The global timber frame fencing market is experiencing steady growth, driven by increasing demand for sustainable construction materials and rising investments in residential and commercial infrastructure. According to Grand View Research, the global wood construction materials market was valued at USD 217.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, with timber framing and fencing systems representing a significant segment of this expansion. Similarly, Mordor Intelligence projects a CAGR of over 5.8% for wood-based building products through 2028, citing growing consumer preference for eco-friendly, durable, and aesthetically pleasing building solutions. As demand rises, especially in North America and Europe, a select group of manufacturers has emerged as leaders in innovation, quality, and scalability within the timber frame fencing space. Here are the top 8 manufacturers shaping the industry’s future.

Top 8 Timber Frame Fencing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading Manufacturer of Steel Backed Timber Guardrail Systems

Domain Est. 2000

Website: cor-ten.com

Key Highlights: Cor-Tenn is your source for Steel-Backed Timber Guardrail / Aesthetic Barriers, Log Home Materials, Log Home Supplies, and Quality Construction Components….

#2 Eglantine Timber

Domain Est. 2011

Website: eglantinetimber.com

Key Highlights: Eglantine Timber – Your One Stop Shop for All Your Timber Needs. We have a large range of Fencing, Decking, Gates, Timber Products, Sheds, …Missing: frame manufacturer…

#3 Trex® Composite Fencing

Domain Est. 1996

Website: trex.com

Key Highlights: Built to Last. Trex composite fencing is backed by its 25-year Residential Limited Warranty and can be trusted to outlast the elements for years to come….

#4 Lumber, Plywood, MDF Boards

Domain Est. 1996

Website: timberproducts.com

Key Highlights: Timber Products has the expertise to provide top quality lumber, plywood, MDF boards and more! 100+ years of industry leadership!…

#5

Domain Est. 2002

Website: uslumber.com

Key Highlights: US LUMBER was founded in Birmingham, Alabama and has grown into a highly-trusted, privately held distributor of specialty building materials….

#6 Timber Frame

Domain Est. 2003

Website: markslumber.us

Key Highlights: Marks Lumber’s master craftsmen can build your timber frame dreams by providing expertise, services, and materials that make your vision a reality….

#7 American Timber and Steel

Domain Est. 2007

Website: americantimberandsteel.com

Key Highlights: American Timber and Steel Corp. manufactures and stocks nearly all of the materials required for your outdoor timber project….

#8 Business Units

Domain Est. 2017

Website: azekco.com

Key Highlights: AZEK Exteriors manufactures premium, low-maintenance exterior building products that are engineered to last. From trim and moulding to innovative siding ……

Expert Sourcing Insights for Timber Frame Fencing

H2: Projected 2026 Market Trends for Timber Frame Fencing

The timber frame fencing market in 2026 is expected to reflect broader construction, sustainability, and consumer lifestyle trends. While precise data for 2026 is inherently predictive, analysis of current trajectories suggests the following key developments under the H2 economic and societal context:

1. Continued Demand Driven by Residential Construction and Aesthetics

Despite potential fluctuations in the H2 housing market—characterized by moderate growth, cautious consumer spending, and possible interest rate stabilization—demand for timber frame fencing is anticipated to remain robust. Homeowners in H2 continue to prioritize outdoor living spaces, privacy, and curb appeal. Timber’s natural aesthetic aligns with popular design trends like biophilic design and rustic-modern architecture, sustaining its appeal over synthetic alternatives in mid-to-high-end residential projects.

2. Sustainability and Eco-Certification as Market Differentiators

Environmental consciousness is a key driver in H2 markets. Consumers and regulatory frameworks increasingly favor sustainably sourced materials. By 2026, timber frame fencing suppliers emphasizing FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) certification will likely gain competitive advantage. Demand for low-impact treatments (e.g., water-based preservatives) and longer product lifecycles will rise, aligning with H2’s focus on circular economy principles and carbon footprint reduction.

3. Price Volatility and Supply Chain Resilience

H2 economic conditions—marked by fluctuating raw material costs and ongoing supply chain adjustments—will impact timber pricing. Increased demand for construction-grade softwoods (like cedar, spruce, and pressure-treated pine) may lead to moderate price increases. Companies investing in localized sourcing, diversified suppliers, and inventory optimization will better navigate these challenges and maintain profitability.

4. Innovation in Hybrid and Engineered Wood Products

To enhance durability and reduce maintenance, timber frame fencing will increasingly incorporate engineered wood components or hybrid designs combining timber with recycled composite or metal supports. These innovations address H2 consumer preferences for low-maintenance, long-lasting solutions while retaining the visual appeal of real wood.

5. Regional Variations in Adoption

In North America and parts of Europe, timber frame fencing will remain dominant in suburban and rural residential markets. In contrast, urban areas and regions with strict fire codes or high moisture may see slower growth, with alternatives like aluminum or composite gaining share. However, H2’s emphasis on green urban planning could boost timber use in approved public and semi-public spaces.

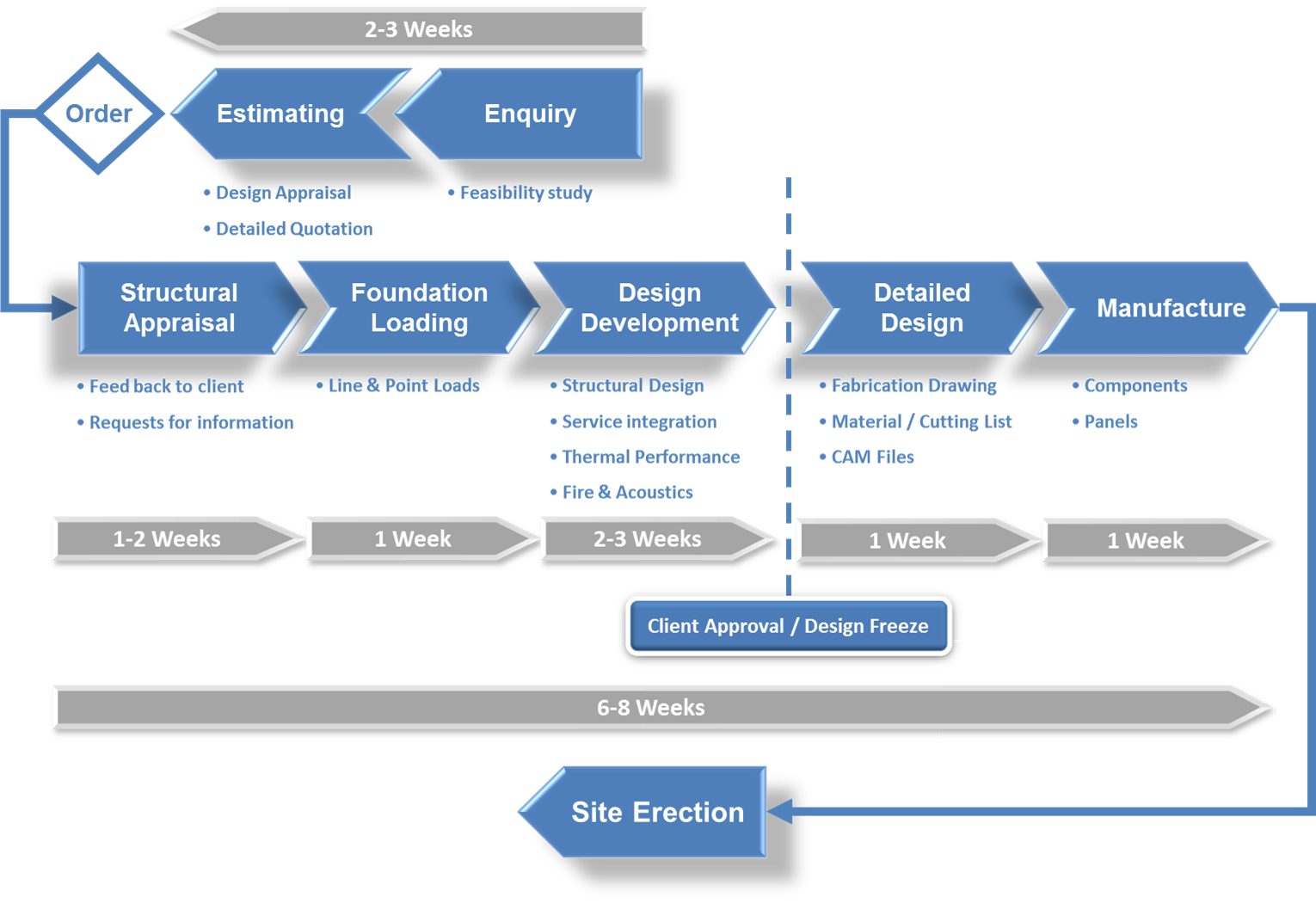

6. Labor and Installation Challenges

Skilled labor shortages in the H2 construction sector may affect fencing installation timelines and costs. This could drive demand for modular, pre-fabricated timber frame systems that reduce on-site labor requirements and installation time—offering a value proposition in efficiency and cost predictability.

Conclusion

By 2026, the timber frame fencing market under H2 conditions will be shaped by enduring aesthetic preferences, sustainability mandates, economic pragmatism, and innovation. Success will depend on adaptability—balancing cost management, environmental responsibility, and product performance to meet evolving consumer expectations in a competitive landscape.

Common Pitfalls When Sourcing Timber Frame Fencing (Quality and Intellectual Property)

Sourcing timber frame fencing can offer durability and aesthetic appeal, but overlooking key quality and intellectual property (IP) considerations can lead to costly setbacks. Being aware of these common pitfalls helps ensure you receive a reliable, compliant, and legally sound product.

Poor Timber Quality and Species Misrepresentation

One of the most frequent issues is receiving timber that does not meet specified quality standards. Suppliers may use lower-grade wood, such as timber with excessive knots, warping, or moisture content above recommended levels (typically over 20%), leading to premature warping, splitting, or rot. Additionally, some suppliers mislabel timber species—passing off less durable softwoods as higher-grade hardwoods—which compromises longevity and performance.

Inadequate or Missing Treatment Certification

Timber frame fencing must be properly treated to resist rot, insects, and weathering. A common pitfall is sourcing fencing without valid treatment certification (e.g., UC3 or UC4 for outdoor ground contact). Without proper preservative treatment documentation, the product may fail prematurely, and warranties may be invalidated.

Lack of Structural Design Compliance

Timber frame fencing systems often involve engineered designs for wind load, height, and stability. Sourcing from manufacturers who do not provide structural calculations or compliance with local building codes (e.g., Eurocode 5 or national standards) can result in unsafe installations and liability issues.

Ignoring Sustainable Sourcing and Chain of Custody

Failing to verify sustainable sourcing can expose buyers to reputational and regulatory risks. Timber should be certified by recognized schemes such as FSC® (Forest Stewardship Council) or PEFC™. Without proper chain-of-custody documentation, there’s a risk of using illegally harvested wood, which may breach environmental regulations.

Overlooking Design and Manufacturing IP Rights

Some timber frame fencing systems incorporate patented design features, connection systems, or proprietary engineering. Sourcing or replicating these designs without authorization infringes on intellectual property rights. This can lead to legal disputes, product seizure, or forced redesigns. Always confirm whether the design is protected and if licensing is required.

Inconsistent Manufacturing Tolerances

Low-cost suppliers may cut corners on precision manufacturing, leading to inconsistent frame dimensions, misaligned joints, or poorly fitted panels. These inconsistencies complicate installation, reduce structural integrity, and degrade the visual quality of the finished fence.

Incomplete or Vague Warranty and Support

Some suppliers offer warranties that exclude key failure modes (e.g., warping or rot) or require specific installation methods without adequate guidance. A lack of clear post-purchase support can leave buyers stranded when quality issues arise.

Failure to Verify Supplier Credentials and References

Engaging with unproven or unverified suppliers increases the risk of poor-quality delivery and IP issues. Always check references, inspect past projects, and verify the supplier’s track record in delivering compliant, high-quality timber systems.

Avoiding these pitfalls requires due diligence in vetting suppliers, demanding documentation (material specs, treatment certs, IP disclaimers), and ensuring all components meet both quality and legal standards.

Logistics & Compliance Guide for Timber Frame Fencing

Overview

Timber frame fencing combines structural strength with aesthetic appeal, making it a popular choice for residential, commercial, and agricultural applications. However, successful installation and long-term durability require careful attention to logistics and compliance with relevant regulations and standards. This guide outlines key considerations to ensure efficient project execution and legal adherence.

Material Sourcing & Supply Chain Management

Selecting the right timber and managing suppliers effectively are critical to project success.

– Sustainable Sourcing: Ensure timber is certified by recognized bodies such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) to comply with environmental regulations and sustainability standards.

– Supplier Verification: Work with reputable suppliers who provide documentation on timber origin, treatment, and compliance with national building codes.

– Lead Times & Delivery Scheduling: Account for potential delays in timber availability, especially for treated or specialty wood. Coordinate deliveries to match installation timelines and minimize on-site storage needs.

Transportation & Handling

Proper handling during transport prevents damage and ensures material readiness.

– Secure Loading: Use straps and edge protectors to prevent movement and surface damage during transit.

– Moisture Protection: Cover timber loads with waterproof tarpaulins to avoid exposure to rain, which can lead to warping or fungal growth.

– On-Site Handling: Use appropriate lifting equipment (e.g., forklifts, cranes) to move heavy timber frames. Store materials on level, elevated, and ventilated platforms to prevent ground moisture absorption.

Site Preparation & Installation Logistics

Efficient site management streamlines the installation process.

– Access Planning: Ensure clear access routes for delivery vehicles and equipment, particularly in residential or confined areas. Obtain necessary permits for road closures or kerb access if required.

– Storage on Site: Designate a secure, dry, and well-drained area for material storage. Keep timber off the ground and covered until installation.

– Installation Sequencing: Plan the order of erection to avoid disruptions. Coordinate with other trades (e.g., landscaping, utilities) to prevent delays or damage.

Regulatory Compliance

Adherence to building codes, environmental laws, and safety standards is mandatory.

– Building Regulations: Comply with local planning laws and building codes (e.g., UK Building Regulations, U.S. International Building Code). Check height restrictions, property line setbacks, and structural requirements.

– Environmental Regulations: In ecologically sensitive areas (e.g., near waterways or protected habitats), obtain environmental permits. Avoid using timber treated with prohibited preservatives (e.g., chromated copper arsenate in residential settings).

– Workplace Safety: Follow health and safety guidelines (e.g., OSHA in the U.S., HSE in the UK). Provide appropriate PPE, train staff in safe handling, and implement fall protection where needed.

Timber Treatment & Durability Standards

Ensure long-term performance through proper treatment and classification.

– Preservative Treatment: Use pressure-treated timber rated for ground contact (e.g., UC4A/B in the UK) when posts are embedded in soil.

– Natural Durability: Select timber species with inherent resistance (e.g., Western Red Cedar, European Oak) where treatment is undesirable. Refer to durability classes in standards like EN 350.

– Fire Retardant Treatment: In fire-prone areas or urban zones, apply fire-retardant treatments compliant with local fire safety codes.

Documentation & Record Keeping

Maintain comprehensive records to demonstrate compliance and support warranties.

– Material Certificates: Keep copies of timber certification (FSC/PEFC), treatment reports, and manufacturer warranties.

– Inspection Logs: Document site inspections, including foundation depth, post alignment, and treatment verification.

– As-Built Drawings: Provide final documentation showing fence layout, materials used, and compliance statements for client and regulatory reference.

Maintenance & Long-Term Compliance

Sustainable fencing requires ongoing care and adherence to usage guidelines.

– Inspection Schedule: Recommend annual checks for rot, insect damage, and structural integrity.

– Repairs & Replacements: Use compliant materials and methods when repairing to maintain original standards.

– End-of-Life Disposal: Follow local waste regulations for disposal or recycling of treated timber, which may be classified as hazardous waste in some jurisdictions.

Conclusion

Effective logistics and strict compliance are essential for the successful deployment of timber frame fencing. By prioritizing sustainable sourcing, careful handling, adherence to regulations, and thorough documentation, contractors and developers can ensure safe, durable, and legally sound installations that meet both client expectations and environmental responsibilities.

In conclusion, sourcing timber frame fencing requires careful consideration of several key factors including material quality, sustainability, durability, cost, and supplier reliability. Opting for responsibly sourced timber not only ensures environmental stewardship but also enhances the longevity and aesthetic appeal of the fencing. By evaluating local versus imported options, comparing treatments and finishes, and selecting reputable suppliers, property owners and contractors can achieve a balance between performance, value, and ecological responsibility. Ultimately, a well-researched sourcing strategy leads to a durable, attractive, and sustainable timber frame fencing solution that meets both practical and environmental objectives.