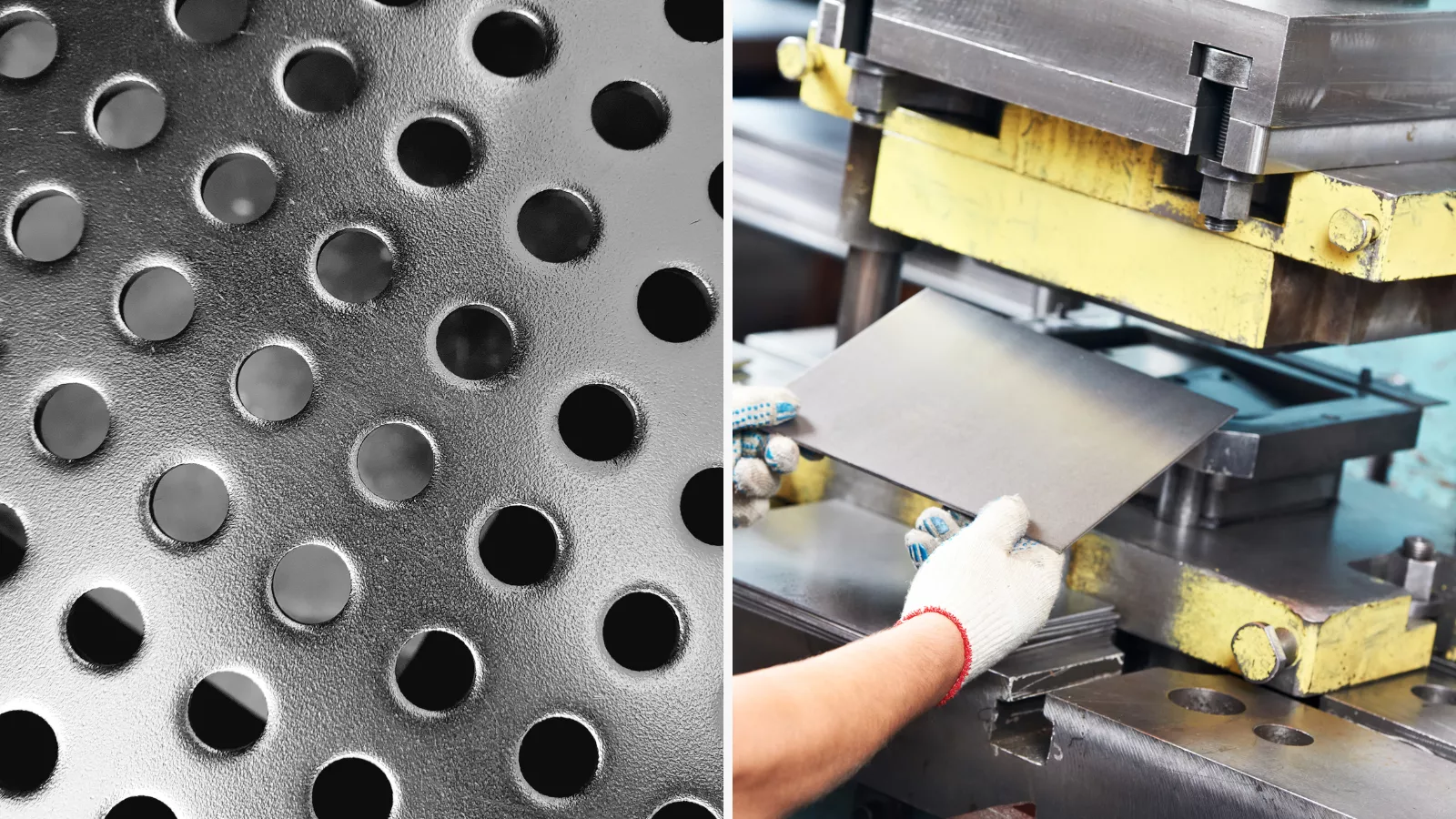

The global hand tools market, which includes essential equipment used by tinsmiths, was valued at USD 13.8 billion in 2022 and is projected to grow at a CAGR of 5.2% from 2023 to 2030, according to Grand View Research. This steady expansion is driven by rising demand in construction, automotive repair, and HVAC industries—all of which rely on precision metalwork and durable hand tools. Within this landscape, tinsmithing remains a niche yet vital craft, requiring specialized tools such as tin snips, dollies, stakes, and hammers. As industrial manufacturing and artisanal metalworking continue to evolve, the demand for high-quality, precision-engineered tinsmith tools has surged. Based on market trends and product innovation, we’ve identified the top 10 manufacturers leading the way in producing reliable, durable, and ergonomically designed tools for professional tinsmiths and metalworkers worldwide.

Top 10 Tinsmith Tools Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

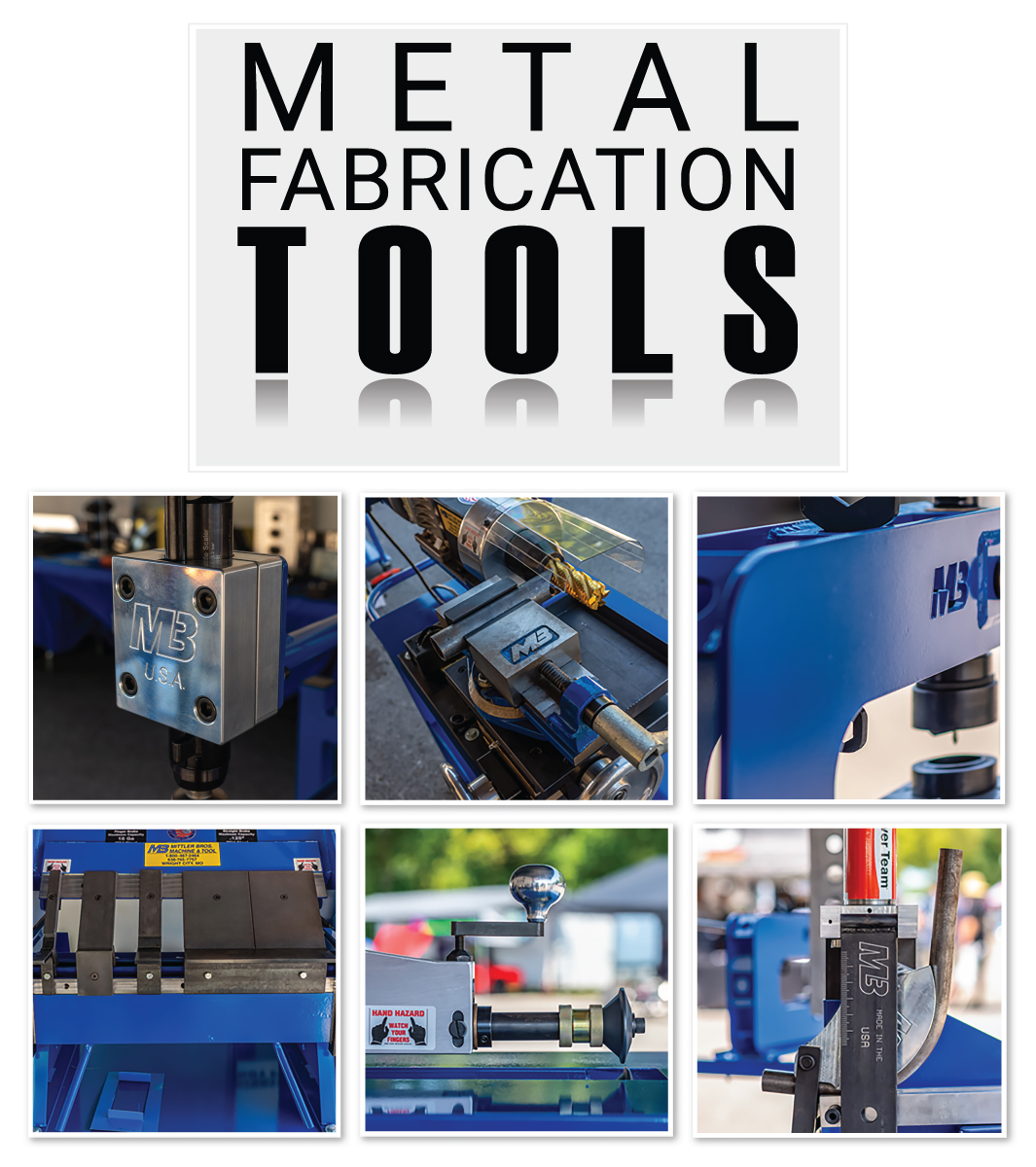

#1 Metal Working Tools & Metal Fabrication Equipment by Mittler Bros.

Domain Est. 1996

Website: mittlerbros.com

Key Highlights: Diversified OEM of Metal Working Tools, Metal Fabrication Equipment, Auto Racing Equipment, Race Car Scales & more. Discover why the Pros prefer “Mittler ……

#2 Klein Tools – For Professionals since 1857

Domain Est. 1998

Website: kleintools.com

Key Highlights: Klein is the only major tool manufacturer worldwide focused on electrical and utility applications. No other manufacturer of hand tools and related products…

#3 HOUGEN MANUFACTURING

Domain Est. 1996

Website: hougen.com

Key Highlights: Built for the toughest jobs in the shop or on site, Hougen® tools cut faster, drill cleaner, & help you stay more productive. · Magnetic Drills · Annular Cutters….

#4 Wilson Tool International

Domain Est. 1996

Website: wilsontool.com

Key Highlights: Wilson Tool provides a wide range of tool solutions for Bending, Punching and Stamping customers around the globe….

#5 Malco Tools

Domain Est. 1996

Website: malcotools.com

Key Highlights: Malco provides a wide range of innovative tools. From cutting and bending to fastening and gripping, our tools are designed to meet your specific needs….

#6 Tennsmith

Domain Est. 1998

Website: tennsmith.com

Key Highlights: We offer a full range of American-made sheet metal tools including Automatic Folders, Hand Brakes, Shears, Slip Rolls, Cleat Benders, Notchers and Rotary ……

#7 Kett Tool Company

Domain Est. 1998

#8 Woodward Fab: Sheet Metal Fabrication Tools

Domain Est. 2003

Website: woodwardfab.com

Key Highlights: Specialize in sheet metal fabrication, metal forming, shaping and metal working tools. Shop best quality Woodward fab’s tools and equipment at best price ……

#9 European Sheet Metal Tools & Roofing Equipment

Domain Est. 2004

#10 Cutting Tools

Website: bessey.de

Key Highlights: Our impressive selection of tin snips is rounded off by special cutting tools such as cutter knives and tools for the tinsmith trade. Learn more. Family ……

Expert Sourcing Insights for Tinsmith Tools

2026 Market Trends for Tinsmith Tools

The tinsmith tools market in 2026 is poised for transformation, driven by evolving craftsmanship, sustainability demands, and technological integration. While rooted in tradition, the sector is adapting to modern pressures and opportunities, shaping a nuanced outlook for tool manufacturers, artisans, and suppliers.

Rising Demand for Artisanal Craftsmanship and Heritage Skills

A growing consumer preference for handmade, bespoke, and culturally significant metalwork is revitalizing interest in traditional tinsmithing. This resurgence, fueled by the maker movement and appreciation for heritage trades, translates into increased demand for authentic, high-quality hand tools—such as snips, hammers, stakes, and soldering implements. Educational workshops and online learning platforms are expanding the tinsmithing community, broadening the customer base for both entry-level and professional-grade tools.

Sustainability and Circular Economy Influence

Environmental consciousness is reshaping material and tool usage. Tinsmiths are increasingly working with recycled metals and repurposed materials, emphasizing repair and reuse over replacement. This trend favors durable, repairable tools with longevity. Manufacturers responding with eco-conscious production practices—such as using recycled steel in tool fabrication or offering refurbishment programs—will gain competitive advantage. Tools designed for precision and material efficiency also align with sustainable production goals.

Technological Integration and Tool Innovation

While hand tools remain central, digital tools are augmenting traditional practices. CNC-assisted cutting and laser templating are being adopted by hybrid workshops to enhance precision and scale. This creates a niche for tinsmith tools compatible with digital workflows—such as jigs designed for CNC templates or marking tools optimized for digital layout transfer. However, the core market continues to value analog craftsmanship, ensuring that innovation complements rather than replaces traditional equipment.

Niche Market Expansion and Customization

The tinsmithing market is fragmenting into specialized niches: architectural restoration, decorative arts, culinary tinware, and sustainable packaging prototypes. Each segment demands specific tool configurations, driving demand for customizable and modular tool systems. In 2026, manufacturers offering bespoke tool packages, ergonomic adaptations, or specialty sets (e.g., restoration-grade or food-safe tool lines) will meet the needs of these focused applications.

Supply Chain Resilience and Regional Manufacturing

Global supply chain volatility continues to impact tool availability and pricing. In response, there is a trend toward regional or local manufacturing of tinsmith tools, particularly in North America and Europe. Artisans and small workshops are prioritizing suppliers with transparent, resilient supply chains and shorter lead times. This shift supports domestic toolmakers and encourages investment in localized production technologies like precision forging and CNC machining.

Digital Marketplaces and Direct-to-Artisan Sales

E-commerce platforms and specialized online marketplaces are becoming primary channels for tool distribution. Artisans seek detailed product information, user reviews, and video demonstrations before purchasing. Brands with strong digital presence, educational content, and direct engagement (e.g., social media, webinars) will outperform traditional catalog-based sellers. Subscription models for tool maintenance or exclusive releases may emerge as value-added services.

In summary, the 2026 tinsmith tools market will be characterized by a blend of tradition and innovation, where durability, craftsmanship, and sustainability drive demand. Success will depend on manufacturers’ ability to serve a growing yet discerning artisan base with high-quality, adaptable tools while embracing responsible production and digital engagement.

Common Pitfalls When Sourcing Tinsmith Tools: Quality and Intellectual Property Concerns

Sourcing tinsmith tools—especially from overseas suppliers or lesser-known manufacturers—can present significant challenges. Two of the most critical areas where buyers encounter problems are tool quality and intellectual property (IP) risks. Avoiding these pitfalls is essential for maintaining production standards, protecting brand integrity, and ensuring long-term operational efficiency.

Quality Inconsistencies

One of the most frequent issues when sourcing tinsmith tools is inconsistent or substandard quality. Many suppliers, particularly in low-cost manufacturing regions, may claim compliance with industry standards but fail to deliver tools that perform reliably.

- Material Deficiencies: Tools may be made from inferior-grade steel or alloys that wear quickly, lose temper, or deform under pressure, leading to frequent replacements and downtime.

- Poor Craftsmanship: Inadequate heat treatment, imprecise machining, or sloppy finishing can compromise tool functionality and safety. For example, unevenly ground snips or misaligned stakes reduce precision and increase the risk of material damage.

- Lack of Quality Control: Suppliers may lack robust quality assurance processes, resulting in batch-to-batch variability. Without third-party inspections or clear specifications, defects may go undetected until tools are in use.

To mitigate these issues, buyers should request material certifications, conduct factory audits, and require sample testing before placing bulk orders.

Intellectual Property Risks

Another major concern when sourcing tinsmith tools—especially high-end or specialty items—is the risk of infringing on intellectual property rights.

- Counterfeit or Copycat Tools: Some suppliers produce unauthorized replicas of well-known branded tools (e.g., vintage-patterned hammers, patented folding tools). Purchasing these may expose buyers to legal liability, customs seizures, or reputational damage.

- Design and Patent Infringement: Tools incorporating patented mechanisms or unique ergonomic designs may violate IP laws if replicated without permission. Even if the supplier assumes responsibility, the end buyer can still be held accountable in certain jurisdictions.

- Unclear IP Ownership: In custom tool development, failure to establish clear IP ownership in contracts can result in disputes. Suppliers may claim rights to tool designs or deny exclusivity, limiting your ability to source elsewhere.

To safeguard against IP issues, conduct due diligence on suppliers, verify original equipment manufacturer (OEM) status, and include explicit IP clauses in sourcing agreements.

By proactively addressing quality and IP concerns, businesses can ensure they source durable, compliant tinsmith tools that support craftsmanship and legal compliance.

Logistics & Compliance Guide for Tinsmith Tools

This guide outlines the essential logistics and compliance procedures for managing the shipment, handling, and regulatory adherence of Tinsmith Tools. Adherence ensures timely delivery, safety, and legal conformity across all operations.

Order Processing & Inventory Management

Ensure all incoming orders are processed within 24 hours of receipt. Maintain accurate inventory records using an integrated warehouse management system (WMS) to prevent stockouts and overstocking. Conduct monthly cycle counts and annual physical audits to verify inventory accuracy. Label all tools with unique SKUs and barcodes for traceability.

Packaging Standards

Package Tinsmith Tools in durable, corrugated cardboard with internal cushioning (e.g., foam inserts or bubble wrap) to prevent damage during transit. Clearly label packages with product details, handling instructions (e.g., “Fragile,” “This Side Up”), and compliance markings where applicable. Use tamper-evident seals for high-value orders.

Domestic & International Shipping

Utilize approved freight carriers with proven experience in handling industrial tools. For domestic shipments within the U.S., comply with DOT regulations and provide accurate bill of lading documentation. For international shipments, ensure compliance with export controls (e.g., EAR), prepare commercial invoices, packing lists, and certificates of origin. Verify destination country import requirements, including tool-specific regulations or certifications.

Customs Compliance

Assign a designated export compliance officer to oversee customs documentation. Classify Tinsmith Tools using correct Harmonized System (HS) codes to determine applicable tariffs and restrictions. Retain all shipping and customs records for a minimum of five years. Screen all international transactions against OFAC and denied party lists prior to shipment.

Safety & Hazard Communication

Although Tinsmith Tools are generally non-hazardous, ensure compliance with OSHA’s Hazard Communication Standard (HCS) for any components involving lubricants or coatings. Provide Safety Data Sheets (SDS) upon request. Train warehouse staff in safe handling and proper use of personal protective equipment (PPE).

Product Certification & Standards

Verify that all tools meet relevant industry standards such as ANSI, ASTM, or ISO, as applicable. Maintain certification documentation for quality assurance and customer requests. Clearly mark CE, UKCA, or other regional conformity marks on products sold in regulated markets.

Returns & Reverse Logistics

Implement a structured returns process requiring prior authorization (RMA). Inspect returned tools for damage or misuse and process refunds or replacements per warranty terms. Refurbish or dispose of defective tools in accordance with environmental regulations.

Regulatory Updates & Training

Designate a compliance coordinator to monitor changes in trade laws, packaging regulations, and safety standards. Conduct biannual training sessions for logistics and operations staff to maintain awareness and ensure ongoing compliance.

Recordkeeping & Audit Preparedness

Maintain digital and physical records of all logistics transactions, compliance certifications, training logs, and audit reports. Conduct internal compliance audits annually and prepare for third-party or regulatory inspections with readily accessible documentation.

In conclusion, sourcing tinsmith tools requires careful consideration of quality, authenticity, functionality, and budget. Whether acquiring traditional hand tools like snips, hammers, stakes, and soldering equipment or modern alternatives, it is essential to identify reputable suppliers, evaluate craftsmanship, and prioritize tools that align with both project requirements and skill level. Exploring local artisans, specialty retailers, online marketplaces, and antique sources can yield valuable finds, especially when restoring historical pieces or practicing traditional tinsmithing techniques. Ultimately, investing in well-made, durable tools not only enhances precision and efficiency but also preserves the integrity of this time-honored craft for future generations.