The global towing equipment market is experiencing steady growth, driven by rising vehicle ownership, increased road accidents, and expanding automotive aftermarket demand. According to a report by Grand View Research, the global towing services market size was valued at USD 13.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth underscores the increasing need for reliable and high-performance towing components, particularly wheel lift systems—essential elements in modern tow trucks that offer efficient, damage-free vehicle recovery. As demand for durable and technologically advanced towing solutions rises, manufacturers of wheel lift parts are playing a pivotal role in shaping industry standards. Based on market presence, innovation, product quality, and global distribution, the following list highlights the top 10 tow truck wheel lift parts manufacturers leading the charge in this expanding sector.

Top 10 Tow Truck Wheel Lift Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Miller Industries

Domain Est. 1997

Website: millerind.com

Key Highlights: Manufacturer and world leader in towing and recovery equipment with brands Century, Vulcan, Chevron, and Holmes. Products range from light, medium, ……

#2 Zacklift International

Domain Est. 1997

Website: zacklift.com

Key Highlights: Zacklift is the world leader in heavy duty detachable wrecker configurations. We design and manufacture heavy duty towing equipment used around the world….

#3 Wheel Lift Towing System Products

Domain Est. 1999

Website: minuteman1.com

Key Highlights: Minute Man Wheel Lift is a wheel lift towing system designed for truck bed attachement to give you the flexibility you need in any situation….

#4 Towing Parts, Towing Supplies & Vehicle Recovery Equipment

Domain Est. 1999

Website: parts.ectts.com

Key Highlights: Free delivery over $149Shop our wide selection of towing supplies including: tow straps, trailer cargo tie downs, towing recovery cables, and lifting ropes with various hook ……

#5 Tow Industries

Domain Est. 2002

Website: towindustries.com

Key Highlights: Tow Industries based in Los Angeles, CA is the most reputable and longest operating tow truck center and tow truck dealer for new and pre-owned trucks….

#6 Towing Products

Domain Est. 2002

Website: liftandtow.com

Key Highlights: Our repo wheel lift for trucks easily install on ¾-ton and larger pickups and come in a variety of models and options to meet your specific requirements. Our ……

#7 NRC Industries

Domain Est. 2006

Website: nrc-industries.com

Key Highlights: NRC Industries manufactures high-performance towing equipment recognized for their outstanding performance, innovative design and excellent craftmanship….

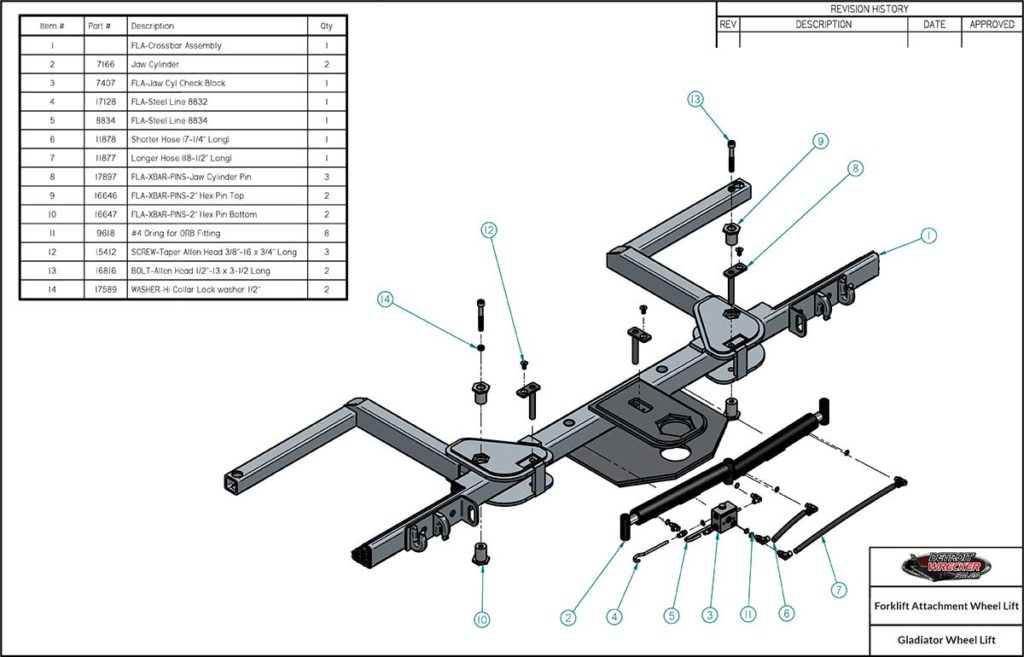

#8 Detroit Wrecker Sales

Domain Est. 2007

Website: detroitwrecker.com

Key Highlights: Detroit Wrecker Sales is the home of The Low Loader rollback carrier and The Little Hercules. We also carry a huge selection of tow tucks parts in our shop….

#9 Wheel Lifts & Towing Systems

Domain Est. 2009

Website: store.batteliniwreckersales.com

Key Highlights: 30-day returnsShop professional wheel lift systems, tow bars, swivel receivers, and towing equipment for wreckers and car carriers. Premium NRC parts and heavy-duty ……

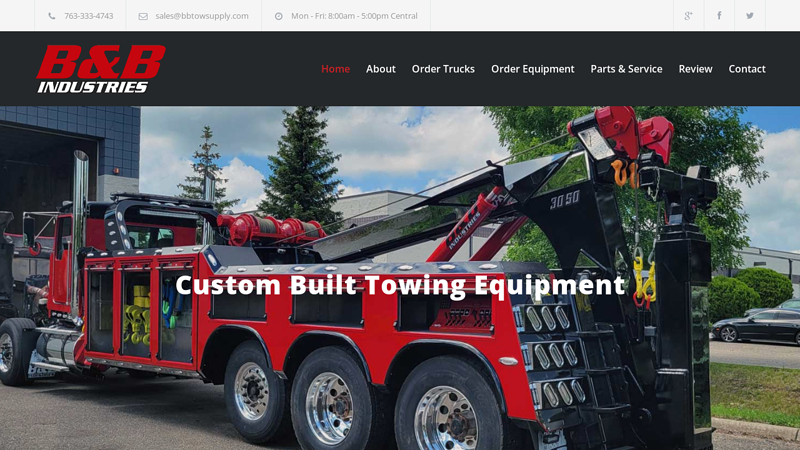

#10 B&B Industries

Domain Est. 2019

Website: bbtowsupply.com

Key Highlights: B&B Industries manufactures the best custom tow trucks and wreckers in the industry….

Expert Sourcing Insights for Tow Truck Wheel Lift Parts

H2: 2026 Market Trends for Tow Truck Wheel Lift Parts

The global market for tow truck wheel lift parts is projected to undergo significant transformation by 2026, driven by technological advancements, increasing demand for vehicle recovery services, and evolving regulatory standards. As the automotive industry adapts to new challenges and innovations, several key trends are expected to shape the landscape of this niche yet critical market segment.

-

Rise in Demand Due to Increased Vehicle Ownership

By 2026, growing vehicle ownership—especially in emerging economies—will lead to higher incidences of roadside breakdowns and accidents, increasing the need for efficient towing services. This, in turn, will drive demand for reliable and durable wheel lift components such as yokes, arms, chains, and hydraulic systems. Urbanization and traffic congestion further amplify the necessity for rapid vehicle recovery, reinforcing the importance of high-performance wheel lift parts. -

Adoption of Lightweight and Corrosion-Resistant Materials

Manufacturers are increasingly shifting toward advanced materials such as high-strength steel alloys, aluminum composites, and polymer-coated components to improve the durability and reduce the weight of wheel lift systems. These materials offer enhanced resistance to corrosion—particularly in regions with harsh weather or road salting practices—thereby extending product lifespan and reducing maintenance costs. By 2026, such innovations are expected to become standard in premium tow truck equipment. -

Integration of Smart Technology and IoT

The trend toward smart towing solutions will influence wheel lift part design. By 2026, expect greater integration of sensors and IoT-enabled monitoring systems into wheel lift assemblies. These technologies will allow real-time diagnostics, load monitoring, and predictive maintenance alerts, improving safety and operational efficiency. For example, smart yokes may include load sensors that prevent overextension or improper attachment, reducing the risk of equipment failure or vehicle damage. -

Focus on Safety and Compliance

Regulatory bodies in North America, Europe, and parts of Asia are tightening safety standards for towing equipment. By 2026, compliance with updated FMVSS (Federal Motor Vehicle Safety Standards) and CE marking requirements will be mandatory for many wheel lift components. This will drive innovation in fail-safe mechanisms, improved locking systems, and enhanced structural integrity testing. Manufacturers will need to prioritize certifications and regular audits to remain competitive. -

Growth in Aftermarket and Replacement Parts

As the average age of tow trucks increases—particularly in developing markets—the aftermarket for replacement wheel lift parts is expected to expand significantly by 2026. Cost-conscious fleet operators will seek high-quality, OEM-compatible components that offer reliability without the premium price tag. This creates opportunities for third-party manufacturers who can deliver value-driven, durable alternatives. -

Sustainability and Circular Economy Initiatives

Environmental concerns are influencing product design and end-of-life management. By 2026, manufacturers may adopt more sustainable production practices, including recyclable materials and modular designs that allow for easy repair and part replacement. Some companies may also launch take-back programs or refurbishment services for used wheel lift assemblies, aligning with broader circular economy goals. -

Regional Market Dynamics

North America and Europe will remain dominant markets due to well-established towing infrastructures and strict safety regulations. However, the Asia-Pacific region—led by countries like India, China, and Indonesia—is expected to witness the highest growth rate, fueled by rapid motorization and infrastructure development. Localized manufacturing and distribution networks will become crucial for companies aiming to capture this emerging demand.

In conclusion, the 2026 market for tow truck wheel lift parts will be characterized by innovation, regulation, and regional diversification. Companies that invest in advanced materials, smart technologies, and sustainable practices will be best positioned to capitalize on growing demand and maintain a competitive edge in this evolving industry.

Common Pitfalls When Sourcing Tow Truck Wheel Lift Parts

Sourcing Tow Truck Wheel Lift Parts requires careful attention to avoid costly mistakes that impact performance, safety, and legal compliance. Two major pitfalls—quality inconsistencies and intellectual property (IP) risks—can significantly undermine operations if not properly managed.

Quality-Related Pitfalls

Inadequate Material Specifications

Many suppliers offer wheel lift components made from substandard steel or alloys that lack the tensile strength required for heavy-duty towing. Using parts that don’t meet industry standards (e.g., ASTM or SAE) increases the risk of component failure during operation, endangering operators and vehicles.

Poor Manufacturing Tolerances

Low-cost manufacturers may cut corners in machining and welding processes, leading to inconsistent fit and alignment. Misaligned yokes, weak weld joints, or improperly threaded rods can cause premature wear or catastrophic failure under load.

Lack of Testing and Certification

Reputable parts should undergo load testing and be certified to relevant safety standards (e.g., ANSI or WreckMaster guidelines). Sourcing from suppliers who cannot provide test reports or third-party certifications exposes fleets to liability and operational downtime.

Inconsistent Coating and Corrosion Protection

Wheel lifts are exposed to harsh environments. Parts with inadequate galvanization or powder coating degrade quickly, leading to rust and structural weakening. Suppliers offering low-cost alternatives often skimp on surface protection, reducing part lifespan.

Intellectual Property (IP) Risks

Counterfeit or Copycat Parts

Many overseas and unauthorized suppliers produce replicas of OEM wheel lift components (e.g., for知名品牌 like Holmes, Century, or Challenger). These knockoffs may infringe on patents, trademarks, or design rights, exposing buyers to legal action, especially in regulated markets.

Voided Warranties and OEM Non-Compliance

Using non-OEM or IP-infringing parts can void manufacturer warranties on the entire towing system. OEMs often specify approved components, and substituting with unlicensed copies may breach service agreements or insurance policies.

Supply Chain Legal Exposure

Purchasing IP-infringing parts—even unknowingly—can result in customs seizures, fines, or lawsuits, particularly in regions with strict IP enforcement (e.g., the U.S. or EU). Buyers may be deemed complicit in trademark or patent violations.

Lack of Traceability and Documentation

IP-compliant suppliers provide detailed documentation, including part numbers, origin, and compliance certificates. Sourcing from vendors who cannot verify the legitimacy of their designs increases the risk of receiving counterfeit goods and complicates liability in case of failure.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Require material test reports and industry certifications.

– Audit suppliers for OEM licensing or IP compliance.

– Prioritize suppliers with proven track records and traceable manufacturing.

– Work with reputable distributors or directly with OEMs when possible.

By focusing on verified quality and respecting intellectual property, fleets can ensure reliable, legal, and safe towing operations.

Logistics & Compliance Guide for Tow Truck Wheel Lift Parts

Overview

This guide outlines essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to tow truck wheel lift parts. Proper management ensures operational efficiency, safety, and legal compliance across supply chain activities.

Product Classification & Specifications

Wheel lift parts include components such as lift arms, yokes, chains, hydraulic cylinders, mounting brackets, and control systems. These parts are typically made from high-strength steel and classified under HS Code 8708.29 (parts and accessories for towing equipment) for import/export purposes. Accurate classification is critical for customs clearance and tariff application.

Packaging & Handling Requirements

Wheel lift parts must be securely packaged to prevent damage during transit. Use wooden crates or heavy-duty cardboard with internal foam or padding for fragile components like hydraulic valves. Label packages with handling instructions (e.g., “Fragile,” “Do Not Stack,” “This Side Up”). Ensure lifting points are accessible and never lift by hydraulic lines or electrical connectors.

Storage Conditions

Store parts in a dry, temperature-controlled environment to prevent corrosion. Metal components should be kept off concrete floors using pallets and treated with rust-inhibiting coatings if stored long-term. Keep hydraulic components sealed and upright to avoid fluid leakage or seal damage. Maintain an organized inventory system with FIFO (First In, First Out) principles.

Transportation Regulations

Transport domestically via flatbed or enclosed freight trailers with proper load securing using straps or chains. Follow FMCSA (Federal Motor Carrier Safety Administration) guidelines for cargo securement (49 CFR Part 393). For international shipments, comply with IMDG Code (if hazardous materials like hydraulic fluid are included) and use IATA standards for air shipments, if applicable.

Import/Export Compliance

Ensure all export documentation includes commercial invoices, packing lists, and certificates of origin. For imports into the U.S., file entry through ACE (Automated Commercial Environment) and comply with CBP (Customs and Border Protection) requirements. Verify if parts require ITAR or EAR classification—most wheel lift components fall under EAR99, meaning they are generally not controlled.

Safety & Regulatory Standards

Wheel lift parts must meet industry safety standards such as those set by the Tow Truck Industry Association (TTIA) and comply with FMVSS (Federal Motor Vehicle Safety Standards) where applicable. Hydraulic systems should adhere to ANSI Z245.1 for mobile equipment safety. Regular inspections and load testing are required to ensure part integrity and operational safety.

Documentation & Traceability

Maintain detailed records including part numbers, serial numbers (if applicable), manufacturing dates, and supplier certifications. Implement a traceability system to support recalls or warranty claims. Certificates of Conformance (CoC) and Material Test Reports (MTRs) should accompany high-stress components like lift arms and mounting hardware.

Environmental & Disposal Compliance

Dispose of damaged or obsolete parts in accordance with EPA and local environmental regulations. Recycle metal components through certified scrap processors. Properly manage disposal of hydraulic fluids and contaminated packaging in line with RCRA (Resource Conservation and Recovery Act) guidelines.

Supplier & Vendor Compliance

Conduct due diligence on suppliers to ensure they comply with ISO 9001 (quality management) and relevant regional standards. Require vendors to provide compliance documentation and adhere to anti-counterfeiting policies. Audit suppliers periodically for ethical labor practices and environmental responsibility.

Conclusion

Effective logistics and compliance management for tow truck wheel lift parts minimizes risk, ensures regulatory adherence, and supports reliable equipment performance. By following this guide, businesses can maintain a safe, efficient, and legally compliant supply chain.

In conclusion, sourcing tow truck wheel lift parts requires careful consideration of quality, compatibility, supplier reliability, and cost-effectiveness. It is essential to partner with reputable suppliers or manufacturers who provide durable, OEM or equivalent-grade components to ensure optimal performance and safety. Conducting thorough research, verifying certifications, and comparing pricing and lead times will help in making informed procurement decisions. Additionally, maintaining strong relationships with trusted vendors supports long-term operational efficiency and minimizes downtime. By prioritizing these factors, fleet operators and towing services can secure reliable wheel lift parts that enhance equipment functionality and extend service life.