The global electrical boxes market is experiencing steady expansion, driven by rising construction activities, increased adoption of smart building technologies, and growing investments in electrical infrastructure. According to Grand View Research, the global electrical boxes and enclosures market was valued at USD 10.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further amplified by stringent safety regulations and the need for durable electrical protection systems in both residential and commercial applications. Within this landscape, three-gang electrical boxes—designed to house multiple wiring connections and support complex electrical installations—have become critical components in modern electrical systems. As demand surges, a select group of manufacturers have emerged as industry leaders, combining innovation, scalability, and compliance with international standards to meet evolving market needs. The following analysis identifies the top eight manufacturers excelling in the production of three-gang electrical boxes, based on market presence, product range, and technological advancement.

Top 8 Three Gang Electrical Box Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

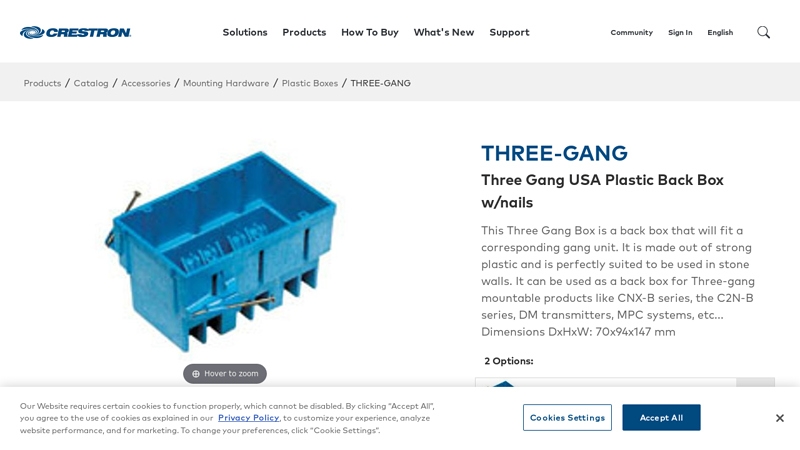

#1 THREE

Domain Est. 1999

Website: crestron.com

Key Highlights: This Three Gang Box is a back box that will fit a corresponding gang unit. It is made out of strong plastic and is perfectly suited to be used in stone ……

#2 3

Domain Est. 1988

Website: buildings.honeywell.com

Key Highlights: 3-Gang Electrical Box. Discontinued. The 3-gang electrical boxes are 5.556 cm deep and intended to be use in semi-flush mount applications….

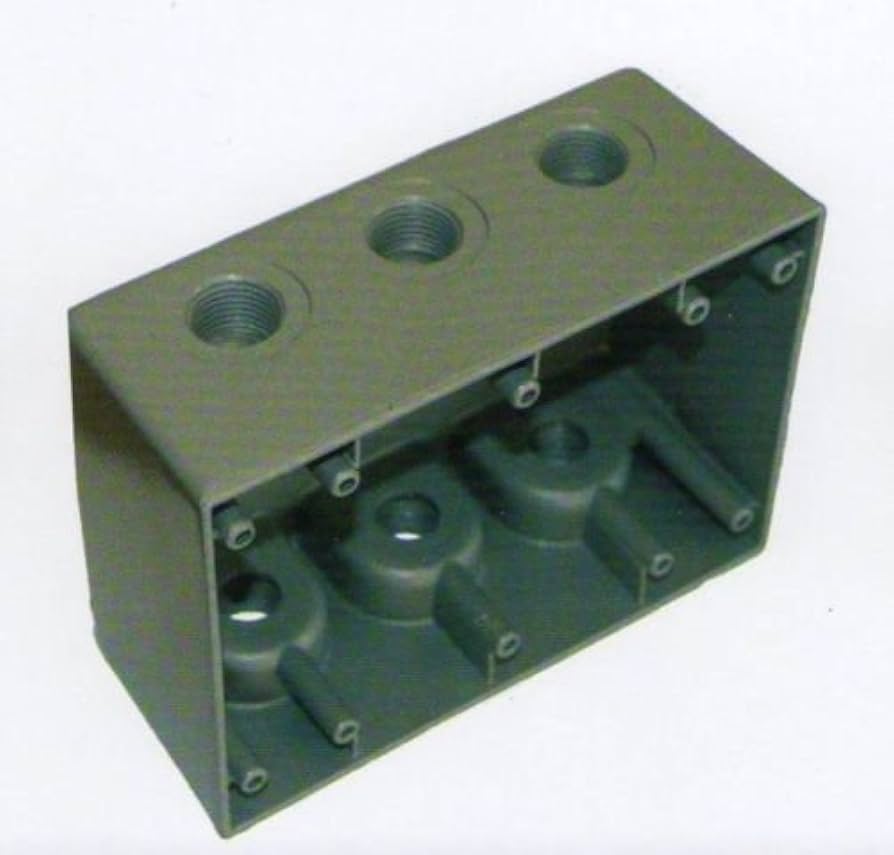

#3 3-WSW

Domain Est. 1990

Website: empower.abb.com

Key Highlights: Three-Gang Device Box, Volume 48 Cubic Inches, Length 3-3/4 Inches, Width 5-3/4 Inches, Depth 2-3/4 Inches, Color Gray, Material Non-Metallic, Cable Entries 12…

#4 Three Gang Non

Domain Est. 1994

Website: southwire.com

Key Highlights: Find the best 3 gang box for your electrical needs. Shop Southwire’s non-metallic Romex box with 57 cubic inches of space….

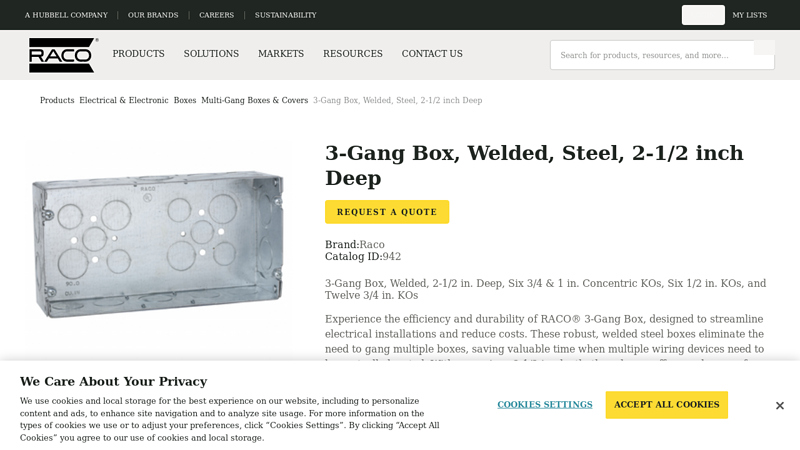

#5 3-Gang Box, Steel, 2-1/2 Inch Deep

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsThese robust, welded steel boxes eliminate the need to gang multiple boxes, saving valuable time when multiple wiring devices need to be centrally located….

#6 BE3 Product Information

Domain Est. 1998

Website: aifittings.com

Key Highlights: Part Number, BE3 ; Description, Box Extender, levels and supports the wiring device where the box is set back from the wall surface extends the box up to 1-1/2″….

#7 Boxes 3-Gang

Domain Est. 2003

Website: scottelectricusa.com

Key Highlights: Wiremold V5747-3 500/700 Series Steel 3-Gang Device Box 1-3/8″ Deep Ivory. Call for availability In Stock at your Branch: 5. In Stock Company Wide: 20….

#8 Three

Domain Est. 2004

Website: legrand.us

Key Highlights: Out of stock Rating 4.0 7 Allows for snug-to-wall placement of your flat-screen TV and handles up to 12 multimedia connections, while the surge-protective outlet protects costly …

Expert Sourcing Insights for Three Gang Electrical Box

H2: Projected 2026 Market Trends for Three-Gang Electrical Boxes

The market for three-gang electrical boxes is poised for steady growth and transformation by 2026, driven by advancements in construction technology, evolving building codes, and increasing demand for smart home infrastructure. As one of the foundational components in residential and commercial electrical systems, the three-gang electrical box—designed to house multiple wiring devices such as switches, outlets, and smart controls—is adapting to meet the needs of modern electrical installations.

-

Rising Demand in Residential Construction

The global surge in residential construction, particularly in North America and parts of Asia-Pacific, is expected to significantly influence the demand for three-gang electrical boxes. With the trend toward larger homes and more complex electrical layouts—including dedicated circuits for home offices, entertainment systems, and EV charging stations—electricians are increasingly specifying multi-gang boxes to consolidate outlets and switches. The three-gang variant offers optimal space efficiency, making it a preferred choice in modern wall designs. -

Integration with Smart Home Systems

By 2026, the adoption of smart home technologies is anticipated to accelerate, directly impacting electrical box specifications. Three-gang boxes are becoming essential for housing combinations of smart switches, USB outlets, motion sensors, and communication modules. Manufacturers are responding by designing deeper, better-ventilated, and retrofit-friendly three-gang models that accommodate the heat dissipation and space requirements of smart devices. -

Regulatory and Safety Standards

Updated electrical codes, such as the 2023 and upcoming 2026 National Electrical Code (NEC) revisions in the U.S., are placing greater emphasis on arc-fault protection, tamper resistance, and box fill calculations. These regulations are driving demand for standardized, code-compliant three-gang boxes with improved internal volume and secure clamping mechanisms. Compliance is becoming a key differentiator in product selection, especially in commercial and multifamily projects. -

Material and Design Innovation

Sustainability and durability are shaping product development. While traditional metal and PVC boxes remain prevalent, there is growing interest in composite materials that offer better fire resistance, lighter weight, and corrosion protection. Additionally, modular three-gang designs that allow for easy reconfiguration during renovations are gaining traction in both new builds and retrofit markets. -

Supply Chain and Regional Market Dynamics

The three-gang electrical box market is seeing regional diversification. North America remains the largest market due to stringent electrical codes and high construction activity. Meanwhile, emerging markets in Southeast Asia and the Middle East are witnessing increased adoption, fueled by urbanization and infrastructure development. Supply chain resilience, localization of manufacturing, and cost-effective distribution will be critical success factors by 2026. -

Competitive Landscape and Consolidation

Leading electrical manufacturers such as Legrand, Eaton, Leviton, and Hubbell are expanding their three-gang product lines with value-added features like pre-marked knockouts, integrated grounding, and compatibility with surface-mount raceways. Increased competition is likely to spur innovation and drive down prices, benefiting contractors and developers.

In summary, the 2026 market for three-gang electrical boxes will be shaped by technological integration, regulatory evolution, and shifting construction trends. As electrical systems grow more complex, the three-gang box is transitioning from a simple utility component to a strategic element in intelligent, future-ready building designs.

Common Pitfalls When Sourcing a Three Gang Electrical Box (Quality, IP)

Sourcing a three gang electrical box that meets both quality standards and the required Ingress Protection (IP) rating can be challenging. Falling into common pitfalls can lead to safety hazards, non-compliance, and costly rework. Here are the key issues to avoid:

Poor Material Quality and Construction

Low-cost electrical boxes may use substandard materials such as thin-gauge or recycled metal, or brittle, UV-sensitive plastics. These materials compromise durability, corrosion resistance, and mechanical strength. Poorly formed knockouts, weak mounting brackets, or inconsistent thread quality can lead to installation difficulties and long-term reliability issues.

Inaccurate or Unverified IP Ratings

Many suppliers advertise high IP ratings (e.g., IP66, IP67), but these claims are often not backed by independent testing or certification. Counterfeit or misleading labeling is common, especially in online marketplaces. Without valid test reports or third-party certifications (e.g., IEC 60529, UL), the box may fail to protect against dust and moisture in harsh environments.

Inadequate Sealing Mechanisms

Even if labeled with a high IP rating, the box may lack proper gaskets, seals, or cable glands. Poorly designed or missing seals around the lid, conduit entries, or mounting surface can allow water and dust ingress. Using standard glands instead of IP-rated ones further undermines protection.

Non-Compliance with Regional Standards

Electrical boxes must comply with local regulations such as NEC (US), IEC (international), or BS (UK). Sourcing boxes designed for one region and using them elsewhere can result in non-compliance. For example, a box meeting European standards may not satisfy North American grounding or mounting requirements.

Inconsistent Dimensions and Spacing

Low-quality boxes may have inaccurate gang spacing or depth, making it difficult to fit standard faceplates, switches, or outlets. Mismatched mounting centers (e.g., not conforming to 45.8 mm spacing) can lead to misalignment and an unprofessional finish.

Lack of Corrosion Resistance

In outdoor or damp locations, materials like galvanized steel or polycarbonate are essential. Sourcing boxes without adequate corrosion protection—such as insufficient zinc coating or non-UV-stabilized plastics—leads to premature degradation, especially in coastal or industrial environments.

Insufficient Thermal and Impact Resistance

Electrical boxes in industrial or outdoor settings must withstand temperature extremes and physical impact. Inferior plastics may become brittle in cold weather or warp in direct sunlight. Thin metal housings may dent or deform, compromising both safety and IP integrity.

Overlooking Certification and Traceability

Reputable suppliers provide product certifications, test reports, and batch traceability. Sourcing from vendors who cannot supply documentation increases the risk of using uncertified or unsafe products, which may fail inspections or void insurance coverage.

Avoiding these pitfalls requires due diligence: verify certifications, request test data, inspect samples, and source from reputable, experienced suppliers with a proven track record in electrical enclosures.

Logistics & Compliance Guide for Three Gang Electrical Box

This guide outlines the essential logistics considerations and compliance requirements for the handling, transportation, and installation of Three Gang Electrical Boxes. Adhering to these guidelines ensures safety, regulatory adherence, and operational efficiency throughout the supply chain and installation process.

Product Specifications and Identification

Ensure all Three Gang Electrical Boxes meet standardized dimensions and material specifications. Typical configurations include:

– Dimensions: Approximately 7.5 inches (190 mm) in width, 4.5 inches (114 mm) in height, and varying depths (2″, 3″, or 4″).

– Material: Galvanized steel, PVC (for non-metallic applications), or aluminum.

– Voltage Rating: Designed for use in standard residential and commercial low-voltage electrical systems (typically up to 600V).

– Certification Marks: Look for labels indicating compliance with relevant standards (e.g., UL 514A, CSA C22.2 No. 18.1, NEC Article 314).

Regulatory Compliance

All Three Gang Electrical Boxes must comply with national and regional electrical codes and safety standards.

National Electrical Code (NEC) – United States

- NEC Article 314: Governs the installation of outlet, device, pull, and junction boxes.

- Box fill calculations must account for conductors, devices, and clamps.

- Minimum box volume must be sufficient based on wire gauge and number of conductors (refer to NEC Table 314.16(B)).

- Boxes must be securely mounted and accessible after installation.

Canadian Electrical Code (CEC) – Canada

- CEC Section 12: Covers similar requirements to NEC, with alignment to CSA standards.

- Ensure compliance with CSA C22.2 No. 18.1: Outlet Boxes and Fittings.

- Boxes must be listed by a recognized certification body (e.g., CSA, cUL).

International Standards (IEC & EU)

- While IEC standards (e.g., IEC 60670) apply more broadly in Europe, North American projects typically follow UL or CSA.

- For EU markets, CE marking may be required under applicable directives (e.g., Low Voltage Directive, Construction Products Regulation), though electrical boxes often fall under national approval systems.

Packaging and Handling

Proper packaging ensures product integrity during shipping and storage.

- Packaging Type: Boxes should be shipped in sturdy corrugated cartons with internal dividers or bundling (for metal boxes) to prevent deformation.

- Labeling: Each package must include:

- Product type (e.g., “3-Gang Metal Electrical Box”)

- Quantity

- Manufacturer name and part number

- Compliance marks (UL, CSA, etc.)

-

Handling symbols (e.g., “Fragile,” “Do Not Stack,” “Protect from Moisture”)

-

Handling Precautions:

- Avoid dropping or impact to prevent warping, especially for metallic boxes.

- Store in a dry, indoor environment to prevent corrosion (for steel boxes).

- Stack cartons no higher than manufacturer recommendations to prevent crushing.

Transportation Requirements

- Domestic (USA/Canada):

- Use enclosed trucks to protect from weather.

- Secure loads to prevent shifting during transit.

-

Follow DOT (USA) or TDG (Canada) regulations if transporting hazardous materials (not typically applicable to standard electrical boxes).

-

International Shipping:

- Use ISPM 15-compliant wooden pallets if applicable.

- Ensure customs documentation includes HS Code: 8538.90 (parts suitable for use with electrical appliances).

- Declare compliance with destination country standards (e.g., UKCA for the UK, INMETRO for Brazil).

Installation Compliance

Installation must follow manufacturer instructions and local codes.

- Mounting: Securely fasten boxes to studs or framing using appropriate screws or nails.

- Grounding: Metal boxes must be bonded to the grounding system per NEC 250.12 or CEC Rule 10-700.

- Accessibility: Installed boxes must remain accessible—no permanent enclosures (e.g., drywall, tile) should cover the face without an access panel.

- Environmental Use:

- Use weather-resistant (WR) or extra-duty boxes for outdoor or damp locations.

- Ensure proper sealing with gaskets or mud rings if required.

Documentation and Traceability

Maintain records for compliance audits and warranty claims.

- Certificates of Compliance (CoC): Obtain from the manufacturer confirming adherence to UL, CSA, or other standards.

- Lot/Batch Tracking: Retain packaging labels with lot numbers for traceability.

- Inspection Reports: For large projects, conduct periodic inspections to ensure correct box usage and installation.

Disposal and Recycling

- Metal Boxes: Recyclable through scrap metal facilities; follow local recycling guidelines.

- PVC/Non-Metallic Boxes: Dispose of in accordance with local plastic waste regulations; may not be recyclable in all areas.

- Avoid landfill disposal where recycling options exist.

Conclusion

Adhering to this logistics and compliance guide ensures that Three Gang Electrical Boxes are handled, transported, and installed safely and in accordance with applicable regulations. Always consult the latest edition of the NEC, CEC, or local codes, and use products bearing recognized certification marks to ensure compliance and performance.

Conclusion for Sourcing a Three-Gang Electrical Box

In conclusion, sourcing a three-gang electrical box requires careful consideration of several key factors, including material type (metal or plastic), size and depth, mounting method (surface, recessed, or modular), compatibility with local electrical codes, and the specific application (residential, commercial, or industrial). After evaluating various suppliers, product specifications, and pricing options, it is evident that selecting the right three-gang box involves balancing durability, ease of installation, and cost-efficiency.

Opting for UL-listed or code-compliant boxes from reputable manufacturers ensures safety and long-term reliability. Additionally, considering future expandability and ease of wiring can save time and labor during installation. Whether sourcing locally or through online distributors, verifying product availability, lead times, and warranty terms is essential for timely project completion.

Ultimately, a well-informed decision based on technical requirements, quality standards, and budget constraints will ensure the successful integration of the three-gang electrical box into the overall electrical system, supporting safe and efficient power distribution.