The global thrust bearing market is experiencing steady growth, driven by increasing demand from industries such as automotive, aerospace, power generation, and industrial machinery. According to a 2023 report by Mordor Intelligence, the market was valued at USD 3.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 5.1% from 2023 to 2028. This expansion is fueled by technological advancements in bearing materials, rising industrial automation, and the need for high-efficiency mechanical systems. As critical components in rotating equipment, thrust plates play a vital role in managing axial loads and ensuring operational stability. With growing investments in renewable energy, particularly in wind turbines, and continued modernization of transportation infrastructure, the demand for high-performance thrust plates is on the rise. This report identifies the top eight manufacturers leading innovation, quality, and market share in the global thrust plate industry.

Top 8 Thrust Plate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Thrust Plates Manufacturer USA

Domain Est. 2000

Website: northernindmfg.com

Key Highlights: Northern Industrial Manufacturing can enhance your supply chain flexibility and drastically reduce your inventory with our high quality thrust plate ……

#2 Thrust Plates

Domain Est. 1995

Website: kennametal.com

Key Highlights: Additive Manufacturing · All Additive Manufacturing · Metal Powders for Additive Manufacturing · Design Optimization & Prototyping · Series Production · Spare ……

#3 Tapered Land Thrust Plates

Domain Est. 1998

Website: americanbabbitt.com

Key Highlights: American Babbitt Bearing, located in Huntington, WV, has been providing quality tapered land thrust plate repairs and manufacture for over 15 years….

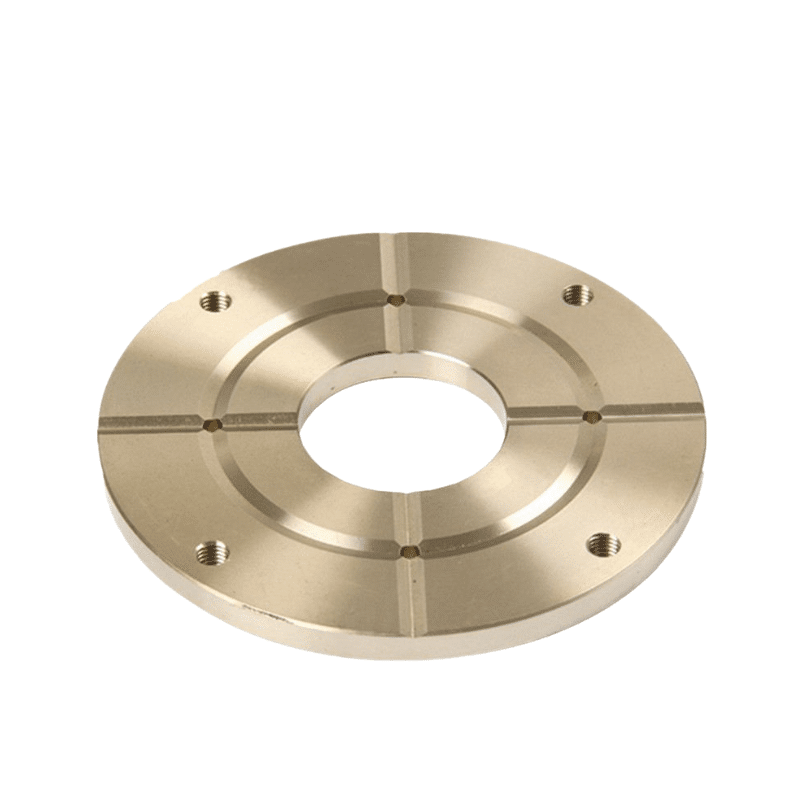

#4 Thrust Plates

Domain Est. 1998

Website: permco.com

Key Highlights: Permco uses a high density bronze alloy in all of their thrust plates. The better wearing characteristics of this alloy assure more hours of pump or motor ……

#5 Thrust Plates

Domain Est. 1999

Website: bearingsplus.com

Key Highlights: For applications with low thrust loads, limited space and negligible misalignment, Bearings Plus designs and supplies thrust plates with simple or compound ……

#6 Thrust Plates & Gibs

Domain Est. 2007

Website: us.misumi-ec.com

Key Highlights: Thrust plates are flat components used in machinery to withstand axial loads, which are forces that act along the axis of a shaft….

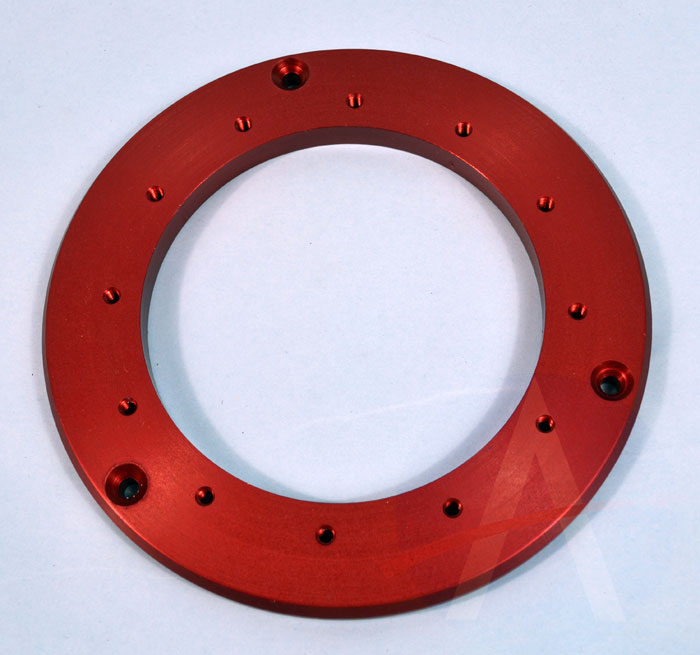

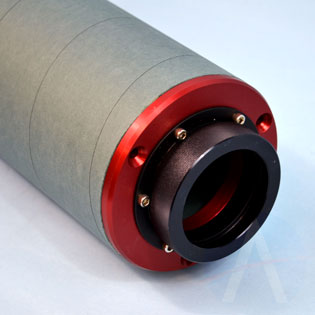

#7 Aluminum Thrust Plate…

Domain Est. 2009

Website: hfbolin.com

Key Highlights: The thrust plates are designed with special aluminum materials,and own good antifriction,wear resistance and yield strength. Improved mechanical & volumetric ……

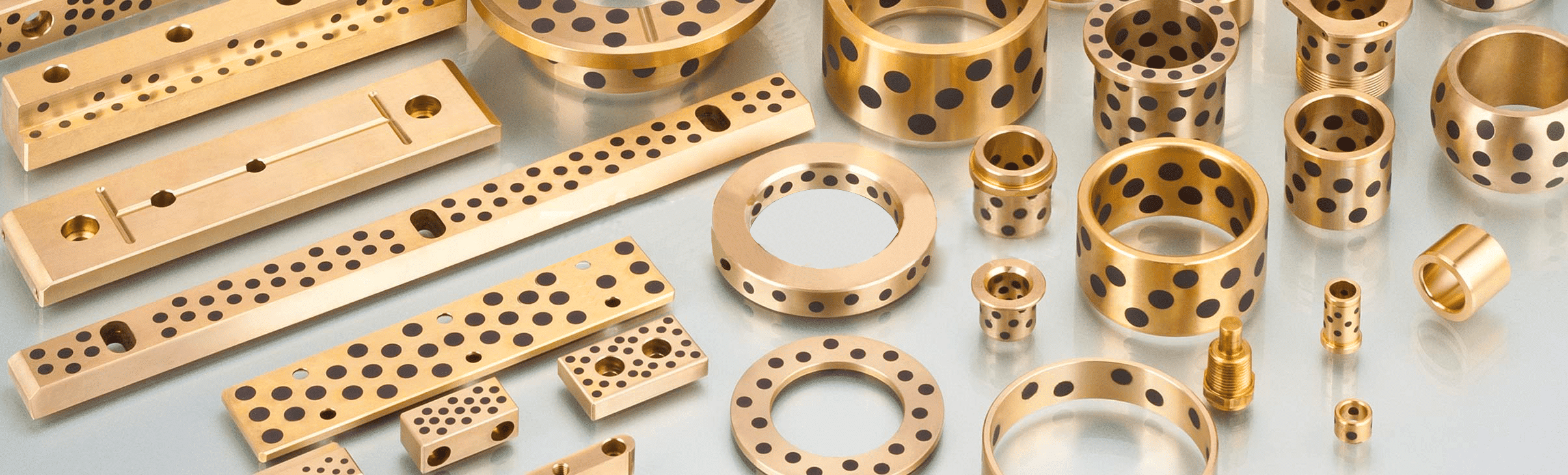

#8 Thrust Plate Mastery

Domain Est. 2019

Website: bronzeoilless.com

Key Highlights: A thrust plate is a specialized mechanical component designed to handle axial loads or thrust loads within a machine or mechanism….

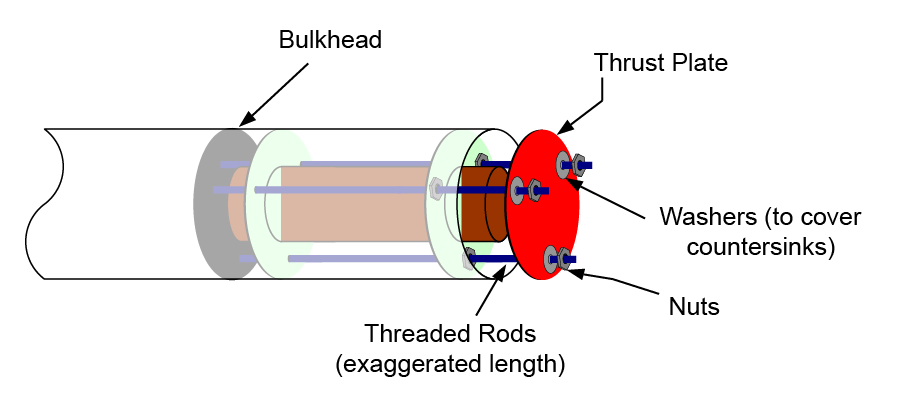

Expert Sourcing Insights for Thrust Plate

H2: 2026 Market Trends for Thrust Plates

The global thrust plate market is poised for significant evolution by 2026, driven by advancements in industrial machinery, transportation systems, and renewable energy technologies. As a critical component in managing axial loads in rotating equipment—such as turbines, compressors, marine propulsion systems, and automotive transmissions—thrust plates are witnessing heightened demand across multiple sectors. Below is an analysis of key market trends expected to shape the thrust plate industry in 2026:

-

Growth in Renewable Energy Infrastructure

The expansion of hydroelectric and wind power generation is a major driver for thrust plate demand. In hydroelectric turbines and large wind turbine gearboxes, thrust plates play a vital role in handling axial thrust under high-load conditions. With global commitments to carbon neutrality, investments in renewable energy infrastructure are accelerating, particularly in Asia-Pacific and Europe. This trend is expected to significantly boost the thrust plate market by 2026. -

Advancements in Material Technology

There is a growing shift toward high-performance materials such as sintered bronze, carbon-graphite composites, and advanced babbitt alloys. These materials offer improved wear resistance, thermal stability, and load-bearing capabilities. By 2026, manufacturers are anticipated to increasingly adopt engineered composites and surface coatings (e.g., PTFE or DLC—diamond-like carbon) to extend service life and reduce maintenance costs, especially in harsh operating environments. -

Increased Demand from Marine and Offshore Sectors

The marine propulsion industry, including commercial shipping and offshore oil & gas platforms, relies heavily on thrust blocks equipped with precision thrust plates. As global shipping activity rebounds and new environmentally compliant vessels are commissioned, demand for reliable, corrosion-resistant thrust plates is rising. Additionally, the growth of offshore wind farms is creating new applications for marine-grade thrust components. -

Automotive Industry Electrification and Efficiency Demands

While traditional internal combustion engines use thrust plates in transmissions and crankshafts, the rise of electric vehicles (EVs) is altering demand patterns. Although EV drivetrains generate less axial load, high-performance electric motors and multi-speed EV transmissions still require precision thrust management. By 2026, the automotive segment is expected to see a transition in thrust plate applications, favoring lightweight, low-friction designs compatible with electric powertrains. -

Regional Market Shifts

Asia-Pacific—particularly China, India, and South Korea—is expected to dominate the thrust plate market by 2026 due to rapid industrialization, infrastructure development, and strong manufacturing bases in shipbuilding and power generation. North America and Europe will maintain steady demand, supported by retrofitting of aging infrastructure and stringent industrial efficiency standards. -

Focus on Predictive Maintenance and Smart Components

Integration of condition monitoring technologies into thrust assemblies is an emerging trend. By 2026, smart thrust plates embedded with sensors to monitor temperature, vibration, and wear are anticipated to gain traction, especially in mission-critical applications. This shift supports predictive maintenance strategies, reducing downtime and improving operational efficiency. -

Sustainability and Supply Chain Resilience

Environmental regulations and supply chain disruptions are pushing manufacturers to localize production and adopt sustainable practices. Recycling of bearing materials and reduction of lead content in babbitt alloys are becoming key considerations. Companies investing in circular economy models and resilient supply chains are likely to gain competitive advantage by 2026.

Conclusion:

By 2026, the thrust plate market will be shaped by technological innovation, expanding renewable energy projects, and evolving industrial needs. Growth will be most pronounced in high-load, high-reliability applications across energy, marine, and advanced manufacturing sectors. Companies that embrace material innovation, digital integration, and sustainable production are expected to lead the market in the coming years.

Common Pitfalls When Sourcing a Thrust Plate (Quality, IP)

Sourcing a thrust plate requires careful attention to both quality standards and intellectual property (IP) considerations. Overlooking these aspects can lead to operational failures, legal disputes, or safety risks. Below are key pitfalls to avoid:

1. Ignoring Material and Manufacturing Quality

One of the most frequent mistakes is focusing solely on price while neglecting the material composition and manufacturing processes. Low-quality thrust plates made from substandard alloys or with poor heat treatment can suffer from premature wear, cracking, or deformation under load. Always verify:

– Material specifications (e.g., ASTM or ISO standards)

– Hardness and surface finish requirements

– Use of proper lubrication grooves and dimensional tolerances

– Certifications (e.g., ISO 9001, AS9100 for aerospace)

2. Overlooking Application-Specific Design Requirements

Thrust plates are highly application-dependent, whether in turbines, compressors, or marine propulsion systems. Sourcing a generic or undersized part can lead to catastrophic failure. Pitfalls include:

– Incorrect load capacity or speed ratings

– Poor fit due to dimensional inaccuracies

– Incompatibility with existing shafts or housings

Always ensure the thrust plate is engineered for the specific operating environment, including temperature, pressure, and rotational speed.

3. Failing to Verify Intellectual Property (IP) Compliance

Using or sourcing thrust plate designs protected by patents, trademarks, or proprietary engineering can expose your organization to legal risks. Common IP-related pitfalls:

– Procuring “copy” or reverse-engineered parts without licensing

– Sourcing from suppliers who infringe on OEM designs

– Lack of clear documentation on design ownership and rights

Always conduct due diligence on supplier IP legitimacy and ensure contracts include IP indemnification clauses.

4. Choosing Suppliers Without Proper Traceability

Traceability of materials and manufacturing processes is critical for quality assurance and regulatory compliance. Sourcing from suppliers who cannot provide:

– Material test reports (MTRs)

– Heat treatment records

– Dimensional inspection data

Increases the risk of receiving non-conforming parts. Ensure your supplier maintains full documentation for each production batch.

5. Neglecting After-Sales Support and Warranty

A low initial cost may be offset by poor post-purchase support. Pitfalls include:

– Lack of technical assistance during installation

– No performance warranty or failure analysis

– Long lead times for replacements

Choose suppliers who offer comprehensive support and stand behind their product quality with clear warranty terms.

By addressing these quality and IP-related pitfalls early in the sourcing process, you can ensure reliable performance, legal compliance, and long-term cost savings.

Logistics & Compliance Guide for Thrust Plate

Overview

This guide outlines the logistics and compliance requirements for the handling, transportation, storage, and regulatory adherence related to thrust plates used in industrial and mechanical applications. Adherence to these guidelines ensures product integrity, operational safety, and compliance with international standards.

Regulatory Compliance

Thrust plates must comply with relevant international and regional standards, including but not limited to:

– ISO 756:2010 (Plain bearings – Thrust washers – Dimensions and tolerances)

– ASTM B271 (Standard Specification for Centrifugal Bronze Castings)

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) – EU Regulation (EC) No 1907/2006

– RoHS (Restriction of Hazardous Substances Directive) 2011/65/EU

– Customs-Trade Partnership Against Terrorism (C-TPAT) – for shipments to the United States

Ensure all thrust plates are accompanied by a Certificate of Conformity (CoC) and Material Test Report (MTR) where applicable.

Packaging Requirements

Thrust plates must be packed to prevent damage during transit and storage:

– Individual plates should be wrapped in anti-corrosion paper or VCI (Vapor Corrosion Inhibitor) film.

– Stack plates with protective interlayers (e.g., cardboard or foam) to avoid surface scratching.

– Securely pack in sturdy corrugated cardboard boxes or wooden crates, clearly labeled with product ID, batch number, quantity, and handling instructions.

– Use desiccants in packaging for long-term storage or humid environments.

Labeling and Documentation

Each shipment must include:

– Properly labeled packages with:

– Product name: “Thrust Plate”

– Part number and specification

– Net weight and gross weight

– Handling symbols (e.g., “This Side Up,” “Do Not Stack”)

– Commercial invoice

– Packing list

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin (if required by destination country)

– Safety Data Sheet (SDS), if applicable (e.g., coated or treated materials)

Transportation Guidelines

- Use ISO-standard containers for sea freight; ensure proper dunnage and blocking to prevent shifting.

- For air freight, comply with IATA regulations; confirm weight and dimensional constraints.

- Overland transport should use enclosed trailers to protect from weather and contamination.

- Avoid exposure to moisture, extreme temperatures, or corrosive environments during transit.

Storage Conditions

Thrust plates should be stored in a dry, temperature-controlled environment:

– Temperature: 10°C to 30°C (50°F to 86°F)

– Relative humidity: <60%

– Store off the floor on pallets or shelves

– Keep away from direct sunlight and sources of vibration

– Rotate stock using FIFO (First In, First Out) method

Import/Export Considerations

- Verify Harmonized System (HS) Code: Typically 8483.30 or 8483.90 for mechanical transmission components.

- Check import restrictions or tariffs in destination country.

- Complete export declarations per local customs authority (e.g., AES for U.S., ENACOM for EU).

- Maintain records for a minimum of 5 years for audit purposes.

Quality and Traceability

- Each batch must be traceable to raw material source, heat number, and manufacturing date.

- Maintain quality inspection records, including dimensional checks and material verification.

- Report any non-conformances immediately through internal quality management systems (e.g., ISO 9001).

Environmental and Safety Compliance

- Dispose of packaging materials in accordance with local waste regulations.

- Used or defective thrust plates containing hazardous coatings must be handled as industrial waste.

- Personnel handling thrust plates should use appropriate PPE (gloves, safety glasses) during inspection or packaging.

Contact Information

For compliance or logistics inquiries, contact:

– Logistics Manager: [Name], [email protected]

– Compliance Officer: [Name], [email protected]

– Emergency Hotline: [Phone Number]

Last Updated: [Insert Date]

Conclusion on Sourcing Thrust Plates

In conclusion, sourcing thrust plates requires a strategic approach that balances quality, cost, availability, and technical specifications. Selecting the right supplier involves evaluating material composition (such as bronze, carbon steel, or specialized alloys), dimensional accuracy, load capacity, and surface finish to ensure compatibility with the intended application—especially in high-stress environments like turbines, compressors, or propulsion systems.

Key considerations include supplier reliability, adherence to industry standards (e.g., ISO, ASTM), lead times, and the ability to provide traceable certifications. Engaging with experienced manufacturers or established distributors can mitigate risks related to performance failures and downtime. Additionally, exploring both domestic and international sourcing options can enhance cost-efficiency, provided quality control measures are rigorously maintained.

Ultimately, a well-informed sourcing decision ensures the long-term reliability and efficiency of the machinery in which thrust plates are deployed, contributing to optimal operational performance and reduced maintenance costs.