The global demand for precision cutting tools, including three-sided knives, has seen consistent growth, driven by expanding applications in packaging, paper converting, and industrial processing. According to Grand View Research, the global cutting tools market was valued at USD 28.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This expansion is fueled by rising automation in manufacturing, increased focus on operational efficiency, and the need for high-precision components in diverse industries. Within this landscape, three-sided knives—prized for their durability, sharp edge retention, and consistent performance in slitting and trimming operations—have become critical components in converting machinery. As demand intensifies, manufacturers that combine advanced materials, tight tolerances, and innovative design are emerging as leaders. Based on market presence, production capabilities, and technical expertise, the following ten companies represent the top manufacturers of three-sided knives worldwide.

Top 10 Three Sided Knife Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Folding Pocket Knives

Domain Est. 2014

Website: weknife.com

Key Highlights: Folding pocket knives are a type of knife that can be folded and stored in a pocket or carried in a sheath. They are commonly used for outdoor activities.Missing: three sided manu…

#2 Mcusta Knives USA Website

Domain Est. 2020

Website: mcustausa.com

Key Highlights: The Mcusta factory is located in the heart of Japan’s knifemaking capital of Seki, and crafts exquisite scissors, cutlery, fixed, and folding knives….

#3 Benchmade Knives

Domain Est. 1995

Website: benchmade.com

Key Highlights: Choose your high-quality cutting companion from Benchmade. Customizable options ensure a personalized design that lasts a lifetime….

#4 Cold Steel Knife and Tool Company

Domain Est. 1996

Website: coldsteel.com

Key Highlights: Featuring traditional and modern daily carry knives to satisfy every blade enthusiasts needs. Shop Now….

#5 Field Knife

Domain Est. 1998

Website: sogknives.com

Key Highlights: Affordable and durable fixed blade knife. Includes a 4-inch clip point stainless steel blade, soft rubber handle, and a GRN sheath with belt clip….

#6 Olamic Custom Knives

Domain Est. 2010

Website: olamiccutlery.com

Key Highlights: Order an Olamic knife, all custom build forms, current Half Baked builds, latest Quickforms, and what’s available now….

#7 USA Made Blade

Domain Est. 2011

Website: usamadeblade.com

Key Highlights: USA Made Blade Carrying popular brands like Rick Hinderer, TM Hunt, Nicholas Nichols, ZT Knives and more! Check out quality made products made right in the ……

#8 Liong Mah Design Premium Everyday Carry Knives

Domain Est. 2015

Website: liongmah.com

Key Highlights: We craft each knife with meticulous attention to detail, using only the finest materials like titanium, Damascus steel, and carbon fiber to ensure exceptional …Missing: three si…

#9 STEELPORT Knife Co.

Domain Est. 2020

Website: steelportknife.com

Key Highlights: We’re the only cutlery brand to offer broadly accessible premium carbon steel knives forged and handcrafted in the US, using all American-made materials….

#10 Outdoor Edge Cutlery: Knives & Tools

Domain Est. 1998

Website: outdooredge.com

Key Highlights: Outdoor Edge combines functional design with the sharpest steels and hand craftsmanship to create quality knives and tools for hunting and the outdoors….

Expert Sourcing Insights for Three Sided Knife

2026 Market Trends for Three-Sided Knife

The three-sided knife, commonly known as a three-edge punch or triangular utility blade, is widely used in industries such as construction, packaging, HVAC, and general maintenance for scoring, cutting, and scraping tasks. As we approach 2026, several key market trends are shaping the demand, innovation, and competitive landscape for this specialized cutting tool.

Rising Demand in Construction and Renovation

The global construction sector is experiencing steady growth, particularly in emerging economies and regions with infrastructure modernization programs. With an increasing focus on energy-efficient buildings and smart homes, the need for precision cutting tools—such as the three-sided knife—for drywall, insulation, and paneling is growing. The tool’s ability to make clean, accurate cuts in sheet materials supports faster installation processes, aligning with labor efficiency goals in construction projects.

Additionally, the surge in residential renovation post-pandemic continues into 2026, further driving demand among DIY enthusiasts and professional contractors alike. Home improvement retail sales remain strong, with tools like the three-sided knife benefiting from bundled product offerings and online tutorials promoting their utility.

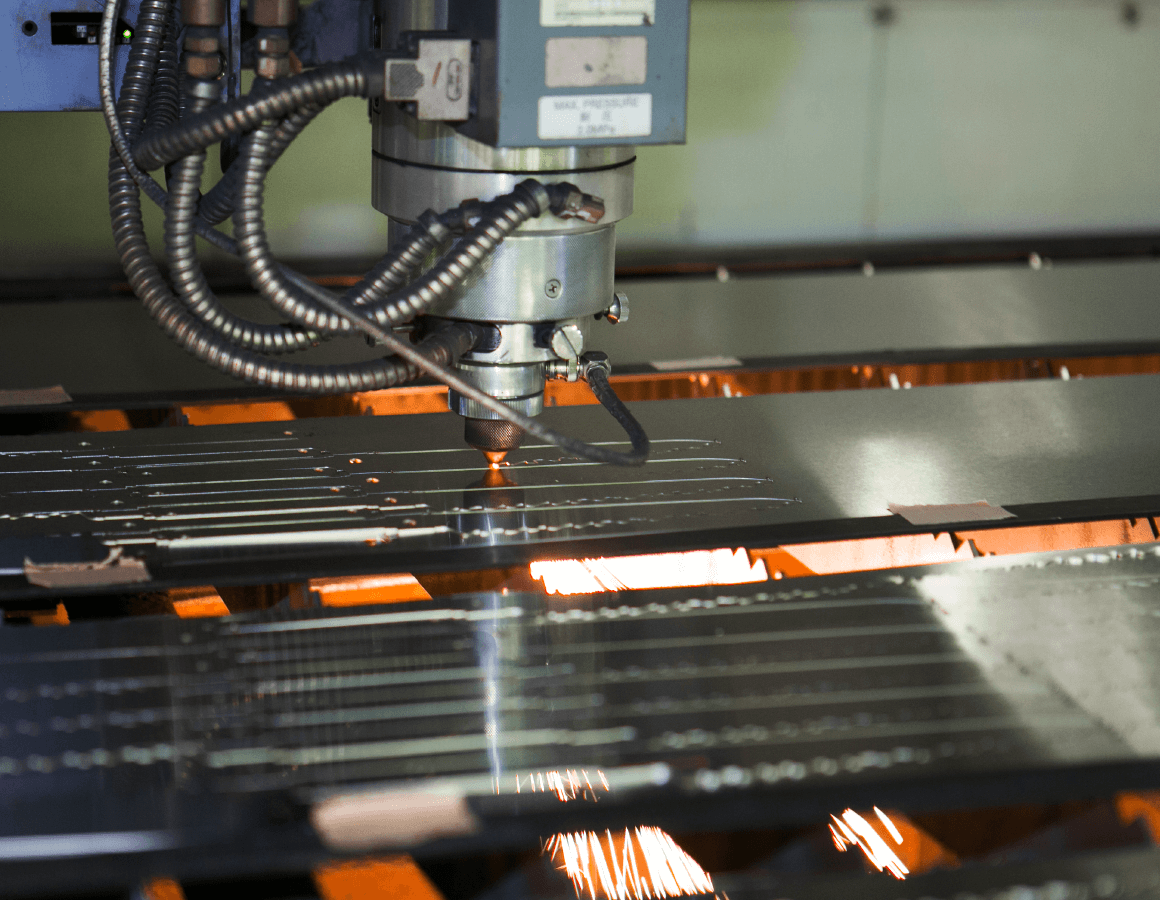

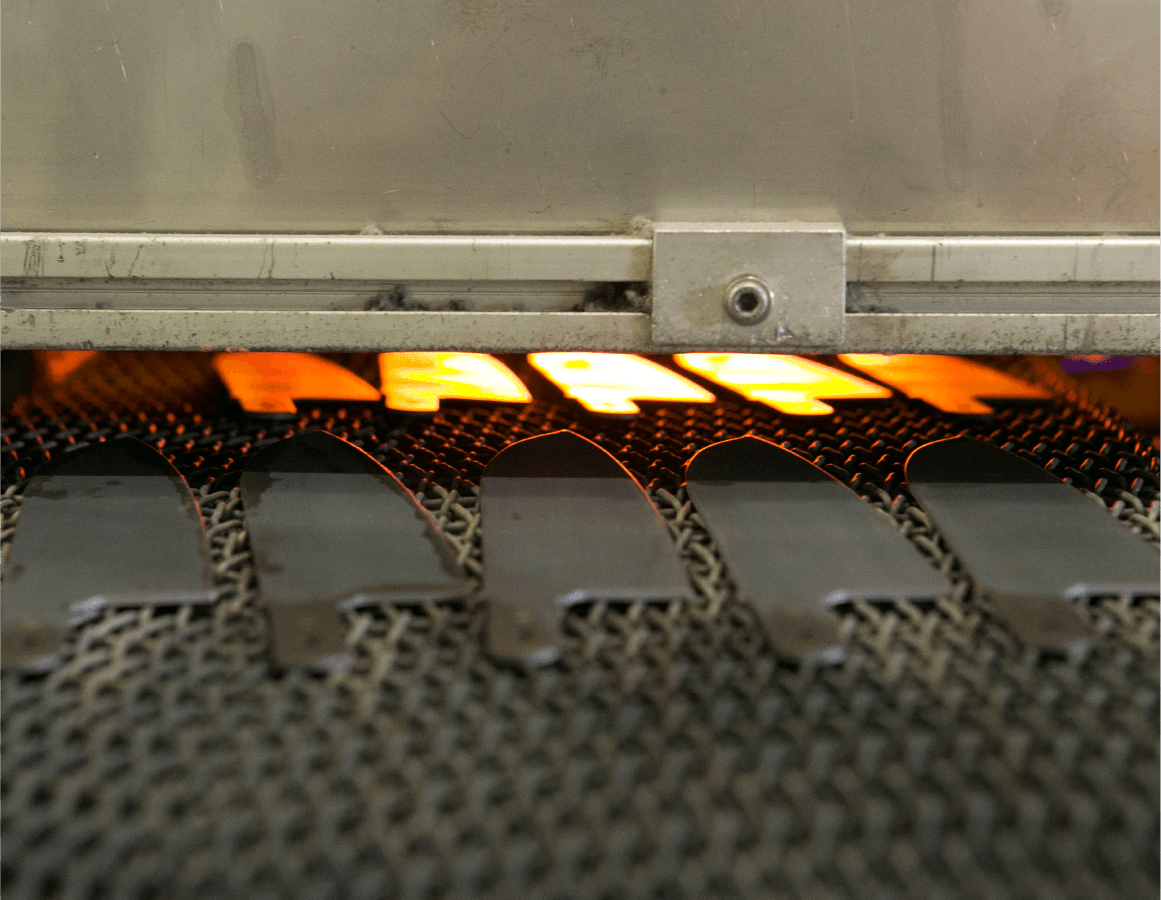

Innovation in Blade Materials and Durability

A significant trend in 2026 is the advancement in blade material technology. Manufacturers are increasingly adopting high-carbon stainless steel and ceramic composites to improve edge retention, corrosion resistance, and overall longevity. These enhancements reduce the frequency of blade changes, appealing to cost-conscious professionals.

Ergonomic handle designs with non-slip grips and quick-change blade mechanisms are also becoming standard. These features not only improve user safety but also increase productivity—critical factors in industrial environments.

Sustainability and Eco-Conscious Manufacturing

As sustainability becomes a priority across manufacturing sectors, companies producing three-sided knives are focusing on reducing environmental impact. In 2026, many brands are introducing recyclable packaging, implementing closed-loop production systems, and offering blade take-back programs to encourage responsible disposal of used blades.

Furthermore, some manufacturers are exploring biodegradable or reusable blade carriers and promoting longer-lasting blade designs to minimize waste—responding to both regulatory pressures and consumer preference for eco-friendly tools.

E-Commerce and Digital Distribution Growth

The three-sided knife market is witnessing a shift in distribution channels. Online marketplaces such as Amazon, Home Depot’s digital platform, and specialized industrial suppliers dominate sales in 2026. Enhanced product descriptions, customer reviews, and video demonstrations are helping buyers make informed decisions.

B2B e-commerce platforms are also gaining traction, allowing contractors and facilities managers to order in bulk with subscription-based restocking options. This digital transformation is streamlining supply chains and reducing lead times, especially for industrial clients.

Regional Market Expansion

While North America and Europe remain strong markets due to mature construction and manufacturing industries, the Asia-Pacific region is emerging as a high-growth area. Countries like India, Vietnam, and Indonesia are investing heavily in urban development and industrial parks, increasing the need for reliable hand tools.

Local production hubs are reducing import dependency and enabling faster customization to meet regional preferences, such as blade size or handle design. This regionalization strategy is helping global brands gain market share while supporting local economies.

Competitive Landscape and Brand Differentiation

The market for three-sided knives is becoming increasingly competitive. Established brands like Stanley, DEWALT, and Olfa continue to lead through innovation and brand trust, while new entrants are leveraging niche marketing—such as ultra-durable blades for HVAC technicians or lightweight versions for detail work.

In 2026, product differentiation is achieved not only through design but also through smart features, such as QR codes on packaging that link to instructional videos or safety guidelines. Some companies are even integrating augmented reality (AR) in their marketing to showcase tool applications.

Conclusion

By 2026, the three-sided knife market is evolving in response to technological advances, sustainability demands, and shifting consumer behaviors. With ongoing innovation and expanding global opportunities, this seemingly simple tool is proving essential in modern construction and industrial workflows. Manufacturers that prioritize durability, safety, and environmental responsibility are best positioned to lead in this resilient and growing market segment.

Common Pitfalls Sourcing a Three-Sided Knife (Quality, IP)

Sourcing a three-sided knife—commonly used in industrial cutting, paper converting, or packaging applications—can present several challenges, particularly concerning product quality and intellectual property (IP) rights. Overlooking these aspects can lead to operational inefficiencies, legal risks, and increased long-term costs. Below are key pitfalls to avoid.

Poor Material Quality and Inconsistent Hardness

One of the most frequent issues when sourcing three-sided knives is receiving blades made from substandard steel or with inconsistent heat treatment. Low-grade materials wear quickly, lose edge retention, and may chip or deform under pressure. Inconsistent hardness across the blade leads to uneven cutting performance and premature failure. Always verify the steel grade (e.g., high-carbon tool steel or stainless variants) and demand hardness test reports (e.g., HRC ratings) from suppliers.

Inaccurate Dimensional Tolerances

Three-sided knives must meet tight dimensional tolerances to fit specific machinery and ensure clean, precise cuts. Poorly manufactured blades may have variations in edge angles, width, or thickness, leading to misalignment, vibration, and machine damage. Confirm that the supplier adheres to ISO or OEM specifications and request sample measurements before bulk ordering.

Lack of Surface Finish and Edge Precision

A poorly finished blade surface increases friction, accelerates wear, and can contaminate the material being cut (e.g., paper or film). Similarly, imprecise edge geometry affects cut quality and blade longevity. Ensure the supplier uses precision grinding techniques and provides surface finish specifications (e.g., Ra values).

Ignoring Intellectual Property (IP) Rights

Many three-sided knife designs, especially OEM-specific models, are protected by patents or design rights. Sourcing generic or reverse-engineered blades that infringe on these IP rights can expose your company to legal action, product seizures, or costly litigation. Always verify that the supplier has the right to manufacture and sell the design, and avoid vendors offering “exact OEM replacements” without licensing.

Unverified Supplier Credentials and Traceability

Working with unverified suppliers—especially through third-party marketplaces—increases the risk of counterfeit or non-compliant products. Lack of material traceability (e.g., mill test certificates) makes it difficult to ensure quality consistency or troubleshoot failures. Choose suppliers with transparent manufacturing processes, quality certifications (e.g., ISO 9001), and full documentation.

Inadequate Testing and Validation

Some suppliers may not conduct real-world performance testing, resulting in knives that fail under actual operating conditions. Request performance data or conduct in-house trials before full deployment. Validate blade life, cut quality, and compatibility with your existing equipment.

Overlooking After-Sales Support and Re-sharpening Services

High-quality sourcing includes access to technical support, warranty coverage, and re-sharpening services. Suppliers offering no after-sales support may leave you stranded when issues arise. Confirm availability of these services, especially for custom or high-volume applications.

By addressing these common pitfalls, businesses can ensure reliable performance, maintain compliance, and protect their operations when sourcing three-sided knives.

Logistics & Compliance Guide for Three-Sided Knife

Product Classification and Regulatory Overview

The Three-Sided Knife, typically used in industrial cutting applications such as paper, film, or textile processing, may be subject to various regulatory controls depending on its design, materials, and intended use. It is generally classified under industrial machinery or tooling components. Confirm the appropriate Harmonized System (HS) code for accurate customs classification—common codes may fall under 8208 (interchangeable tools for hand tools or machine tools) or 8466 (parts and accessories for machinery). Always verify with local customs authorities or a licensed trade consultant.

Export Controls and Licensing Requirements

Due to its sharp and potentially hazardous nature, the Three-Sided Knife may be subject to export controls in certain jurisdictions. Evaluate whether the item meets criteria under dual-use regulations (e.g., EU Dual-Use Regulation or U.S. Export Administration Regulations). While typically not controlled as a weapon, knives designed for military or tactical applications could face stricter scrutiny. In most cases, industrial knives used in manufacturing are not export-controlled, but documentation such as a commercial invoice and bill of lading must be accurate and complete.

Packaging and Handling Instructions

Ensure the Three-Sided Knife is securely packaged to prevent damage and injury during transit. Use rigid, puncture-resistant materials such as heavy-duty corrugated boxes with internal foam or plastic holders to immobilize the blade. Clearly label packages with “Sharp Object” and “Handle with Care” warnings. Individual blades should be sheathed or covered with protective caps. Proper packaging reduces liability and ensures compliance with carrier safety standards.

Transportation and Carrier Compliance

Freight carriers (e.g., FedEx, DHL, UPS) have specific rules for shipping sharp objects. While industrial knives are generally permissible, they must be properly declared and packaged. Air shipment may require additional documentation or restrictions depending on destination. Always check current carrier guidelines before dispatch. For international shipments, include a detailed packing list and ensure the product description avoids ambiguous terms like “knife” without context—prefer “industrial cutting blade” or “machinery component.”

Import Regulations by Region

Different countries impose varying import rules on industrial tools. For example:

– United States: No special licensing required for industrial knives, but accurate HS code reporting is essential.

– European Union: Subject to general product safety directives; CE marking is not typically required for replacement parts unless part of a complete machine.

– Canada: Industrial blades are generally admissible but must comply with Canada Border Services Agency (CBSA) documentation requirements.

– Australia: May require import declaration; check with the Department of Home Affairs for specific tool regulations.

Always verify destination-specific rules before shipping.

Safety and Workplace Compliance (End-Use)

While this guide focuses on logistics, end-users should be informed of relevant safety standards such as OSHA (U.S.) or PUWER (UK), which govern the safe use of industrial cutting equipment. Provide safety data or handling instructions with the product to support compliance at the user level.

Documentation Checklist

Ensure all shipments include:

– Commercial invoice (with clear product description and value)

– Packing list

– Bill of lading or air waybill

– Export declaration (if required)

– Certificate of Origin (if claiming preferential tariffs)

Avoid terms like “weapon” or “combat” in documentation to prevent delays.

Risk Mitigation and Best Practices

- Conduct a classification review for every new product variant.

- Maintain records of compliance decisions for audits.

- Train logistics staff on proper handling and declaration of sharp tools.

- Use Incoterms clearly (e.g., FOB, DDP) to define responsibilities.

Adhering to this guide ensures safe, legal, and efficient global distribution of Three-Sided Knives.

In conclusion, sourcing a three-sided knife requires careful consideration of the intended application, material quality, supplier reliability, and compliance with safety and industry standards. Whether for industrial use, construction, or specialized cutting tasks, selecting a durable, precision-engineered tool from a reputable supplier ensures optimal performance and longevity. Evaluating factors such as blade material, ergonomics, certification, and cost-effectiveness will lead to a sourcing decision that balances quality and value. By conducting thorough research and due diligence, organizations can secure a reliable supply of three-sided knives that meet operational demands and contribute to efficient, safe workflows.