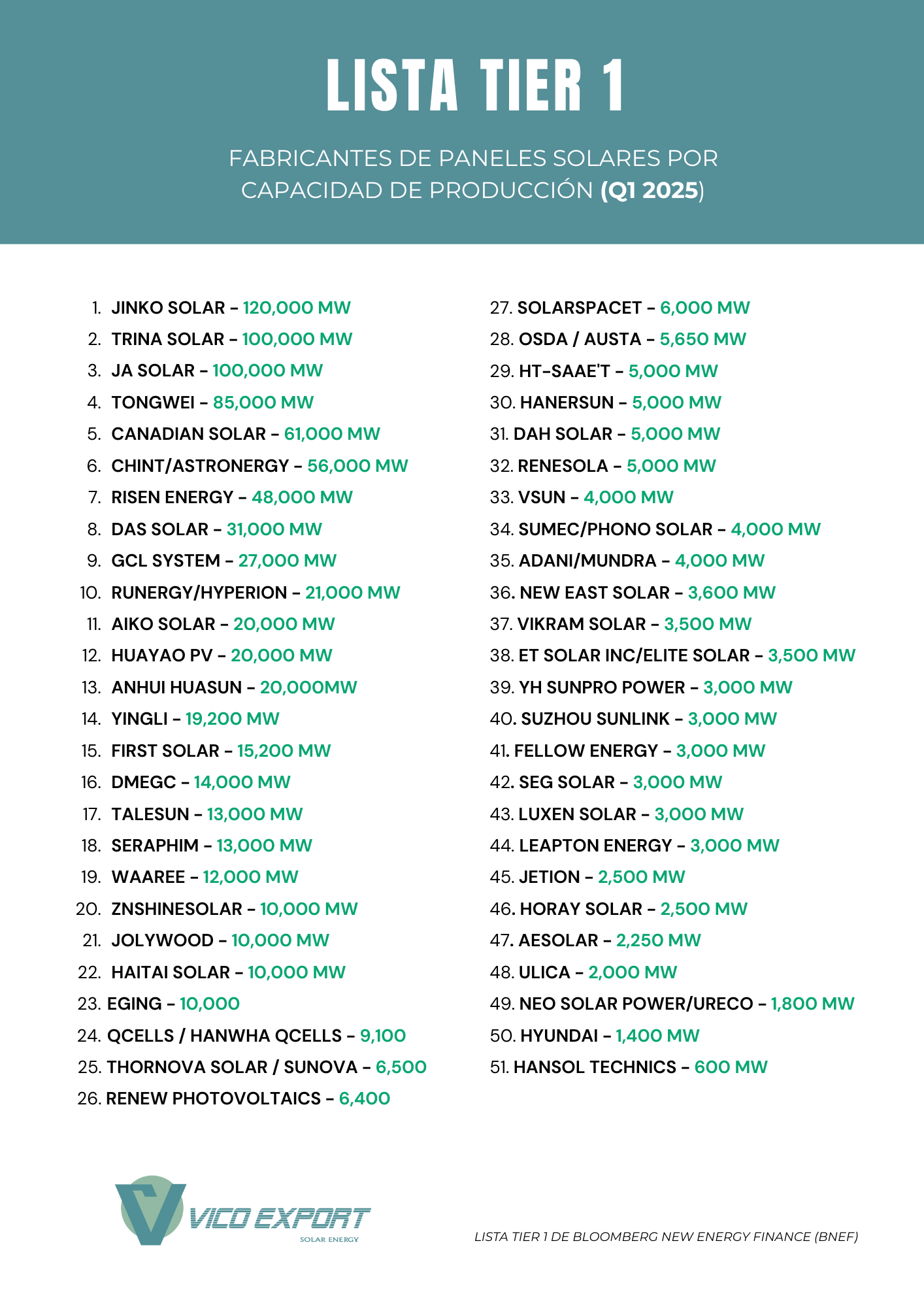

The global solar panel market is experiencing robust growth, driven by increasing demand for renewable energy, favorable government policies, and declining technology costs. According to a report by Mordor Intelligence, the solar photovoltaic (PV) market was valued at USD 171.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.9% from 2024 to 2029. Similarly, Grand View Research estimates the global solar panel market size at USD 153.8 billion in 2023, with a CAGR of 7.2% over the same forecast period. This expansion is fueled by rising energy security concerns, corporate decarbonization goals, and utility-scale solar adoption across emerging and developed economies. As market demand intensifies, Tier1 solar panel manufacturers—recognized by BloombergNEF for their bankability, financial strength, and vertical integration—have emerged as key players shaping industry standards, innovation, and global supply chains. These manufacturers not only dominate production capacity but also lead in efficiency improvements and sustainability practices, making them critical to achieving global net-zero targets. The following list highlights the top 10 Tier1 solar companies based on global shipment data, technological leadership, and market influence.

Top 10 Tier1 Solar Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 2025 Tier 1 cleantech companies

Domain Est. 1998

Website: spglobal.com

Key Highlights: Tier 1 PV Module Suppliers · Chint New Energy Technology Co. Ltd. (Astronergy) · Canadian Solar Inc. · First Solar Inc. · GCL System Integration ……

#2 Boviet Solar

Domain Est. 2017

Website: bovietsolar.com

Key Highlights: Boviet Solar is a solar energy technology company specializing in manufacturing top-performing solar PV modules for solar projects….

#3 Philadelphia Solar

Domain Est. 2008

Website: philadelphia-solar.com

Key Highlights: Philadelphia Solar is a leading Tier-1 solar panel manufacturer with 15+ years of experience in the industry. Our specialized expertise ensures top-quality ……

#4 Tier 1 Solar Panels List 2025

Domain Est. 2012

Website: renvu.com

Key Highlights: The latest Tier 1 Solar Panel List for 2025 is here. See which solar module manufacturers have earned Tier 1 status this year….

#5 Solar for , Utility, and Commercial

Domain Est. 2004

Website: trinasolar.com

Key Highlights: Trina Solar is a world leader in solar energy innovation and reliability. Power your energy future with industry-leading solar panels and solutions….

#6 Tier 1 Solar Panel List 2025

Domain Est. 2008

Website: solarinsure.com

Key Highlights: Solar Insure’s Approved Vendor and Tier 1 Solar Panel list is dedicated to elevating the solar industry’s safety, reliability, and financial stability….

#7 Top Solar Installers for Your Energy Needs

Domain Est. 2017

Website: tier1solar.com

Key Highlights: Choose Tier 1 Solar, LLC for expert solar panel installation, battery backup solutions, and professional solar panel cleaning services….

#8 T1 Energy

Domain Est. 2020

Website: t1energy.com

Key Highlights: T1 delivers durable solar components that efficiently convert sunlight into electricity. T1 engineers next-generation solar energy solutions that are low-cost ……

#9 Top Solar Energy FAQs Answered

Website: tier1solar.solutions

Key Highlights: Discover expert answers to the most frequently asked questions about solar energy with TIER 1 Solar Solutions. Learn why solar is a smart choice for your ……

#10 TIER 1 Solar Panels

Domain Est. 2019

Website: pvclick.com

Key Highlights: In this in-depth article, we will explore what it really means to be a TIER 1 solar panel manufacturer, how this classification is awarded, and which leading ……

Expert Sourcing Insights for Tier1 Solar Panel

2026 Market Trends for Tier 1 Solar Panels: A Hydrogen-Driven Outlook (H2 Perspective)

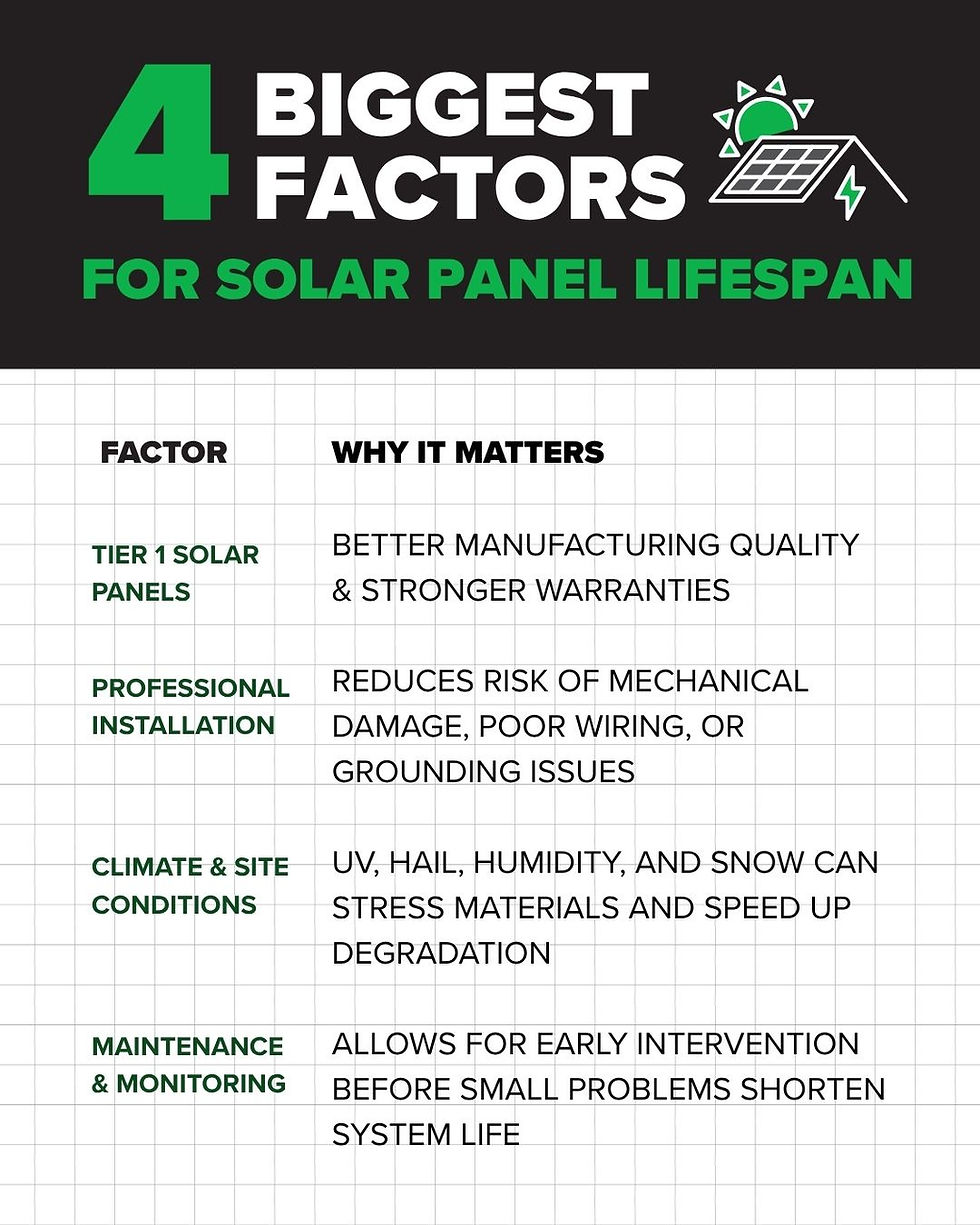

The global solar photovoltaic (PV) market, particularly the segment for Tier 1 solar panels (defined by rigorous bankability criteria including financial stability, vertical integration, proven track record, and technological leadership), is poised for significant evolution by 2026. While driven primarily by fundamental energy transition forces, the emerging hydrogen (H2) economy is set to become an increasingly influential secondary driver shaping demand, manufacturing, and integration strategies. Here’s an analysis of the key trends, with a specific lens on the H2 connection:

1. Sustained Global Growth, But Shifting Geographies & Intensifying Competition:

* Continued Expansion: Global solar installations will remain strong, driven by decarbonization mandates, falling LCOE (Levelized Cost of Energy), and energy security concerns. Tier 1 players will capture a significant share, particularly in utility-scale and commercial & industrial (C&I) segments requiring bankable solutions.

* Geographic Diversification: Growth will accelerate beyond traditional leaders (China, US, EU) into emerging markets (Southeast Asia, Latin America, Africa, Middle East). Tier 1 manufacturers will need agile supply chains and localized partnerships to serve these diverse regions effectively.

* Hyper-Competition: The market remains fiercely competitive. While Tier 1 status provides an advantage, pressure on margins persists due to oversupply (especially from non-Tier 1 Chinese manufacturers) and commoditization of standard panels. Differentiation through technology, service, and integration becomes paramount.

2. Technological Dominance: n-Type Technologies Take Center Stage:

* Rapid n-Type Adoption: By 2026, n-type technologies (TOPCon, HJT, IBC) will likely dominate the Tier 1 premium product portfolio, surpassing p-type PERC. Their higher efficiency (>24%+ for leading modules), better temperature coefficients, and lower degradation rates offer superior performance and value.

* Efficiency Race Intensifies: The push for higher module efficiencies (approaching 25% commercially) will continue. Tier 1 players investing heavily in R&D (tunneling oxides, advanced metallization, wafer quality) will lead.

* Bifacial Gains Traction: Bifacial modules, especially when paired with trackers in high-albedo environments, will see broader adoption in utility-scale projects, offering incremental energy yield gains that Tier 1 manufacturers can capitalize on.

3. The Hydrogen (H2) Confluence: A Growing Strategic Imperative:

The H2 economy is not the primary driver of solar panel sales, but by 2026, it will be a significant strategic factor influencing Tier 1 players:

* Demand Pull for Dedicated Solar Capacity: Green hydrogen production (via electrolysis powered by renewables) requires massive, dedicated, and often co-located solar farms. These “H2-ready” or “H2-dedicated” projects represent a new, large-scale, and bankable market segment. Tier 1 manufacturers, with their proven reliability and project finance credibility, are the natural suppliers for these critical infrastructure projects. Expect dedicated product lines or service packages.

* Focus on LCOH (Levelized Cost of Hydrogen): The economics of green H2 hinge on minimizing electricity cost (LCOE) and maximizing electrolyzer utilization. This drives demand for:

* Ultra-High Efficiency Panels: Maximizing kWh per m² directly reduces land use and capital cost per kg H2.

* High Energy Yield: Panels with superior performance in real-world conditions (low irradiance, high temperatures) are crucial. Tier 1 n-type panels excel here.

* Durability & Reliability: Electrolyzers require stable, long-term power. Tier 1 panels’ proven low degradation and high reliability over 30+ years directly impact H2 project bankability and operating costs.

* Integration & System Solutions: Tier 1 players may evolve beyond selling panels to offering integrated solutions for H2 projects, potentially bundling with trackers, monitoring, and even partnering with electrolysers or EPCs. Their brand trust is essential for securing project financing.

* Policy Synergy: Government H2 strategies (e.g., EU Hydrogen Strategy, US H2 Hubs) often include mandates or incentives for renewable-powered production. Tier 1 manufacturers can leverage these policies to secure long-term offtake agreements for solar projects feeding H2 facilities.

4. Supply Chain Resilience & Sustainability Imperatives:

* Diversification & Localization: Geopolitical risks and trade policies (e.g., UFLPA, EU CBAM) will push Tier 1 players to diversify manufacturing (e.g., Southeast Asia, Americas) and secure polysilicon supply chains, potentially increasing costs but enhancing resilience.

* Sustainability & Circularity: ESG pressures will intensify. Tier 1 leaders will need transparent, low-carbon manufacturing footprints, robust recycling programs (driven by EU mandates), and use of sustainable materials. This is critical for reputation and accessing green finance, including for H2 projects which are inherently ESG-focused.

* Raw Material Volatility: Prices for polysilicon, silver, and other materials will remain volatile. Tier 1 players with vertical integration and strong procurement will have an advantage.

5. Beyond Panels: The Rise of Integrated Solutions:

* Energy Storage Integration: Pairing solar with batteries (solar+storage) will become standard, especially for C&I and grid stability. Tier 1 players may expand into or partner on storage solutions.

* Digitalization & O&M: Advanced monitoring, predictive maintenance, and performance optimization platforms will be key differentiators, maximizing energy yield and reducing O&M costs – critical for both traditional projects and H2 applications.

Conclusion: Tier 1 in 2026 – Leaders in a Complex, H2-Integrated Landscape

By 2026, Tier 1 solar panel manufacturers will operate in a market characterized by intense competition, technological sophistication (dominated by n-type), and increasingly intertwined with the green hydrogen economy. Their core strengths – bankability, technological leadership, manufacturing scale, and financial stability – will be more valuable than ever.

The H2 connection is pivotal: It creates a high-value, large-scale application demanding the very attributes Tier 1 players excel at (efficiency, reliability, bankability). Success will depend on:

1. Leading the n-type transition and pushing efficiency boundaries.

2. Actively targeting and adapting to the H2 project market, potentially offering integrated solutions.

3. Building resilient, sustainable, and diversified supply chains.

4. Leveraging their brand and financial strength to secure financing for complex projects, including H2-dedicated solar farms.

Tier 1 players who strategically position themselves at the intersection of advanced solar technology and the burgeoning green hydrogen demand will be best positioned to thrive in 2026 and beyond.

Common Pitfalls Sourcing Tier 1 Solar Panels (Quality, IP)

Sourcing Tier 1 solar panels is often seen as a guarantee of quality and reliability, but several critical pitfalls related to quality assurance and intellectual property (IP) can undermine this perception. Being aware of these risks is essential for making informed procurement decisions.

Overreliance on the Tier 1 Classification

The “Tier 1” label, originally coined by BloombergNEF (BNEF), primarily indicates a manufacturer’s financial strength and bankability—not necessarily superior product quality or technological innovation. Relying solely on this classification can lead buyers to overlook critical differences in actual panel performance, durability, and manufacturing consistency. Many Tier 1 suppliers outsource production or use third-party cells, which may not meet the expected quality benchmarks.

Inconsistent Quality Control Across Production Facilities

Large Tier 1 manufacturers often operate multiple production lines across different countries. Quality control standards can vary significantly between facilities, especially when capacity is outsourced to subcontractors. Buyers may receive panels from lower-tier production lines under the same brand, resulting in performance issues such as microcracks, delamination, or premature power degradation—despite the Tier 1 branding.

Use of Third-Party or Generic Solar Cells

Some Tier 1 brands do not manufacture their own solar cells and instead source them from external suppliers. These generic or commoditized cells may lack proprietary technology and performance optimization. This reliance increases the risk of supply chain inconsistencies and reduces control over the core component of the panel, potentially affecting long-term reliability and efficiency.

Intellectual Property (IP) Misrepresentation

A significant but often overlooked pitfall is the misrepresentation of IP ownership. Some Tier 1 suppliers market panels with advanced features (e.g., half-cut cells, multi-busbar, or PERC technology) without owning the underlying IP. Instead, they license or replicate technologies developed by others, which can lead to legal disputes, supply restrictions, or sudden discontinuation of product lines. This also limits the manufacturer’s ability to innovate or customize products.

Lack of Transparency in Supply Chain

Tier 1 manufacturers may not fully disclose their supply chain, particularly regarding cell and material sources. This opacity makes it difficult to verify claims about anti-dumping compliance, ethical sourcing, or the use of restricted substances (e.g., forced labor concerns). It also hampers traceability in case of product failures or warranty claims, creating risks for project developers and financiers.

Warranty Limitations and Enforcement Challenges

While Tier 1 brands typically offer strong product and performance warranties, enforcing these warranties across international borders can be challenging. Some manufacturers have complex claims processes or limit coverage based on installation practices, even when failures stem from manufacturing defects. Additionally, extended warranties may be backed by third-party insurers with varying financial stability, creating potential gaps in long-term protection.

Conclusion

Sourcing Tier 1 solar panels offers advantages in financial credibility, but it does not automatically ensure superior quality or robust IP protection. Buyers must go beyond the Tier 1 label by conducting thorough due diligence—including factory audits, supply chain verification, IP assessments, and independent product testing—to mitigate risks and ensure long-term project success.

Logistics & Compliance Guide for Tier 1 Solar Panels

Overview of Tier 1 Solar Panel Specifications

Tier 1 solar panels are manufactured by financially stable, bankable companies with vertically integrated production processes and proven performance in the field. These panels meet stringent international quality standards, including IEC 61215 (crystalline silicon performance), IEC 61730 (safety), and UL 61730 (North American safety certification). They typically offer performance warranties of 25+ years and product warranties of 10–12 years. Understanding these specifications is essential for logistics planning, as they influence packaging requirements, handling procedures, and compliance documentation.

Packaging and Handling Requirements

Tier 1 solar panels must be packaged to withstand international transit, including maritime, air, and overland transport. Panels are typically shipped in robust wooden crates or palletized bundles with edge protectors and interlayer padding to prevent micro-cracks or glass breakage. Crates must be weather-resistant and secured to prevent shifting. Handling requires forklifts with wide, padded forks to avoid frame damage. Workers must follow no-stack protocols (unless designed for stacking) and avoid tilting panels beyond recommended angles. Labels must clearly indicate “Fragile,” “This Side Up,” and orientation arrows.

International Shipping and Transportation

Solar panels are generally transported via ocean freight due to their size and weight, with air freight reserved for urgent, small-volume shipments. Standard 40-foot high cube containers can accommodate 700–800 panels depending on model dimensions. Proper container loading ensures even weight distribution and prevents movement. Route planning should minimize exposure to extreme temperatures, humidity, and salt spray. Use of GPS tracking and temperature/humidity data loggers is recommended to monitor conditions during transit. Incoterms (e.g., FOB, CIF, DDP) must be clearly defined in contracts to allocate risk and responsibility.

Import/Export Documentation and Regulations

Export from the manufacturing country (typically China, Vietnam, or Malaysia) requires a commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Many Tier 1 manufacturers provide IEC and UL certification documents, test reports, and warranty statements. Import requirements vary by destination: the U.S. requires entry through U.S. Customs and Border Protection (CBP), possibly subject to anti-dumping/countervailing duties (AD/CVD) on panels from certain countries. The EU mandates CE marking, conformity with the Construction Products Regulation (CPR) where applicable, and compliance with the EU Green Public Procurement (GPP) criteria. Importers must also adhere to local electrical safety standards.

Customs Clearance and Duties

Customs clearance involves submission of documentation to the destination country’s customs authority. Harmonized System (HS) codes for solar panels (e.g., 8541.40) determine duty rates and eligibility for trade agreements or exemptions. Some countries offer reduced or zero tariffs under initiatives like the U.S. Section 301 exclusions or the EU’s Generalized System of Preferences (GSP). Importers must verify country-of-origin rules and ensure anti-dumping measures do not apply. Pre-arrival submission of electronic data accelerates clearance. Engaging a licensed customs broker familiar with renewable energy equipment is strongly advised.

Environmental and Safety Compliance

Transportation of solar panels must comply with international safety standards, including IMDG Code for sea freight and IATA regulations for air shipment—though panels are generally non-hazardous. However, damaged panels may contain small amounts of lead or cadmium, requiring special handling. End-of-life management must align with the destination country’s WEEE (Waste Electrical and Electronic Equipment) directive in the EU or equivalent recycling laws. Importers should confirm manufacturer participation in take-back programs. On-site storage must follow fire safety codes, particularly when panels are stored in large quantities near flammable materials.

Quality Assurance and Inspection Protocols

Pre-shipment inspections (PSI) are recommended to verify panel quantity, packaging integrity, labeling, and visible defects. Third-party inspectors can conduct EL (electroluminescence) testing on sample units to detect micro-cracks or cell defects. Documentation should include a certificate of inspection and test reports. Upon arrival, a receiving inspection should confirm shipment condition and compliance with purchase order specifications. Any discrepancies must be reported immediately to initiate claims with carriers or suppliers under warranty or insurance terms.

Warranty and After-Sales Logistics

Tier 1 manufacturers offer comprehensive warranties, but logistics play a role in warranty fulfillment. Replacement panels for defective units must be shipped under warranty terms, often requiring return of failed units (RMAs). Logistics providers should support reverse logistics with secure packaging and tracking. Maintain records of panel serial numbers, installation dates, and shipment details to streamline warranty claims. Coordinate with manufacturers on regional service hubs to reduce replacement lead times.

Conclusion for Sourcing Tier 1 Solar Panels

Sourcing Tier 1 solar panels is a strategic decision that ensures high performance, long-term reliability, and strong manufacturer credibility in solar energy projects. These panels, produced by financially stable and technologically advanced manufacturers, offer superior efficiency, extended warranties, and proven bankability—essential factors for maximizing return on investment and project bankability. By partnering with reputable Tier 1 suppliers, developers and installers mitigate risks related to product failure, supply chain disruptions, and performance shortfalls. Additionally, Tier 1 panels often meet strict international quality standards, facilitating smoother project financing and compliance with industry regulations.

In conclusion, prioritizing Tier 1 solar panels in procurement strategies supports project sustainability, enhances energy yield, and strengthens client confidence. As the solar market continues to evolve, sourcing from certified Tier 1 manufacturers remains a cornerstone of responsible, high-quality solar deployment.