The global automotive diagnostic equipment market is experiencing robust growth, driven by increasing vehicle electrification, regulatory emissions standards, and rising demand for precision maintenance tools. According to a report by Mordor Intelligence, the automotive diagnostic equipment market was valued at USD 7.6 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. This surge is particularly benefiting specialized tools like timing lights with rev counters—essential instruments for engine tuning and performance calibration in both professional repair shops and DIY automotive applications. As vehicles become more technologically advanced, the need for accurate ignition timing and real-time RPM monitoring has elevated the demand for high-precision, digitally integrated timing lights. In response, manufacturers are innovating with features such as inductive pickups, digital displays, and wireless connectivity. Based on market availability, performance metrics, and technological advancements, the following are the top 10 timing light with rev counter manufacturers shaping the industry landscape in 2024.

Top 10 Timing Light With Rev Counter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Computerized Tachometer/Advance/Timing Light

Domain Est. 1995

Website: honda.snapon.com

Key Highlights: This sophisticated unit uses computer technology to present three units in one–a built-in digital tachometer, an advance meter and a timing light.Missing: rev counter manufacture…

#2 Timing Equipment

Domain Est. 2000

Website: tinytach.com

Key Highlights: Timing / Strobe Light for Tach-n-Time Model 3300S (Light only). $80.00. Add to Cart. Engine Timing Light $40.00. Engine Timing Light. Click to see larger image ……

#3 Timing Light

Domain Est. 1996

Website: jegs.com

Key Highlights: 1–3 day deliveryAccurate Timing Up To 14,000 RPM; 48 in. Pickup Lead · View Details. $85.99 … Estimated to ship direct from manufacturer on 01/12/26, pending manufacturer ……

#4 Innova 3568 Digital Timing Light

Domain Est. 2024

Website: ferndalenailsbar.com

Key Highlights: In stock Rating 4.0 (72) 3 days ago · The INNOVA 3568 Digital Timing Light is a top-of-the line timing light with a precise split-screen digital LCD readout that displays …Miss…

#5 MSD 8992 MSD Timing Pro Timing Light

Domain Est. 1995

#6 Automotive Timing Lights

Domain Est. 1995

#7 MSD Inductive Timing Light

Domain Est. 1997

Website: performancebodies.com

Key Highlights: MSD 8992 Timing Pro timing light is made with solid-state circuitry and uses a Silicon Controlled Rectifier (SCR) that provides accurate and stable timing ……

#8 Electronic Specialties Inc 125

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock Rating 4.1 14 Professional Timing Light with High Visibility LED display Very bright display indicates: – Tach (RPM) – Degree s Advance · Measures ignition spark advance…

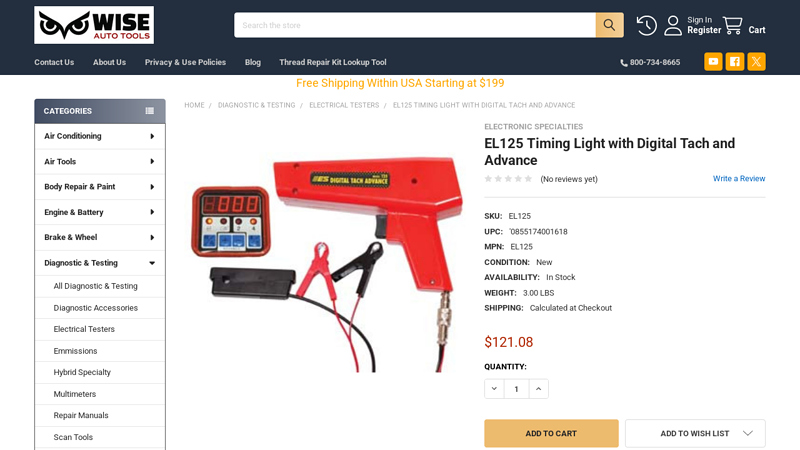

#9 EL125 Timing Light with Digital Tach and Advance

Domain Est. 2012

Website: wiseautotools.com

Key Highlights: In stock Rating 4.1 14 Professional Timing Light with High Visibility LED display · Measures ignition spark advance from 0-90 degrees · 2 and 4 Stroke Tachometer measures engine …

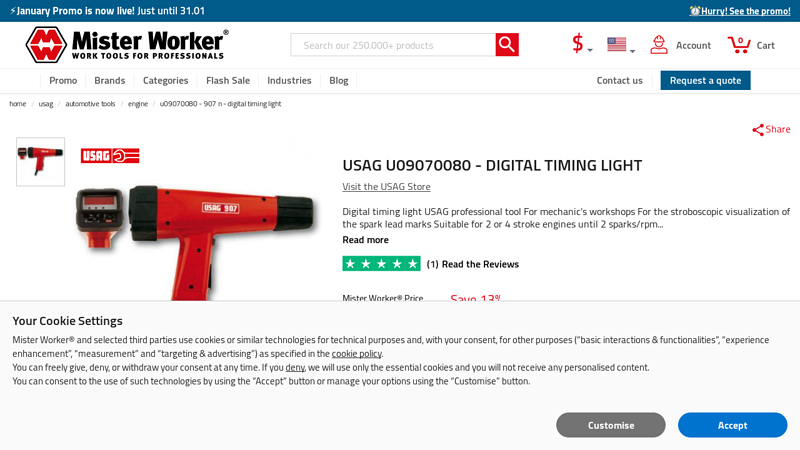

#10 USAG 907 N Digital timing light

Domain Est. 2017

Website: misterworker.com

Key Highlights: In stock Rating 5.0 (1) With a torque capacity of 50 Nm and a maximum RPM of 10,000 , this timing light provides precise timing adjustments. The tool measures approximately 250 m…

Expert Sourcing Insights for Timing Light With Rev Counter

H2: 2026 Market Trends for Timing Lights with Rev Counters

The market for timing lights with integrated rev counters in 2026 is poised for continued evolution, driven by technological advancements, changing vehicle complexity, and shifting user demands. While traditional mechanical timing lights maintain a niche, the dominant trends point toward digital integration, enhanced diagnostics, and adaptation to modern powertrains.

1. Digital Dominance and Feature Integration:

By 2026, digital timing lights with built-in rev counters will solidify their market leadership. These devices offer superior accuracy, easier readability, and expanded functionality. Expect increased integration with diagnostic features such as dwell angle measurement, cylinder balance testing, and basic OBD-II compatibility. The rev counter function will become more sophisticated, with improved signal processing for reliable RPM readings across various ignition systems, including modern coil-on-plug (COP) setups.

2. Smart Connectivity and App Integration:

A growing trend will be the incorporation of Bluetooth or Wi-Fi connectivity. Timing lights will sync with smartphones or tablets via dedicated apps, enabling real-time data logging, performance trend analysis, and remote parameter adjustment. This connectivity enhances usability for professional mechanics and performance tuners, allowing for more comprehensive engine diagnostics beyond basic timing and RPM checks.

3. Adaptation to Evolving Vehicle Technologies:

As hybrid and electric vehicles (EVs) gain market share, the traditional role of timing lights diminishes. However, internal combustion engines (ICEs) will remain prevalent in many markets and applications (e.g., performance, classic cars, emerging economies). Timing light manufacturers will focus on compatibility with advanced ignition systems, including those in turbocharged and direct-injection engines, ensuring relevance in the service of remaining ICE vehicles.

4. Market Consolidation and Niche Specialization:

The market may see consolidation among manufacturers, with larger tool companies acquiring specialized brands. Simultaneously, a niche segment will thrive: high-end, precision tools for automotive enthusiasts, restoration specialists, and performance tuners. These premium models will emphasize durability, accuracy, and advanced features like strobe brightness adjustment and non-contact RPM sensing.

5. Sustainability and Durability Focus:

Environmental and durability concerns will influence product design. Manufacturers will increasingly use recyclable materials, reduce packaging waste, and design products for longer lifespans. Rechargeable battery systems will become standard, replacing disposable batteries to reduce environmental impact and operating costs.

In conclusion, the 2026 timing light with rev counter market will be characterized by smarter, more connected digital tools focused on ICE diagnostics in a transitioning automotive landscape. Success will depend on adaptability, integration with modern service workflows, and meeting the precision demands of both professional and enthusiast users.

Common Pitfalls Sourcing a Timing Light With Rev Counter (Quality, IP Rating)

When sourcing a timing light with an integrated rev counter, especially for professional or industrial use, several pitfalls related to quality and Ingress Protection (IP) ratings can compromise performance, safety, and longevity. Being aware of these issues helps ensure you select a reliable and durable tool.

Overlooking Build Quality and Component Durability

Many low-cost timing lights use substandard materials such as brittle plastic housings, flimsy cables, and poorly shielded connectors. These components are prone to cracking, fraying, or short-circuiting in demanding workshop environments. Additionally, internal electronics may lack proper heat dissipation, leading to premature failure when used for extended periods. Always verify that the device uses robust materials and has undergone reliability testing.

Insufficient or Misrepresented IP Rating

The IP (Ingress Protection) rating indicates a device’s resistance to dust and moisture. A common pitfall is assuming all timing lights are suitable for workshop conditions. Units with low or no IP rating (e.g., IP20) are vulnerable to oil, coolant splashes, and dust—common in engine bays. Always confirm the actual IP rating (e.g., IP54 or higher for splash and dust resistance) and ensure it’s independently verified, not just claimed by the manufacturer.

Inaccurate or Unreliable Rev Counter Readings

Low-quality timing lights may suffer from electromagnetic interference (EMI) due to poor shielding, leading to erratic or inaccurate RPM readings. This is especially problematic on modern vehicles with complex ignition systems. Ensure the device includes EMI-resistant cabling and reliable signal processing to maintain accuracy across different engine types and conditions.

Lack of Temperature and Environmental Resilience

Some timing lights fail under extreme temperatures common in engine compartments. Poor thermal design can cause screen distortion, battery issues, or internal component damage. Check for operating temperature specifications and ensure the device is rated for use in both hot engine environments and cold outdoor conditions if needed.

Inadequate Safety Certifications

Using a non-compliant tool near high-voltage ignition systems poses safety risks. Avoid units without recognized safety certifications (e.g., CE, RoHS, or UL). These certifications indicate the product meets electrical safety and environmental standards, reducing the risk of shock, fire, or hazardous material exposure.

Poor Cable and Connector Quality

The inductive pickup cable and alligator clips are critical for reliable performance. Cheaply made cables may have thin insulation, weak clamps, or poor coil windings, leading to intermittent signal loss or damage when clipped to spark plug wires. Look for thick, abrasion-resistant cables with reinforced connectors and secure, corrosion-resistant clips.

By addressing these pitfalls during sourcing, you can select a timing light with rev counter that delivers accurate performance, withstands harsh environments, and ensures user safety over the long term.

Logistics & Compliance Guide for Timing Light With Rev Counter

Product Classification and HS Code

The Timing Light With Rev Counter is typically classified under the Harmonized System (HS) Code 9031.80, which covers measuring or checking instruments, appliances, and machines not elsewhere specified or included. Accurate classification is essential for international shipping, customs clearance, and duty assessment. Confirm the correct HS code with local customs authorities or a licensed customs broker, as classifications may vary slightly by country.

Import/Export Regulations

Import and export of Timing Lights With Rev Counter must comply with the trade regulations of both the exporting and importing countries. Ensure all required export licenses are obtained, especially if shipping to restricted regions. Some countries may impose additional controls on electronic diagnostic tools. Verify compliance with export control lists such as the U.S. Commerce Control List (CCL) or EU Dual-Use Regulations, although these devices generally do not require special authorization.

Packaging and Labeling Requirements

Package the Timing Light With Rev Counter in durable, shock-resistant materials to prevent damage during transit. Include protective foam or dividers if shipping multiple units. Label each package with:

– Product name and model number

– HS code

– Country of origin (e.g., “Made in China”)

– Weight and dimensions

– Handling symbols (e.g., “Fragile,” “Do Not Stack”)

Ensure labels are clearly visible and resistant to moisture and wear.

Shipping and Transportation

Use reputable freight carriers experienced in handling electronic tools. For air freight, comply with IATA regulations—ensure batteries (if rechargeable) are installed securely and meet capacity limits (typically under 100 Wh for lithium-ion). For sea freight, secure cargo to prevent shifting and use moisture-absorbing desiccants to protect against humidity. Maintain a cold chain if specified by the manufacturer.

Regulatory Compliance

Ensure the Timing Light With Rev Counter meets essential regulatory standards in the destination market:

– CE Marking (Europe): Complies with EMC Directive 2014/30/EU and RoHS 2011/65/EU

– FCC Certification (USA): Meets Part 15 Class B for electromagnetic interference

– RCM Mark (Australia/New Zealand): Conforms to AS/NZS standards

– PSE Mark (Japan): Required if AC-powered or containing specified components

Provide technical documentation, including test reports and Declaration of Conformity, upon request.

Documentation

Prepare the following documents for customs clearance:

– Commercial Invoice (with item description, value, and Incoterms)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential tariffs)

– Test Reports and Compliance Certificates (FCC, CE, etc.)

Ensure all documents are accurate and match the shipped goods to avoid delays.

Environmental and Safety Compliance

Adhere to environmental regulations such as:

– RoHS (Restriction of Hazardous Substances): Limits lead, mercury, cadmium, and other hazardous materials

– WEEE Directive (Europe): Requires producers to facilitate end-of-life recycling

Include user instructions on proper disposal and recycling. Comply with local safety standards regarding electrical insulation and operational safety.

Warranty and After-Sales Support

Provide clear warranty terms compliant with local consumer laws (e.g., 2-year legal warranty in the EU). Include multilingual user manuals and safety instructions. Establish a local service or returns process to meet compliance with right-to-repair regulations in certain jurisdictions.

Recordkeeping and Audits

Maintain detailed records of shipments, compliance certifications, and test reports for a minimum of 5–10 years, depending on jurisdiction. These records may be required during customs audits or regulatory inspections.

Summary

Proper logistics and compliance management ensures smooth international distribution of Timing Lights With Rev Counter. Focus on correct classification, regulatory certification, accurate documentation, and safe packaging to minimize delays and legal risks. Partner with experienced logistics providers and stay updated on changing import regulations in target markets.

In conclusion, sourcing a timing light with a built-in rev counter is a practical and efficient choice for both professional mechanics and DIY automotive enthusiasts. This dual-function tool not only simplifies the process of setting and verifying ignition timing but also provides real-time engine RPM readings, enhancing accuracy and diagnostic capability. By combining these two essential functions into a single device, it reduces the need for multiple tools, saves time, and improves overall workflow during engine tuning and maintenance. When selecting a model, it is important to consider factors such as build quality, ease of use, compatibility with different engine types, and additional features like adjustable advance settings or LED illumination. Ultimately, investing in a reliable timing light with a rev counter ensures greater precision in engine performance optimization, leading to improved fuel efficiency, reduced emissions, and prolonged engine life.