The global ignition coil market is experiencing steady growth, driven by rising vehicle production, increasing demand for fuel-efficient engines, and the proliferation of advanced ignition systems in modern automobiles. According to a report by Mordor Intelligence, the ignition coil market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. A significant contributor to this demand is the widespread use of ignition coils in high-volume models like the Toyota Corolla, one of the best-selling vehicles globally. Due to its reputation for reliability and efficiency, the Corolla requires consistently high-quality replacement components, particularly ignition coils, that meet OEM standards. As a result, a competitive ecosystem of manufacturers has emerged, specializing in durable, performance-optimized coils tailored to the Corolla’s engine specifications. In this data-driven landscape, selecting the right supplier involves evaluating output performance, longevity, compliance with OE specifications, and global distribution capacity. Based on market presence, product reliability, and technical alignment with Toyota’s engineering standards, here are the top six ignition coil manufacturers serving the Toyota Corolla market.

Top 6 Toyota Corolla Ignition Coil Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Genuine OEM Toyota Coils

Domain Est. 1998

Website: parts.olathetoyota.com

Key Highlights: 4–7 day deliveryWe Have Genuine OEM Toyota Coils At Wholesale Prices! Don’t Buy Local When You Can Save Big Online. Shop Now – Orders Ship Fast!…

#2 Genuine Toyota Corolla Ignition Coil

Domain Est. 2015

Website: toyotapartsdeal.com

Key Highlights: 1–4 day deliveryShop wholesale-priced OEM Toyota Corolla Ignition Coils at ToyotaPartsDeal.com. All fit 1975-2024 Toyota Corolla and more….

#3 Spark Plug, Ignition Coil & Glow Plug

Domain Est. 1994

Website: autoparts.toyota.com

Key Highlights: Free deliveryEnhance your Toyota’s performance with spark plugs, ignition coils, and glow plugs. Explore our quality selection for reliable starting power….

#4 Ignition coil

Domain Est. 1996

Website: hella.com

Key Highlights: HELLA ignition coils guarantee ignition even under extreme conditions and also electromagnetic compatibility with the magnetic field-sensitive elements of ……

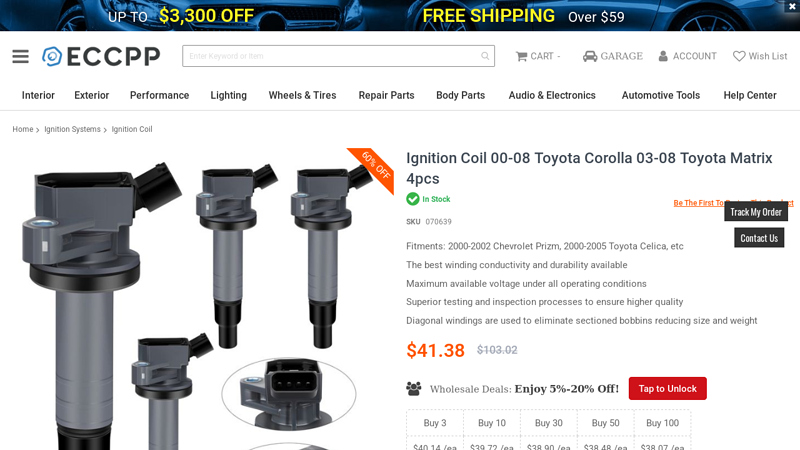

#5 Ignition Coil 00

Domain Est. 2017

#6 Ignition Coil

Domain Est. 2023

Website: toyotaparts.ourismantoyotaofrichmond.com

Key Highlights: In stock Rating 4.4 37 Genuine Official Toyota Ignition Coil part# 90919-A2009 for 2018-2025 Toyota | Ourisman Toyota Parts | Official Toyota Online Parts Store….

Expert Sourcing Insights for Toyota Corolla Ignition Coil

H2: 2026 Market Trends for Toyota Corolla Ignition Coil

The market for Toyota Corolla ignition coils in 2026 is expected to reflect broader shifts in automotive technology, consumer behavior, and sustainability initiatives. As one of the most popular compact cars globally, the Toyota Corolla continues to maintain a large installed base, supporting steady demand for replacement parts such as ignition coils. However, several key trends are shaping the trajectory of this market.

-

Declining Demand Due to Electrification

By 2026, the global push toward electric vehicles (EVs) will continue to impact internal combustion engine (ICE) component markets. While the Corolla still offers gasoline and hybrid variants, Toyota’s increasing investment in fully electric models (e.g., bZ series) may gradually reduce the long-term demand for ignition coils. As newer Corolla models emphasize hybrid and plug-in hybrid systems, the reliance on traditional ignition systems will diminish, particularly in key markets like Europe and North America. -

Growth in Aftermarket Replacement Demand

Despite the shift toward electrification, the vast number of Corollas currently on the road ensures robust aftermarket demand for ignition coils through 2026. These components typically require replacement every 80,000 to 120,000 miles, meaning aging Corolla fleets—especially models from 2015 to 2022—will continue to drive replacement sales. Regions with high Corolla ownership, such as North America, Southeast Asia, and the Middle East, will remain key markets. -

Rise of High-Performance and OEM-Compatible Aftermarket Coils

Consumers and repair shops are increasingly favoring high-quality aftermarket ignition coils that match or exceed OEM specifications. Brands offering enhanced durability, improved ignition efficiency, and better resistance to heat and vibration are gaining market share. In 2026, expect continued innovation in coil-on-plug (COP) designs tailored specifically for Corolla models, with a focus on reliability and ease of installation. -

Supply Chain Optimization and Localization

Automotive parts manufacturers are adapting to post-pandemic supply chain challenges by localizing production and improving inventory management. By 2026, companies supplying Toyota Corolla ignition coils are likely to have strengthened regional distribution networks, reducing lead times and costs. This trend supports faster turnaround for repair shops and DIY consumers, further stimulating aftermarket activity. -

Integration with Vehicle Diagnostics and Smart Repair Tools

As vehicles become more connected, ignition coil diagnostics are increasingly integrated into onboard systems and mobile repair apps. In 2026, aftermarket ignition coils may be paired with diagnostic support features or QR-coded installation guides to assist technicians. This trend enhances customer confidence and reduces misdiagnoses, a common issue with ignition-related symptoms like misfires. -

Sustainability and Recycling Initiatives

Environmental regulations are prompting parts manufacturers to explore recyclable materials and eco-friendly packaging. While ignition coils contain minimal hazardous materials, companies are beginning to adopt greener production practices to align with corporate sustainability goals—a factor that may influence brand preference among environmentally conscious consumers and fleet operators.

In summary, the 2026 market for Toyota Corolla ignition coils will be characterized by a transitional phase: sustained demand from the existing ICE and hybrid fleet, tempered by the long-term decline driven by vehicle electrification. Success in this market will depend on adaptability, quality differentiation, and alignment with emerging service and sustainability trends.

Common Pitfalls Sourcing Toyota Corolla Ignition Coil (Quality, IP)

Sourcing a reliable ignition coil for a Toyota Corolla can be challenging, with several common pitfalls related to quality and intellectual property (IP) issues. Avoiding these is crucial for vehicle performance and longevity.

Poor Quality Materials and Construction

Many aftermarket coils use substandard materials such as low-grade copper windings, inferior epoxy resins, or weak insulating casings. These components degrade quickly under engine heat and vibration, leading to premature failure, misfires, and reduced fuel efficiency. Cheaply made coils often lack proper resistance to moisture and thermal expansion, increasing the risk of internal short circuits.

Inaccurate Fitment and Compatibility

Not all ignition coils marketed for the Corolla are engineered for specific model years or engine types (e.g., 1.8L 2ZR-FE vs. older 1ZZ-FE). Misrepresented compatibility can result in improper fit, electrical mismatches, or ECU communication errors. Always verify part numbers against OEM specifications to ensure correct application.

Counterfeit or IP-Infringing Products

A significant risk in the aftermarket is counterfeit ignition coils that mimic genuine Toyota or reputable brands like Denso or Bosch. These fake products often infringe on intellectual property and bypass quality control standards. They may feature forged logos, packaging, or serial numbers and fail to meet original performance and safety specifications, potentially damaging the engine or triggering check engine lights.

Lack of Certification and Testing

Reputable ignition coils undergo rigorous testing for voltage output, durability, and electromagnetic interference. Many low-cost suppliers skip these steps or fail to provide certification (e.g., ISO, TS 16949). Without proper testing, coils may not deliver consistent spark, leading to poor engine performance and increased emissions.

Inadequate Warranty and Support

Lower-quality coils often come with limited or no warranty. Sellers may be unresponsive when issues arise, making it difficult to resolve failures. Genuine or high-quality aftermarket coils typically include solid warranty coverage and technical support, reflecting confidence in their product.

To avoid these pitfalls, purchase ignition coils from authorized dealers, verify OEM part numbers, and choose brands with established reputations and IP legitimacy.

Logistics & Compliance Guide for Toyota Corolla Ignition Coil

This guide outlines the essential logistics considerations and compliance requirements for handling, transporting, storing, and distributing Toyota Corolla ignition coils. Adhering to these guidelines ensures product integrity, regulatory compliance, and supply chain efficiency.

Product Overview

The Toyota Corolla ignition coil is an automotive electrical component responsible for converting the battery’s low voltage into the high voltage required to create an electric spark in the spark plugs, thereby igniting the air-fuel mixture in the engine. It is a critical OEM (Original Equipment Manufacturer) or aftermarket part typically used in servicing and repairing Corolla models across various model years.

Packaging Requirements

Ignition coils must be packaged to prevent physical damage, moisture exposure, and electrostatic discharge (ESD). Standard packaging includes:

- Rigid corrugated cardboard boxes with internal foam or molded plastic inserts to secure each unit.

- Anti-static bags for ESD-sensitive variants, especially in electronic ignition systems.

- Clear labeling indicating part number, model compatibility (e.g., Corolla 2015–2020), and handling instructions (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”).

- Barcodes and RFID tags for inventory tracking in automated logistics systems.

Storage Conditions

To maintain performance and longevity:

- Store in a dry, climate-controlled environment with temperatures between 10°C and 30°C (50°F–86°F).

- Humidity levels should not exceed 65% to prevent internal corrosion or insulation degradation.

- Keep away from direct sunlight, chemicals, and sources of electromagnetic interference.

- Use first-in, first-out (FIFO) inventory rotation to prevent long-term storage issues.

Transportation Guidelines

- Use enclosed, secure vehicles to protect against weather, dust, and physical shock.

- Palletize boxes securely using stretch wrap; limit stacking height to prevent crushing lower layers (typically no more than 5 layers unless specified).

- Avoid exposure to extreme temperatures during transit (e.g., do not leave in unventilated trucks in hot climates).

- For international shipments, ensure compliance with IATA (air) or IMDG (sea) regulations if applicable—though ignition coils typically do not contain hazardous materials, verify per local regulations.

Regulatory Compliance

International Trade

- Classify the product under the correct Harmonized System (HS) code (e.g., 8511.50 for ignition apparatus).

- Comply with import/export regulations in destination countries, including customs documentation, certificates of origin, and import duties.

- Verify country-specific requirements (e.g., CE marking for Europe, E-Mark for automotive components, DOT compliance for certain markets).

Environmental & Safety Standards

- Ensure compliance with RoHS (Restriction of Hazardous Substances) and REACH regulations, especially if selling in the EU.

- Confirm that packaging materials meet recyclability standards and local environmental laws.

- Adhere to WEEE (Waste Electrical and Electronic Equipment) directives for end-of-life handling, where applicable.

Automotive Industry Standards

- Parts labeled as OEM equivalents must meet or exceed Toyota’s original specifications (Toyota TSM or JIS standards).

- Aftermarket suppliers should comply with ISO 9001 and IATF 16949 quality management systems.

- Documentation such as test reports, material declarations, and conformity certificates may be required by distributors or regulatory authorities.

Labeling and Documentation

Each shipment must include:

– Commercial invoice with detailed product description, quantity, value, and Harmonized Code.

– Packing list matching the physical contents.

– Bill of Lading or Air Waybill with proper consignee and shipper details.

– Safety Data Sheet (SDS) only if required—typically not necessary for ignition coils unless containing hazardous potting compounds (verify with manufacturer).

– Compliance labels (e.g., part number, manufacturing date, country of origin) clearly visible on outer packaging.

Reverse Logistics & Returns

- Establish a process for handling customer returns, including inspection for damage or misuse.

- Returned ignition coils should be evaluated for refurbishment or proper disposal per environmental regulations.

- Track return reasons to identify potential quality or logistics issues.

Conclusion

Proper logistics and compliance management for Toyota Corolla ignition coils ensures product reliability, legal adherence, and customer satisfaction. By following this guide, suppliers, distributors, and logistics providers can maintain high standards throughout the supply chain while minimizing risks and delays. Always consult the latest manufacturer specifications and regional regulations for updates.

In conclusion, sourcing a Toyota Corolla ignition coil requires careful consideration of compatibility, quality, and reliability. It is essential to identify the exact model year, engine type, and engine size of the Corolla to ensure the correct fitment. Opting for OEM (Original Equipment Manufacturer) parts or reputable aftermarket brands guarantees performance and longevity. Purchasing from trusted suppliers—whether online or local—ensures authenticity and often provides access to warranties and customer support. Additionally, comparing prices and reading customer reviews can help in making a cost-effective and informed decision. Proper selection and installation of the ignition coil will contribute to optimal engine performance, fuel efficiency, and overall vehicle reliability.