prominent. Toyota, known for its durability and widespread vehicle adoption, accounts for a significant share of engine replacements and performance upgrades, fueling strong interest in factory-built and aftermarket crate motor solutions. As modular, drop-in powertrain systems, Toyota crate motors offer reduced installation time, improved quality control, and OEM-level engineering—making them a preferred choice for builders and fleet operators alike. This growing market momentum has elevated competition and innovation among manufacturers specializing in Toyota crate engines, setting the stage for the top eight performers leading in reliability, customization, and technical support.

Top 8 Toyota Crate Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Performance Engine Accessories

Domain Est. 1994

Website: autoparts.toyota.com

Key Highlights: Free deliveryBoost your ride with Genuine Toyota performance engine accessories. Explore quality upgrades for power, efficiency, and smooth driving….

#2 There’s a New V

Domain Est. 1996

Website: caranddriver.com

Key Highlights: A Toyota specialist in Arizona has a new V-6 crate motor for Toyota trucks from the ’90s. It’s not a powerhouse, but it’s a durability boost ……

#3 Performance Crate Engine & Motors

Domain Est. 1996

Website: jasperengines.com

Key Highlights: JASPER offers four levels of crate engines, or crate motors, aimed at improving the performance of your project vehicle….

#4 Engines

Domain Est. 2000

Website: toyota-industries.com

Key Highlights: Toyota Industries manufactures engines for Toyota vehicles sold all around the world. We develop and manufacture clean diesel engines that strike a balance ……

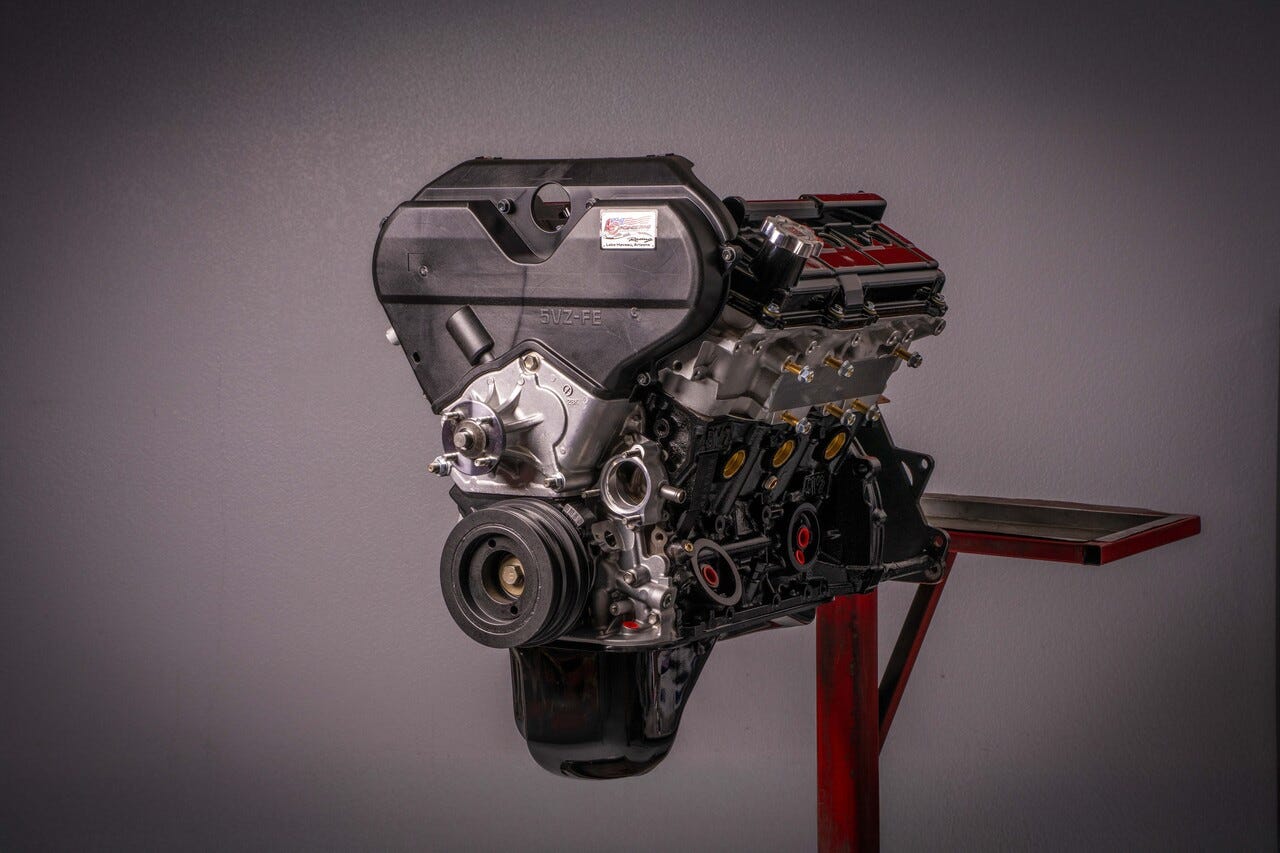

#5 Performance Toyota Engines

Domain Est. 2008

#6 TOYOTA 22R 22R

Domain Est. 2008

Website: sandjengines.com

Key Highlights: IT WILL BE A REVOLUTION. Our Toyota 22R series engines arrive ready for duty, sporting performance and durability above the original manufacture specifications….

#7 Toyota New Engines

Domain Est. 2009

#8 GR HERITAGE PARTS

Domain Est. 2015

Website: toyotagazooracing.com

Key Highlights: GR Heritage Parts was set up to reproduce and resell spare parts for old school Toyota sportscars, ensuring that they can race on for many years to come….

Expert Sourcing Insights for Toyota Crate Motor

H2: Projected 2026 Market Trends for Toyota Crate Motors

As the automotive industry evolves toward electrification and advanced performance technologies, the market for Toyota crate motors is expected to undergo significant transformation by 2026. While traditionally associated with restoration projects, custom builds, and performance upgrades, crate motors—pre-assembled, ready-to-install engines—are adapting to shifting consumer demands, regulatory pressures, and technological advancements.

-

Niche Market Expansion

By 2026, the demand for Toyota crate motors is expected to remain strong within enthusiast and aftermarket communities, particularly for classic models like the 2JZ-GTE, 1JZ, and 4A-GE. These engines continue to command premium prices due to their reliability, tunability, and legendary status in motorsports and drifting. Toyota’s growing support for heritage and performance parts could lead to the official release of factory-backed crate motors, enhancing authenticity and quality assurance for restorers and custom builders. -

Hybrid and Performance Crate Solutions

Toyota’s leadership in hybrid technology may result in the introduction of hybrid-compatible crate motor packages by 2026. These could combine internal combustion engines with modular electric assist systems, appealing to eco-conscious performance enthusiasts. For example, a crate version of the Dynamic Force engine paired with a hybrid transaxle could serve both performance and efficiency markets, especially in regions with tightening emissions regulations. -

Increased Emphasis on Sustainability and Reconditioning

With global sustainability initiatives gaining momentum, reconditioned or remanufactured Toyota crate motors are likely to gain market share. Certified rebuilt engines from Toyota or authorized partners could offer cost-effective, environmentally friendly alternatives to new powertrains. This trend aligns with circular economy models and appeals to younger, sustainability-minded consumers entering the automotive hobby space. -

Integration with Emerging Vehicle Platforms

The rise of electric vehicle (EV) conversions presents a new opportunity for Toyota crate motors. Enthusiasts may opt for Toyota engines in retrofitted classic cars where EV powertrains feel inauthentic. Conversely, Toyota may develop crate motors specifically designed for swap compatibility with popular EV platforms, enabling hybrid retrofit solutions. The 2.4L turbo engine from the 2024 Tacoma, for instance, could become a sought-after crate option for off-road and overlanding builds. -

Digital Sales and Customization Platforms

By 2026, Toyota and third-party suppliers are expected to leverage e-commerce and digital configurators to streamline crate motor sales. Customers may be able to customize engine specs (e.g., horsepower output, fuel system, accessories) online and receive factory-tested, serialized units with warranty support. Augmented reality (AR) tools could assist in visualizing engine swaps, further driving adoption. -

Regulatory and Regional Variability

Emissions standards, especially in markets like California, the EU, and Japan, will influence the availability and certification of crate motors. Toyota may focus on offering CARB-compliant or “off-road use only” certified engines to navigate these restrictions. International demand, particularly in Southeast Asia and Latin America, may drive exports of durable, cost-effective diesel and gasoline crate engines for commercial and agricultural applications.

In summary, the 2026 market for Toyota crate motors will likely reflect a convergence of nostalgia, performance innovation, and sustainability. While traditional V6 and inline-six engines maintain cultural relevance, Toyota’s strategic integration of hybrid technology, remanufacturing, and digital services will shape the future of its crate motor offerings, ensuring continued relevance in a rapidly changing automotive landscape.

Common Pitfalls When Sourcing a Toyota Crate Motor

Sourcing a Toyota crate motor can be an excellent way to power a restoration, custom build, or performance upgrade. However, several pitfalls can lead to wasted time, money, and potential legal issues if not carefully navigated. Be aware of the following key concerns:

Quality and Authenticity Concerns

One of the biggest risks is receiving a motor that doesn’t meet advertised quality standards. Many sellers market “Toyota crate engines” that are not genuine Toyota Remanufactured or Genuine Toyota Performance Parts (TPI). Instead, they may be rebuilt locally with mixed-quality components. Without proper documentation or certification, it can be difficult to verify compression, machining precision, or the use of OEM-spec parts. Buyers may end up with engines prone to premature wear, leaks, or performance issues.

Intellectual Property and Trademark Infringement

Using the term “Toyota Crate Motor” or featuring Toyota logos and part numbers can expose buyers and resellers to intellectual property (IP) risks. Toyota Motor Corporation strictly controls the use of its trademarks, and unauthorized sellers may misrepresent their engines as factory-original or Toyota-certified. Purchasing from such sources not only risks receiving a subpar product but could also implicate the buyer in trademark misuse—especially if the engine is used in a commercial application or resale. Always verify that the seller is an authorized Toyota distributor or licensed remanufacturer to avoid IP complications.

Lack of Warranty and Support

Many third-party or gray-market crate motors come with limited or no warranty, especially if sourced from non-authorized vendors. Genuine Toyota crate engines typically include comprehensive warranty coverage and technical support. Without this, buyers may face significant repair costs and downtime if the engine fails. Ensure the seller provides clear warranty terms and access to customer service before finalizing a purchase.

Misrepresentation of Specifications

Some sellers exaggerate performance metrics, such as horsepower, torque, or engine displacement. For example, a “2JZ-GTE crate engine” may be advertised with 400 hp, but without proper internal upgrades and dyno verification, this claim may be misleading. Always request supporting documentation like build sheets, dyno reports, and component lists to validate performance claims.

Import and Compliance Issues

When sourcing internationally, crate motors may not comply with local emissions or safety regulations. Engines built for markets outside the U.S. or Europe might lack required certifications (e.g., EPA, CARB). Importing such engines could result in legal penalties or inability to register the vehicle. Confirm that the engine meets regional compliance standards before purchase.

Avoiding these pitfalls requires due diligence: buy from authorized dealers, verify documentation, and confirm the legal and technical legitimacy of the product.

Logistics & Compliance Guide for Toyota Crate Motor

This guide provides essential information for the safe, efficient, and compliant handling, transportation, and documentation of Toyota Crate Motors. Adherence to these guidelines ensures regulatory compliance, protects product integrity, and supports smooth delivery.

Shipping and Handling

Toyota Crate Motors are heavy, precision-engineered assemblies that require careful handling throughout the logistics chain. Always use appropriate material handling equipment such as forklifts or pallet jacks rated for the motor’s weight (typically 350–500 lbs depending on configuration). Never lift the motor by its oil filter, exhaust manifolds, or accessory brackets. The crate is designed for secure transit—ensure all wooden or metal skids and corner protectors remain intact until final delivery. Store motors indoors in a dry, temperature-controlled environment to prevent corrosion and moisture damage.

Packaging Requirements

Each Toyota Crate Motor is shipped in a custom-designed wooden crate or heavy-duty composite container that meets international shipping standards (e.g., ISPM 15 for wooden components). The packaging includes internal cushioning, protective wraps, and desiccants to prevent vibration damage and moisture exposure during transit. Tamper-evident seals are applied to verify cargo integrity. Do not open or modify the crate unless necessary for inspection or installation—any damage to packaging may void warranty or compliance status.

Transportation Regulations

Transport of crate motors must comply with local and international transportation laws. In the U.S., ensure compliance with Department of Transportation (DOT) regulations for heavy freight, including proper vehicle loading, securement, and weight distribution. For air freight, adhere to IATA Dangerous Goods Regulations if applicable (e.g., motors with residual fluids). Ground shipments must display proper freight classification (typically NMFC 156160-2, Class 85) and be palletized for compatibility with standard logistics networks.

Customs and Import Compliance

For cross-border shipments, ensure all documentation is accurate and complete. Required documents include a commercial invoice, packing list, bill of lading, and certificate of origin. The motor’s HS Code (e.g., 8407.34 for internal combustion engines) must be correctly declared to determine duty rates. Confirm emissions compliance (e.g., EPA or CARB certification) if importing into regulated markets like the United States. Some crate motors may be considered “new engines” subject to specific environmental regulations upon installation.

Environmental and Safety Compliance

Toyota Crate Motors are subject to environmental regulations regarding emissions and hazardous materials. Ensure motors are drained of all oils and fluids unless shipped as “wet” units per factory specification. Comply with EPA and local regulations for handling, storage, and disposal of any residual fluids. Workers involved in handling must follow OSHA safety guidelines, including the use of personal protective equipment (PPE) when unpacking or moving motors.

Documentation and Traceability

Maintain full documentation throughout the logistics chain for audit and compliance purposes. Each crate motor includes a unique serial number tracked in Toyota’s parts and logistics system. Retain records of shipping manifests, customs filings, inspection reports, and delivery confirmations for a minimum of five years. This traceability supports warranty claims, recalls, and regulatory audits.

Final Delivery and Inspection

Upon delivery, inspect the crate for visible damage before accepting the shipment. Document any issues with photos and file a freight claim immediately if necessary. Perform a preliminary inspection of the motor for shipping damage after unpacking, verifying that all components listed on the packing slip are present and undamaged. Report discrepancies to Toyota Parts Logistics or your authorized distributor within 48 hours.

In conclusion, sourcing a Toyota crate motor can be a smart and reliable choice for engine replacements, restorations, or performance upgrades, thanks to Toyota’s reputation for durability, efficiency, and long-term support. Whether you’re rebuilding a classic Toyota truck, upgrading a project car, or ensuring minimal downtime in a commercial vehicle, factory-supplied or certified crate engines offer peace of mind with tested quality, warranty coverage, and compatibility with OEM specifications.

While the initial cost may be higher than used or aftermarket alternatives, the investment often pays off in reliability, reduced labor time, and lower long-term maintenance. Proper research—verifying the correct engine model, checking availability through Toyota dealers or authorized distributors, and understanding warranty terms—is essential to ensure a successful outcome. Additionally, considering options from reputable re-manufacturers can provide flexibility in budget and performance enhancements.

Ultimately, sourcing a Toyota crate motor combines the dependability of a factory-engineered powertrain with the convenience of a drop-in solution, making it a prudent choice for both professional mechanics and DIY enthusiasts seeking performance, longevity, and resale value.