The global waffle maker market is experiencing robust growth, projected to expand at a CAGR of 4.8% from 2023 to 2028, according to Mordor Intelligence. Rising consumer demand for convenient, time-efficient kitchen appliances—especially compact and specialized models like thin waffle makers—has fueled innovation and competition among manufacturers. As breakfast-on-the-go trends and home baking continue to gain traction, thin waffle machines have emerged as a popular niche, combining European-style crispness with modern functionality. This growing segment has attracted a wave of manufacturers focused on design, energy efficiency, and multi-functionality, setting new standards in performance and affordability. Below, we spotlight the top 9 thin waffle machine manufacturers leading this evolution, based on market presence, product innovation, and customer feedback.

Top 9 Thin Waffle Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Waffle and sandwich maker

Domain Est. 1998 | Founded: 1955

Website: lagrange.fr

Key Highlights: Each waffle maker combines tradition and innovation to guarantee ideal cooking and perfect waffles. Waffle and sandwich maker – French manufacturer since 1955….

#2 Sephra Skinny Waffle Plates

Domain Est. 2004

Website: sephra.com

Key Highlights: Make delicious, sweet or savoury snacks with Sephra’s new Skinny Waffle Maker, which is twice as cost effective as its standard Belgian counterpart!Missing: thin manufacturer…

#3 Top 53 Waffle Maker Manufacturers in China (2025)

Domain Est. 2022

Website: ensun.io

Key Highlights: CHRT is a professional manufacturer that offers a Mini Electric Commercial Thin Waffle Maker, ideal for both home and commercial use. Their product line ……

#4 Waffle Makers

Domain Est. 1998

Website: proctorsilex.com

Key Highlights: Free delivery 60-day returnsOur convenient waffle makers heat up quickly and produce delicious waffles in just minutes. Versatile and built to last, these fun kitchen appliances ar…

#5 Waffle Makers

Domain Est. 1998

Website: hamiltonbeach.com

Key Highlights: Free delivery over $75 Free 60-day returns…

#6 Commercial belgian waffle makers

Domain Est. 1998 | Founded: 1983

Website: ampi.be

Key Highlights: Ampi.be is specialised in manufacturing AMPI® branded professional waffle makers since 1983. A large range of waffle machines made of genuine cast iron and ……

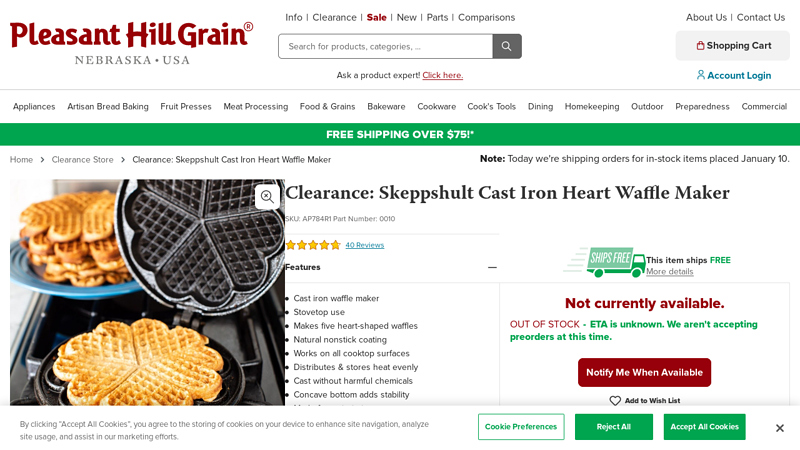

#7 Skeppshult Cast Iron Heart Waffle Maker

Domain Est. 1999

Website: pleasanthillgrain.com

Key Highlights: Rating 4.8 (40) · Free delivery over $75 · 30-day returnsCast iron waffle maker; Stovetop use; Makes five heart-shaped waffles; Natural nonstick coating; Works on all cooktop …

#8 Waffle Machines

Domain Est. 2015

Website: akasainternational.com

Key Highlights: Akasa Indian American Waffle Maker – Thin Waffle · Waffle Shape: Round · Power: 1000 W · Number Of Plates: 1 · Usage: Bakery, Cafe, Restaurant, Food Truck · Body ……

#9 Belgian Waffle Makers

Expert Sourcing Insights for Thin Waffle Machine

H2: Projected 2026 Market Trends for Thin Waffle Machines

The global market for thin waffle machines is poised for notable evolution by 2026, driven by shifting consumer preferences, technological advancements, and expanding foodservice applications. As demand for convenient, customizable, and artisan-style food experiences grows, thin waffle machines—known for producing crispy, delicate waffles—are gaining traction across both commercial and residential segments. The following trends are expected to shape the 2026 landscape:

1. Rising Demand in the Foodservice Sector

By 2026, the foodservice industry—including cafes, dessert parlors, and gourmet food trucks—is anticipated to be a key growth driver. Thin waffles are increasingly featured in premium dessert menus, breakfast offerings, and even savory applications (e.g., waffle tacos or sandwich bases). This versatility is prompting restaurants and street food vendors to invest in high-efficiency, durable thin waffle machines capable of consistent output.

2. Technological Integration and Smart Features

The integration of smart technology into kitchen appliances is extending to waffle machines. By 2026, expect increased adoption of IoT-enabled thin waffle machines with features such as temperature precision control, automatic batter dispensing, real-time performance monitoring, and remote diagnostics. These advancements will enhance operational efficiency, particularly in commercial settings.

3. Emphasis on Energy Efficiency and Sustainability

Environmental concerns are influencing appliance design. Manufacturers are expected to prioritize energy-efficient models in 2026, incorporating rapid heating elements, improved insulation, and eco-friendly materials. Certifications such as ENERGY STAR may become standard, appealing to sustainability-conscious businesses and consumers.

4. Growth in E-commerce and Direct-to-Consumer Sales

The online retail channel will continue to expand, enabling wider access to specialized thin waffle machines. By 2026, brands are likely to leverage e-commerce platforms and social media to target home bakers and culinary enthusiasts, offering compact, aesthetically pleasing models with customizable plates (e.g., heart, round, or Belgian-style options).

5. Regional Market Expansion

While North America and Western Europe remain strong markets, Asia-Pacific—especially countries like Japan, South Korea, and China—is expected to see accelerated growth. The popularity of street food culture and dessert innovation in urban centers will fuel demand for portable and commercial-grade thin waffle machines.

6. Innovation in Design and Customization

To differentiate products, manufacturers will focus on ergonomic designs, non-stick coatings, and interchangeable plates for multi-functionality. In 2026, modular and compact designs suitable for small kitchens or mobile operations will be particularly sought after.

In conclusion, the 2026 thin waffle machine market will be defined by innovation, sustainability, and diversification. As consumer tastes evolve and the foodservice industry embraces new culinary formats, thin waffle machines will transition from niche appliances to essential tools in both professional and home kitchens.

Common Pitfalls Sourcing Thin Waffle Machine (Quality, IP)

Sourcing thin waffle machines, especially from international suppliers, involves several potential pitfalls related to product quality and intellectual property (IP) risks. Being aware of these challenges can help buyers make informed decisions and protect their business interests.

Quality-Related Pitfalls

Inconsistent Build and Material Standards

Many suppliers, particularly in competitive manufacturing regions, may use substandard materials to cut costs. Thin waffle machines often feature non-stick coatings, heating elements, and mechanical hinges—all of which can vary significantly in durability. Poorly sourced machines may suffer from uneven heat distribution, warping plates, or premature failure, leading to customer dissatisfaction and increased warranty claims.

Lack of Safety and Compliance Certifications

A common issue is sourcing machines that lack proper safety certifications (e.g., CE, UL, ETL, or RoHS). Without these, importers risk customs delays, product recalls, or legal liabilities, especially when selling in regulated markets like the EU or North America. Some suppliers may claim compliance without providing verifiable documentation.

Inadequate Temperature Control and Performance Testing

Thin waffle machines require precise temperature control to achieve consistent results. Low-cost models may have poorly calibrated thermostats or lack overheat protection, resulting in undercooked or burnt waffles. Suppliers may not conduct sufficient performance testing, leading to inconsistent product behavior across units.

Intellectual Property (IP) Pitfalls

Risk of Copying or Infringing on Patented Designs

Many thin waffle machine designs—especially compact, aesthetic, or dual-mold variants—are protected by patents. Sourcing generic versions that closely resemble branded models can expose buyers to IP infringement claims. Some manufacturers produce “look-alike” products that violate design or utility patents, putting the importer at legal risk.

Unauthorized Use of Brand Logos or Trademarks

Suppliers might include unauthorized branding or misleading logos on packaging or the product itself. Even if unintentional, importing such goods can result in trademark violations, shipment seizures, or litigation, particularly if the product resembles a well-known brand.

Lack of IP Protection Agreements with Suppliers

Buyers often fail to secure proper IP ownership when developing custom designs. Without clear contractual agreements, the supplier may retain rights to the design or sell the same product to competitors. This undermines exclusivity and long-term market advantage.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct factory audits and request third-party quality inspections.

– Verify compliance certifications with official documentation.

– Perform sample testing for performance, durability, and safety.

– Conduct IP clearance searches before launching a product.

– Use legal agreements that assign IP rights and prohibit unauthorized replication.

By addressing these quality and IP concerns proactively, businesses can reduce risks and ensure a reliable, legally sound supply chain for thin waffle machines.

Logistics & Compliance Guide for Thin Waffle Machine

Product Classification & Regulatory Requirements

The Thin Waffle Machine is classified as a small kitchen appliance and must comply with electrical safety, food contact, and consumer product regulations in each target market. Key regulatory standards include:

- Electrical Safety: Compliance with IEC 60335-1 (General Safety) and IEC 60335-2-9 (Particular Requirements for Grills, Toasters, and Similar Portable Cooking Appliances).

- Electromagnetic Compatibility (EMC): Must meet directives such as the EU’s EMC Directive 2014/30/EU or FCC Part 15 in the U.S.

- Food Contact Materials: Surfaces contacting food must comply with food safety regulations such as FDA 21 CFR (U.S.) or EU Regulation (EC) No 1935/2004 and (EU) No 10/2011 for plastics.

- RoHS (EU): Restriction of Hazardous Substances Directive 2011/65/EU must be met for electronic components.

- REACH (EU): Compliance with Regulation (EC) No 1907/2006 for chemical substances.

- Energy Efficiency: Where applicable, adherence to energy labeling standards (e.g., EU Energy Labeling Regulation 2017/1369).

Ensure all applicable certifications are obtained prior to market entry. CE marking (for EU), UKCA (for UK), and FCC (for U.S.) are mandatory.

Packaging & Labeling Requirements

All packaging must include the following:

- Manufacturer/importer name and address

- Model number and serial number (if applicable)

- Electrical ratings (voltage, frequency, power)

- Safety warnings and symbols as required by IEC 60417

- CE/UKCA/FCC marks and other required certification logos

- QR code or URL linking to user manual and safety information (where required)

- Language-specific labeling for each target market (e.g., English, French, German)

- Recycling symbol (WEEE compliance in EU)

Packaging must be durable enough for international shipping and designed to minimize environmental impact (e.g., recyclable materials, minimal plastic use).

Import & Export Documentation

Ensure all shipments are accompanied by the following documentation:

- Commercial Invoice (with full product description, HS code, value, and Incoterms)

- Packing List (detailed contents per package)

- Certificate of Origin

- Bill of Lading or Air Waybill

- Product Compliance Certificates (e.g., CE, FCC, RoHS)

- Risk Assessment and Technical File (available upon request)

- Import License or Permit (if required by destination country)

The Harmonized System (HS) code for Thin Waffle Machines is typically 8516.60 (Electro-thermal appliances, other). Confirm with local customs authorities for accuracy.

Shipping & Handling

- Mode of Transport: Ocean freight (for bulk shipments), air freight (for urgent or small volumes).

- Incoterms: Use appropriate terms such as FOB (Free On Board), CIF (Cost, Insurance, Freight), or DDP (Delivered Duty Paid) depending on agreement with buyer.

- Palletization: Machines should be securely packed in cartons, stacked on standard EUR/ISO pallets, and stretch-wrapped.

- Temperature & Humidity: Store and transport in dry, climate-controlled environments (10–30°C, RH <75%).

- Handling: Label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” as needed.

Customs Clearance & Duties

- Verify tariff classification and import duty rates with local customs authority.

- Provide accurate product valuation to avoid delays or penalties.

- Some countries may require third-party inspection (e.g., SABER in Saudi Arabia, SONCAP in Nigeria).

- Be aware of anti-dumping or safeguard measures that may apply to appliances from certain regions.

- Maintain records for audit purposes (minimum 5 years in EU and U.S.).

Warranty & Post-Market Compliance

- Provide a minimum 1-year warranty covering manufacturing defects.

- Register products with national market surveillance authorities where required (e.g., RAPEX in EU).

- Monitor customer feedback and report any safety incidents promptly.

- Maintain a technical file and EC Declaration of Conformity (DoC) for at least 10 years after last product placement on the market.

- Plan for end-of-life handling per WEEE Directive (EU) or equivalent local e-waste regulations.

Summary

Adherence to logistics and compliance standards ensures smooth global distribution of the Thin Waffle Machine while protecting brand reputation and consumer safety. Always consult local regulatory experts before entering new markets.

In conclusion, sourcing a thin waffle machine requires careful consideration of several key factors including machine specifications, production capacity, energy efficiency, build quality, and after-sales support. Whether for commercial use in a café, food truck, or retail setting, selecting the right supplier involves evaluating reliability, certifications, and cost-effectiveness. It is essential to compare multiple vendors, request product samples or demonstrations, and ensure compatibility with local voltage and operational standards. Additionally, long-term maintenance and spare parts availability should be factored into the decision-making process. Ultimately, investing time in due diligence when sourcing a thin waffle machine ensures consistent product quality, operational efficiency, and a strong return on investment.