The global trailer hitch and towing accessories market is experiencing steady expansion, driven by rising demand from automotive, off-road, and recreational vehicle sectors. According to Grand View Research, the global trailer hitch market was valued at USD 6.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by increasing vehicle customization, rising off-road vehicle adoption, and a surge in consumer preference for DIY outdoor adventure travel—all of which emphasize the need for reliable towing and recovery solutions. As a critical component in off-road recovery systems, tow hitch recovery points have become essential for vehicle safety and performance in rugged conditions. With the market’s upward trajectory, several manufacturers have emerged as leaders in producing high-strength, durable recovery points that meet rigorous industry standards. The following analysis identifies the top 8 tow hitch recovery point manufacturers shaping this niche but vital segment of the automotive aftermarket.

Top 8 Tow Hitch Recovery Point Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 What is the consensus on Subaru factory recovery points/tow hooks?

Domain Est. 2003

Website: subaruoutback.org

Key Highlights: Rhino USA Shackle hitch receiver with ¾” d-ring is one of the safest and most effective ways to connect your tow strap, kinetic rope, or snatch ……

#2 Teton Workshop Receiver Hitch Recovery Point

Domain Est. 2016

Website: 4runnerlifestyle.com

Key Highlights: In stock Free deliveryReceiver hitch recovery point for 2″ receivers. Designed for use with soft shackles, a wider opening giving a nice recovery point on the rear of the vehicle ….

#3 Soft Shackle Hitch Recovery Point

Domain Est. 2021

Website: range-industries.com

Key Highlights: 2″ hitch soft shackle recovery point – CNC machined from aircraft grade 6061-T6 aluminum. Matte Black Type III hard anodize per MIL-A-8625 for superior wear …Missing: tow manufa…

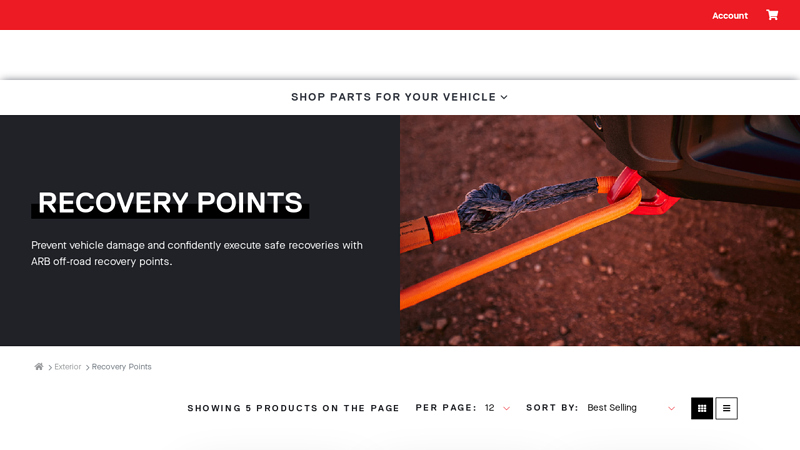

#4 Recovery Point Hooks – Front & Hitch

Domain Est. 1998

Website: store.arbusa.com

Key Highlights: Recovery Points. Prevent vehicle damage and confidently execute safe recoveries with ARB off-road recovery points….

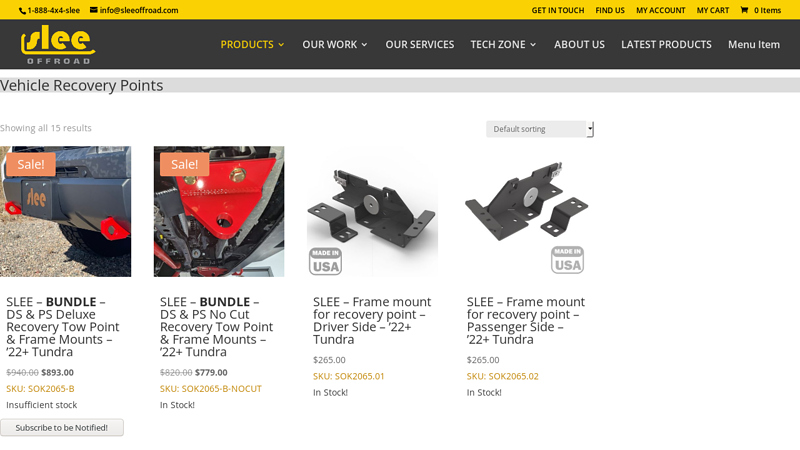

#5 Vehicle Recovery Points

Domain Est. 1999

Website: sleeoffroad.com

Key Highlights: 15-day returnsSLEE – BUNDLE – DS & PS No Cut Recovery Tow Point & Frame Mounts – ’22+ Tundra. $820.00 Original price was: $820.00. $779.00 Current price is: $779.00….

#6 B&W Trailer Hitches

Domain Est. 2011

Website: bwtrailerhitches.com

Key Highlights: B&W – American made hitches featuring the Turnoverball Gooseneck Hitch, Companion Fifth Wheel Hitch, Tow & Stow Adjustable Ball Mount, and Continuum Weight ……

#7 5 1/4 Tons 10500lbs Heavy Duty Recovery Hitch Point 3/4″ Shackle …

Domain Est. 2013

Website: speedmaster79.com

Key Highlights: Free delivery over $100 30-day returnsSpeedmaster recovery hitch point is fitted with a 4.75 tonne quality bow shackle. Perfect for those vehicles who have trouble mounting rear re…

#8 Recovery Hard Parts

Domain Est. 2023

Website: carbonoffroadusa.com

Key Highlights: 5-day deliveryCarbon Offroad MegaPro Tow Hitch 5000kg – Tow Bar Mounted Recovery Hitch $59.00. The Carbon Offroad MegaPro Tow Hitch Receiver Recovery Point is a premium ……

Expert Sourcing Insights for Tow Hitch Recovery Point

H2: 2026 Market Trends for Tow Hitch Recovery Points

The market for tow hitch recovery points is poised for significant evolution by 2026, driven by converging trends in off-road vehicle popularity, vehicle technology, safety regulations, and consumer preferences. While tow hitches are primarily designed for towing, their increasing use as recovery points highlights a critical niche market shaped by practicality, cost, and accessibility. Here’s an analysis of the key trends expected to define this segment in 2026:

1. Surge in Off-Roading and Overlanding Drives Demand

The continued rise in off-road and overlanding activities—fueled by post-pandemic outdoor recreation trends and social media influence—will directly increase the need for reliable recovery solutions. As more consumers modify pickup trucks, SUVs, and even electric off-roaders for trail use, the tow hitch offers a convenient, factory-installed anchor point for recovery straps or synthetic winch lines. This trend will sustain strong demand for hitch-based recovery accessories, especially among budget-conscious adventurers.

2. Integration with Electric and Hybrid 4×4 Platforms

By 2026, electric trucks and SUVs (e.g., Rivian, Ford F-150 Lightning, Chevrolet Silverado EV) will represent a growing share of off-road-capable vehicles. These models often feature robust tow ratings and standardized Class III/IV hitches, making them viable recovery points. However, manufacturers may impose stricter guidelines due to complex underbody components. Expect OEMs and aftermarket brands to develop certified hitch-mounted recovery kits specifically engineered for EV platforms, emphasizing load rating transparency and electrical safety.

3. Emphasis on Safety and Certification Standards

Incidents involving improper use of tow hitches for recovery (e.g., hitch failure, vehicle damage) will push regulatory bodies and insurers to advocate for clearer standards. The market will likely see increased adoption of recovery-rated hitches marked with WLL (Working Load Limit) and certifications from organizations like SAE or D.O.T. Aftermarket brands will respond with reinforced hitch receivers, recovery-specific shackle mounts (e.g., MaxxTow, CURT Off-Road), and educational campaigns promoting safe recovery practices.

4. Growth of the Aftermarket Accessory Ecosystem

The tow hitch recovery point will remain a cornerstone of the broader off-road accessory market. By 2026, expect innovation in modular hitch-mounted systems—such as multi-functional receiver tubes that support recovery shackles, winch mounts, and storage solutions. Compatibility with popular recovery gear (e.g., ARB, X-Bull) will be a key selling point, driving partnerships between hitch manufacturers and recovery equipment brands.

5. Sustainability and Material Innovation

Environmental concerns will influence material choices. Lightweight, high-strength alloys and corrosion-resistant coatings (e.g., ceramic or eco-friendly zinc finishes) will gain favor to improve durability and reduce environmental impact. Recyclability of steel and aluminum components may become a differentiating factor for eco-conscious consumers and fleet operators.

6. Digital Integration and Smart Recovery Solutions

Though still emerging, smart recovery tools may begin integrating with vehicle telematics by 2026. While not directly part of the tow hitch, companion apps could assess hitch load capacity based on vehicle model and usage history, providing real-time safety alerts during recovery operations. This trend will enhance user confidence and reduce misuse.

Conclusion

By 2026, the tow hitch recovery point will remain a pragmatic and widely adopted solution, particularly as off-roading becomes more mainstream. Success in this market will depend on balancing convenience with safety, driven by certified products, education, and innovation tailored to new vehicle technologies—especially electric platforms. Manufacturers and retailers who prioritize safety compliance, compatibility, and consumer trust will lead the evolving landscape of hitch-based recovery solutions.

Common Pitfalls Sourcing Tow Hitch Recovery Point (Quality, IP)

Sourcing a Tow Hitch Recovery Point involves critical considerations around quality and intellectual property (IP). Overlooking these aspects can lead to safety risks, legal issues, and supply chain disruptions. Below are common pitfalls to avoid:

Poor Material and Manufacturing Quality

Many low-cost suppliers use substandard steel alloys or inadequate heat treatment, resulting in recovery points that may fail under load. Look for products made from high-tensile steel (e.g., Grade 8 or above) with proper welding and surface finish. Lack of third-party testing or certifications (such as CE, ISO 9001, or load-rated validation) is a red flag.

Inadequate Load Rating and Testing Documentation

Some suppliers provide exaggerated or unverified load ratings without supporting test data. Always request certified proof of dynamic and static load testing. A genuine recovery point should have a clear working load limit (WLL) and safety factor (typically 3:1 or higher) documented by an accredited lab.

Misalignment with Vehicle Specifications

Generic or “universal fit” recovery points may not align precisely with specific vehicle tow hitch dimensions or chassis mounting points. This can cause stress concentration, improper fitment, or interference with other components. Ensure the design matches OEM specifications for the target vehicle model.

Intellectual Property (IP) Infringement Risks

Copying patented recovery point designs—especially those integrated into branded aftermarket bumpers or OEM systems—can lead to legal action. Avoid suppliers offering look-alike products that mimic proprietary mounting systems or patented geometries without licensing. Conduct IP due diligence, including patent searches in relevant markets (e.g., USPTO, EPO).

Lack of Traceability and Compliance

Products without batch traceability, material certifications (e.g., mill test reports), or compliance with regional safety standards (e.g., ADR in Australia, FMVSS in the U.S.) pose sourcing risks. Non-compliant parts may be blocked at customs or recalled, disrupting operations.

Insufficient Corrosion Protection

Recovery points are exposed to harsh environments. Suppliers using thin powder coating or inadequate plating (e.g., low-grade zinc) risk premature rust and structural degradation. Specify durable finishes like Dacromet, zinc-nickel plating, or high-quality powder coating with salt spray test results (e.g., 500+ hours).

Overlooking Design for Manufacturability (DFM)

Complex geometries or tight tolerances may lead to high defect rates or production delays. Work with suppliers who provide DFM feedback and can consistently produce parts with minimal rework. Poor weld penetration or inconsistent thread quality are common defects.

Failure to Secure IP Ownership in Custom Designs

When developing a custom recovery point, ensure contracts clearly assign IP rights to your company. Ambiguous agreements may leave you without control over tooling, drawings, or the ability to switch manufacturers, creating long-term dependency and risk.

Avoiding these pitfalls requires thorough supplier vetting, technical due diligence, and clear contractual terms protecting both quality and intellectual property rights.

Logistics & Compliance Guide for Tow Hitch Recovery Point

Overview

A Tow Hitch Recovery Point is a specialized attachment designed to enable safe vehicle recovery using the tow hitch. It must balance strength, durability, and regulatory compliance to ensure operational safety during off-road or emergency recovery scenarios.

Regulatory Compliance Requirements

- DOT and FMVSS Standards: Ensure the recovery point complies with U.S. Department of Transportation (DOT) and Federal Motor Vehicle Safety Standards (FMVSS) regarding vehicle modifications and towing equipment.

- SAE J684 Certification: Verify that the recovery point meets SAE J684 standards for strength and performance of towing components.

- Vehicle Manufacturer Specifications: Confirm compatibility with the vehicle’s OEM tow hitch rating. Installation must not void the manufacturer’s warranty or exceed gross trailer weight rating (GTWR).

- International Standards (if applicable): For cross-border logistics, ensure compliance with regional regulations such as ECE R55 (Europe) or ADR (Australia).

Material and Construction Standards

- Grade Materials: Use high-strength steel (e.g., ASTM A572 or equivalent) with minimum yield strength of 50,000 psi.

- Finish and Corrosion Resistance: Apply zinc plating, powder coating, or similar protective finishes to resist rust and environmental degradation.

- Load Rating: Clearly mark the recovery point with its maximum working load limit (WLL), typically rated at 1/3 of ultimate tensile strength (UTS). Minimum WLL should support at least 10,000 lbs for light to medium-duty vehicles.

Installation Guidelines

- Torque Specifications: Follow manufacturer-recommended torque values when securing hitch bolts. Use thread-locking compounds where specified.

- Alignment: Ensure the recovery point is centered and aligned with the vehicle’s longitudinal axis to prevent uneven stress during recovery.

- Hardware: Use Grade 8.8 or higher metric or SAE-grade bolts, washers, and locking mechanisms. Replace OEM hardware if required for secure fitment.

Operational Safety Protocols

- Inspection Before Use: Check for cracks, deformation, or wear prior to each recovery operation.

- Angle of Pull: Limit recovery pulls to within 30 degrees of horizontal to avoid side-loading the tow hitch.

- Use of Recovery Accessories: Employ rated recovery straps, shackles (minimum 3/4” diameter, Grade 100), and dampening blankets to mitigate snap-back hazards.

- No Dynamic Loading: Avoid kinetic or “snatch” recovery methods unless the tow hitch and recovery point are explicitly rated for such use.

Logistics and Handling

- Packaging: Ship recovery points in protective packaging to prevent damage during transit. Include all mounting hardware and installation instructions.

- Storage Conditions: Store in a dry, temperature-controlled environment to prevent corrosion. Avoid prolonged outdoor exposure.

- Labeling: Clearly label each unit with model number, load rating, compliance certifications, and country of origin for customs and inventory tracking.

Documentation and Traceability

- Certificates of Conformance (CoC): Provide CoC with each shipment, confirming compliance with referenced standards.

- User Manual: Include detailed installation, usage, and safety instructions in multiple languages if distributed internationally.

- Batch Tracking: Maintain lot or serial number traceability for quality control and recall readiness.

Environmental and Disposal Considerations

- Recyclability: Design for end-of-life recyclability using standardized, separable materials.

- Hazardous Substances: Comply with RoHS and REACH regulations by avoiding restricted substances in coatings or plating.

Training and Support

- Distributor Training: Offer technical training for installation and safety best practices.

- Customer Support: Provide accessible support for compliance questions, warranty claims, or incident reporting.

Adherence to this guide ensures safe, legal, and efficient deployment of Tow Hitch Recovery Points across logistics and field operations.

Conclusion: Sourcing a Tow Hitch Recovery Point

In conclusion, sourcing a tow hitch recovery point requires careful consideration of compatibility, strength, material quality, and compliance with safety standards. It is essential to select a recovery point specifically designed for use with your vehicle’s tow hitch class and rated to handle the loads associated with off-road recovery—typically exceeding the vehicle’s gross vehicle weight (GVW). Durable materials such as forged steel and corrosion-resistant finishes ensure longevity and reliability in harsh environments. Additionally, prioritizing products with recognized certifications and positive user feedback helps guarantee performance and safety. By choosing a reputable supplier and verifying product specifications, you can ensure that your tow hitch recovery point provides a secure and effective solution for emergency vehicle recovery, enhancing both safety and off-road capability.