The global carburetor market continues to hold steady ground in specific niche and emerging applications, despite the broader shift toward fuel injection systems. According to a 2023 report by Mordor Intelligence, the global carburetor market was valued at approximately USD 5.2 billion in 2022 and is projected to grow at a CAGR of 3.8% from 2023 to 2028. This sustained demand is largely driven by the ongoing use of small-engine applications in agriculture machinery, two-wheelers, and off-road equipment—particularly in Asia-Pacific and Latin America. Additionally, Grand View Research highlights the resilience of throttle valve carburetors in cost-sensitive markets where simplicity, ease of maintenance, and affordability remain key purchasing factors. With continued production in countries like India, China, and Indonesia, the competitive landscape is dominated by manufacturers balancing legacy expertise with incremental innovation. As demand persists in developing economies and replacement markets, identifying the top players becomes essential for OEMs and aftermarket suppliers alike. Here are the top 10 throttle valve carburetor manufacturers shaping the current industry landscape.

Top 10 Throttle Valve Carburetor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

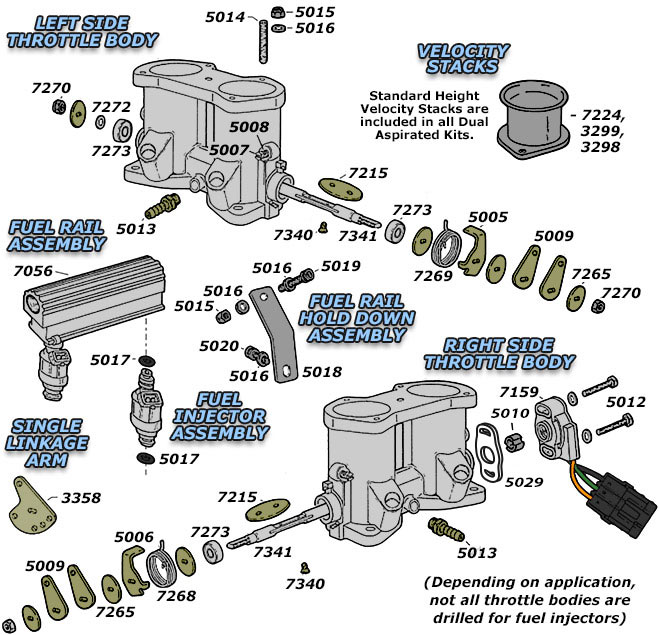

#1 Throttle Body(Sports Injection Body) & Option Parts

Domain Est. 2018

Website: oer-carburetor.site

Key Highlights: OER Official Online Shop — Your factory-authorized source for authentic OER Racing Carburetors and performance parts, proudly crafted 100% in Japan….

#2 Mikuni American Corporation

Domain Est. 1994

Website: mikuni.com

Key Highlights: The Mikuni Group manufactures superior products for a wide range of industries, including automotive, commercial vehicles, powersports, general purpose, ……

#3 Parts & Service

Domain Est. 1994

Website: walbro.com

Key Highlights: Looking for a Carburetor or Parts? Available below is our: Catalog, where you can find carburetors and their associated kits; Online Store, where you can ……

#4 Holley

Domain Est. 1995

Website: holley.com

Key Highlights: Free delivery over $149Holley Performance Brands is the undisputed leader in carburetors, fuel pumps, fuel injection, intake manifolds, fuel injection, and fuel systems….

#5 BLP Racing Products

Domain Est. 1995

Website: blp.com

Key Highlights: BLP designs and manufactures high-quality performance racing fuel systems, drive components, and engine accessory parts….

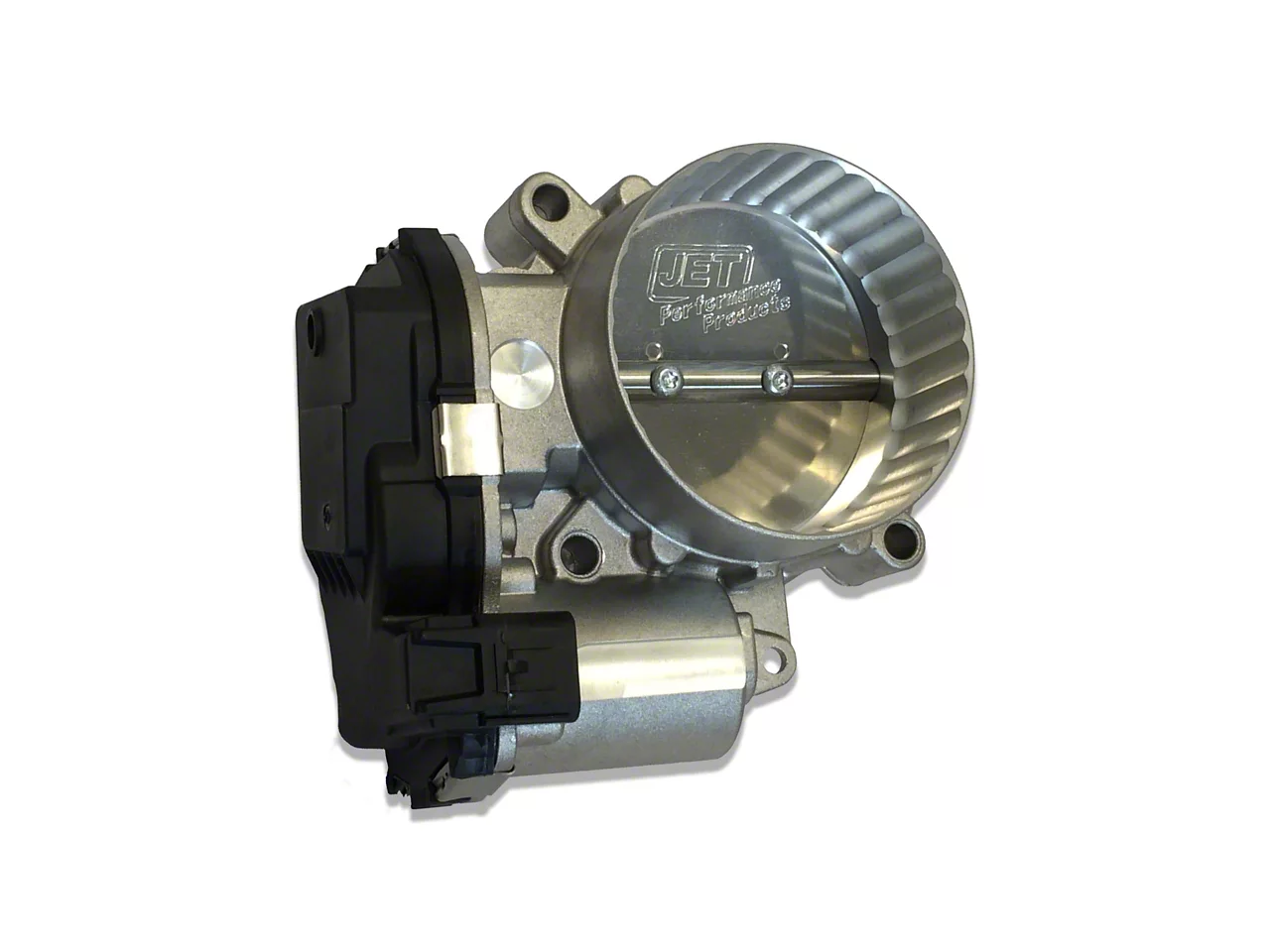

#6 Jet Performance Products

Domain Est. 1996

#7 Bing Carburetor

Domain Est. 1999

Website: bingcarburetor.com

Key Highlights: BING AGENCY INTERNATIONALSOLE DISTRIBUTORFOR BING CARBURETORS AND THROTTLE BODIES IN THE US, CANADA,SOUTH AMERICA AND AUSTRALIA….

#8 Allstate Carburetor

Domain Est. 2000

Website: allcarbs.com

Key Highlights: 30-day returnsThrottle Accessories, Throttle Position Sensor, Tools, Tubes and Pipes … Company Info. Learn more about Allstate Carburetor & Fuel Injection, our online ……

#9 Electronic Throttle Bodies (ETB)

Domain Est. 2014

Website: aftermarket.astemo.com

Key Highlights: World’s Best Value With Extensive Applications. Our electronic throttle bodies are available for millions of vehicles in operation, both domestic and imported. ……

#10 Accufab Racing

Domain Est. 1998

Website: accufabracing.com

Key Highlights: Accufab’s Mustang throttle bodies are second to none! Our Mustang throttle bodies are CNC machined from 6061-T6 billet aluminum and the exterior is polished….

Expert Sourcing Insights for Throttle Valve Carburetor

2026 Market Trends for Throttle Valve Carburetors

While throttle valve carburetors represent mature technology, their market in 2026 will be shaped by a complex interplay of decline in mainstream applications, resilience in niche segments, and adaptation to evolving regulations and user preferences.

H2: Steady Decline in Automotive and High-Performance Applications

The most significant trend remains the continued displacement of carburetors by electronic fuel injection (EFI) systems. By 2026, this shift will be nearly complete in new production vehicles globally. Stricter emissions regulations (Euro 7, Tier 4 Final, Bharat Stage VII) and fuel efficiency standards make the precise fuel metering and closed-loop control of EFI systems essential. Even in performance and racing segments, where carburetors held on longer due to simplicity and tradition, EFI adoption is accelerating due to superior tunability, consistency, and integration with engine management systems (ECUs) for features like traction control and launch control. This trend will significantly contract the new market for throttle valve carburetors in these high-volume and high-value sectors.

H2: Resilience and Niche Dominance in Small Engines and Legacy Equipment

Despite the overall decline, the throttle valve carburetor will maintain a strong foothold in specific niches by 2026:

* Small Engine Applications: Lawnmowers, chainsaws, generators, pressure washers, and small outboard motors will remain major markets. The simplicity, low cost, ease of repair, and tolerance for varying fuel quality make carburetors highly suitable for these cost-sensitive, often DIY-maintained machines. While EFI is entering some premium small engines, carburetors will dominate the volume segment due to cost advantages.

* Legacy Equipment and Restoration: The vast global fleet of older vehicles, motorcycles, and industrial machinery (tractors, pumps) relies on carburetors. The aftermarket for replacement parts, rebuild kits, and new carburetors for restorations will remain robust. Enthusiast communities and the “classic” market ensure sustained demand.

* Emerging Markets: In regions with less stringent emissions regulations, lower infrastructure costs, and a focus on affordability and repairability, carbureted engines for two/three-wheelers, small agricultural equipment, and generators will persist, supporting demand for new carburetors.

H2: Impact of Regulatory Pressures and Fuel Evolution

Evolving regulations will increasingly pressure carburetor use:

* Emissions: Regulations targeting non-road mobile machinery (NRMM) and small off-road engines (SORE) will push manufacturers towards cleaner alternatives, potentially accelerating the shift to EFI or other technologies (like direct injection) even in small engines over the long term, though the transition will be slower than in automotive.

* Fuel Composition: The increasing blend of biofuels (like higher ethanol E15, E85) and potential future fuels can degrade traditional carburetor materials (rubber, certain plastics, zinc alloys) and alter fuel volatility, leading to performance issues (vapor lock, poor cold starts). Carburetor manufacturers will need to adapt materials (more ethanol-resistant components) and potentially designs to handle these fuel changes, adding complexity and cost.

H2: Focus on Aftermarket, Performance Tuning, and Cost Leadership

The 2026 market will be characterized by strategic shifts:

* Aftermarket Focus: Leading manufacturers will increasingly prioritize the replacement and restoration aftermarket, offering comprehensive rebuild kits, specialized components (jets, needles), and technical support.

* Performance Niche: Companies catering to the hot rod, custom motorcycle, and vintage racing segments will emphasize high-quality, precisely calibrated, and aesthetically pleasing carburetors (e.g., performance four-barrels). Customization and tuning services will be key differentiators.

* Cost and Reliability: For the small engine and emerging market segments, competition will be fierce on price and proven reliability. Manufacturers will focus on robust, simple designs using cost-effective materials while meeting basic emission requirements (e.g., CARB Phase 3, EPA standards for small engines).

* Consolidation: The shrinking overall market may lead to further consolidation among carburetor manufacturers, with smaller players exiting or being acquired.

In conclusion, the 2026 throttle valve carburetor market is not one of growth, but of adaptation and focus. Its future lies firmly in serving resilient niche applications – small engines, legacy equipment, and performance/restoration – where its core advantages of simplicity, low cost, and repairability outweigh the benefits of modern fuel injection. Success will depend on navigating regulatory headwinds, adapting to fuel changes, and excelling in the specific needs of these targeted segments.

Common Pitfalls Sourcing Throttle Valve Carburetor (Quality, IP)

Sourcing throttle valve carburetors involves significant risks, particularly concerning product quality and intellectual property (IP) rights. Overlooking these pitfalls can lead to performance failures, safety hazards, legal disputes, and reputational damage. Below are key challenges to be aware of:

Quality Pitfalls

Inconsistent Material Specifications

Suppliers may use substandard or non-compliant materials (e.g., inferior aluminum, low-grade elastomers) to cut costs, leading to premature wear, corrosion, or failure under operational stress. Always verify material certifications and conduct batch testing.

Poor Manufacturing Tolerances

Carburetors require precise machining for proper airflow and fuel metering. Inadequate quality control can result in inconsistent bore diameters, misaligned throttle shafts, or improper valve seating—compromising engine performance and fuel efficiency.

Lack of Functional Testing

Many low-cost suppliers do not perform comprehensive performance testing (e.g., air-fuel ratio calibration, leak testing, idle stability checks). This increases the risk of receiving units that fail in real-world conditions.

Inadequate Environmental Resistance

Carburetors must withstand temperature extremes, moisture, and vibration. Poor sealing or coating can lead to icing, vapor lock, or internal contamination, especially in demanding applications.

Intellectual Property (IP) Pitfalls

Unauthorized Replication of Patented Designs

Many throttle valve carburetors are protected by patents. Sourcing from suppliers who reverse-engineer or copy OEM designs without licensing exposes buyers to legal liability, including infringement claims and import seizures.

Trademark and Branding Violations

Suppliers may affix counterfeit logos or mimic original equipment manufacturer (OEM) part numbers. Even unintentional distribution of such components can result in trademark infringement lawsuits.

Lack of IP Due Diligence

Buyers often assume suppliers have the right to produce the part. Without requesting proof of IP ownership, licenses, or design freedom-to-operate documentation, companies risk becoming complicit in IP theft.

Grey Market and Unauthorized Distribution

Purchasing from unauthorized distributors or grey market sources may mean the product, while functional, was produced without IP holder consent—posing legal and warranty risks.

Mitigation Strategies

- Conduct Supplier Audits: Evaluate manufacturing processes and quality management systems (e.g., ISO 9001 certification).

- Require Material and Test Reports: Insist on Certificates of Conformance (CoC) and third-party test data.

- Perform IP Screening: Engage legal counsel to verify freedom-to-operate and request IP warranties in contracts.

- Use Authorized Channels: Source through OEMs or licensed distributors to ensure authenticity and compliance.

Ignoring these quality and IP pitfalls can result in costly recalls, legal penalties, and operational downtime. Due diligence during sourcing is essential to ensure reliability and legal compliance.

Logistics & Compliance Guide for Throttle Valve Carburetor

Product Classification & Identification

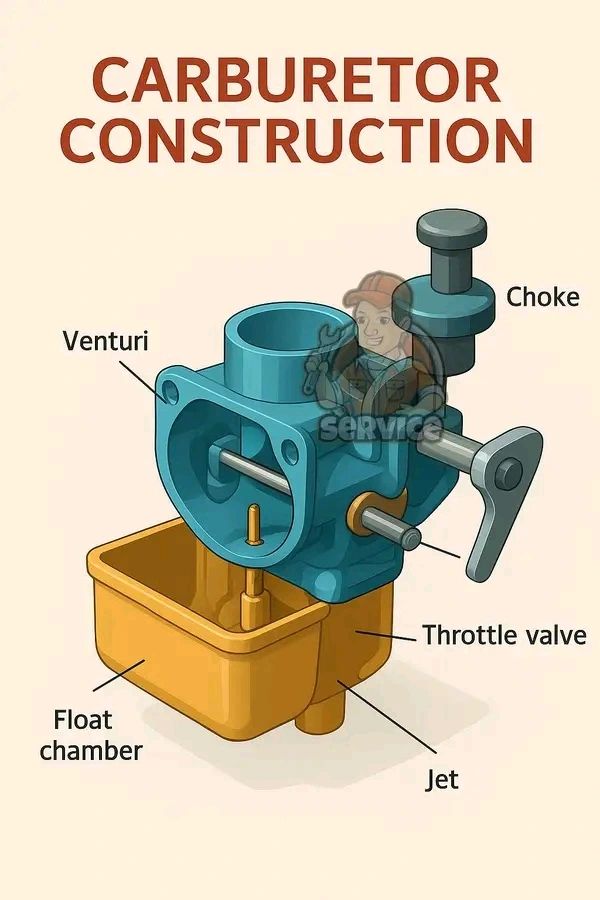

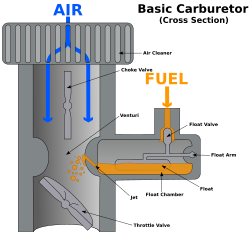

The Throttle Valve Carburetor is a mechanical fuel delivery component used in internal combustion engines to regulate the amount of air entering the engine and mix it with fuel. Proper identification is essential for logistics and regulatory compliance. Key identifiers include:

- HS Code (Harmonized System Code): Typically classified under 8409.91 – Parts suitable for use solely or principally with internal combustion piston engines. Final classification may vary by country; verify with local customs authorities.

- ECCN (Export Control Classification Number): Generally falls under EAR99 (subject to Export Administration Regulations but not specifically listed). Confirm with the U.S. Department of Commerce if exporting from the U.S.

- UN Number: Not applicable (non-hazardous under normal transport conditions, unless residual fuel is present).

- Product Model & Part Number: Specify exact manufacturer part number and model for traceability.

Packaging & Handling Requirements

Proper packaging ensures product integrity during transit and compliance with international shipping standards:

- Protective Packaging: Use anti-corrosion wrapping (e.g., VCI paper) and enclosed containers to prevent moisture, dust, and mechanical damage.

- Internal Cushioning: Employ foam inserts or molded packaging to prevent movement inside the shipping box.

- Labeling: Include:

- Product name and part number

- Manufacturer and supplier information

- “Fragile” and “This Side Up” handling labels if applicable

- Barcodes or QR codes for inventory tracking

- Stacking & Palletization: Limit stacking height per packaging specifications. Secure on standard pallets (e.g., EUR/EPAL or ISO) using stretch wrap or banding.

Transportation & Shipping

Compliance with transport regulations ensures smooth cross-border movement:

- Mode of Transport: Suitable for air, sea, and land freight. Choose based on cost, lead time, and destination.

- Incoterms: Clearly define responsibility using standard terms (e.g., FOB, EXW, DDP). Recommended: FOB (Free On Board) for exporter control up to port of shipment.

- Documentation: Essential shipping documents include:

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (required by some countries for tariff determination)

- Temperature & Environment: Store and transport in dry, temperature-controlled environments (10–30°C recommended) to prevent condensation and material degradation.

Regulatory & Compliance Standards

Ensure adherence to regional and international regulations:

- REACH (EU): Comply with Registration, Evaluation, Authorisation and Restriction of Chemicals. Confirm no restricted substances (e.g., lead, cadmium) exceed allowable limits in materials.

- RoHS (EU): Although primarily for electronics, verify if applicable due to potential electronic components (e.g., sensors in modern carburetors).

- EPA (USA): Not subject to EPA emissions certification as a replacement part, but must not modify or defeat original engine emissions systems (per Clean Air Act).

- DOT (USA): Not regulated as hazardous material when clean and dry. If contaminated with fuel, may require hazardous materials declaration (Hazmat Class 3).

- Country-Specific Approvals: Some markets may require local certification (e.g., INMETRO in Brazil, PVoC in Kenya). Verify requirements with import agents.

Import & Customs Clearance

Facilitate smooth customs processing with accurate documentation:

- Duties & Tariffs: Duty rates vary by destination. For example:

- EU: Typically 0–4% under 8409.91

- USA: 2.5% under HTSUS 8409.91.00

- Customs Broker: Use a licensed broker to handle declarations and tariff classification.

- Import Licenses: Generally not required for carburetor parts, but confirm based on end-use (e.g., military or dual-use applications).

- Anti-Dumping/Countervailing Duties: Check for applicability, particularly if manufactured in countries under trade scrutiny.

Environmental & End-of-Life Considerations

Address sustainability and disposal obligations:

- WEEE (EU): Not applicable unless classified as electronic equipment. Confirm based on component design.

- Recycling: Encourage return or recycling programs for end-of-life units. Metals (aluminum, brass) should be recycled according to local waste regulations.

- Packaging Waste: Use recyclable or biodegradable packaging materials where possible to meet local packaging waste directives (e.g., German Packaging Act).

Recordkeeping & Traceability

Maintain compliance and support audits:

- Documentation Retention: Keep shipping, compliance, and transaction records for a minimum of 5 years (longer if required by jurisdiction).

- Serial Number Tracking: Implement lot or batch tracking for quality control and recall preparedness.

- Audit Readiness: Prepare for customs, environmental, or safety audits with up-to-date compliance certificates and material declarations.

By following this guide, logistics and compliance teams can ensure efficient, legal, and safe distribution of Throttle Valve Carburetors across global markets. Always consult local regulatory authorities and legal counsel for region-specific requirements.

Conclusion for Sourcing a Throttle Valve Carburetor:

Sourcing a throttle valve carburetor requires careful consideration of compatibility, quality, supplier reliability, and cost-effectiveness. Whether for replacement, restoration, or performance enhancement, selecting the right carburetor involves matching specifications such as engine type, airflow requirements, fuel efficiency, and emission standards. After evaluating multiple suppliers, original equipment manufacturer (OEM) parts offer guaranteed fit and performance, while aftermarket options may provide cost savings and customization benefits. Ultimately, a balanced approach—prioritizing technical alignment, durability, and supplier reputation—ensures optimal engine performance and long-term reliability. Proper sourcing not only enhances operational efficiency but also minimizes downtime and maintenance costs, making it a critical step in engine management and vehicle maintenance.