The global market for pipe connectors, including three-way variants, has seen consistent growth driven by rising infrastructure development, expansion in oil & gas networks, and increased demand from industrial and commercial construction sectors. According to Grand View Research, the global pipe fittings market was valued at USD 33.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth trajectory is further supported by Mordor Intelligence, which highlights increased investments in water treatment plants and energy transportation systems as key demand drivers. With such momentum, the need for reliable, high-performance three-way pipe connectors has become critical across industries. As suppliers scale production and innovate in materials and design, a select group of manufacturers have emerged as leaders in quality, global reach, and technical expertise. Here’s a look at the top 8 three-way pipe connector manufacturers shaping the current and future landscape of fluid system solutions.

Top 8 Three Way Pipe Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Threeway Steel Co.,Ltd.

Domain Est. 2010

Website: threewaysteel.com

Key Highlights: Threeway Steel Co., Ltd. is an industrial steel pipe manufacturer with 30 years of experience. The main products are LSAW pipe, SSAW pipe, ERW pipe, ……

#2 three way industrial pipe fittings online manufacture

Domain Est. 2014

Website: m.metalpipeconnectors.com

Key Highlights: Good quality three way industrial pipe fittings from three way industrial pipe fittings manufacturers, We sell three way industrial pipe fittings online ……

#3 Industrial Fittings, Tube Fittings and Pressure Fittings

Domain Est. 1996

Website: products.swagelok.com

Key Highlights: Find reliable tube, pipe, weld, and face seal fittings in a variety of materials and shapes to ensure leak-tight connections in your industrial fluid ……

#4 John Guest

Domain Est. 2000

Website: johnguest.com

Key Highlights: John Guest is the world’s leading OEM supplier for pipe connections including plastic push-to-connect fittings and other fluid control products….

#5 Pipe Fittings

Domain Est. 2020

Website: asc-es.com

Key Highlights: Anvil’s Beck Brand is the nation’s top manufacturer of high quality steel pipe nipples and steel couplings. Beck pipe nipples and couplings are ……

#6 U.S. Pipe

Domain Est. 1995

Website: uspipe.com

Key Highlights: US Pipe, a Quikrete company, offers a complete range of Ductile Iron Pipe, Restrained Joint Pipe, Fabrication, Gaskets, and Fittings….

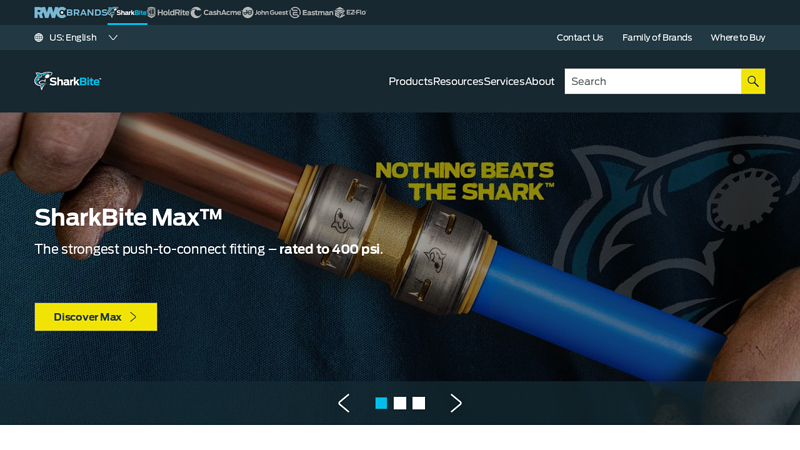

#7 SharkBite Plumbing Products

Domain Est. 2003

Website: sharkbite.com

Key Highlights: Cut repair & install time in half with SharkBite Plumbing Products. Explore our complete line of plumbing fittings, PEX pipe, valves, adapters and more….

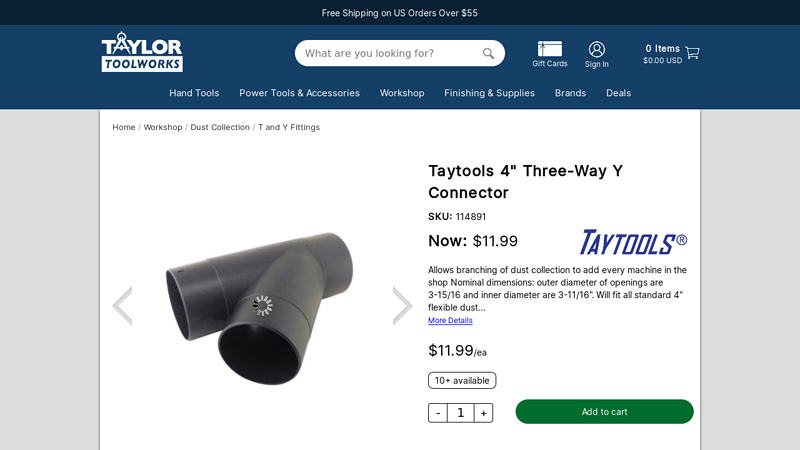

#8 Taytools 4″ Three-Way Y Connector

Domain Est. 2014

Website: taytools.com

Key Highlights: Allows branching of dust collection to add every machine in the shop · Nominal dimensions: outer diameter of openings are 3-15/16 and inner diameter are 3-11/16″ ……

Expert Sourcing Insights for Three Way Pipe Connector

H2: 2026 Market Trends for Three-Way Pipe Connectors

The global market for three-way pipe connectors is poised for steady growth through 2026, driven by expanding infrastructure development, rising demand in industrial and residential applications, and advancements in material technology. As a critical component in plumbing, HVAC (heating, ventilation, and air conditioning), oil and gas, and water treatment systems, three-way pipe connectors enable efficient fluid and gas distribution across complex networks. The following analysis highlights key market trends expected to shape the three-way pipe connector industry by 2026.

1. Increased Infrastructure Investment

Governments worldwide are prioritizing infrastructure modernization and expansion, particularly in emerging economies across Asia-Pacific, Latin America, and Africa. Large-scale urban development, smart city initiatives, and upgrades to water and wastewater systems are fueling demand for reliable piping components. Three-way connectors, essential for branching pipelines, are benefiting from these investments, with construction and municipal water projects representing major end-use sectors.

2. Growth in Residential and Commercial Construction

The global construction boom, especially in countries like India, China, and Southeast Asian nations, is boosting demand for plumbing and HVAC systems. As urbanization accelerates, new residential and commercial buildings require extensive piping networks, increasing the need for high-quality three-way connectors. Energy-efficient building standards are also promoting the use of advanced piping materials such as PPR (polypropylene random copolymer) and stainless steel, which are often integrated with durable three-way fittings.

3. Shift Toward Corrosion-Resistant and Sustainable Materials

Environmental regulations and the need for longer service life are driving a shift from traditional materials like galvanized steel to more sustainable alternatives. Three-way connectors made from stainless steel, brass, PVC, and engineered polymers are gaining traction due to their resistance to corrosion, reduced maintenance, and compatibility with green building certifications (e.g., LEED). The push for sustainability is also encouraging manufacturers to adopt recyclable materials and eco-friendly production processes.

4. Technological Advancements and Smart Integration

Innovation in manufacturing, such as precision molding and automated threading, is improving the reliability and consistency of three-way connectors. Additionally, the integration of smart monitoring systems in industrial and municipal pipelines is creating demand for connectors compatible with sensors and IoT-enabled devices. While the three-way connector itself may not be “smart,” its design is evolving to support connectivity within intelligent fluid management systems.

5. Regional Market Dynamics

– Asia-Pacific is expected to dominate the market by 2026, driven by rapid industrialization, population growth, and government-led infrastructure projects.

– North America will see steady growth due to aging pipeline infrastructure replacement and stringent plumbing codes.

– Europe will emphasize sustainable and high-efficiency solutions, aligning with EU environmental directives.

– Middle East & Africa will experience rising demand, particularly in oil and gas and desalination projects.

6. Competitive Landscape and Supply Chain Optimization

The market is moderately fragmented, with key players focusing on product differentiation, cost efficiency, and global distribution. Companies are investing in R&D to develop lightweight, high-pressure-rated connectors and are expanding manufacturing bases closer to high-growth markets to mitigate supply chain disruptions post-pandemic.

Conclusion

By 2026, the three-way pipe connector market will be shaped by infrastructural expansion, material innovation, and sustainability trends. As industries seek more durable, efficient, and environmentally friendly solutions, manufacturers who adapt to these evolving demands will gain a competitive edge. The integration of advanced materials and support for smart systems will further solidify the role of three-way connectors in modern fluid and gas distribution networks.

Common Pitfalls When Sourcing Three-Way Pipe Connectors (Quality & IP)

Sourcing three-way pipe connectors—especially for critical applications in industries like oil and gas, chemical processing, or pharmaceuticals—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, safety hazards, legal disputes, and increased long-term costs. Below are key pitfalls to avoid:

Poor Material and Manufacturing Quality

One of the most frequent issues is receiving connectors made from substandard materials or with poor workmanship. Low-quality alloys may not withstand high pressure, extreme temperatures, or corrosive environments, leading to leaks, ruptures, or premature failure.

Key Risks:

– Use of non-certified or counterfeit materials (e.g., incorrect stainless steel grades like 304 vs. 316)

– Inadequate welding or threading, causing weak joints

– Dimensional inaccuracies affecting system integration and sealing

Best Practice: Always verify material certifications (e.g., MTRs—Mill Test Reports), conduct third-party inspections, and source from suppliers with recognized quality standards (e.g., ISO 9001, ASME B16.9).

Lack of Compliance with Industry Standards

Three-way connectors must meet specific standards such as ASME, ANSI, DIN, or ISO, depending on the region and application. Sourcing non-compliant fittings can result in system incompatibility, regulatory violations, or safety incidents.

Common Issues:

– Mislabeling of pressure ratings (e.g., Class 150 vs. Class 300)

– Incorrect thread types (NPT, BSP) or port configurations

– Failure to meet dimensional tolerances

Best Practice: Require documentation proving compliance with relevant standards and conduct audits or spot checks on delivered goods.

Intellectual Property (IP) Infringement

Using or sourcing connectors that replicate patented designs without authorization exposes buyers to legal liability. Some suppliers, especially in less-regulated markets, may offer “compatible” or “generic” versions that infringe on proprietary designs.

Risks Include:

– Lawsuits from original equipment manufacturers (OEMs)

– Seizure of goods at customs due to IP violations

– Reputational damage and forced project delays

Best Practice: Vet suppliers for IP compliance, request proof of design rights or licensing, and avoid suppliers offering “exact copies” of branded components.

Inadequate Traceability and Documentation

Lack of proper traceability—such as heat numbers, batch codes, or test records—makes it difficult to verify quality or respond to failures. This is especially critical in regulated industries where audit trails are mandatory.

Pitfalls:

– Missing or falsified documentation

– Inability to track components back to raw material sources

– No access to pressure test or NDT (non-destructive testing) reports

Best Practice: Insist on full documentation packages and ensure suppliers have robust traceability systems in place.

Overlooking Environmental and Operational Suitability

Not all three-way connectors are suitable for every application. Sourcing a connector without verifying its compatibility with the operating environment (e.g., temperature, pressure, fluid type) can lead to rapid degradation.

Examples:

– Using carbon steel in corrosive environments without proper coating

– Selecting a connector with insufficient pressure rating for high-pressure systems

– Ignoring thermal expansion considerations

Best Practice: Clearly define operational requirements upfront and confirm connector specifications with technical datasheets and engineering reviews.

Choosing Low-Cost Suppliers Without Due Diligence

While cost is a major factor, prioritizing price over reliability often results in higher total cost of ownership due to replacements, downtime, or safety incidents.

Red Flags:

– Unusually low quotes compared to market average

– Vague product descriptions or refusal to provide samples

– No online presence, certifications, or verifiable references

Best Practice: Conduct supplier audits, request samples for testing, and favor suppliers with a proven track record and transparent operations.

By being aware of these common pitfalls and implementing due diligence in the sourcing process, organizations can ensure they procure high-quality, compliant, and legally sound three-way pipe connectors that support system integrity and long-term performance.

Logistics & Compliance Guide for Three Way Pipe Connector

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and lawful handling, transport, and use of Three Way Pipe Connectors across supply chains and industrial applications.

Product Description and Specifications

A Three Way Pipe Connector, also known as a pipe tee or T-fitting, is a component used to connect three sections of pipe, allowing flow diversion or combination at a 90-degree or other specified angle. These connectors are commonly manufactured from materials such as stainless steel, carbon steel, PVC, or brass, depending on application requirements including pressure, temperature, and fluid compatibility. Key specifications include nominal pipe size (NPS), schedule (wall thickness), connection type (threaded, socket weld, butt weld, or flanged), pressure rating, and material grade.

Regulatory Compliance Requirements

Three Way Pipe Connectors must comply with relevant international, national, and industry-specific standards to ensure safety and performance. Key compliance standards include:

- ASME B16.9: Covers factory-made wrought butt-welding fittings, including pipe tees.

- ASME B16.11: Applies to forged fittings, including socket weld and threaded types.

- ASTM Standards: Material-specific standards such as ASTM A234 (wrought carbon steel fittings), ASTM A403 (stainless steel), or ASTM D2466 (PVC).

- PED (Pressure Equipment Directive 2014/68/EU): Required for placement on the European market; mandates CE marking based on risk classification.

- CRN (Canadian Registration Number): Required in Canada for fittings used in pressure systems; varies by province.

- API 5L/6A: Relevant if used in oil and gas applications requiring API certification.

Manufacturers and suppliers must provide documentation such as Material Test Reports (MTRs), Certificates of Conformance (CoC), and, where applicable, EU Declarations of Conformity.

Packaging and Handling Guidelines

Proper packaging ensures product integrity during storage and transit:

- Protect connectors from moisture, corrosion, and physical damage using sealed plastic wraps, rust-inhibitive coatings, or VCI (Vapor Corrosion Inhibitor) paper.

- Use sturdy wooden crates or pallets for bulk shipments; secure individual or grouped fittings to prevent movement.

- Clearly label packages with part number, material, size, heat number, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

- For threaded connectors, use protective caps on all openings to prevent damage.

Handle with care using appropriate lifting equipment; avoid dropping or dragging fittings to prevent deformation or thread damage.

Transportation and Shipping Considerations

Transport methods (road, rail, sea, or air) must align with connector size, weight, and destination. Key factors include:

- Hazard Classification: Most metallic or plastic pipe connectors are non-hazardous; however, confirm absence of hazardous coatings or residues.

- Incoterms: Clearly define responsibilities using standard trade terms (e.g., FOB, CIF, DDP) to allocate costs and risks between buyer and seller.

- Export Controls: Verify if fittings made from strategic materials (e.g., certain alloys) are subject to export regulations such as ITAR or EAR.

- Customs Documentation: Prepare commercial invoices, packing lists, and certificates of origin. Include HS (Harmonized System) codes (e.g., 7307.23 for steel pipe fittings).

- Import Requirements: Comply with destination country regulations, including conformity assessments, labeling, and registration (e.g., INMETRO in Brazil, GOST in Russia).

Storage and Inventory Management

Store Three Way Pipe Connectors in a dry, indoor environment to prevent rust, contamination, or UV degradation (for plastic variants):

- Organize by material, size, and specification to avoid mix-ups.

- Implement a first-in, first-out (FIFO) inventory system to reduce obsolescence.

- Protect threaded or polished surfaces with caps or covers during long-term storage.

Regularly inspect stored fittings for signs of corrosion or damage.

Quality Assurance and Traceability

Maintain full traceability from raw material to final product:

- Assign unique batch or heat numbers to each production lot.

- Retain quality control records, including dimensional checks, pressure tests, and material certifications.

- Conduct periodic audits of manufacturing and supply chain partners to ensure ongoing compliance.

Environmental and Safety Considerations

- Ensure manufacturing processes comply with environmental regulations (e.g., EPA, REACH) regarding emissions, waste, and chemical usage.

- Provide Safety Data Sheets (SDS) if connectors contain or are treated with regulated substances.

- Train personnel in safe handling practices to prevent injuries from sharp edges or heavy lifting.

Conclusion

Adhering to this logistics and compliance guide ensures that Three Way Pipe Connectors meet required standards, arrive undamaged, and are legally permissible for use in target markets. Consistent attention to specifications, documentation, and regulatory frameworks supports operational reliability and mitigates supply chain risks.

Conclusion: Sourcing a Three-Way Pipe Connector

In conclusion, sourcing a three-way pipe connector requires careful consideration of material compatibility, pressure and temperature ratings, connection types (e.g., threaded, socket weld, or flanged), and compliance with relevant industry standards such as ASTM, ASME, or ISO. After evaluating various suppliers, pricing, lead times, and quality certifications, it is evident that selecting the right connector is crucial for ensuring system integrity, safety, and long-term performance. A balance between cost-effectiveness and reliability must be achieved, prioritizing vendors with proven track records and consistent product quality. Ultimately, the successful sourcing of a three-way pipe connector supports efficient system assembly and operation across plumbing, HVAC, industrial processing, or oil and gas applications.