The global basement waterproofing and sump pump market is experiencing steady growth, driven by rising infrastructure development, increasing urbanization, and heightened awareness of flood prevention in residential and commercial buildings. According to Grand View Research, the global sump pump market size was valued at USD 1.03 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is further fueled by extreme weather events and the need for reliable water management systems in below-grade constructions. As demand for durable and efficient toilet sump pump solutions rises—particularly in flood-prone and high-water-table regions—manufacturers are innovating with advanced wastewater handling capabilities tailored for basement installations. In this competitive landscape, a handful of companies have emerged as leaders, combining engineering excellence, energy efficiency, and reliability. Based on performance metrics, market presence, and customer reviews, here are the top 5 toilet sump pump basement manufacturers shaping the industry today.

Top 5 Toilet Sump Pump Basement Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Liberty Pumps

Website: libertypumps.com

Key Highlights: Liberty Pumps, is a leading pump manufacturer producing high-quality waste water pumps, sewage pumps and sump pumps – designed for commercial and residential…

#2 Barnes Residential Wastewater Pump

Domain Est. 1996

Website: cranepumps.com

Key Highlights: Sump pumps are instrumental in preventing basement flooding by efficiently removing accumulated water, safeguarding homes against potential water damage….

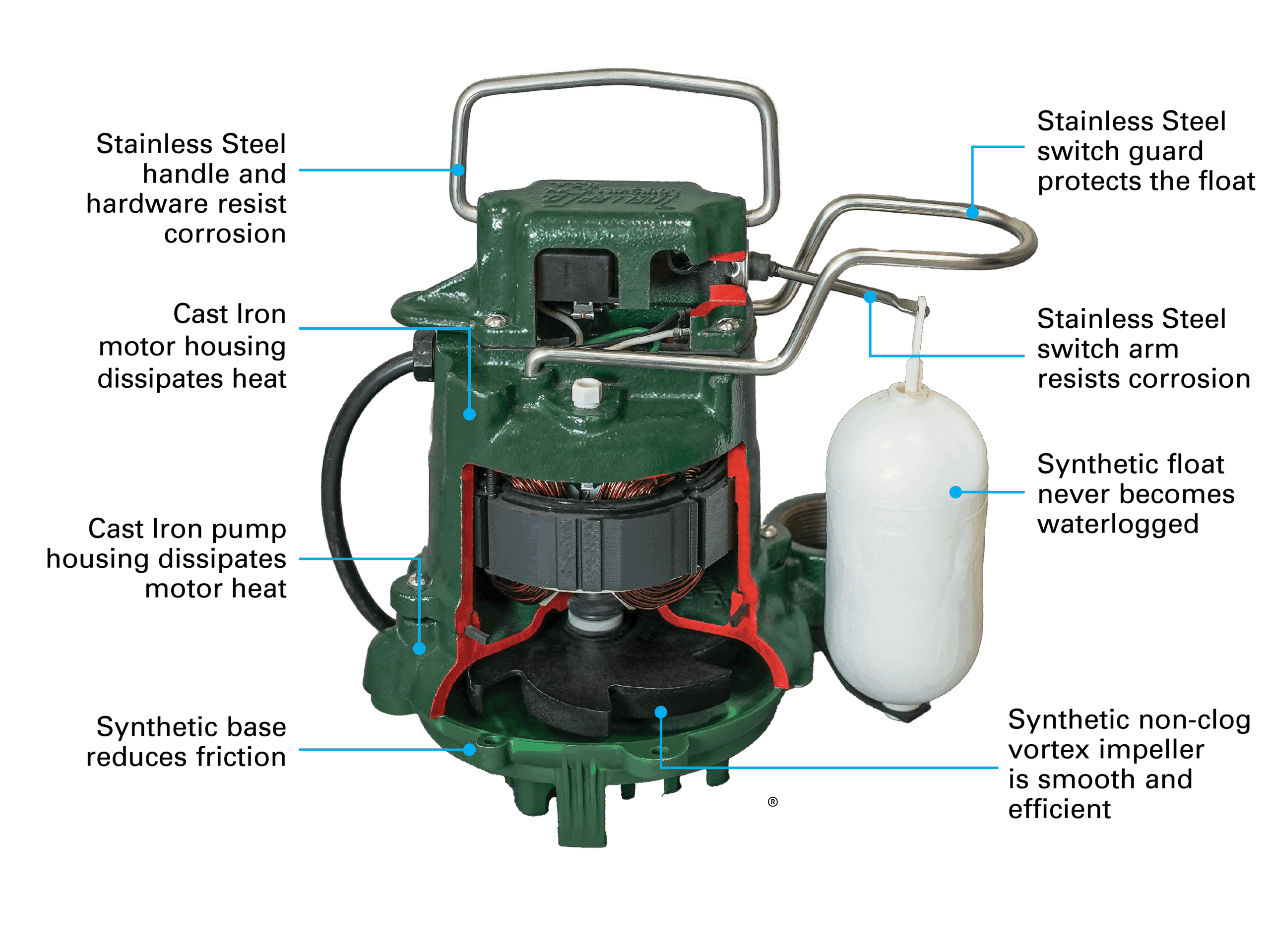

#3 Zoeller Pump Company

Domain Est. 1999

Website: zoellerpumps.com

Key Highlights: The best-in-class 3/10 HP Zoeller M63 automatic Sump Pump is designed to remove groundwater from basement sump applications….

#4 Myers Submersible Effluent Sump & Sewage Pumps

Domain Est. 2000

#5 Zoeller At

Domain Est. 2018

Website: zoellerathome.com

Key Highlights: Keep your basement dry and protected with the 1099-0001 3/4 HP Dual Switch Submersible Sump Pump. Built tough for reliable performance and peace of mind….

Expert Sourcing Insights for Toilet Sump Pump Basement

H2: 2026 Market Trends for Toilet Sump Pump Basement

The market for basement toilet sump pumps is poised for significant transformation by 2026, driven by technological innovation, increasing urbanization, and growing consumer awareness about home resilience and flood prevention. Below are key trends shaping the industry:

1. Rising Demand Due to Climate-Related Flooding

With climate change intensifying extreme weather events, basement flooding has become more frequent in residential areas. This has led homeowners and builders to prioritize waterproofing solutions, including reliable toilet sump pump systems. By 2026, demand is expected to surge, particularly in flood-prone regions across North America and Europe.

2. Integration of Smart Technology

Smart sump pumps equipped with Wi-Fi connectivity, real-time monitoring, and mobile alerts are gaining traction. By 2026, a growing share of toilet sump pump installations will feature IoT-enabled systems that notify homeowners of water levels, pump performance, and maintenance needs. This shift enhances reliability and reduces the risk of basement damage.

3. Growth in Basement Conversions and Finished Living Spaces

As housing affordability pushes homeowners to maximize existing square footage, there’s a rising trend of converting basements into livable areas—such as home offices, gyms, or guest suites. These renovations often include full bathroom installations, increasing the need for specialized toilet sump pumps capable of handling blackwater and maintaining hygiene standards.

4. Emphasis on Energy Efficiency and Sustainability

Manufacturers are responding to eco-conscious consumers by developing energy-efficient sump pumps with longer lifespans and lower power consumption. By 2026, green building certifications (such as LEED) and energy efficiency standards are expected to influence product design and consumer purchasing decisions.

5. Regulatory and Building Code Changes

Building codes in many regions are evolving to require backup sump pump systems and improved drainage solutions in new constructions. These regulations are expected to boost market growth, especially for systems that include battery backups or water-powered auxiliary pumps for uninterrupted operation during power outages.

6. Expansion of Online Sales and Direct-to-Consumer Models

E-commerce platforms and home improvement retailers are increasingly offering comprehensive sump pump kits, including macerating toilets and compact pump units. By 2026, DIY installation options supported by detailed online guides and video tutorials will broaden market accessibility and reduce reliance on professional installers.

7. Competitive Landscape and Innovation

Major players such as Zoeller, Liberty Pumps, and SFA Saniflo are investing in R&D to improve pump durability, noise reduction, and ease of maintenance. The market will see increased competition, driving innovation and lowering prices for consumers.

In conclusion, the 2026 market for toilet sump pump basement systems will be defined by smarter, more resilient, and user-friendly solutions. Driven by environmental, technological, and regulatory factors, the industry is set for steady growth, with a focus on reliability, sustainability, and integration into modern smart homes.

Common Pitfalls When Sourcing a Toilet Sump Pump for Basement Installations

Poor Quality Construction

One of the most frequent issues when sourcing a basement toilet sump pump is selecting a unit made with substandard materials. Many low-cost models use plastic housings and impellers that degrade quickly when exposed to wastewater and continuous operation. These pumps often fail prematurely due to motor burnout or clogging from inadequate grinding mechanisms. Always verify that the pump is designed specifically for macerating solid waste, as regular sump pumps are not suitable for toilet effluent.

Inadequate IP (Ingress Protection) Rating

Another critical pitfall is overlooking the IP rating of the sump pump. The IP rating indicates the level of protection against dust and moisture ingress. For basement toilet sump pumps—especially those installed in damp or flood-prone environments—a minimum IP68 rating is recommended. Units with lower IP ratings (e.g., IP64 or below) may not be fully sealed, risking electrical failure or safety hazards when exposed to water. Always confirm the IP rating matches the installation environment to ensure long-term reliability and safety.

Incorrect Pump Capacity and Sizing

Choosing a pump that lacks sufficient head pressure or flow rate can lead to poor performance, especially when discharging waste vertically or over long horizontal runs. Many users underestimate the required pumping height (total dynamic head), resulting in backups or slow evacuation. Ensure the pump is rated to handle both the vertical lift and pipe friction losses for your specific installation.

Lack of Compliance with Local Codes and Standards

Some imported or budget sump pumps may not meet regional plumbing codes or safety standards (e.g., UPC, CE, or ASME A112.3.4). Using non-compliant equipment can void warranties, fail inspections, or create health hazards. Always source pumps that are certified for toilet waste applications in your jurisdiction.

Insufficient Noise Dampening

Basement installations often double as living spaces, making noise a key concern. Cheap sump pumps can be excessively loud during operation due to poor motor insulation or vibration. Look for models designed with noise-reducing features to maintain comfort in nearby rooms.

Absence of Backup or Alarm Systems

Failing to include a battery backup or high-water alarm increases the risk of basement flooding during power outages. Many low-cost pumps lack these critical safety features. Investing in a system with backup capabilities ensures continued operation during emergencies.

Avoiding these pitfalls requires careful evaluation of product specifications, certifications, and real-world performance—not just upfront cost.

Logistics & Compliance Guide for Toilet Sump Pump Basement Installations

Purpose and Scope

This guide outlines the essential logistics and compliance considerations for installing a toilet sump pump system in a basement environment. It ensures adherence to building codes, safety standards, and efficient operational performance while addressing transportation, handling, and regulatory requirements.

Regulatory Compliance Requirements

Plumbing Codes

Compliance with local and national plumbing codes is mandatory. In the United States, installations must adhere to the International Plumbing Code (IPC) or Uniform Plumbing Code (UPC), depending on jurisdiction. Key provisions include:

– Approval of macerating or grinder pumps specifically rated for human waste.

– Proper venting of the discharge system to prevent sewer gas infiltration.

– Installation of backflow prevention devices to protect potable water systems.

Electrical Standards

Electrical components must meet National Electrical Code (NEC) standards:

– Dedicated GFCI-protected circuit for the pump.

– Wiring methods must be rated for damp or wet locations.

– Junction boxes and power connections installed above potential flood levels.

Building Permits and Inspections

– Obtain required permits before installation.

– Schedule inspections after rough-in and prior to final wall closures.

– Maintain documentation of approved products and inspection sign-offs.

Product Selection and Specifications

Pump Type and Capacity

– Use only wastewater or sewage ejector pumps rated for solid-handling (typically 2″ discharge with ≥ ½” solid passage).

– Ensure pump capacity matches anticipated usage (e.g., number of fixtures, peak flow).

– Verify sound rating (< 60 dB recommended for residential basements).

Fixture Compatibility

– Only connect toilets and sometimes bathroom sinks/showers to the sump system.

– Do not connect appliances such as washing machines or dishwashers unless explicitly approved by the manufacturer and code.

Tank and Enclosure Requirements

– Holding tank must be corrosion-resistant (typically polyethylene or fiberglass).

– Lid must be secure and odor-sealed, with accessible service points.

– Clear access for maintenance and pump removal.

Transportation and Handling Logistics

Delivery and Site Access

– Confirm delivery window with installer and site supervisor.

– Ensure clear access path from delivery vehicle to basement location (e.g., staircase width, elevator capacity).

– Protect flooring during equipment transport.

Storage Prior to Installation

– Store pump and components indoors in a dry, temperature-controlled environment.

– Avoid exposure to freezing conditions or direct sunlight.

– Keep packaging intact until installation to prevent damage.

Lifting and Positioning Equipment

– Use appropriate lifting aids (dollies, straps) for heavy tanks and pumps.

– Coordinate team lifts for units over 50 lbs to prevent injury.

Installation Best Practices

Location Planning

– Position the sump basin near the toilet and main stack to minimize pipe runs.

– Ensure adequate clearance for service (minimum 18” around the unit).

– Avoid placing under structural beams or near egress windows.

Piping and Venting

– Use Schedule 40 PVC for discharge lines.

– Maintain minimum 1/4” per foot upward slope in discharge piping.

– Vent line must tie into home’s main vent stack above the flood rim of the highest fixture.

Discharge Routing

– Discharge must connect to the building’s main sewer line or septic inlet, never to a storm drain.

– Avoid long horizontal runs; use cleanouts every 50 feet or at direction changes.

Maintenance and Safety Protocols

Routine Maintenance Schedule

– Monthly: Check for alarms, unusual noises, or leaks.

– Annually: Inspect pump impeller, clean basin, and test float switch operation.

– Replace backup battery (if equipped) every 2–3 years.

Alarm and Backup Systems

– Install a high-water alarm with audible and visual alerts.

– Equip with battery backup for power outage protection.

– Test backup system quarterly.

Emergency Response

– Post emergency contact numbers and shutoff valve locations.

– Train occupants on alarm response procedures.

– Keep spare pump or temporary pump kit on hand for critical applications.

Documentation and Recordkeeping

As-Built Documentation

– Maintain a system schematic showing pump location, piping, and electrical connections.

– File manufacturer manuals, warranty information, and permit approvals.

Compliance Sign-Off

– Retain copy of final inspection certificate.

– Provide homeowner with compliance summary and maintenance checklist.

Environmental and Disposal Considerations

End-of-Life Disposal

– Follow local regulations for disposal of pumps containing electrical components and oils.

– Recycle plastic tanks and metal parts where possible.

Spill Prevention

– Use drip trays during maintenance.

– Have absorbent materials available for accidental wastewater release.

By adhering to this guide, stakeholders ensure a safe, code-compliant, and durable toilet sump pump installation in basement environments, minimizing risks and maximizing system longevity.

In conclusion, sourcing a toilet sump pump for your basement is an essential step in ensuring proper wastewater management and preventing potential flooding or backups in below-grade plumbing installations. When selecting the right system, it’s crucial to consider factors such as pump capacity, durability, noise level, ease of maintenance, and compliance with local plumbing codes. Opting for a reliable, properly sized macerating or grinder pump system specifically designed to handle toilet waste will provide long-term performance and peace of mind. Additionally, professional installation and regular maintenance are key to maximizing efficiency and avoiding costly repairs. By carefully evaluating your basement’s layout, usage needs, and local regulations, you can choose a suitable toilet sump pump solution that enhances functionality, protects your property, and supports a healthy living environment.