The global watchmaking industry is experiencing steady transformation, driven by rising demand for precision instruments, luxury timepieces, and advancements in both mechanical and smartwatch technologies. According to a 2023 report by Mordor Intelligence, the global watch market was valued at USD 63.73 billion in 2022 and is projected to grow at a CAGR of 7.3% from 2023 to 2028. This growth is fueled by increasing disposable incomes, a resurgence in appreciation for Swiss craftsmanship, and expanding e-commerce channels that connect niche manufacturers with global audiences. As competition intensifies, watchmaker manufacturers are increasingly reliant on advanced tools—ranging from CNC lathes and laser welders to micro oiling systems and digital timing analyzers—to maintain precision, efficiency, and innovation. In this evolving landscape, the adoption of specialized tooling solutions has become a critical differentiator for manufacturers aiming to balance traditional horological artistry with modern production demands. The following list highlights the top 10 tools essential to today’s leading watchmaker manufacturers, underpinned by industry trends and market insights.

Top 10 Tools Watchmaker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Watchmaker

Domain Est. 1999

Website: thewatchmaker.com

Key Highlights: With nearly 40 years of expertise, The Watchmaker delivers factory-level service to Swiss standards, using advanced equipment and rigorous processes to restore …Missing: tools m…

#2

Domain Est. 1997 | Founded: 1953

Website: beco-technic.com

Key Highlights: Beco Technic GmbH – Technology for watchmakers and goldsmiths since 1953. Your specialist for tools, consumables, workshop equipment and after-sales service ……

#3 Watchmaker Tools, Bergeon

Domain Est. 2020

Website: watchmakershop.com

Key Highlights: In our online shop “WatchmakerShop.com”, you will be able find amazing watchmaker tools from world class leading manufacturers: Bergeon, Boley, Horotec, Dumont ……

#4 Watchmaker Tools

Domain Est. 1997

Website: esslinger.com

Key Highlights: Browse our large selection of watch repair tools to find the exact watchmaker tool needed for your specific watchmaking needs. Tool offerings include watch ……

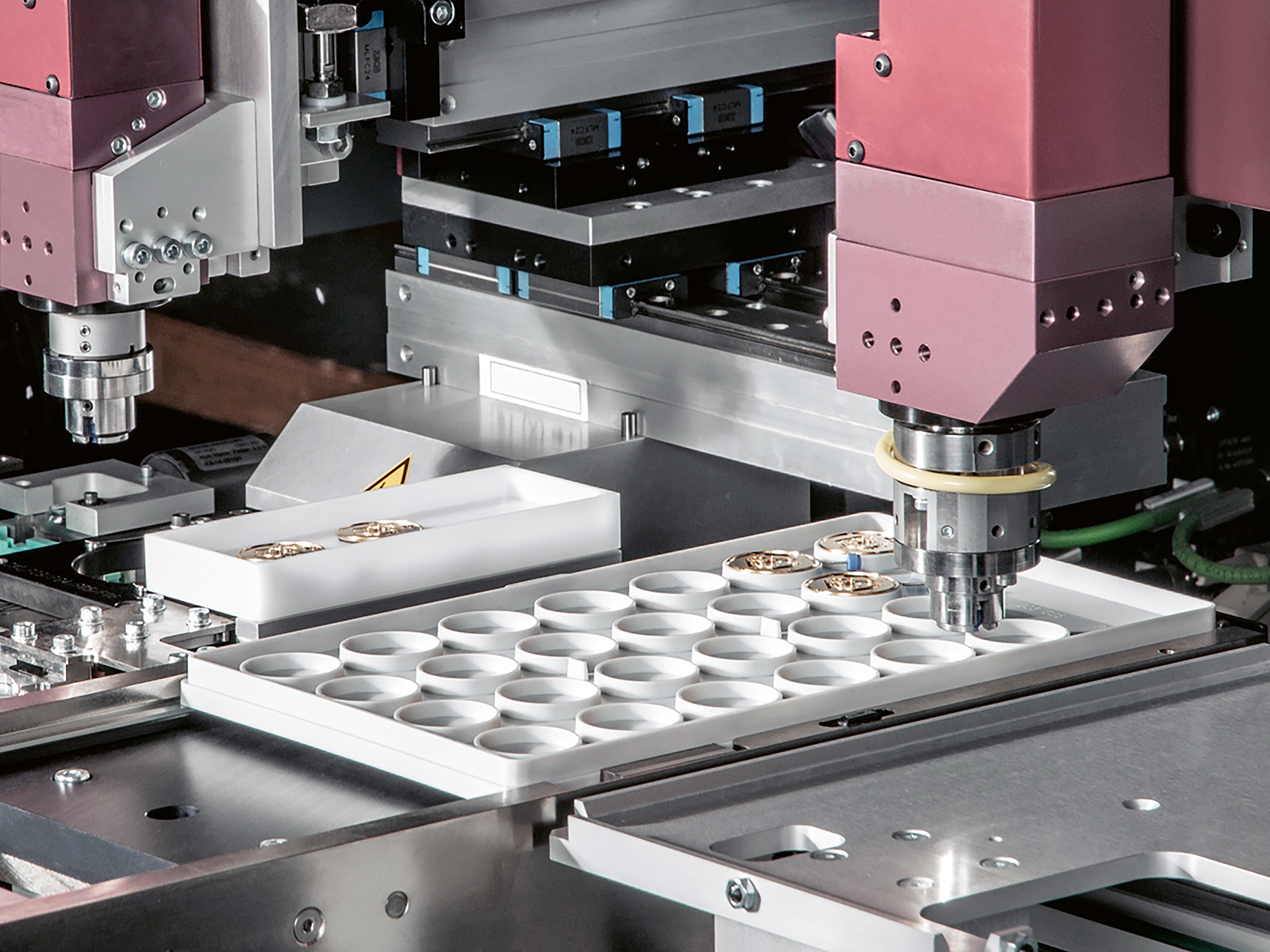

#5 WATCHMAKING

Domain Est. 2001

Website: willemin-macodel.com

Key Highlights: Our range of high-precision machine-tools designed for the watchmaking industry is the result of expertise and experience acquired by Willemin-Macodel over ……

#6 McCaw Company

Domain Est. 2006 | Founded: 1913

Website: mccawcompany.com

Key Highlights: 4-day delivery 30-day returnsMcCaw Company: Supplier to the Jeweler, Watchmaker and Hobbyist since 1913….

#7 Shop Bergeon

Domain Est. 2016

Website: bergeon.swiss

Key Highlights: Tools for movement, support, movement holder, escapement, adjustment, tool kit · 03. Tool for strap, case, crystal, dial and hand · 04. Ultrasound, cleaning ……

#8 BeWatchmaker

Domain Est. 2022

Website: bewatchmaker.com

Key Highlights: Are you a watchmaking enthusiast? Discover the only 100% Swiss made kits on the market, adapted to all levels and made by specialists….

#9 watch tool

Website: watch-tools.de

Key Highlights: Europe’s biggest online watchmaker tool & watch winder shop. 98% immediately available – we have over 34.000 items on stock. Shopping 24 hours – 365 days….

#10 Watch Industry

Website: brw.ch

Key Highlights: Brütsch/Rüegger Tools acquired the watchmaking tools division of AF Switzerland SA in 2020 and has since ensured the marketing and further development of its ……

Expert Sourcing Insights for Tools Watchmaker

H2 2026 Market Trends for Tools Watchmaker

As we look ahead to the second half of 2026, the market for tools used by professional watchmakers and precision artisans is undergoing significant transformation, driven by technological innovation, evolving consumer preferences, and shifts in global supply chains. Here’s a breakdown of the key trends shaping the Tools Watchmaker industry in H2 2026:

1. Rise of Smart and Connected Tools

Watchmaker tools are increasingly integrating digital capabilities. Devices such as smart loupes with AR overlays, connected screwdrivers that log torque data, and IoT-enabled timing machines are gaining traction. These tools enhance precision, streamline diagnostics, and allow for real-time performance tracking and maintenance logging—especially valuable in high-end restoration and service centers.

2. Demand for Modular and Multi-Functional Toolkits

With rising workspace efficiency needs and the popularity of independent watchmakers, there is strong demand for modular tool systems. In H2 2026, manufacturers are focusing on customizable, compact kits that adapt to a wide range of calibers and complications. Magnetic screw trays with digital inventory tracking and interchangeable tip systems are becoming industry standards.

3. Sustainability and Ethical Sourcing

Environmental responsibility is influencing material choices. Watch tool brands are shifting toward recyclable metals, bio-based polymers, and conflict-free sourcing. Tools with longer lifespans, repairable components, and take-back programs are gaining favor—especially among European and North American professionals responding to regulatory and consumer pressure.

4. Growth in Micro-Innovation and Niche Tools

As haute horlogerie expands, so does demand for hyper-specialized tools. Examples include nano-polishing kits for modern ceramic cases, anti-magnetic tweezers for silicon components, and micro-adjustment tools for high-frequency escapements (e.g., 10 Hz+ movements). The independent watchmaking community is a key driver here, fueling a cottage industry of artisan toolmakers.

5. Expansion of E-Commerce and Direct-to-Consumer (DTC) Models

Traditional distributors are being challenged by DTC platforms offering global shipping, educational content, and community engagement. Brands are investing in subscription-based tool updates, virtual training via app integration, and 3D-printed custom accessories—creating new revenue streams and brand loyalty.

6. AI-Assisted Tool Design and Training

Artificial intelligence is beginning to influence tool development. Simulation software helps optimize tool ergonomics and material stress points, while AI-driven training apps guide users through complex servicing procedures using real-time visual feedback. This lowers the learning curve for new watchmakers and increases precision across skill levels.

7. Geopolitical Shifts and Supply Chain Resilience

Ongoing supply chain diversification—accelerated by past disruptions—is pushing tool manufacturers to localize production in regions like Eastern Europe, Southeast Asia, and Mexico. This reduces lead times and import dependencies, particularly for precision-machined components such as arbors, pegwood holders, and balance truing calipers.

Conclusion:

In H2 2026, the Tools Watchmaker market is defined by smart integration, sustainability, and specialization. Watchmakers are no longer just buying tools—they are investing in intelligent, durable, and eco-conscious systems that support both craftsmanship and efficiency. Brands that embrace connectivity, modular design, and ethical manufacturing are best positioned to lead in this dynamic landscape.

Common Pitfalls When Sourcing Tools for Watchmakers (Quality and Intellectual Property)

Sourcing high-precision tools for watchmaking requires careful consideration, as missteps can compromise product quality, brand reputation, and legal compliance. Below are key pitfalls related to quality and intellectual property (IP) to avoid.

Inadequate Tool Quality and Precision

Watchmaking demands micron-level accuracy. Sourcing substandard tools leads to inconsistent craftsmanship, increased error rates, and damage to delicate components. Common issues include poor material selection (e.g., using low-grade steel that wears quickly), imprecise machining tolerances, and lack of calibration. Tools that don’t meet ISO or industry-specific standards can result in malfunctioning timepieces and costly rework.

Lack of Supplier Verification and Traceability

Without thorough vetting, buyers risk engaging suppliers who outsource production to unqualified subcontractors or falsify certifications. This lack of traceability increases the likelihood of receiving counterfeit or inferior tools. Always validate supplier credentials, request material test reports, and conduct on-site audits when possible to ensure consistent quality and manufacturing integrity.

Ignoring Intellectual Property (IP) Rights

Many precision watchmaking tools—such as specialized jacks, winding machines, or case openers—carry patented designs or are protected under industrial design rights. Sourcing generic copies or unlicensed replicas can expose your business to legal action, especially in jurisdictions with strong IP enforcement like Switzerland, Germany, or the U.S. Always confirm that tools do not infringe on existing patents or trademarks.

Purchasing Counterfeit or “Clone” Tools

The market is flooded with imitation tools marketed as equivalents to premium brands (e.g., Bergeon, Horotec, or Berthieu). While cheaper, these clones often lack durability and precision. More critically, they may violate IP laws, leading to customs seizures, fines, or reputational damage. Avoid suppliers offering “exact copies” or suspiciously low prices without proper documentation.

Overlooking Compliance with Regional Standards

Different regions have tool certification requirements (e.g., CE marking in Europe, ANSI standards in the U.S.). Tools that don’t meet these standards may be restricted from import or use in professional environments. Ensure sourced tools comply with local regulations to avoid logistical delays and legal complications.

Failure to Secure Licensing for Proprietary Tool Designs

If sourcing tools designed for a specific brand or movement (e.g., Rolex-specific case tools), verify whether usage rights or licenses are required. Unauthorized production or distribution of such tools can lead to IP disputes, even if the tool itself is not branded. Partner with suppliers who can provide proof of licensing or design freedom.

Conclusion

To mitigate risks, establish a sourcing protocol that includes quality audits, IP due diligence, and compliance checks. Building relationships with reputable, transparent suppliers ensures both the precision required in horology and legal safety in tool acquisition.

Logistics & Compliance Guide for Tools Watchmaker

This guide outlines essential logistics and compliance considerations for the Tools Watchmaker business, ensuring efficient operations and adherence to legal, safety, and industry standards.

Supply Chain Management

Establish reliable relationships with suppliers of precision tools, components, and packaging materials. Prioritize vendors who comply with international quality standards such as ISO 9001. Implement a vendor qualification process to verify reliability, lead times, and adherence to ethical sourcing practices. Maintain inventory records using a just-in-time (JIT) or lean inventory model to minimize storage costs while ensuring availability of critical tools.

Import and Export Regulations

Comply with customs regulations when sourcing tools or materials internationally. Ensure accurate product classification using Harmonized System (HS) codes, and maintain proper documentation such as commercial invoices, packing lists, and certificates of origin. Be aware of export controls, especially when shipping precision instruments that may be subject to dual-use regulations (e.g., items with potential military applications). Engage a licensed customs broker if necessary to facilitate smooth clearance.

Product Safety and Certification

Ensure all tools meet relevant safety standards for their intended market (e.g., CE marking for the EU, FCC for the U.S. if applicable, or RoHS compliance for hazardous substances). Tools involving electrical components or lasers must undergo appropriate testing and certification. Maintain technical documentation and conformity declarations to demonstrate compliance during audits or inspections.

Packaging and Labeling Requirements

Design packaging to protect delicate watchmaking tools during transit. Use anti-static and shock-absorbent materials where necessary. Labels must include essential information such as product identification, country of origin, safety warnings, and compliance marks. For international shipments, include multilingual labeling if required by destination country regulations.

Shipping and Distribution

Partner with logistics providers experienced in handling high-value, low-weight precision goods. Use tracked and insured shipping methods to mitigate loss or damage risks. Clearly define delivery timelines and service level agreements (SLAs). Offer customers options for express or standard delivery while remaining transparent about costs and estimated arrival times.

Regulatory Compliance (General)

Stay updated on trade sanctions, embargoes, and restricted party lists (e.g., OFAC, EU Consolidated List). Conduct regular compliance audits and train staff on anti-bribery laws (such as the U.S. Foreign Corrupt Practices Act or UK Bribery Act) and data protection regulations (e.g., GDPR for EU customer data). Implement internal controls to prevent violations.

Warranty and Returns Management

Establish a clear returns policy compliant with consumer protection laws in your operating regions (e.g., 14-day right of withdrawal under EU law). Process warranty claims efficiently, documenting defects and repair actions. Ensure returned tools are inspected, sanitized, and either repaired, replaced, or refunded as per policy.

Environmental and Sustainability Compliance

Adhere to environmental regulations regarding waste disposal, particularly for electronic components or hazardous materials. Where possible, use recyclable or biodegradable packaging. Comply with WEEE (Waste Electrical and Electronic Equipment) directives if applicable. Communicate sustainability efforts transparently to customers to build brand trust.

Recordkeeping and Audits

Maintain comprehensive records of shipments, compliance certifications, supplier agreements, and customer transactions for a minimum of seven years. These records support audit readiness and regulatory inquiries. Conduct annual internal compliance reviews to identify and correct gaps proactively.

Training and Continuous Improvement

Provide regular training for staff on logistics procedures, compliance updates, and customer service standards. Encourage feedback from customers and partners to refine logistics performance and compliance practices continuously. Stay informed about evolving regulations in the precision tools and horology sectors.

Conclusion: Sourcing Tools for Watchmakers

Sourcing the right tools is a critical factor in ensuring precision, efficiency, and quality in watchmaking. Whether you are a seasoned horologist or an emerging artisan, selecting high-quality, specialized tools from reliable suppliers directly impacts the accuracy and durability of timepiece assembly, repair, and maintenance. The market offers a wide range of options—from hand tools like screwdrivers, tweezers, and poising tools, to advanced equipment such as timing machines, ultrasonic cleaners, and lathe attachments.

Effective sourcing involves balancing cost, quality, and authenticity. Purchasing from reputable suppliers, whether direct manufacturers like Bergeon, Esslinger, or Cousins UK, or trusted distributors, ensures authenticity and after-sales support. Additionally, considering factors like tool material, ergonomic design, and calibration accuracy is essential for long-term performance.

In an era where both traditional craftsmanship and modern technology coexist, investing in the right tools enhances both productivity and professional credibility. Ultimately, a well-curated toolkit, sourced thoughtfully and maintained diligently, is a watchmaker’s most valuable asset—laying the foundation for excellence in the intricate art of horology.