The global demand for reliable and standardized power connectivity solutions continues to surge, driven by expanding electronics manufacturing and heightened infrastructure development. According to Mordor Intelligence, the global power cord market was valued at USD 22.67 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2030, underpinned by rising adoption in IT & telecommunications, healthcare, and industrial equipment sectors. A critical subset of this market is three-prong AC power cords—essential for grounded electrical devices requiring enhanced safety and stability. With stricter regulatory standards and growing emphasis on product reliability, sourcing from reputable manufacturers has become a strategic priority for OEMs and supply chain managers. As competition intensifies, data-driven selection based on certifications, production capacity, geographic reach, and compliance history is key. The following analysis identifies the top 10 three-prong AC power cord manufacturers shaping the industry’s landscape through innovation, scalability, and global supply chain integration.

Top 10 Three Prong Ac Power Cord Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL offers a comprehensive power solution with our versatile series of power supplies. You can use this product overview tool to find product ……

#2 Power Supply Manufacturer

Domain Est. 1998

Website: synqor.com

Key Highlights: SynQor designs and manufactures high-efficiency, high-reliability DC-DC power converters, AC-DC power converters, EMI filters and power systems….

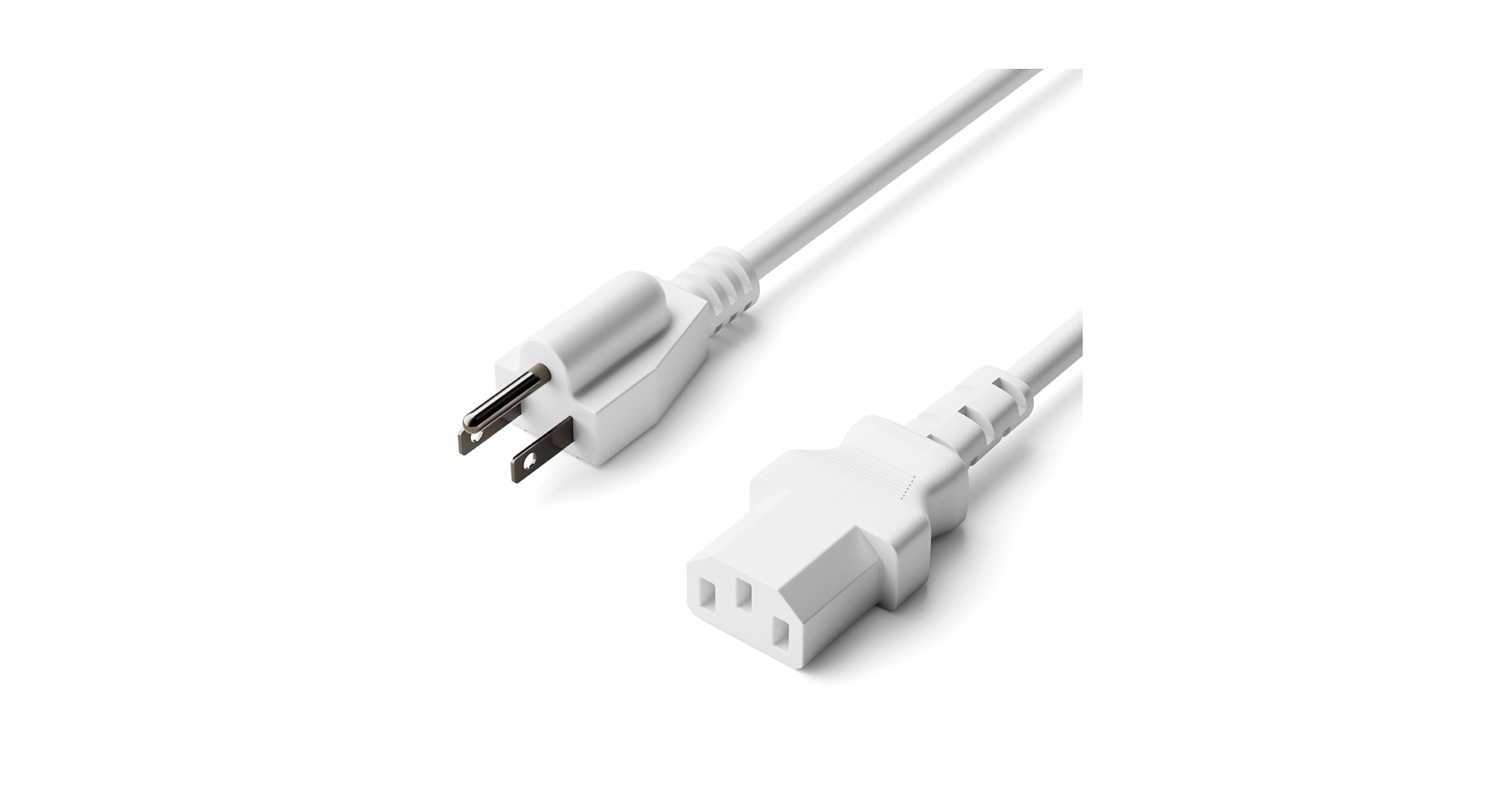

#3 Power Cord Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: For a broad selection of power cord products, detailed industry resources, and direct supplier connections, check out our Power Cords website….

#4 Power Cord Manufacturers

Domain Est. 2019

Website: powercordmanufacturers.com

Key Highlights: Type A plugs have two prongs, while Type B plugs have three, with the third prong providing additional electrical flow and grounding. A snug fit between the ……

#5 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: We offer many types of connectors for computers and connectors in electronics as well as wire plug connectors, electrical connector plugs, and electrical cable ……

#6 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: We offer AC power cords, extension cords, splitters and adapters for computers, servers and PDUs. Our cords have innovative features like coiled cords and ……

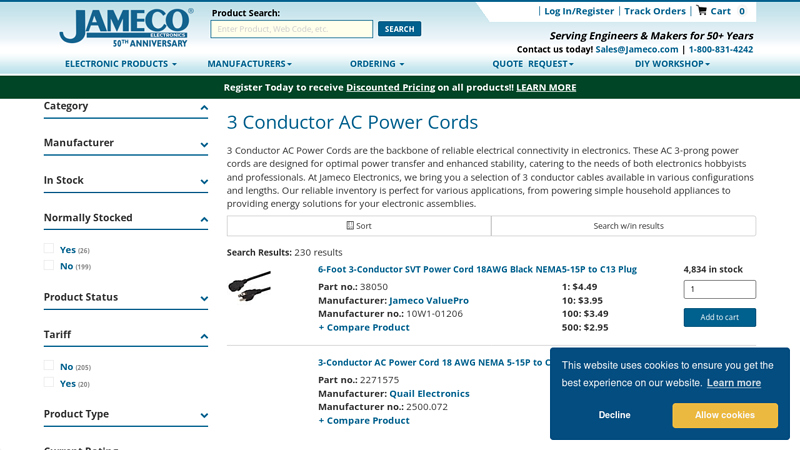

#7 3 Conductor AC Power Cords

Domain Est. 1998

Website: jameco.com

Key Highlights: Free delivery over $50AC 3-prong power cords are designed for maximum power transfer and stability when working on electronic projects. Shop 3-conductor cables at Jameco ……

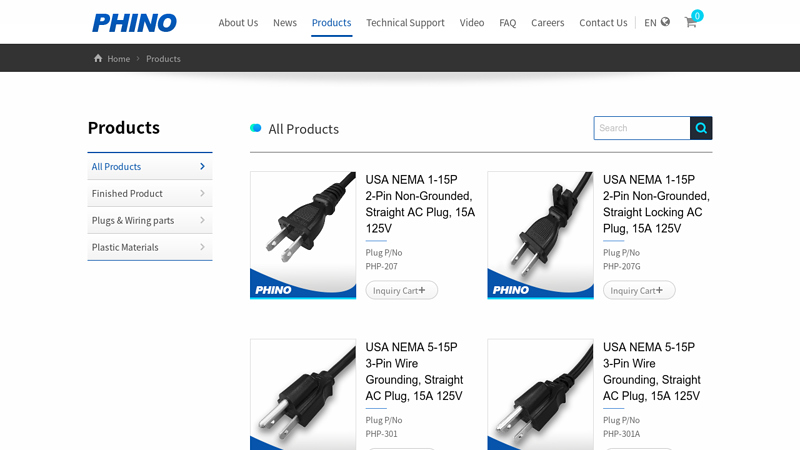

#8 Products

Domain Est. 1999

Website: phino.com

Key Highlights: Phino Electric is certified for sales of AC power cords, plugs, sockets, connectors around the world.Missing: three prong…

#9 3

Domain Est. 2009

Website: fireplaceblowersonline.com

Key Highlights: In stock Rating 5.0 (1) Nov 23, 2022 · 3-Prong AC grounded power cord with a ring terminal grounding lead. 18AWG, 105°C (221°F) and water resistant. Fits most blower applications…

#10 3 Prong C13 Power Cords Black

Domain Est. 2010

Website: vericomsolutions.com

Key Highlights: The Vericom AC power cord 3 conductor C13 is ideal for computers, printers, monitors, and other devices in a commercial or residential environment….

Expert Sourcing Insights for Three Prong Ac Power Cord

H2: Projected 2026 Market Trends for Three-Prong AC Power Cords

The global market for three-prong AC power cords is expected to experience steady growth and notable shifts by 2026, driven by advancements in technology, evolving safety standards, and increasing demand across consumer electronics, industrial applications, and smart home ecosystems. Below are the key trends projected to shape the market:

-

Increased Demand for Safety and Grounding Efficiency

As electrical safety regulations become stricter worldwide, the three-prong AC power cord—featuring a grounding pin—will remain the preferred choice for appliances requiring enhanced protection against electrical surges and faults. Regions such as North America and Europe are expected to maintain stringent compliance standards, boosting demand for grounded cords in household and commercial equipment. -

Growth in Consumer Electronics and Home Appliances

The proliferation of high-end consumer electronics—including gaming consoles, home theater systems, refrigerators, and washing machines—will continue to drive demand for reliable three-prong power solutions. Manufacturers are prioritizing compatibility with energy-efficient devices, further reinforcing the need for stable, grounded power delivery. -

Expansion of Smart Home Infrastructure

The rise of smart home devices that require constant and safe power connectivity will contribute to market growth. Smart HVAC systems, security appliances, and networked kitchen devices often utilize three-prong cords to ensure grounding and reduce interference, making them essential components in modern connected homes. -

Regional Regulatory Influences

Regulatory bodies such as UL (Underwriters Laboratories) in the U.S. and IEC (International Electrotechnical Commission) globally are expected to reinforce standards requiring grounded connections for certain device categories. These regulations will support sustained demand for three-prong cords, particularly in commercial and industrial sectors. -

Sustainability and Material Innovation

Environmental concerns are pushing manufacturers toward sustainable materials and recyclable cable jackets. By 2026, a growing number of three-prong cords are expected to be produced using halogen-free, flame-retardant, and RoHS-compliant materials, aligning with corporate ESG (Environmental, Social, and Governance) goals. -

E-Commerce and Aftermarket Sales Growth

Online retail platforms will continue to dominate aftermarket sales of replacement and specialty power cords. Consumers seeking longer, heavier-duty, or aesthetically designed cords (e.g., braided or color-coded) will fuel demand through e-commerce channels, particularly in emerging markets. -

Industrial and Medical Sector Adoption

Beyond consumer use, the industrial automation and medical equipment sectors will rely on three-prong cords for their grounding reliability. Medical devices, diagnostic machines, and industrial control systems require fail-safe power connections, ensuring continued demand in these high-stakes environments.

In summary, the three-prong AC power cord market in 2026 will be shaped by safety regulations, technological integration, and sustainability trends. While competition from wireless power and two-prong alternatives exists, the need for reliable grounding will ensure the three-prong configuration remains a staple in global power infrastructure.

Common Pitfalls When Sourcing Three-Prong AC Power Cords (Quality and IP)

Sourcing three-prong AC power cords may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to safety hazards, compliance failures, and legal risks. Here are the most common pitfalls to avoid:

Poor Electrical Safety and Component Quality

Using substandard materials—such as undersized gauge wires, low-grade insulation, or poorly molded connectors—can result in overheating, short circuits, or fire hazards. Many low-cost suppliers cut corners on internal conductor thickness, insulation integrity, or strain relief, increasing the risk of electrical shock or equipment damage. Always verify compliance with safety standards like UL, CSA, or IEC, and insist on certified components.

Non-Compliance with Regional Certification Requirements

Three-prong cords must meet specific regulatory standards depending on the target market (e.g., UL 817 in the U.S., CCC in China, or GS in Germany). Sourcing cords without the proper certifications can delay product launches, trigger customs rejections, or expose your company to liability. Ensure suppliers provide valid test reports and certification marks traceable to accredited labs.

Inadequate Strain Relief and Durability

A frequent design flaw is weak or missing strain relief at the plug and connector ends. Without proper reinforcement, repeated bending or tugging can break internal wires, creating intermittent connections or exposed conductors. Inspect samples for robust overmolding and internal anchoring to ensure long-term reliability in real-world use.

Counterfeit or IP-Infringing Connectors

Many low-cost power cords use connectors that mimic well-known branded designs (e.g., IEC 60320 C13/C14) but are manufactured without proper licensing. This constitutes intellectual property infringement and may violate trademark or design patents. Using such components exposes your business to legal action, product recalls, or seizure by customs authorities.

Misrepresentation of Cable Specifications

Suppliers may falsely advertise cable gauge (e.g., listing 16 AWG when it’s actually 18 AWG), length, or temperature rating. This discrepancy can lead to inadequate current handling and potential safety risks. Always request independent test data or conduct your own verification testing before mass procurement.

Lack of Traceability and Supplier Vetting

Sourcing from unknown or unqualified manufacturers increases the risk of inconsistent quality and supply chain disruptions. Avoid suppliers who cannot provide material traceability, production records, or quality control documentation. Conduct factory audits or use third-party inspection services to verify capabilities and compliance practices.

Ignoring Environmental and RoHS Compliance

Some power cords contain hazardous substances like lead, phthalates, or brominated flame retardants banned under RoHS, REACH, or other environmental regulations. Failing to confirm compliance can result in market access restrictions and reputational damage. Require full material disclosure and compliance certificates from suppliers.

Logistics & Compliance Guide for Three-Prong AC Power Cord

Overview

A three-prong AC power cord is a commonly used electrical component designed to safely connect electronic devices to an alternating current (AC) power source. It includes three conductors: live (hot), neutral, and ground, with the third prong providing a grounding path for enhanced electrical safety. Proper logistics handling and compliance with international and regional regulations are critical to ensure product safety, market acceptance, and legal distribution.

Regulatory Compliance

Electrical Safety Standards

Three-prong AC power cords must comply with electrical safety standards in the target market. Key certifications include:

– UL (Underwriters Laboratories) – USA/Canada: UL 817 covers cord sets and power-supply cords. Must be listed with UL and marked accordingly.

– CSA (Canadian Standards Association): CSA 22.2 No. 21 for cord sets in Canada. Often harmonized with UL standards.

– IEC (International Electrotechnical Commission): IEC 60204-1 and IEC 60320 series (e.g., C13/C14 connectors) for international use.

– EN (European Norm): EN 50525 for flexible cables and cords in the EU; compliance with Low Voltage Directive (2014/35/EU).

– PSE (Japan): Required for electrical goods under the Electrical Appliance and Material Safety Law; Class A or B depending on use.

RoHS and REACH Compliance

- RoHS (Restriction of Hazardous Substances): Applies in the EU and other regions. Limits the use of lead, mercury, cadmium, hexavalent chromium, PBB, PBDE, and four phthalates.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Requires disclosure of Substances of Very High Concern (SVHC) in products above threshold levels.

Country-Specific Plug and Voltage Requirements

- Ensure plug type matches destination (e.g., NEMA 5-15P in North America, Type G in the UK, Type F in Germany).

- Voltage and frequency compatibility must align with local grid standards (e.g., 120V/60Hz in the US, 230V/50Hz in Europe).

- Power cords should be rated for the maximum voltage and amperage of the connected device.

Packaging and Labeling

Product Labeling

Each power cord must be clearly marked with:

– Manufacturer or brand name

– Model or part number

– Voltage and current rating (e.g., 125V 10A)

– Compliance marks (e.g., UL, CE, CSA, PSE)

– Manufacturing date or batch code

– Cable type and gauge (e.g., SJT, 16 AWG)

Packaging Requirements

- Use anti-static or protective packaging to prevent damage during shipping.

- Include compliance documentation (e.g., Declaration of Conformity, test reports) in export shipments.

- Label outer cartons with handling instructions: “Fragile,” “Do Not Bend,” “Keep Dry.”

- Include country of origin marking per destination regulations (e.g., “Made in China”).

Shipping and Logistics

Transportation Considerations

- Avoid sharp bending or compression of cords during transit; use spools or coiled packaging.

- Store in dry, temperature-controlled environments to prevent insulation degradation.

- Comply with IATA/IMDG regulations if shipping internationally via air or sea (no hazardous materials, but proper classification as electrical components).

Import and Customs Clearance

- Provide Harmonized System (HS) Code: Typically 8544.42 (insulated wire, cable, or cord for voltage ≤1000V).

- Submit certificates of conformity, test reports, and commercial invoice with accurate product description.

- Be aware of country-specific import duties, taxes, and registration requirements (e.g., EAC in Russia, KC in South Korea).

Quality Assurance & Documentation

Testing and Certification

- Conduct routine electrical testing: continuity, insulation resistance, high-potential (hi-pot) testing.

- Maintain records of third-party certification (e.g., UL file number, CE test report).

- Perform periodic audits of manufacturing facilities to ensure ongoing compliance.

Required Documentation

- Certificate of Compliance (CoC)

- Test reports from accredited labs

- Bill of Materials (BOM) with RoHS/REACH compliance statements

- Safety Data Sheet (SDS), if requested

End-of-Life and Sustainability

Waste Electrical and Electronic Equipment (WEEE)

- Comply with WEEE Directive (2012/19/EU) in Europe by registering and contributing to recycling programs.

- Mark products with the “crossed-out wheeled bin” symbol.

- Provide take-back or recycling instructions where required.

Sustainable Practices

- Use recyclable cable jacket materials (e.g., PVC-free thermoplastic elastomers).

- Minimize packaging waste through efficient design and recyclable materials.

Conclusion

Proper logistics handling and comprehensive regulatory compliance are essential for the safe and legal distribution of three-prong AC power cords. Adherence to electrical safety standards, accurate labeling, and thorough documentation will ensure market access and consumer trust. Regular monitoring of evolving regulations in key markets is recommended to maintain compliance.

In conclusion, sourcing a three-prong AC power cord requires careful consideration of electrical standards, safety certifications, and compatibility with the intended device and regional power outlets. Ensuring the cord meets regulatory requirements such as UL, CE, or other applicable certifications is essential for safety and compliance. Additionally, verifying specifications like gauge (AWG), voltage rating, length, and connector type (e.g., NEMA 5-15P to IEC 60320 C13) will guarantee reliable and efficient performance. Whether for replacement, manufacturing, or procurement purposes, choosing a high-quality, properly rated three-prong AC power cord from a reputable supplier mitigates risks and supports long-term operational safety and reliability.