The global three-phase AC motor market continues to expand, driven by rising industrial automation, energy efficiency regulations, and increasing demand across sectors such as manufacturing, HVAC, and water treatment. According to a report by Mordor Intelligence, the global AC motor market is projected to grow at a CAGR of over 5.2% during the forecast period of 2024–2029, with three-phase motors dominating due to their superior efficiency, reliability, and performance in industrial applications. Additionally, Grand View Research valued the global AC motor market at USD 105.3 billion in 2023 and forecasts steady growth through 2030, citing advancements in motor design and integration with variable frequency drives (VFDs) as key drivers. As demand for high-performance, energy-efficient motors rises, a select group of manufacturers has emerged as industry leaders, combining engineering excellence, global reach, and innovation to capture significant market share. Below is a data-informed overview of the top nine three-phase AC motor manufacturers shaping the future of industrial motion.

Top 9 Three Phase Ac Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Baldor.com

Domain Est. 1995

Website: baldor.com

Key Highlights: ABB is the world’s number-one manufacturer of NEMA motors, and we’re proud to support you locally with the Baldor-Reliance product brand….

#2 Bodine Electric Company: Gearmotors

Domain Est. 1997

Website: bodine-electric.com

Key Highlights: Bodine Electric Company is a leading manufacturer of fractional horsepower gearmotors, motors, parallel shaft gearmotors, and motor speed controls….

#3 WorldWide Electric Corporation

Domain Est. 1999

Website: worldwideelectric.com

Key Highlights: WorldWide Electric manufactures electric motors, gear reducers, controls, & generators – backed by our reliable service and fast shipping….

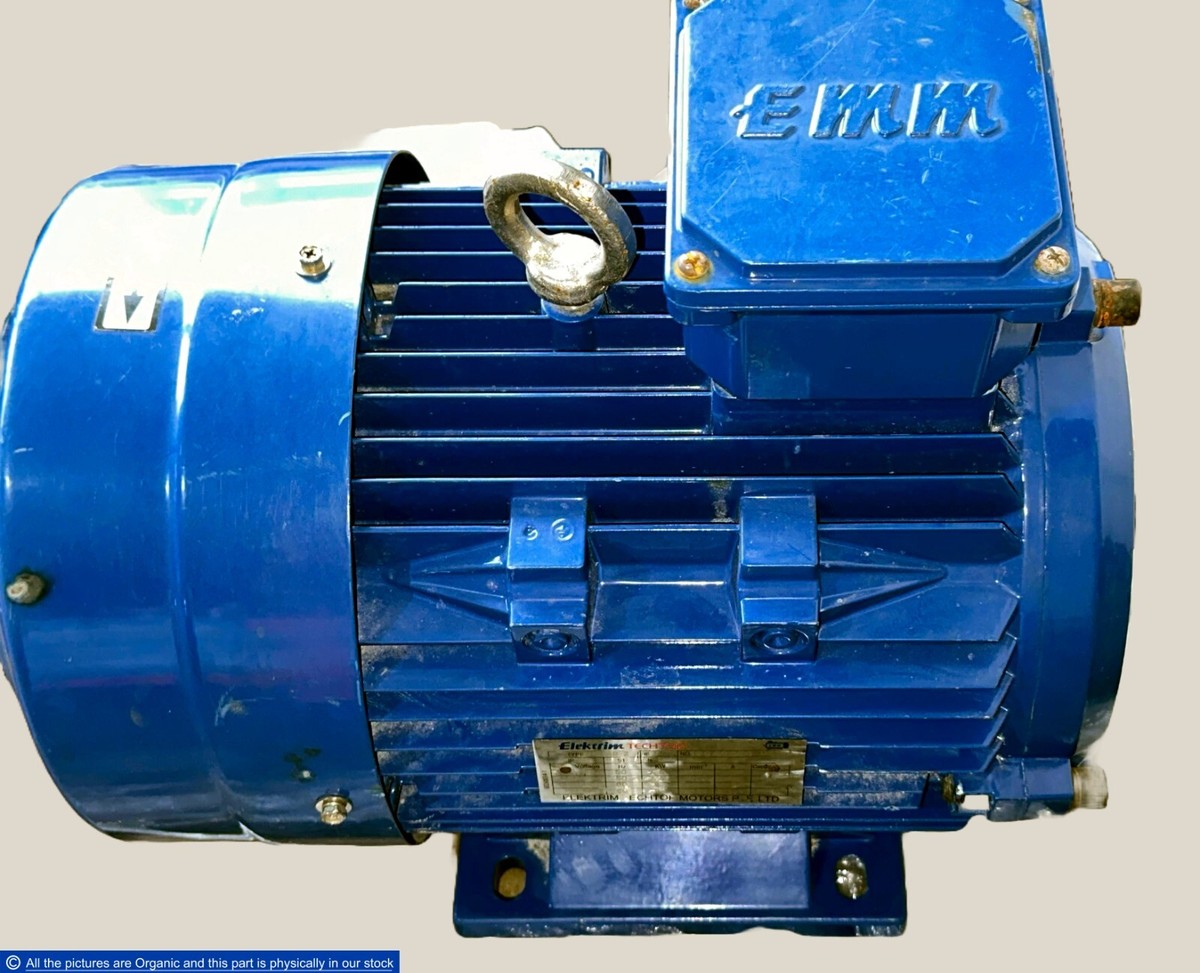

#4 TECHTOP Electric Motors

Domain Est. 2007

Website: techtopind.com

Key Highlights: Techtop Motors is one of the fastest-growing electric motor manufacturers in the industry today. Each Techtop motor is engineered with precision and built for ……

#5 ABB Motors and Generators

Domain Est. 1990

Website: new.abb.com

Key Highlights: ABB NEMA motors. NEMA 3-phase AC motors are built on a solid reputation for rugged and durable motor performance · DC motors. DC motors offer performance and ……

#6 MF three

Domain Est. 1996

Website: lenze.com

Key Highlights: The energy-efficient, inverter-optimized MF three-phase AC motors are particularly suitable for tasks that demand large setting ranges with minimal sizes….

#7 Electro Adda S.p.A.

Domain Est. 1998

Website: electroadda.com

Key Highlights: Our products · Search for motor range. Squirrel cage three-phase asynchronous motors C Series · Squirrel cage three-phase asynchronous brake motors FE, FECCL, ……

#8 TECO-Westinghouse

Domain Est. 1999

Website: tecowestinghouse.com

Key Highlights: Stock Motors · Single Phase ODP Motors · Single Phase TEFC Motors · Three Phase ODP Motors · Three Phase TEFC Motors · Medium Voltage ODP Motors · Medium ……

#9 WEG

Domain Est. 2004

Website: weg.net

Key Highlights: WEG provides global solutions for electric motors, variable frequency drives, soft starters, controls, panels, transformers, and generators….

Expert Sourcing Insights for Three Phase Ac Motor

2026 Market Trends for Three-Phase AC Motors

The global market for three-phase AC motors is poised for significant transformation and growth by 2026, driven by technological advancements, regulatory pressures, and shifting industrial priorities. Key trends shaping the landscape include:

Increasing Demand for Energy Efficiency and Regulatory Compliance

Stringent global energy efficiency regulations, such as the International Electrotechnical Commission (IEC) IE4 (Super Premium Efficiency) and the upcoming IE5 standards, are compelling manufacturers and end-users to adopt higher-efficiency motors. By 2026, compliance will be a major market driver, especially in regions like the European Union, North America, and parts of Asia-Pacific. Industries are increasingly replacing older, less efficient models (IE1 and IE2) with IE3 and IE4 motors to reduce energy consumption and operational costs, aligning with corporate sustainability goals and carbon reduction mandates.

Growth in Automation and Industrial IoT Integration

The rise of Industry 4.0 and smart manufacturing is accelerating the integration of three-phase AC motors with sensors, variable frequency drives (VFDs), and IoT platforms. By 2026, demand will grow for intelligent motors capable of real-time monitoring, predictive maintenance, and remote diagnostics. This trend enhances operational efficiency, reduces downtime, and supports data-driven decision-making in sectors such as automotive, food & beverage, and pharmaceuticals. Motor manufacturers are increasingly offering connected motor solutions as part of broader digital transformation strategies.

Expansion in Renewable Energy and Electric Infrastructure

The global shift toward renewable energy and electrification is creating new applications for three-phase AC motors. In wind turbines, solar tracking systems, and energy storage facilities, these motors are critical components. Additionally, the expansion of electric vehicle (EV) charging infrastructure requires robust motor-driven cooling and pumping systems. By 2026, investments in green energy projects are expected to significantly boost demand for reliable and high-performance three-phase motors.

Regional Market Growth in Asia-Pacific

Asia-Pacific, particularly China, India, and Southeast Asian nations, will remain the fastest-growing regional market due to rapid industrialization, urbanization, and government initiatives promoting industrial modernization. Local manufacturing hubs are expanding, and policies supporting energy efficiency are stimulating domestic demand. By 2026, Asia-Pacific is projected to hold the largest market share, driven by infrastructure development and the adoption of smart factory technologies.

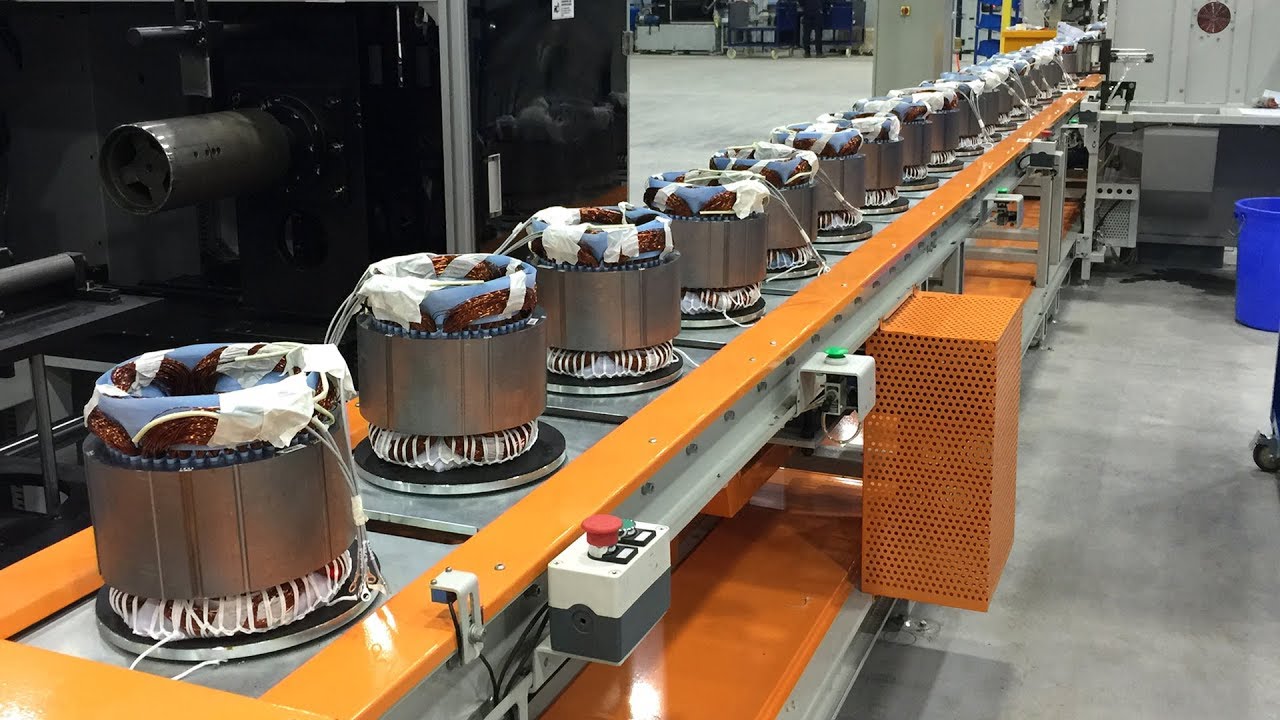

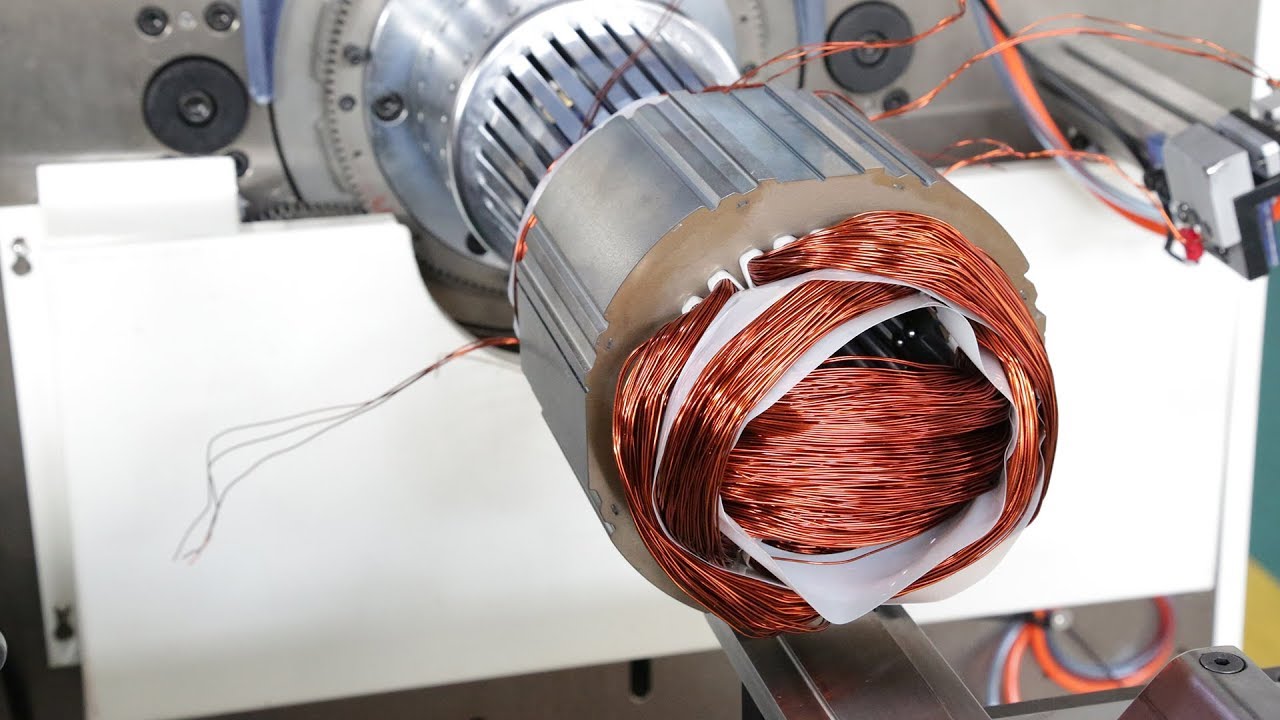

Advancements in Motor Design and Materials

Innovation in motor design—such as permanent magnet-assisted synchronous reluctance motors (PMa-SynRM) and improved thermal management—is enabling higher efficiency, reduced size, and lower noise levels. The use of advanced materials like high-grade electrical steel and better insulation systems contributes to longer motor lifespans and improved performance under harsh conditions. These technological improvements will be key differentiators for manufacturers competing in the premium segment by 2026.

Supply Chain Resilience and Localization

Ongoing geopolitical tensions and supply chain disruptions have prompted a shift toward regionalization and localization of motor production. By 2026, companies are expected to diversify sourcing, invest in local manufacturing, and adopt digital supply chain tools to enhance resilience. This trend supports faster delivery times, reduces dependency on single markets, and aligns with sustainability and ESG (Environmental, Social, and Governance) objectives.

In summary, the three-phase AC motor market in 2026 will be defined by a convergence of energy efficiency mandates, digital integration, green energy adoption, and regional growth dynamics. Stakeholders who embrace innovation, sustainability, and smart manufacturing technologies will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing Three-Phase AC Motors (Quality and IP Protection)

Sourcing three-phase AC motors requires careful attention to both quality and ingress protection (IP) ratings to ensure reliable and safe operation. Overlooking key factors can lead to premature failure, safety hazards, and increased maintenance costs. Below are common pitfalls to avoid:

Overlooking IP Rating Suitability for the Environment

Choosing a motor with an inappropriate IP rating for the operating environment is a frequent mistake. For example, selecting an IP54 motor for a washdown or outdoor application exposes it to moisture and dust ingress, leading to insulation failure and corrosion. Always match the IP rating to the environment—use IP55 or higher for wet or dusty conditions, and consider IP65 or IP66 for high-pressure cleaning or outdoor exposure.

Assuming Higher IP Rating Always Equals Better Quality

While a high IP rating (e.g., IP68) offers superior protection, it doesn’t guarantee overall motor quality. Motors can still suffer from poor winding insulation, substandard bearings, or inefficient cooling despite a high IP rating. Always evaluate the motor’s full specifications, including insulation class (e.g., Class F), duty cycle, and manufacturer reputation.

Ignoring Quality of Seals and Gaskets

Even with a high IP rating, poor-quality or improperly installed seals and gaskets can compromise protection. Low-grade rubber materials degrade quickly when exposed to oils, UV light, or extreme temperatures. Verify that seals are made from durable materials like nitrile or silicone and are properly integrated into the motor housing.

Failing to Verify Certification and Testing Standards

Some suppliers provide misleading or self-declared IP ratings without third-party verification. Always request test certificates from accredited laboratories (e.g., IEC 60529 compliance reports) and check for additional certifications like CE, UL, or CCC, which indicate adherence to international quality and safety standards.

Prioritizing Low Cost Over Long-Term Reliability

Opting for the cheapest motor often results in compromised materials and workmanship. Low-cost motors may use inferior copper windings, lower-grade steel laminations, or inadequate varnish coating, leading to overheating and reduced efficiency. Investing in a higher-quality motor from a reputable manufacturer typically results in lower total cost of ownership due to longer lifespan and reduced downtime.

Neglecting Thermal and Insulation Class Compatibility

A motor’s IP rating doesn’t reflect its thermal performance. Using a motor with an insufficient insulation class (e.g., Class B in a high-temperature environment) can lead to winding degradation, even if the enclosure is dust-tight. Ensure the motor’s insulation class and temperature rise rating align with the application’s thermal demands.

Inadequate Attention to Cooling Mechanisms in Sealed Motors

Totally enclosed motors (e.g., IP55, IP65) rely on external cooling fins or fan designs. Poor thermal management in such motors can cause overheating, especially in high-duty applications. Verify that the motor includes proper cooling features and is rated for the intended load and ambient temperature.

Skipping On-Site Environmental Assessment

Relying solely on catalog specifications without evaluating the actual installation site can lead to mismatched IP and quality requirements. Factors like chemical exposure, vibration, humidity, and ambient temperature must be assessed to choose the right motor protection and build quality.

By avoiding these common pitfalls, buyers can ensure they source three-phase AC motors that deliver optimal performance, durability, and safety for their specific application.

Logistics & Compliance Guide for Three Phase AC Motors

Overview

Three Phase AC Motors are widely used in industrial, commercial, and infrastructure applications due to their efficiency, reliability, and performance. Proper logistics planning and compliance with international and regional regulations are essential to ensure safe, timely, and legal transportation and operation of these motors. This guide outlines key considerations for logistics and compliance.

Packaging & Handling Requirements

Proper packaging protects motors from damage during transit. Follow these guidelines:

– Use sturdy wooden crates or skids with cushioning material to prevent vibration and shock.

– Secure motors with straps or bolts to avoid internal movement.

– Include protective caps on shafts and conduit openings.

– Clearly label packages with “Fragile,” “This Side Up,” and motor specifications.

– Avoid exposure to moisture; use desiccants or moisture barriers when necessary.

Transportation & Shipping

Choose appropriate transport modes based on motor size, weight, and destination:

– Domestic shipments: Use flatbed trucks or freight carriers; confirm weight and dimension limits.

– International shipments: Coordinate with freight forwarders for sea or air freight.

– For oversized motors, special permits or route planning may be required.

– Comply with carrier-specific regulations (e.g., IATA for air, IMDG for sea).

Import & Export Compliance

Ensure adherence to international trade regulations:

– Classify motors using the correct Harmonized System (HS) Code (e.g., 8501.31 or 8501.32 for AC motors).

– Obtain necessary export licenses if shipping to restricted countries.

– Prepare commercial invoices, packing lists, and certificates of origin.

– Check for import duties, tariffs, and local certification requirements.

Regulatory & Safety Standards

Three Phase AC Motors must comply with relevant electrical and safety standards:

– International: IEC 60034 series (rotating electrical machines).

– North America: NEMA MG-1 (USA), CSA C38 (Canada).

– European Union: CE marking per Machinery Directive and Low Voltage Directive; compliance with EN 60034.

– Other regions: Confirm local certifications (e.g., CCC in China, BIS in India, RCM in Australia).

– Motors used in hazardous environments must meet ATEX (EU) or NEC/CEC (North America) standards.

Energy Efficiency Regulations

Many countries enforce minimum efficiency performance standards (MEPS):

– IEC 60034-30-1 defines efficiency classes (IE1, IE2, IE3, IE4, IE5).

– USA: Complies with DOE 10 CFR 431, requiring IE3 (NEMA Premium) for most motors.

– EU: Ecodesign Directive (EU) 2019/1781 mandates IE3 or IE2 with VSD for certain motors.

– Verify that motors meet local efficiency standards before import or sale.

Documentation & Labeling

Accurate documentation ensures compliance and smooth customs clearance:

– Include motor nameplate data (voltage, frequency, power, speed, IP rating, insulation class).

– Provide technical manuals, installation guides, and conformity declarations.

– Label motors with manufacturer details, model number, serial number, and compliance marks (CE, UL, CSA, etc.).

– Retain records for traceability and warranty support.

Customs Clearance & Duties

Facilitate timely customs processing by:

– Assigning correct HS codes and declaring accurate motor values.

– Submitting required documentation (bill of lading, certificate of conformity, test reports).

– Consulting with customs brokers for complex shipments.

– Anticipating delays due to inspections or missing paperwork.

End-of-Life & Environmental Compliance

Follow environmental regulations for disposal or recycling:

– Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU.

– Handle copper windings, steel casings, and insulating materials according to local recycling laws.

– Avoid landfill disposal where regulated.

Summary

Effective logistics and compliance for Three Phase AC Motors require attention to packaging, transportation, international regulations, energy standards, and proper documentation. Proactive planning ensures on-time delivery, avoids penalties, and supports sustainable operations. Always consult local authorities and certification bodies for up-to-date requirements.

Conclusion for Sourcing a Three-Phase AC Motor

Sourcing a three-phase AC motor requires a thorough evaluation of technical specifications, operational requirements, supplier reliability, and total cost of ownership. Three-phase motors are preferred for industrial and commercial applications due to their superior efficiency, reliability, and ability to deliver consistent power with smoother operation compared to single-phase alternatives. When selecting a motor, critical factors such as power rating, speed (RPM), frame size, efficiency class (e.g., IE3, IE4), protection rating (IP code), and duty cycle must align with the application’s demands.

Additionally, sourcing from reputable suppliers ensures compliance with international standards (such as IEC or NEMA), access to technical support, and long-term serviceability. Considering energy efficiency not only reduces operational costs but also supports sustainability goals. Ultimately, a well-informed sourcing decision—balancing performance, durability, cost, and supplier credibility—ensures optimal integration and performance of the three-phase AC motor in the intended system, contributing to enhanced productivity and reduced lifecycle expenses.