The global towel machine manufacturing market is witnessing robust growth, driven by rising demand for automated hygiene solutions across healthcare, hospitality, and commercial sectors. According to Grand View Research, the global hand dryer market—closely linked to towel dispensing systems—was valued at USD 1.2 billion in 2022 and is projected to expand at a CAGR of 6.8% from 2023 to 2030. Similarly, Mordor Intelligence forecasts increasing adoption of touchless dispensing systems, citing hygiene awareness and technological advancements as key growth catalysts. As facilities prioritize operational efficiency and sanitation, investment in high-performance towel machines has surged. This trend has elevated the prominence of leading manufacturers that combine innovation, reliability, and scalability. Based on market presence, technology integration, and global distribution reach, the following six companies stand out as the top towel machine manufacturers shaping the industry’s future.

Top 6 Towel Machines Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

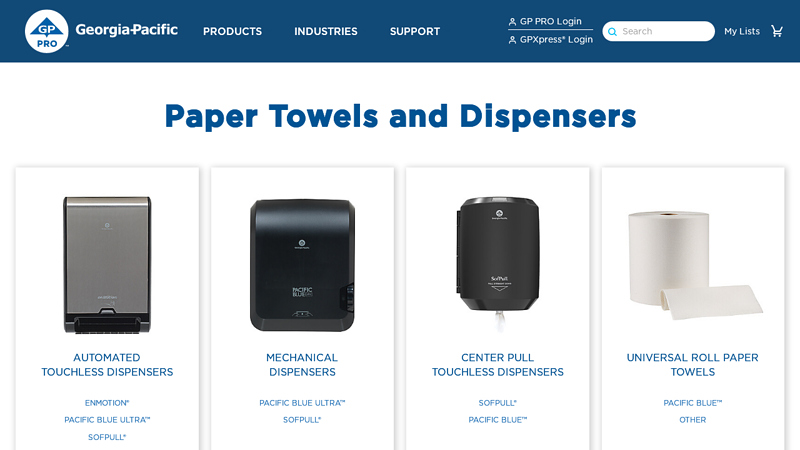

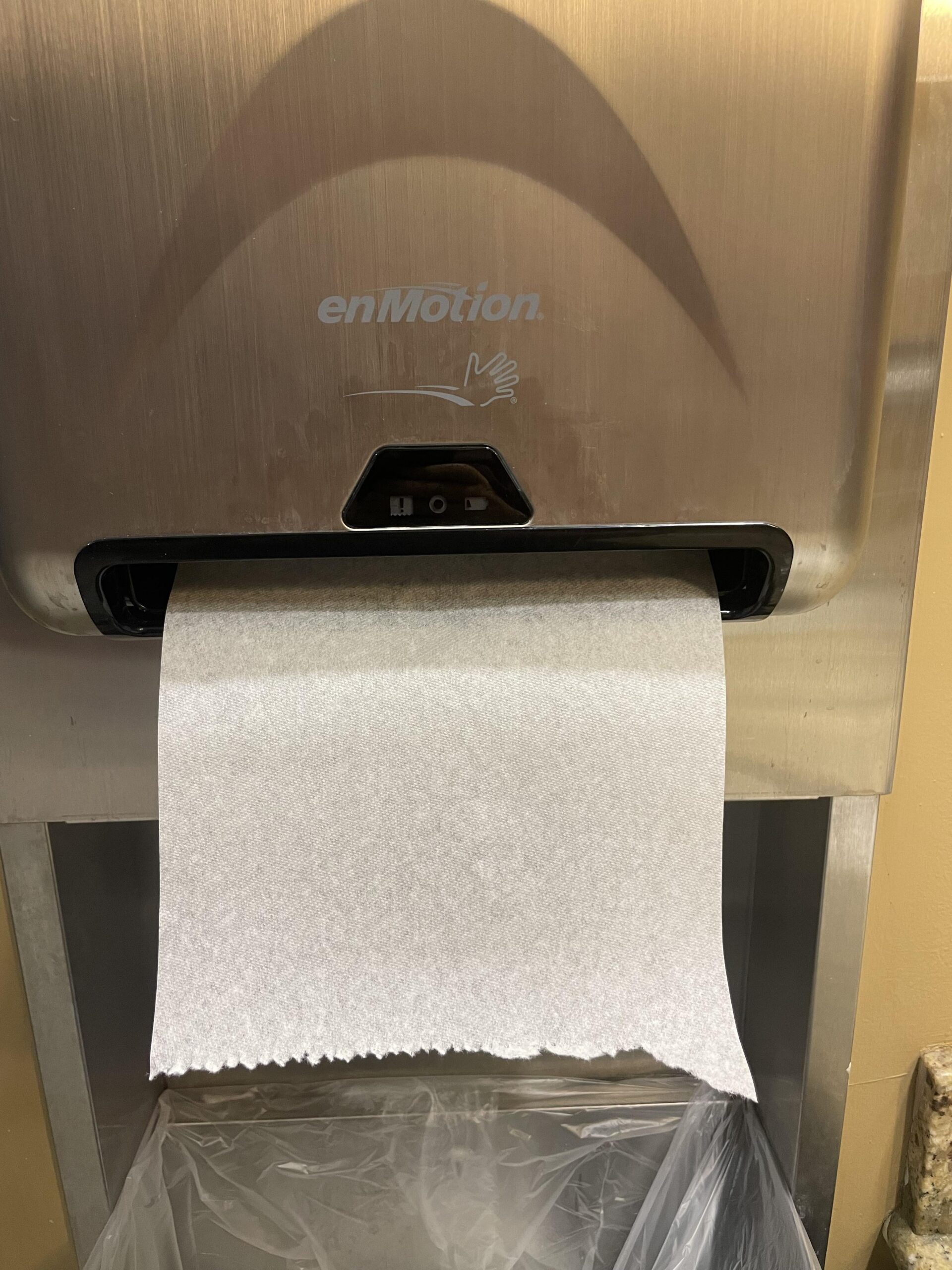

#1 Commercial Paper Towels & Dispensers

Domain Est. 2002

Website: gppro.com

Key Highlights: GP Pro by Georgia-Pacific offers innovative industrial paper towels and paper towel dispenser products – Learn more about our hygienic and efficient ……

#2 Marcal Paper

Domain Est. 1996 | Founded: 1950

Website: marcalpaper.com

Key Highlights: Since 1950, customers have trusted Marcal to provide quality paper towel and tissue products backed with outstanding service….

#3 Paper Towels & Dispensers

Domain Est. 2001

Website: kcprofessional.com

Key Highlights: Give Us a Call. 1-800-241-3146 7:30 a.m. – 7:00 p.m. ET Monday – Friday ; Chat with Us. 8:00 a.m. – 6:00 p.m. ET Monday – Friday ; KCP Advantage. Tools, ……

#4 Tork

Domain Est. 2003

Website: torkglobal.com

Key Highlights: Enhanced cleaning efficiency and improved satisfaction in your workplace may be only a few clicks away with Tork. Explore solutions for your industry….

#5 Quality Paper Products

Domain Est. 2013

Website: morcontissue.com

Key Highlights: Morcon Tissue is a leading converter of commercial paper products including napkin, towel, tissue, and dispensers for the Away-From-Home market in North ……

#6 Rulomatik™ Car Drying Towel Vending Machine

Domain Est. 2014

Website: rulomatik.com

Key Highlights: Say Hello to the World’s Most Advanced disposable Vending Machines Practical, Crisis-Proof and Growing. Disposable Vending Machines….

Expert Sourcing Insights for Towel Machines

2026 Market Trends for Towel Machines

The towel machine market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological innovation, and heightened focus on hygiene and sustainability. Key trends shaping the industry include:

Smart Technology Integration and IoT Connectivity

By 2026, smart towel machines equipped with IoT (Internet of Things) capabilities will become standard in commercial and premium residential settings. These devices will offer real-time monitoring of towel inventory, usage patterns, and maintenance alerts, enabling proactive service and reducing downtime. Integration with building management systems and mobile apps will allow facility managers to optimize operations, track hygiene compliance, and manage multiple units remotely. AI-driven analytics will further enhance efficiency by predicting peak usage times and automating restocking schedules.

Emphasis on Hygiene and Contactless Operation

Post-pandemic hygiene concerns will continue to influence design, with contactless operation via motion sensors, foot pedals, or smartphone apps becoming a dominant feature. UV-C sterilization within towel dispensers and antimicrobial surface coatings will be increasingly adopted to ensure cleanliness and build user confidence, particularly in healthcare, hospitality, and public restrooms.

Sustainability and Eco-Friendly Materials

Environmental regulations and consumer demand will push manufacturers toward sustainable solutions. Towel machines in 2026 will increasingly support biodegradable, recycled, or reusable towel rolls. Energy-efficient motors and solar-powered or low-power operation will gain traction, especially in eco-conscious markets. Lifecycle assessments and reduced plastic content in machine construction will become key selling points.

Expansion in Non-Traditional Applications

Beyond restrooms, towel machines will see growing adoption in fitness centers, spas, electric vehicle charging stations, co-working spaces, and smart homes. Customization for specific environments—such as waterproof designs for pools or compact models for RVs—will drive market segmentation and innovation.

Regional Growth and Market Consolidation

Asia-Pacific, particularly China and India, will experience rapid market growth due to urbanization and rising commercial infrastructure development. North America and Europe will focus on retrofitting existing facilities with smart models. Increased competition will likely lead to consolidation among manufacturers and partnerships with facility service providers to offer bundled solutions.

In summary, the 2026 towel machine market will be defined by intelligent, hygienic, and sustainable systems that enhance user experience while reducing operational costs and environmental impact. Companies that innovate in connectivity, materials, and application diversity will lead the next phase of industry growth.

Common Pitfalls When Sourcing Towel Machines: Quality and Intellectual Property Risks

Sourcing towel machines—especially automated towel dispensers or rental systems—can present significant challenges if due diligence is not performed. Two of the most critical areas where businesses often encounter problems are product quality and intellectual property (IP) compliance. Failing to address these can lead to operational disruptions, legal liabilities, and reputational damage.

Quality-Related Pitfalls

-

Inconsistent Manufacturing Standards

Many towel machines sourced from low-cost manufacturers, particularly in regions with lax regulatory oversight, may not adhere to international quality standards (e.g., ISO, CE, UL). Components such as motors, sensors, and housing materials may degrade quickly under frequent use, leading to frequent breakdowns and high maintenance costs. -

Poor Material Durability

Low-quality plastics or corrosion-prone metals are often used to cut costs. In high-moisture environments like restrooms or spas, this can result in premature wear, discoloration, or mechanical failure, reducing the machine’s lifespan and increasing total cost of ownership. -

Inadequate Testing and Certification

Some suppliers provide machines that have not undergone proper environmental, electrical, or safety testing. This increases the risk of malfunctions, safety hazards (e.g., electric shock or fire), and non-compliance with local regulations, potentially leading to fines or liability claims. -

Lack of After-Sales Support and Spare Parts

Poor-quality machines are often backed by weak warranty terms and limited availability of spare parts. If the supplier lacks a local service network, repairs can be delayed, resulting in prolonged downtime and customer dissatisfaction. -

Misleading Performance Claims

Suppliers may exaggerate the machine’s capacity, cycle speed, or hygiene features (e.g., touchless operation). Without third-party verification or on-site testing, buyers may end up with underperforming units that fail to meet user expectations.

Intellectual Property (IP) Risks

-

Supplying Counterfeit or Copycat Designs

Some manufacturers produce towel machines that closely mimic patented or trademarked designs from established brands. Purchasing such products—even unknowingly—can expose your business to legal action for IP infringement, especially if the machines are distributed or used publicly. -

Use of Unauthorized Software or Firmware

Modern towel dispensers often include proprietary software for inventory tracking, user authentication, or remote monitoring. Sourcing machines with pirated or reverse-engineered software can lead to cybersecurity vulnerabilities and legal exposure under copyright law. -

Lack of IP Documentation from Supplier

Reputable suppliers should provide proof of IP ownership or licensing for their designs and technology. Failure to obtain these documents can leave buyers vulnerable if third parties later assert IP rights over the product. -

Grey Market Imports and Voided Warranties

Towel machines sourced through unauthorized distributors may be grey market products, potentially infringing on regional IP protections or distribution agreements. These units often come with voided warranties and lack regulatory approvals, increasing long-term risk. -

Difficulty in Enforcement Across Borders

If a supplier in another country violates IP rights, pursuing legal action can be costly and complex due to jurisdictional challenges. This makes prevention—through thorough vetting and contractual safeguards—essential.

Best Practices to Avoid These Pitfalls

- Conduct factory audits and request third-party quality certifications.

- Require detailed IP documentation and include IP indemnification clauses in contracts.

- Test prototypes under real-world conditions before bulk ordering.

- Partner with reputable suppliers who have a proven track record and transparent supply chains.

- Consult legal experts to review compliance with local and international IP laws.

By proactively addressing quality and IP concerns, businesses can ensure reliable, legally compliant towel machine operations and protect their brand reputation.

Logistics & Compliance Guide for Towel Machines

Overview

Towel machines, commonly used in gyms, spas, and public facilities for dispensing or collecting reusable towels, require careful planning in both logistics (transportation, installation, maintenance) and compliance (safety, hygiene, and regulatory standards). This guide outlines key considerations to ensure efficient deployment and regulatory adherence.

Transportation and Delivery Logistics

Ensure towel machines are transported securely to prevent damage. Use padded packaging or crates for protection during transit. Coordinate with freight carriers experienced in handling commercial equipment. Confirm site accessibility—check doorway widths, elevator capacity, and floor load limits—before scheduling delivery. Schedule deliveries during off-peak hours to minimize disruption at the installation site.

Installation Requirements

Install towel machines on level, stable surfaces with access to power (typically 110–120V AC) and, if applicable, network connectivity for monitoring. Maintain adequate clearance around the unit for maintenance and user access. Follow manufacturer guidelines for mounting (wall or floor-standing) and ensure plumbing connections (for sanitizing models) meet local codes. Document installation with photos and completion checklists.

Hygiene and Sanitation Compliance

Towel machines must comply with public health standards. If the machine dispenses laundered towels, ensure they are cleaned using EPA-approved detergents and sanitizers at appropriate temperatures (minimum 160°F/71°C for hot water washing). Maintain a log of laundering cycles and machine cleaning schedules. Units with built-in sanitization systems (e.g., UV-C, antimicrobial coatings) must be validated and maintained per manufacturer and health department guidelines.

Electrical and Safety Standards

All towel machines must meet electrical safety certifications such as UL (Underwriters Laboratories) or ETL in the U.S., or CE in Europe. Units should include ground-fault protection and overcurrent safeguards. Perform routine inspections for frayed cords, overheating, or casing damage. Install warning labels where applicable, particularly near moving parts or hot surfaces.

Data Privacy and Connectivity (Smart Models)

Smart towel machines that collect user data (e.g., via RFID, app integration, or touchscreens) must comply with data protection regulations such as GDPR or CCPA. Ensure data encryption, anonymization where possible, and clear user consent mechanisms. Regularly update firmware to address security vulnerabilities and maintain cybersecurity best practices.

Local Regulatory Compliance

Verify compliance with local health department, fire code, and accessibility regulations (e.g., ADA in the U.S.). Some jurisdictions may require permits for commercial towel distribution systems. Maintain up-to-date documentation, including equipment certifications, maintenance records, and compliance audits, for inspection readiness.

Maintenance and Servicing

Establish a preventive maintenance schedule for mechanical, electrical, and hygiene systems. Train staff or contract technicians to perform routine checks, cleaning, and part replacements. Use only manufacturer-approved components and consumables. Keep a service log to track interventions and ensure timely repairs.

Environmental and Waste Management

Dispose of worn towels responsibly—recycle or compost if possible, following local waste regulations. For machines using disposable liners or packaging, minimize plastic use and opt for recyclable materials. Consider energy-efficient models to reduce environmental impact and operating costs.

Training and User Communication

Train facility staff on proper operation, troubleshooting, and hygiene protocols. Provide clear signage for users explaining how to use the machine, towel return procedures, and hygiene reminders. Include emergency contact information for technical support.

Documentation and Recordkeeping

Maintain comprehensive records including:

– Equipment manuals and warranty information

– Installation and maintenance logs

– Sanitation and laundering records

– Compliance certifications

– Incident reports (if applicable)

Regular audits of these documents support continuous compliance and operational efficiency.

Conclusion

Successfully deploying towel machines requires coordination across logistics, safety, health, and data regulations. By adhering to this guide, organizations can ensure reliable operation, regulatory compliance, and a hygienic user experience.

In conclusion, sourcing towel machines requires a strategic approach that balances cost, quality, reliability, and long-term operational efficiency. Key considerations include evaluating suppliers based on their reputation, technical support, after-sales service, and compliance with industry standards. It is essential to assess the specific needs of your facility—such as production volume, towel type, and automation requirements—when selecting the appropriate machine. Conducting thorough due diligence, including site visits, product testing, and reference checks, can mitigate risks and ensure a successful investment. Ultimately, choosing the right towel machine from a reputable supplier contributes to improved productivity, reduced downtime, and enhanced product consistency, supporting the growth and sustainability of your operation.