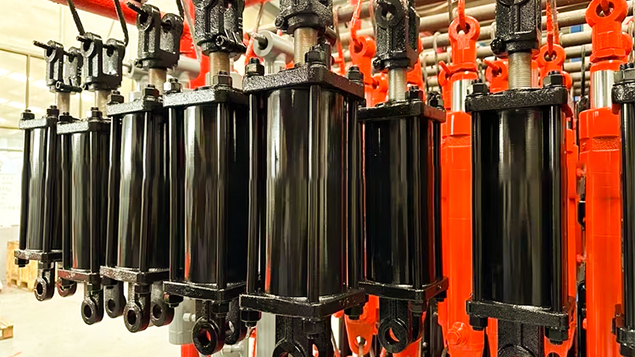

The global hydraulic cylinder market is experiencing robust growth, driven by rising demand across construction, agriculture, and industrial machinery sectors. According to a report by Mordor Intelligence, the hydraulic cylinder market was valued at USD 5.2 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029, fueled by advancements in heavy machinery automation and infrastructure development. Tie rod hydraulic cylinders, known for their versatility, serviceability, and standardized design, constitute a significant segment of this market. As industries prioritize efficiency and durability in hydraulic systems, manufacturers of tie rod cylinders are expanding capacity, enhancing material technologies, and investing in precision engineering. This report identifies the top 10 tie rod hydraulic cylinder manufacturers leading this growth, evaluated on production scale, technological innovation, global footprint, and market presence, drawing insights from industry benchmarks and market analytics by Mordor Intelligence.

Top 10 Tie Rod Hydraulic Cylinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydraulic Cylinder Manufacturer

Domain Est. 1999

Website: cylval.com

Key Highlights: Cylinders & Valves, Inc. offers a wide variety of standard and custom hydraulic cylinders, pneumatic cylinders, replacement parts, and cylinder repair….

#2 Hydraulic Cylinders

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker manufactures a diverse range of standard and special tie rod, roundline and ‘mill’ type cylinders to suit all types of industrial cylinder applications….

#3 Tie

Domain Est. 1996

Website: princehyd.com

Key Highlights: Prince Manufacturing Corporation is a premier manufacturer of high quality hydraulic tie-rod cylinders. We have a wide and diverse variety of standard hydraulic ……

#4 Milwaukee Cylinder

Domain Est. 1999

Website: milwaukeecylinder.com

Key Highlights: Milwaukee Cylinder is a premium manufacturer of air cylinders and hydraulic cylinders for standard and custom tie rod cylinder applications….

#5 Tie

Domain Est. 2014

Website: magisterhyd.com

Key Highlights: Free delivery 30-day returnsMagister Hydraulics is a leading manufacturer of custom Tie-Rod hydraulic cylinders for a wide range of applications. We offer a wide range of options t…

#6 Tie

Domain Est. 1995

Website: danfoss.com

Key Highlights: Our tie-rod cylinders offer a wide range of bore and stroke sizes combined with robust features to withstand extreme environmental conditions and constant use….

#7 Tie Rod Hydraulic Cylinders

Domain Est. 1996

Website: energymfg.com

Key Highlights: Energy Mfg. Co. designs and manufactures tie rod hydraulic cylinders. These hydraulic cylinders are commonly used in low-pressure applications….

#8 Tie Rod Cylinders

Domain Est. 1999

Website: yatesind.com

Key Highlights: Yates Industries manufactures, supplies, replaces and repairs hydraulic cylinders, pneumatic cylinders, tie rod cylinders, mill cylinders……

#9 Tie Rod Hydraulic Cylinders

Domain Est. 1999

Website: wenproducts.com

Key Highlights: Free delivery over $25Our double-acting steel-welded tie-rod hydraulic cylinders create operating pressures of 2500 PSI. Our hydraulic cylinders include a reinforced O-ring tube se…

#10 Tie

Domain Est. 2013

Website: baileyhydraulics.com

Key Highlights: Free delivery over $35 45-day returnsThese tie-rod hydraulic cylinders are durable and easy to install perfect for light to medium-duty applications. Explore our tie-rods today!…

Expert Sourcing Insights for Tie Rod Hydraulic Cylinder

H2: 2026 Market Trends for Tie Rod Hydraulic Cylinders

The global tie rod hydraulic cylinder market is projected to undergo significant transformation by 2026, driven by technological advancements, evolving industrial demands, and a growing emphasis on energy efficiency and durability. As a critical component in hydraulic systems across construction, agriculture, manufacturing, and material handling sectors, tie rod hydraulic cylinders are expected to benefit from increased automation and infrastructure development worldwide.

One key trend shaping the 2026 outlook is the rising demand for compact, high-performance cylinders in mobile and industrial machinery. Manufacturers are focusing on lightweight yet robust designs using advanced materials such as high-tensile steel and corrosion-resistant coatings to enhance lifespan and reduce maintenance costs. This shift is particularly evident in emerging markets where infrastructure expansion is accelerating the need for reliable construction and agricultural equipment.

Another significant trend is the integration of smart technologies and Industry 4.0 principles. By 2026, an increasing number of tie rod hydraulic cylinders are expected to feature embedded sensors and condition monitoring systems. These smart cylinders enable real-time performance tracking, predictive maintenance, and improved system efficiency—features increasingly demanded in automated production lines and smart construction fleets.

Additionally, sustainability is influencing product development. Hydraulic system manufacturers are prioritizing energy-efficient designs that reduce fluid leakage and improve sealing technologies. This aligns with global regulatory trends aimed at minimizing environmental impact and supporting circular economy models through improved recyclability and longer product life cycles.

Regionally, Asia-Pacific is anticipated to lead market growth due to rapid industrialization in countries like China and India. North America and Europe will maintain strong demand, supported by ongoing investments in automation and equipment modernization. Meanwhile, advancements in aftermarket services and customization options are enabling suppliers to capture niche applications across diverse industries.

In conclusion, the 2026 market for tie rod hydraulic cylinders will be characterized by innovation in materials, digital integration, and sustainability. Companies that adapt to these trends by offering smarter, more efficient, and environmentally friendly solutions are poised to gain a competitive advantage in an increasingly dynamic global marketplace.

Common Pitfalls When Sourcing Tie Rod Hydraulic Cylinders: Quality and IP Concerns

Sourcing tie rod hydraulic cylinders involves several potential pitfalls, especially when evaluating quality and Ingress Protection (IP) ratings. Avoiding these common mistakes ensures reliability, safety, and long-term performance in demanding applications.

Inadequate Assessment of Build Quality

One major pitfall is failing to thoroughly assess the cylinder’s construction quality. Buyers may focus only on price or basic specifications, overlooking critical factors such as rod material (e.g., chrome-plated hard chrome vs. inadequate plating), weld integrity, seal quality, and precision machining. Low-quality cylinders often use inferior seals and coatings, leading to premature leaks, pitting, and rod scoring—especially in harsh or high-cycle environments.

Misunderstanding or Overlooking IP Ratings

Another common mistake is misinterpreting or ignoring the IP (Ingress Protection) rating. While tie rod cylinders are typically used indoors or in moderate environments, exposure to dust, moisture, or washdown conditions requires appropriate sealing. Assuming all cylinders offer sufficient protection without verifying the IP rating (e.g., IP65 for dust-tight and low-pressure water resistance) can result in contamination, seal failure, and reduced service life.

Relying Solely on Manufacturer Claims Without Verification

Many suppliers advertise high-quality components or specific IP ratings without third-party certification or test data. Relying solely on marketing materials without requesting performance test reports, material certifications, or independent reviews can lead to sourcing substandard products. Always verify claims through documentation or sample testing.

Ignoring Environmental and Application-Specific Needs

Sourcing cylinders without considering the actual operating environment is a critical oversight. For example, using a standard cylinder in a humid, dusty, or corrosive setting without enhanced wipers, corrosion-resistant coatings, or proper IP-rated seals accelerates wear and failure. Matching the cylinder’s specifications—including IP protection and material quality—to the application is essential.

Choosing Suppliers Without Quality Assurance Processes

Partnering with suppliers who lack robust quality control systems increases the risk of receiving inconsistent or defective cylinders. Avoid vendors without ISO certifications, in-process inspections, or traceability procedures. A reliable supplier should offer consistent quality, documentation, and responsive support when issues arise.

Logistics & Compliance Guide for Tie Rod Hydraulic Cylinders

Product Overview and Classification

Tie rod hydraulic cylinders are industrial components used to convert hydraulic energy into linear mechanical force. They are widely used in construction, agriculture, material handling, and manufacturing equipment. Proper classification under international trade systems is essential for compliance. These cylinders are typically classified under Harmonized System (HS) code 8412.21, which covers hydraulic cylinders and rams. Accurate classification ensures correct duty application and adherence to import/export regulations.

Export Documentation Requirements

To ship tie rod hydraulic cylinders internationally, complete and accurate documentation is required. Essential documents include a commercial invoice, packing list, bill of lading (for sea freight) or air waybill (for air freight), and a certificate of origin. Depending on the destination country, additional documentation such as an Export Control Classification Number (ECCN) or a Shipper’s Letter of Instruction (SLI) may be necessary. Always verify specific country requirements through official customs authorities or trade advisors.

International Regulatory Compliance

Tie rod hydraulic cylinders may be subject to various international regulations depending on the materials used and end-use applications. Components containing restricted substances (e.g., certain metals or coatings) must comply with regulations such as REACH (EU) and RoHS. Additionally, if the cylinders are used in military or aerospace applications, International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR) may apply. Conduct a compliance review prior to export to determine applicable controls.

Packaging and Handling Standards

Proper packaging is critical to prevent damage during transit. Tie rod hydraulic cylinders should be securely crated or palletized with protective materials to shield rods, ports, and seals from impact and corrosion. Use desiccants and vapor corrosion inhibitors (VCI) when shipping to humid environments. Clearly label packages with handling instructions, including “Fragile,” “This Side Up,” and product identification tags. Ensure all ports are capped or plugged to prevent contamination.

Transportation Modes and Considerations

Choose the appropriate transportation mode (air, sea, or ground) based on delivery timelines, cost, and cylinder size/weight. For sea freight, ensure containers are weatherproof and secured against shifting. For air freight, confirm weight and dimensional restrictions with the carrier. When transporting domestically or internationally by truck, secure loads with straps and avoid exposure to extreme temperatures or moisture. Coordinate with freight forwarders experienced in handling industrial machinery.

Import Regulations and Duties

Importing tie rod hydraulic cylinders requires compliance with destination country customs regulations. Duties and taxes vary by country and are based on the declared value, HS code, and country of origin. Some countries may require product certification (e.g., CE marking for the EU, CCC for China) or inspection prior to clearance. Importers must also adhere to local safety and environmental standards. Engage a licensed customs broker to facilitate smooth entry.

Environmental and Safety Compliance

Manufacturers and distributors must ensure tie rod hydraulic cylinders meet relevant environmental and occupational safety standards. This includes compliance with OSHA (USA), WHMIS (Canada), and similar frameworks. Cylinders must be designed and tested to withstand rated pressures and include safety warnings. Proper disposal of packaging and any hazardous components (e.g., hydraulic fluid residue) must follow local environmental regulations.

Recordkeeping and Audit Preparedness

Maintain detailed records of all transactions involving tie rod hydraulic cylinders for a minimum of five years. Records should include export licenses (if applicable), certificates of compliance, shipping documents, and customer declarations. These records support audits by customs, regulatory agencies, or internal compliance reviews. Implement a document management system to ensure traceability and readiness for regulatory inquiries.

Conclusion for Sourcing Tie Rod Hydraulic Cylinders

In conclusion, sourcing tie rod hydraulic cylinders requires a balanced approach that considers quality, cost, reliability, and supplier capabilities. These cylinders are critical components in various industrial and mobile applications, where performance, durability, and precision are essential. When selecting a supplier, it is important to evaluate factors such as manufacturing standards (e.g., ISO or NFPA compliance), material quality, customization options, lead times, after-sales support, and overall total cost of ownership.

Sourcing from reputable manufacturers—whether domestic or international—can provide long-term value through reduced downtime, lower maintenance costs, and improved system efficiency. Additionally, establishing strong partnerships with suppliers who offer technical expertise and responsive service helps ensure compatibility with application requirements and supports continuous operational success.

Ultimately, a strategic sourcing approach focused on quality assurance, supply chain stability, and lifecycle performance will enable organizations to maximize the reliability and efficiency of their hydraulic systems while maintaining cost-effectiveness.