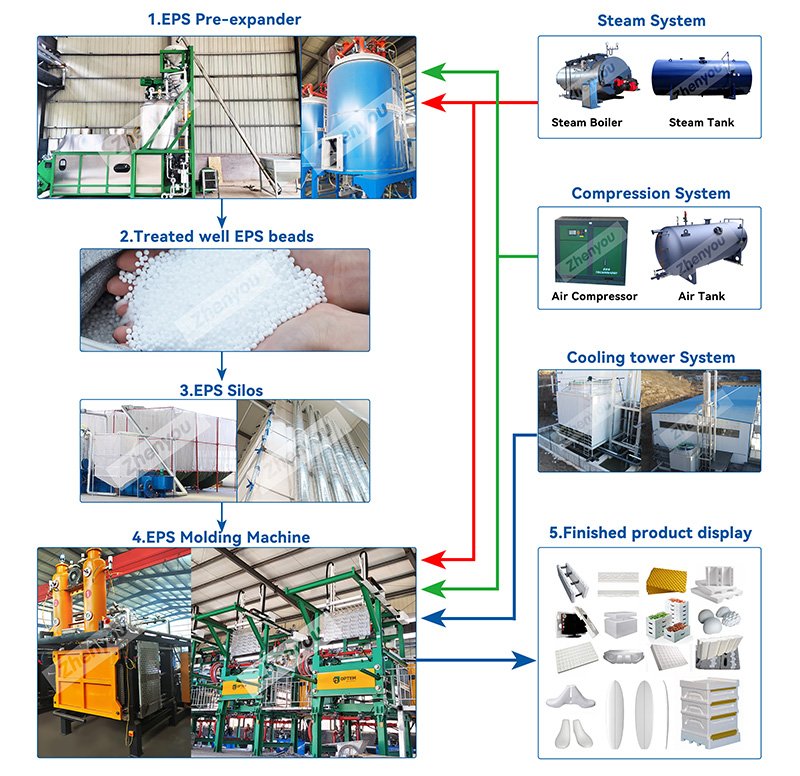

The global expanded polystyrene (EPS) market, commonly known as thermocol, is experiencing steady growth driven by rising demand in packaging, construction, and consumer goods industries. According to a report by Mordor Intelligence, the EPS market was valued at USD 13.87 billion in 2023 and is projected to reach USD 18.23 billion by 2029, growing at a CAGR of approximately 4.9% during the forecast period. This growth is fueled by thermocol’s lightweight properties, thermal insulation capabilities, and cost-effectiveness across logistics and building applications. With increasing urbanization and e-commerce expansion, particularly in Asia-Pacific and Latin America, the demand for high-quality thermocol sheets continues to rise. As supply chains prioritize protective and sustainable packaging solutions, selecting reliable manufacturers becomes critical. Based on production capacity, geographic reach, innovation in recycling, and industry reputation, here are the top 10 thermocol sheet manufacturers shaping the market landscape.

Top 10 Thermocol Sheet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 EPS Thermocol Blocks, Moulding Boxes, Manufacturer, Supplier, India

Domain Est. 2009

Website: kamakshathermocol.com

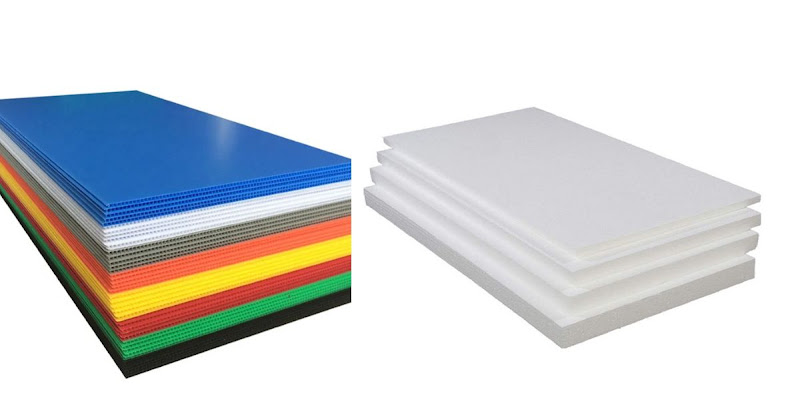

Key Highlights: We are manufacturing and supply the Expanded Polystyrene (ie EPS or Thermocol), Corrugated Boxes, expandable polyethylene (EPE FOAM), bubble bag, epe foam bag, ……

#2 Thermocol Box Manufacturer In Gujarat, Thermocol Sheet …

Domain Est. 2014

Website: divyapackaging.in

Key Highlights: Divya Packaging was established in the year 2009 offering best grade Thermocol Sheets, Air Bubble Pouch, Thermocol Pipe Section…

#3 Thermocole Foam Sheet ND Manufacturer from New Delhi

Domain Est. 2015

Website: foamtapes.in

Key Highlights: We are a leading firm offering Thermocol Foam Sheet. The product is manufactured using quality components under the supervision of our skilled workers….

#4 Shrushi Polymers Private Limited, Ahmedabad

Domain Est. 2017

Website: shrushipolymers.com

Key Highlights: We, ‘Shrushi Polymers Private Limited’is a prominent Manufacturer of Corrugated Box, Thermocol Box, Thermocol and XPS Sheet, Air Bubble Bags and Envelope, etc….

#5 Thermocol Insulation items Manufacturer, Supplier in India

Domain Est. 2018

Website: thermocolinsulation.com

Key Highlights: EPACK India is one of the largest manufacturer & supplier of EPS Thermocol Insulation sheets, pipe section in Delhi / NCR. Call @ 8800194670….

#6 I

Domain Est. 2019

Website: iconpolymers.com

Key Highlights: We are amongst the prominent manufacturers of the wide assortment of Thermocol Box and Sheets. These are famous for their lightweight and user-friendly….

#7 Thermocol Sheet Manufacturer,Thermocol Ice Box Supplier,Mumbai

Domain Est. 2022

Website: thermoshields.com

Key Highlights: THERMO SHIELD – As a manufacturer and supplier,our offered range of Thermocol Packaging Products includes Thermocol Packaging Sheet,Thermocol Ice Box ……

#8 Shree Bharath Packing

Domain Est. 2023

Website: shreebharathpacking.in

Key Highlights: We “Shree Bharath Packing” are Manufacturer And Retailer of Thermocol Box, Packaging Roll, Thermocol Packaging, Packaging Sheet and many more. Nature of ……

#9 Buy Premium Quality Thermocol Sheet at Wholesale Price …

Website: thermocolsheet.com

Key Highlights: We take pride in being recognized as the No. 1 Thermocol manufacturer in Pakistan, delivering high-quality thermocol sheets, boxes, and customized packaging ……

#10 Lightweight Styrofoam (EPS) Insulation Sheets

Domain Est. 2001

Website: madar.com

Key Highlights: These lightweight yet rigid foam sheets are easy to handle, cut, and shape, making them a popular choice for both commercial and DIY projects….

Expert Sourcing Insights for Thermocol Sheet

H2: 2026 Market Trends for Thermocol Sheets

The global Thermocol sheet market—commonly known as expanded polystyrene (EPS) sheets—is projected to undergo significant transformation by 2026, shaped by evolving environmental regulations, shifting consumer preferences, and advancements in sustainable packaging solutions. Thermocol sheets are widely used in packaging, construction, and insulation due to their lightweight, thermal insulation, and shock-absorbing properties. However, growing concerns about plastic pollution and non-biodegradability are driving innovation and regulatory scrutiny, which will heavily influence market dynamics in the coming years.

-

Regulatory Pressures and Environmental Awareness

By 2026, stringent environmental regulations across North America, Europe, and parts of Asia-Pacific are expected to restrict the use of non-biodegradable plastics, including conventional EPS. Countries are increasingly enforcing bans on single-use plastics, pushing manufacturers to develop recyclable or biodegradable alternatives. This regulatory environment will likely lead to a decline in traditional Thermocol sheet usage in consumer packaging, particularly in food service and electronics. -

Growth in Construction and Insulation Applications

Despite challenges in packaging, the construction sector is anticipated to become a key growth driver for Thermocol sheets by 2026. With rising demand for energy-efficient buildings, EPS sheets are being increasingly adopted for thermal insulation in walls, roofs, and floors. Governments promoting green building standards and net-zero energy homes are likely to boost demand for EPS insulation materials, especially in emerging economies such as India, Southeast Asia, and parts of the Middle East. -

Innovation in Sustainable Alternatives

Leading material science companies are investing in bio-based and recyclable EPS alternatives to meet sustainability goals. By 2026, we expect to see a rise in hybrid Thermocol sheets incorporating recycled content or plant-based polymers. Additionally, closed-loop recycling systems for EPS are gaining traction, reducing landfill waste and improving the material’s environmental footprint. These innovations may help sustain market growth despite regulatory headwinds. -

Regional Market Shifts

Asia-Pacific is projected to dominate the Thermocol sheet market by 2026, fueled by rapid urbanization, industrialization, and booming e-commerce sectors in China, India, and Indonesia. In contrast, Europe and North America may experience slower growth due to strict environmental laws, but demand will persist in specialized industrial and construction applications where alternatives are less viable. -

Price Volatility and Supply Chain Dynamics

Fluctuations in crude oil prices—since polystyrene is petroleum-based—could impact Thermocol sheet production costs through 2026. However, advancements in recycling technologies and the use of post-consumer recycled EPS may help stabilize input costs and reduce dependency on virgin materials.

In conclusion, the 2026 Thermocol sheet market will be characterized by a dual trajectory: contraction in traditional packaging uses due to environmental concerns, and expansion in construction and insulation driven by energy efficiency mandates. Companies that adapt through innovation, recycling initiatives, and compliance with green regulations are likely to maintain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Thermocol Sheets (Quality & IP)

Sourcing Thermocol (expanded polystyrene or EPS) sheets can be cost-effective, but several quality and intellectual property (IP)-related pitfalls can lead to project delays, compromised performance, or legal issues. Being aware of these common challenges helps ensure a successful procurement process.

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues is receiving Thermocol sheets that do not meet the required physical or mechanical standards. Suppliers may provide material with inconsistent density, poor dimensional accuracy, or weak structural integrity. Low-quality EPS may have uneven cell structure, leading to reduced insulation efficiency or insufficient load-bearing capacity in packaging or construction applications.

Misrepresentation of Grade and Density

Suppliers sometimes advertise a higher-grade or denser sheet than what is delivered. For example, claiming a 20 kg/m³ density when the actual product is closer to 12–15 kg/m³. This affects the material’s thermal insulation, compressive strength, and longevity, especially in construction or cold chain packaging.

Lack of Certification and Compliance Documentation

Reputable Thermocol sheets should come with certifications for fire retardancy (e.g., ASTM E84, BS 476), environmental compliance (e.g., recyclability), and material safety. Sourcing from suppliers who cannot provide verifiable test reports or compliance documents increases the risk of using non-compliant materials, particularly in regulated industries.

Intellectual Property (IP) Infringement Risk

Using custom-molded or branded Thermocol sheets without proper authorization can lead to IP violations. Some suppliers may offer sheets that replicate patented designs or incorporate copyrighted logos, especially in packaging for electronics or consumer goods. Sourcing such materials—even unknowingly—can expose your company to legal liability.

Counterfeit or Recycled Material Mislabeling

Some suppliers pass off recycled or regrind EPS as virgin material. While recycled EPS has its uses, it typically has lower strength and consistency. Mislabeling not only affects performance but may also breach contractual or regulatory requirements, especially in sensitive applications like food packaging or medical transport.

Inadequate Packaging and Handling Leading to Damage

Thermocol is fragile and susceptible to moisture, heat, and physical damage. Poor packaging during transit—such as lack of protective wrapping or improper stacking—can result in chipped edges, surface dents, or warped sheets, rendering them unusable.

Limited Traceability and Supplier Reliability

Many low-cost suppliers, especially from unverified sources, lack transparent supply chains. This makes it difficult to trace material origin, verify claims, or hold them accountable for defects. Without reliable traceability, resolving quality disputes or recalls becomes problematic.

Overlooking Environmental and Safety Standards

Sourcing from suppliers who do not adhere to environmental regulations (e.g., using ozone-depleting blowing agents) or safety standards (e.g., off-gassing of styrene) can lead to sustainability issues and health risks, especially in enclosed environments.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting samples and certifications, clearly defining specifications in contracts, and conducting regular quality audits. Additionally, ensuring that designs and molds used do not infringe on existing IP rights is critical to avoid legal complications.

Logistics & Compliance Guide for Thermocol Sheets

Thermocol sheets, also known as expanded polystyrene (EPS) sheets, are widely used for packaging, insulation, and construction due to their lightweight and insulating properties. However, their handling, transportation, and regulatory compliance require careful attention due to environmental, safety, and logistical considerations. This guide outlines key logistics and compliance aspects for managing Thermocol sheets across the supply chain.

Transportation & Handling

Thermocol sheets are bulky and lightweight, which can impact transportation efficiency and cost. Proper handling ensures product integrity and safety.

- Packaging: Secure sheets with stretch wrap or strapping to prevent shifting during transit. Use corner protectors if stacking to avoid damage.

- Loading: Stack sheets flat to avoid warping. Avoid placing heavy objects on top to prevent compression and deformation.

- Moisture Protection: Store and transport under cover or in sealed containers to protect from rain and humidity, which can degrade material performance.

- Temperature Control: Avoid prolonged exposure to high temperatures (above 75°C), which can cause softening or deformation. Store in cool, dry areas.

Storage Requirements

Proper storage is essential to maintain the physical properties and usability of Thermocol sheets.

- Environment: Store indoors in a dry, well-ventilated area away from direct sunlight to prevent UV degradation.

- Stacking: Limit stack height to prevent bottom sheets from being crushed. Use pallets for easier handling and to elevate from the floor.

- Fire Safety: Keep away from open flames, sparks, and heat sources. EPS is flammable and can release toxic fumes when burned.

Regulatory Compliance

Thermocol sheets are subject to various national and international regulations, especially concerning environmental impact and safety.

- Environmental Regulations:

- Many jurisdictions restrict or tax single-use EPS products due to non-biodegradability and recycling challenges.

- Check local bans on EPS packaging (e.g., in food service or consumer goods) before shipping to specific regions.

-

Ensure compliance with Extended Producer Responsibility (EPR) schemes where applicable.

-

Recycling & Waste Management:

- Provide clear labeling indicating material type (EPS, resin identification code #6).

- Encourage or facilitate return and recycling programs. EPS is recyclable but requires specialized facilities.

-

Comply with local waste disposal regulations; landfilling EPS may be restricted or taxed.

-

Hazard Communication:

- While EPS is generally non-toxic in solid form, safety data sheets (SDS) should be available, especially for cut or processed forms generating dust.

- Warn against incineration without proper emission controls due to styrene and other hazardous byproducts.

International Shipping Considerations

When exporting or importing Thermocol sheets, additional compliance steps are required.

- Customs Classification: Use the correct Harmonized System (HS) code—typically 3921.11 or 3921.12 for expanded polystyrene plates/sheets.

- Documentation: Include product specifications, material composition, and SDS in shipping documents.

- Phytosanitary & Fumigation: Generally not required for EPS, but verify destination country requirements, especially if used in packaging for agricultural goods.

- Packaging Standards: If used as protective packaging, ensure compliance with ISPM 15 if combined with wood components.

Sustainability & Alternatives

Due to growing environmental scrutiny, businesses are encouraged to explore sustainable practices.

- Reduce & Optimize: Minimize sheet size and thickness to reduce material use and shipping volume.

- Recycled Content: Source EPS sheets with post-consumer recycled content where available.

- Alternative Materials: Consider biodegradable or compostable substitutes (e.g., molded fiber, PLA) for applications where performance allows.

Conclusion

Transporting and managing Thermocol sheets requires attention to their physical characteristics, environmental impact, and evolving regulatory landscape. By following proper logistics protocols and staying informed about compliance obligations, businesses can ensure efficient, safe, and responsible handling of EPS sheets across global markets.

Conclusion for Sourcing Thermocol Sheets:

In conclusion, sourcing thermocol (expanded polystyrene or EPS) sheets requires a careful evaluation of quality, cost, supplier reliability, and specific application requirements. It is essential to identify suppliers who offer consistent product dimensions, density, and insulation properties tailored to the intended use—whether for packaging, construction, modeling, or display purposes. Comparing multiple vendors, considering bulk purchase discounts, and verifying certifications for environmental and safety standards can lead to optimal procurement outcomes. Additionally, factoring in logistics and sustainability aspects, such as recyclability and transportation impact, supports responsible sourcing. With due diligence, businesses can secure thermocol sheets that balance performance, affordability, and environmental considerations effectively.