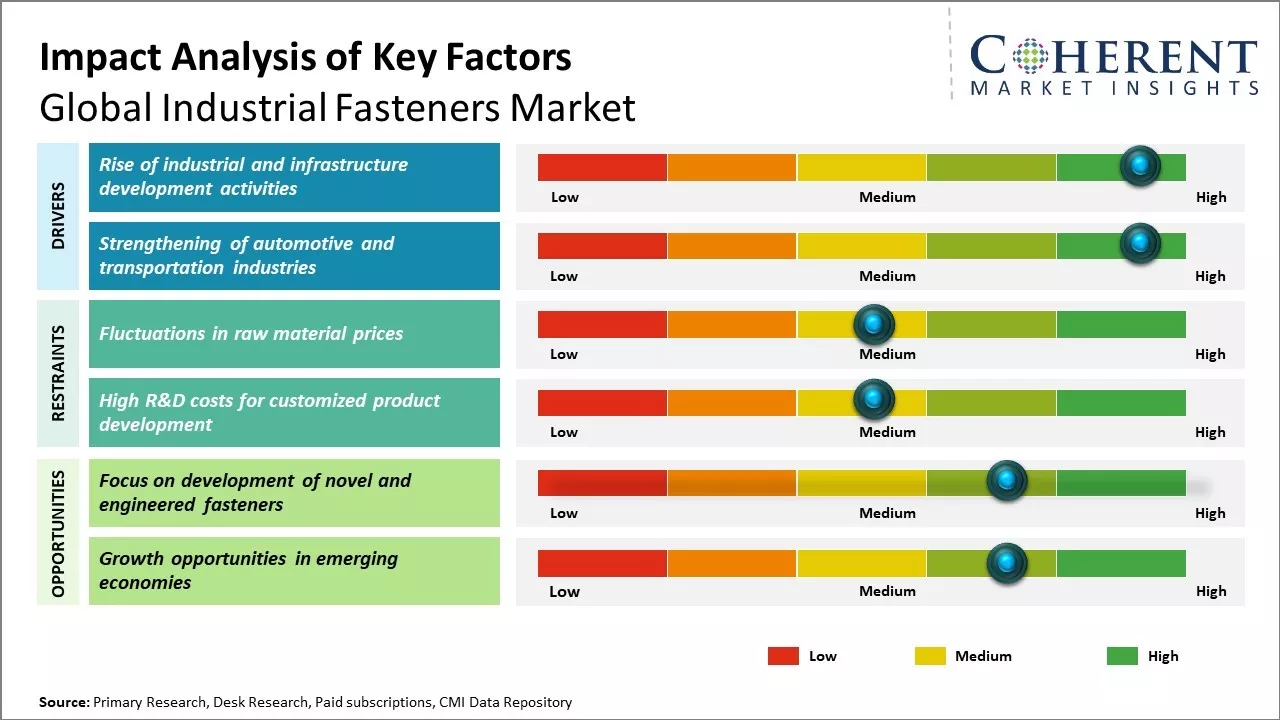

The global through bolts market is experiencing steady expansion, driven by rising demand across construction, infrastructure, and industrial manufacturing sectors. According to Grand View Research, the global fasteners market—of which through bolts are a critical component—was valued at USD 118.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increased infrastructure development in emerging economies, stringent regulatory standards requiring reliable fastening solutions, and the expanding automotive and renewable energy sectors. As structural integrity becomes a priority in modern engineering, through bolts—known for their strength, durability, and ease of installation—are gaining prominence. With the Asia Pacific region leading in production and consumption, and North America witnessing a construction rebound, the competitive landscape is evolving rapidly. Here, we examine the top 10 through bolts manufacturers shaping this dynamic market, evaluating them on production capacity, innovation, geographic reach, and compliance with international quality standards.

Top 10 Through Bolts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AMPG

Domain Est. 1997

Website: ampg.com

Key Highlights: AMPG is a trusted USA manufacturer of high-quality fasteners. We provide precision-engineered sex bolts, shoulder screws, washer, shims and other industrial ……

#2 OEM Speciality Nuts & Bolts Made in USA

Domain Est. 1995

Website: wyandotte.com

Key Highlights: Choose American-made nuts and bolts for unmatched strength and precision. Specialty fasteners and CNC parts built in the USA. Get a quote today!…

#3 EJOT COM

Domain Est. 1997

Website: ejot.com

Key Highlights: EJOT – your partner for self-tapping fasteners ✓ complex cold-formed parts ✓ fastening solutions ✓ for Industry & Automotive and the construction industry….

#4 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#5 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: Explore a wide range of rivets and lockbolts engineered for high performance and reliability. Stud Welding Systems….

#6 Specialty Fastening Solutions for the Commercial Construction …

Domain Est. 1996

Website: itwbuildex.com

Key Highlights: We manufacture self-drilling and tapping screws, anchors, toggles, and other fastening systems under the Teks, Sammys, Dec-King, EZ Ancor, and Rock-On-brands….

#7 Copper State

Domain Est. 1996

Website: copperstate.com

Key Highlights: Our ISO 9001:2015 by TUV Rheinland of North America certified manufacturing facility specializes in large diameter bolts and custom fasteners. If you have ……

#8

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: ARP was the first company to design and engineer fasteners specifically for racing. We developed many patented process for manufacturing high strength ……

#9 American Bolt

Domain Est. 1998

Website: americanbolt.com

Key Highlights: American Bolt has been a trusted supplier of fasteners for many years, with a consistent focus: delivering reliable fastening solutions with unmatched service….

#10 Metallics

Domain Est. 2004

Website: nsiindustries.com

Key Highlights: Metallics, a part of the NSI family, is more than just a supplier—we’re your source for innovative, reliable, high-quality fasteners and anchors….

Expert Sourcing Insights for Through Bolts

H2: 2026 Market Trends for Through Bolts

The global through bolt market is poised for steady growth and transformation by 2026, driven by expanding construction activities, infrastructure development, and advancements in material engineering. Through bolts—used primarily in structural applications requiring high tensile strength and reliable load transfer—are witnessing increased demand across multiple sectors. Key trends shaping the market in 2026 include:

-

Rising Infrastructure and Construction Investments

Governments worldwide are prioritizing infrastructure modernization and urban development, especially in emerging economies in Asia, Africa, and Latin America. Projects such as bridges, highways, and public transit systems are boosting demand for structural fasteners like through bolts. The emphasis on durable and seismic-resistant construction is further enhancing their adoption. -

Growth in Prefabricated and Modular Construction

The shift toward off-site construction methods is increasing the need for reliable, standardized fastening solutions. Through bolts are preferred in modular and pre-engineered buildings due to their ease of installation and high shear and tensile strength. This trend is particularly strong in residential and commercial developments seeking faster project completion times. -

Advancements in Material Technology

There is growing demand for high-performance through bolts made from stainless steel, alloy steel, and corrosion-resistant coatings. Innovations in surface treatments (e.g., hot-dip galvanizing, Dacromet) are extending product life in harsh environments, making them ideal for marine, industrial, and outdoor applications. By 2026, environmentally resistant and lightweight composite-compatible through bolts are expected to gain traction. -

Sustainability and Regulatory Compliance

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to adopt sustainable production practices. Recyclable materials and energy-efficient manufacturing processes are becoming competitive advantages. Additionally, stricter safety standards in construction are mandating the use of certified through bolts, supporting market standardization. -

Regional Market Dynamics

Asia-Pacific dominates the through bolt market due to rapid urbanization and industrialization, particularly in China, India, and Southeast Asia. North America and Europe maintain strong demand driven by infrastructure renewal and stringent building codes. Meanwhile, the Middle East and Africa show high growth potential due to ongoing megaprojects and economic diversification efforts. -

Digitalization and Supply Chain Optimization

Manufacturers are integrating digital tools such as IoT-enabled quality control, predictive maintenance, and blockchain for traceability. E-commerce platforms and digital distribution channels are also streamlining access to through bolts, especially for small and medium-sized construction firms.

In conclusion, the 2026 through bolt market is characterized by innovation, sustainability, and regional expansion. As structural integrity remains paramount in construction and engineering, through bolts will continue to evolve in design and functionality, ensuring their critical role in modern infrastructure.

Common Pitfalls Sourcing Through Bolts (Quality, IP)

When sourcing through bolts, overlooking critical quality and intellectual property (IP) considerations can lead to product failures, safety hazards, compliance issues, and legal risks. Understanding these common pitfalls helps ensure reliable, compliant, and legally sound procurement.

Poor Material Quality and Non-Compliant Specifications

Suppliers may offer through bolts made from substandard materials or fail to adhere to required mechanical properties (e.g., tensile strength, yield strength). This often occurs when sourcing from low-cost manufacturers who cut corners. Bolts that do not meet international standards (e.g., ASTM, ISO, DIN) can compromise structural integrity, especially in critical applications such as construction or machinery.

Misrepresentation of Grade and Certification

A frequent issue is the mislabeling or falsification of bolt grades (e.g., claiming Grade 8.8 when the actual product is lower quality). Some suppliers provide fake or incomplete mill test certificates (MTCs), making it difficult to verify material traceability and compliance. Always request verifiable documentation and consider third-party testing for high-risk applications.

Inadequate or Improper Surface Treatments

Corrosion resistance is crucial for through bolts, particularly in outdoor or harsh environments. Poorly applied coatings (e.g., zinc plating, hot-dip galvanizing) or omission of required treatments can lead to premature rust and failure. Be cautious of inconsistent coating thickness or hydrogen embrittlement risks in high-strength bolts.

Counterfeit or Non-OEM Parts

Sourcing through unauthorized channels increases the risk of counterfeit bolts that mimic reputable brands but lack the engineering and quality control. These parts often infringe on intellectual property rights and fail to deliver the performance expected. Always verify supplier authenticity and use authorized distributors when possible.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including heat numbers and manufacturing records. A red flag is the absence of such documentation, which not only affects quality assurance but can also violate regulatory requirements in industries like aerospace, automotive, or infrastructure.

Ignoring Intellectual Property Rights

Using or sourcing bolts that replicate patented designs or branded fasteners (e.g., specialized thread profiles or locking mechanisms) without licensing can lead to IP infringement claims. Even if functionally similar, copying proprietary features poses legal and reputational risks.

Inconsistent Thread Quality and Dimensional Accuracy

Poor thread cutting, incorrect pitch, or out-of-tolerance dimensions can prevent proper fitment and reduce clamping force. These inconsistencies often stem from low-quality tooling or lack of inspection at the manufacturing stage, leading to assembly issues or joint failure.

Insufficient Testing and Quality Control

Many suppliers, especially in unregulated markets, lack rigorous in-house testing (e.g., load testing, chemical analysis). Without proper QC processes, defects may go undetected until after installation, increasing liability and maintenance costs.

To avoid these pitfalls, conduct thorough supplier vetting, require certifications, perform incoming inspections, and prioritize partners with transparent manufacturing and IP-compliant practices.

Logistics & Compliance Guide for Through Bolts

Product Overview

Through bolts, also known as anchor bolts or through-rods, are fasteners designed to secure structural elements by passing completely through a material and being secured on both ends with nuts and washers. They are commonly used in construction, machinery installation, and structural anchoring. This guide outlines the logistics and compliance considerations for handling, shipping, storing, and using through bolts in accordance with industry standards and regulatory requirements.

Packaging and Labeling Requirements

- Packaging: Through bolts should be packaged in moisture-resistant materials to prevent corrosion during transit and storage. Bundling with protective end caps or coating is recommended for threaded sections.

- Labeling: Each package must include:

- Product description (e.g., diameter, length, material grade)

- Quantity and part number

- Manufacturer name and batch/lot number

- Compliance markings (e.g., ASTM, ISO, or DIN standards)

- Hazard warnings if applicable (e.g., sharp edges)

- Unit Load Marking: Pallets or crates should display handling symbols (e.g., “This Side Up,” “Do Not Stack”) and weight information.

Transportation and Handling

- Mode of Transport: Through bolts can be shipped via road, rail, sea, or air. For international shipments, ensure compliance with IATA (air), IMDG (sea), or ADR (road) regulations, although through bolts are typically non-hazardous.

- Load Securing: Secure bundles or pallets to prevent shifting during transport. Use edge protectors and strapping to maintain integrity.

- Handling Equipment: Use forklifts, cranes, or pallet jacks with appropriate lifting gear. Avoid dragging or dropping bundles to prevent thread damage or deformation.

- Environmental Protection: Protect loads from rain, snow, and excessive humidity during transit. Use waterproof covers or climate-controlled containers when necessary.

Storage Conditions

- Location: Store in a dry, well-ventilated indoor area off the ground (on pallets or racks).

- Temperature and Humidity: Maintain ambient temperatures between 10°C and 30°C with relative humidity below 60% to prevent rusting.

- Segregation: Store by size, grade, and coating type. Keep galvanized and stainless steel bolts separate from carbon steel to avoid galvanic corrosion.

- Inventory Rotation: Apply FIFO (First In, First Out) practices to minimize prolonged storage and potential degradation.

Regulatory and Compliance Standards

- Material Standards: Ensure through bolts comply with recognized standards such as:

- ASTM A307, A325, or A490 (U.S.)

- ISO 898-1 (International)

- DIN 931, 933 (Germany)

- Coatings and Corrosion Resistance: Confirm plating (e.g., hot-dip galvanizing, zinc plating) meets environmental exposure requirements (e.g., ISO 1461, ASTM B633).

- Certification Documentation: Provide mill test certificates (MTCs) or Certificates of Conformance (CoC) verifying material composition, mechanical properties, and compliance.

- Import/Export Regulations: For cross-border shipments, comply with customs documentation (e.g., commercial invoice, packing list, certificate of origin). Check for import restrictions or tariffs in destination countries.

Safety and Handling Protocols

- Personal Protective Equipment (PPE): Personnel should wear gloves, safety glasses, and steel-toed boots when handling through bolts due to sharp edges and heavy weights.

- Lifting Precautions: Use mechanical aids for bundles over 25 kg. Train staff in safe lifting techniques.

- Workplace Safety: Follow OSHA (U.S.) or equivalent national safety regulations. Clearly mark storage aisles and ensure clear exit routes.

Environmental and Sustainability Considerations

- Recyclability: Steel through bolts are fully recyclable. Provide recycling instructions on packaging or in documentation.

- Waste Management: Dispose of packaging materials (e.g., plastic wraps, wooden pallets) in accordance with local waste regulations.

- Sustainable Sourcing: Procure from suppliers with ISO 14001 certification or verified sustainable manufacturing practices.

Quality Assurance and Traceability

- Batch Tracking: Maintain lot traceability from raw material to final product to support recalls or audits.

- Inspection Procedures: Conduct periodic checks for dimensional accuracy, thread integrity, and surface defects upon receipt and before dispatch.

- Non-Conformance Management: Establish a process for identifying, quarantining, and reporting defective products in line with ISO 9001 requirements.

Conclusion

Proper logistics and compliance management for through bolts ensure product integrity, safety, and regulatory adherence throughout the supply chain. By following this guide, organizations can minimize risk, enhance operational efficiency, and maintain customer trust in bolt performance and reliability.

Conclusion for Sourcing Through Bolts:

Sourcing through bolts effectively requires a strategic approach that balances quality, cost, availability, and reliability of supply. Through careful evaluation of material specifications, strength grades, dimensional accuracy, and compliance with industry standards (such as ISO, ASTM, or DIN), organizations can ensure the bolts meet the required performance criteria for their intended applications. Additionally, selecting reputable suppliers, considering lead times, and managing logistics play a crucial role in minimizing downtime and maintaining operational efficiency. By establishing strong supplier relationships and implementing robust quality control processes, businesses can secure a consistent supply of high-quality through bolts, ultimately supporting structural integrity, safety, and long-term project success.