The global thermoplastic olefin (TPO) hose market is experiencing steady expansion, driven by increasing demand across automotive, industrial, and construction sectors. According to Grand View Research, the global automotive hose market size was valued at USD 9.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030, with TPO and other advanced polymer-based hoses gaining traction due to their durability, flexibility, and resistance to extreme temperatures. Similarly, Mordor Intelligence forecasts a CAGR of over 4% for the automotive hose market through 2028, highlighting the rising adoption of lightweight materials to meet fuel efficiency regulations. As demand for high-performance, cost-effective hoses grows, several manufacturers have emerged as leaders in TPO hose innovation and production. The following list highlights the top 8 TPO hose manufacturers leading the market through technological advancements, broad product portfolios, and strong global supply chains.

Top 8 Toc Hose Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Yokohama Industrial Products

Domain Est. 2014

Website: y-yokohama.com

Key Highlights: – Production and sales of TOC piping for automobiles. Total site area. 53,450 … We are currently a hose piping company specializing in hydraulic hoses….

#2 Continental Industry

Domain Est. 2018

Website: continental-industry.com

Key Highlights: Continental is a world leader in manufacturing technical and decorative surface materials from plastic for vehicles to those for the interior. Read More. Detail ……

#3 Transmission Oil Cooler Hose

Domain Est. 1994

Website: gates.com

Key Highlights: Trust Gates to deliver safe, reliable engine hoses and components, guaranteed to help your trucks, vintage model cars, and heavy-duty vehicles meet EPA ……

#4 Hose for Transportation – Hose Products Division

Domain Est. 1995

Website: parker.com

Key Highlights: Parker’s hoses and tubing for transportation are specifically engineered with rugged durability, expansive operating temperatures and flexible sizes….

#5 TOC – TRANSMISSION OIL COOLER

Domain Est. 2001

Website: normagroup.com

Key Highlights: TOC (Transmission Oil Cooler) tube systems are designed for engine and transmission oil cooling. The product has a flexible tube system connecting the ……

#6 Transmission Oil Cooler Lines

Domain Est. 2012

Website: yokohamaia.com

Key Highlights: We offer Transmission Oil Cooler (TOC) solutions using Ethylene Acrylic Rubber (AEM) Hose, known for its reliability and extended durability….

#7 Transmission Oil Cooler Hose

Domain Est. 2018

Website: continental-engineparts.com

Key Highlights: Designed for use in connecting add-on and external transmission oil coolers for auto and light truck. Construction. Tube, Black Chemigum (Nitrile)….

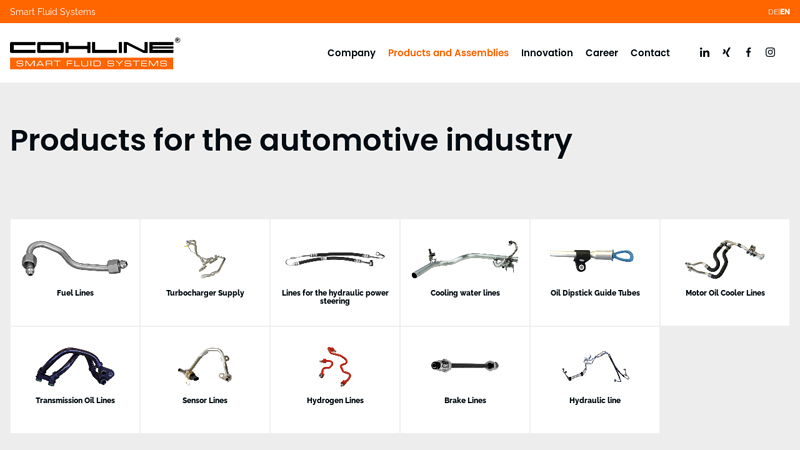

#8 Products

Website: cohline.de

Key Highlights: We manufacture pipe and hose line systems for various applications including oil supply, turbochargers, fuel, cooling and hydraulics….

Expert Sourcing Insights for Toc Hose

H2: 2026 Market Trends for Toc Hose

The global Toc Hose (Thermoplastic Olefin Composite Hose) market is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and sustainability imperatives. As industries across oil & gas, chemical processing, marine, and mining sectors seek durable, flexible, and corrosion-resistant fluid transfer solutions, Toc Hose technology is gaining traction due to its superior performance over traditional rubber and metal hoses.

-

Rising Demand in Oil & Gas and Petrochemical Sectors

By 2026, the oil & gas industry remains a primary driver for Toc Hose adoption. Offshore drilling, LNG transfer, and refinery operations increasingly favor Toc Hoses for their lightweight, high-pressure tolerance, and resistance to hydrocarbons. The shift toward modular and floating production systems further amplifies demand, as Toc Hoses offer easier installation and reduced maintenance. -

Expansion in Chemical and Industrial Applications

Chemical manufacturers are adopting Toc Hoses for handling aggressive solvents and acids due to their excellent chemical resistance and low permeability. The trend is bolstered by stricter environmental and safety regulations, pushing industries to replace older hose types with safer, longer-lasting alternatives. -

Sustainability and Environmental Compliance

Environmental concerns are shaping product development. By 2026, manufacturers are expected to prioritize recyclable Toc Hose materials and energy-efficient production methods. Regulatory frameworks such as REACH and EPA standards are prompting companies to offer eco-friendly, low-emission hose solutions, giving environmentally conscious producers a competitive edge. -

Technological Innovations and Smart Hoses

Advancements in material science are enabling next-generation Toc Hoses with enhanced temperature resistance (up to 120°C) and UV stability. Additionally, integration of IoT sensors for real-time pressure, temperature, and wear monitoring is emerging—particularly in critical infrastructure—paving the way for predictive maintenance and improved operational safety. -

Regional Growth Dynamics

Asia-Pacific is expected to lead market growth by 2026, fueled by industrial expansion in China, India, and Southeast Asia. Meanwhile, North America and Europe will see steady demand due to infrastructure upgrades and offshore energy projects. Latin America and the Middle East present high-potential opportunities, especially in oil export terminals and petrochemical hubs. -

Competitive Landscape and Strategic Alliances

Market consolidation is anticipated, with leading players investing in R&D and forming strategic partnerships with engineering firms and end-users. Customization and technical support are becoming key differentiators, as clients demand application-specific hose solutions.

In conclusion, the 2026 Toc Hose market will be defined by innovation, regulatory adaptation, and geographic diversification. Companies that invest in sustainable materials, smart technologies, and global distribution networks will be best positioned to capture emerging opportunities.

Common Pitfalls When Sourcing Toco Hose (Quality, IP)

Sourcing Toco hose—commonly used in industries such as mining, agriculture, and construction for high-pressure applications—can present several challenges, particularly concerning quality consistency and intellectual property (IP) issues. Being aware of these common pitfalls helps ensure reliable supply and legal compliance.

Poor Quality Control and Material Inconsistencies

One of the most frequent issues when sourcing Toco hose is inconsistent quality. Lower-cost suppliers, especially in unregulated markets, may use substandard materials such as inferior rubber compounds or weak reinforcement layers (e.g., polyester instead of high-tensile steel wire). This results in hoses that fail prematurely under pressure, leading to safety hazards and increased downtime. Lack of adherence to international standards (e.g., ISO 1436 or SAE J517) further exacerbates reliability concerns.

Misrepresentation of Performance Ratings

Some suppliers misrepresent pressure ratings, temperature tolerance, or chemical resistance to appear competitive. For example, a hose may be marketed as “equivalent to Toco Grade X” without proper testing or certification. Without third-party verification or traceable test reports, buyers risk purchasing hoses unsuitable for their operational environment, potentially causing leaks, bursts, or contamination.

Counterfeit or Non-Genuine Products

Counterfeiting is a significant issue when sourcing branded hoses like Toco. Unauthorized manufacturers replicate packaging and branding, selling inferior products as genuine. These counterfeit hoses often lack proper quality assurance and traceability, posing serious safety and liability risks. Verifying authenticity through official distributors or certification documents is critical.

Intellectual Property (IP) Infringement

Sourcing Toco hose from unauthorized or offshore manufacturers can lead to IP violations. Toco hose designs, trademarks, and technical specifications are often protected under patent or trademark law. Purchasing from suppliers who replicate proprietary designs—even if labeled generically—may expose the buyer to legal risk, particularly in regulated industries or export markets with strict IP enforcement.

Lack of Traceability and Documentation

Reputable hose suppliers provide full traceability, including batch numbers, material certifications (e.g., MTRs), and compliance documentation. Many low-cost suppliers fail to offer this, making it difficult to investigate failures or meet industry audit requirements. Absence of documentation also complicates warranty claims and liability assessments.

Inadequate After-Sales Support and Warranty Coverage

Cheaper alternatives often come with limited or no warranty and minimal technical support. When hose failures occur, the lack of responsive service or replacement logistics can disrupt operations. Genuine Toco products typically include technical support and clear warranty terms, which are often missing with non-authorized sources.

Supply Chain and Logistics Risks

Sourcing from distant or unstable regions may lead to delays, customs issues, or inconsistent batch quality. Poor logistics can also impact hose integrity during shipping—exposure to extreme temperatures or moisture can degrade rubber components before installation.

To mitigate these risks, buyers should source Toco hose through authorized distributors, require full compliance documentation, and conduct supplier audits when possible. Prioritizing long-term reliability and safety over initial cost savings helps avoid costly failures and legal exposure.

Logistics & Compliance Guide for Toc Hose

Product Overview

Toc Hose refers to a type of industrial hose commonly used in hydraulic, pneumatic, and fluid transfer applications. These hoses are engineered to meet rigorous performance standards and are subject to various regulatory requirements depending on region, application, and industry.

Regulatory Compliance Standards

Toc Hose products must comply with international and regional safety and performance standards. Key regulations include:

– ISO 1436: Standard for rubber hoses and hose assemblies for petroleum-based hydraulic fluids.

– EN 853 / EN 856: European standards for hydraulic hoses (reinforced, wire-braided, or spiral).

– SAE J517: Society of Automotive Engineers standard for hydraulic hose construction and performance.

– REACH & RoHS: European regulations governing chemical substances and hazardous materials in products.

– FDA Compliance: Required if the hose is used in food, beverage, or pharmaceutical applications involving consumable fluids.

Ensure all Toc Hose products are certified with appropriate documentation (e.g., Declaration of Conformity, test reports).

Transportation & Shipping Guidelines

- Packaging: Hoses must be coiled or drum-wound as per manufacturer specifications to prevent kinking or deformation. Use protective end caps and moisture-resistant wrapping.

- Labeling: Each package must include product identification, batch/lot number, compliance markings (e.g., CE, UKCA), and handling instructions (e.g., “Do Not Kink,” “Protect from UV”).

- Mode of Transport:

- Sea Freight: Use moisture-barrier packaging; avoid condensation with desiccants.

- Air Freight: Comply with IATA regulations if transporting flammable or pressurized components.

- Ground Transport: Secure loads to prevent shifting; avoid sharp impacts.

- Hazardous Materials: Standard Toc Hoses are typically non-hazardous, but verify if accessories (e.g., adhesives, lubricants) have hazardous properties.

Storage Requirements

- Environment: Store in a cool, dry, and well-ventilated area away from direct sunlight, ozone sources (e.g., electric motors), and extreme temperatures (recommended: 0°C to 35°C).

- Shelving: Keep hoses elevated off the floor on racks; avoid long-term stacking.

- Shelf Life: Most rubber and thermoplastic hoses have a shelf life of 5–6 years. Monitor expiration dates and rotate stock using FIFO (First In, First Out).

Import/Export Documentation

For international logistics, ensure the following documents are prepared:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Test Certificates and Compliance Declarations (e.g., ISO, CE)

– Bill of Lading or Air Waybill

– Import Licenses (if required by destination country)

Verify customs tariff classification (HS Code) for Toc Hose, typically under 4009.11–4009.33 (new pneumatic or hydraulic hoses of vulcanized rubber).

Quality Control & Traceability

- Maintain lot traceability from raw materials to final product.

- Conduct periodic batch testing for pressure rating, burst strength, and flexibility.

- Keep records of inspections, non-conformance reports, and corrective actions.

Environmental & Disposal Compliance

- End-of-life hoses should be disposed of in accordance with local waste regulations.

- Rubber and synthetic materials may require specialized recycling or incineration facilities.

- Avoid landfill disposal where prohibited by regional legislation (e.g., EU Landfill Directive).

Training & Handling Procedures

- Train warehouse and logistics staff on proper handling to avoid abrasion, crushing, or excessive bending.

- Use appropriate lifting equipment for large reels or bulk shipments.

- Enforce PPE (gloves, safety glasses) during loading/unloading.

Audit & Continuous Improvement

- Conduct regular internal audits of logistics and compliance processes.

- Stay updated on changes to international standards and trade regulations.

- Engage third-party certification bodies for periodic compliance verification.

By adhering to this guide, companies can ensure safe, efficient, and compliant handling, transport, and use of Toc Hose products across global supply chains.

Conclusion for Sourcing TOC Hose:

In conclusion, sourcing TOC (Total Organic Carbon) hoses requires a careful evaluation of material compatibility, regulatory compliance, and performance requirements to ensure the integrity of high-purity fluid transfer in critical applications, particularly in the pharmaceutical, biotechnology, and semiconductor industries. It is essential to select hoses made from chemically inert, non-leaching materials such as high-purity fluoropolymers (e.g., PTFE, FEP, or PFA) that can withstand sterilization processes and maintain low TOC extractables. Working with reputable suppliers who provide comprehensive documentation, including extractable profiles, quality certifications (e.g., USP Class VI, FDA compliance), and validation support, is crucial for meeting industry standards and audit requirements.

Additionally, considering factors such as hose design, connector compatibility, service life, and supplier lead times will contribute to a reliable and cost-effective sourcing strategy. By prioritizing quality, compliance, and long-term performance over initial cost savings, organizations can ensure the consistent delivery of high-purity fluids while minimizing contamination risks and operational downtime. Ultimately, a well-executed TOC hose sourcing plan supports process reliability, regulatory compliance, and product safety in sensitive manufacturing environments.