The global thermal mass flow controller (MFC) market is experiencing robust expansion, driven by increasing demand for precision flow control in high-tech industries such as semiconductor manufacturing, pharmaceuticals, and renewable energy. According to a 2023 report by Mordor Intelligence, the mass flow controller market was valued at USD 1.35 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2028, reaching an estimated USD 2.01 billion by the end of the forecast period. This growth is largely fueled by advancements in automation, escalating investments in clean energy technologies like hydrogen fuel cells, and the rising complexity of fabrication processes in the semiconductor sector, which require highly accurate and reliable gas flow measurement and control. As demand intensifies, a select group of manufacturers continue to lead the market through innovation, product diversification, and strategic global partnerships—shaping the landscape of thermal MFC supply worldwide.

Top 10 Thermal Mass Flow Controller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Flow Control & Measurement

Domain Est. 1996

Website: brooksinstrument.com

Key Highlights: As the leading global mass flow control and flow meter manufacturer, Brooks Instrument offers the world’s most comprehensive line of precision flow control and ……

#2 Fluid Components International

Domain Est. 1996

Website: fluidcomponents.com

Key Highlights: Mass Flow Meters … FCI designs, manufactures and sells a broad line of air / gas mass flow meters utilizing thermal dispersion and measurement technology….

#3 Alicat Scientific

Domain Est. 2000

Website: alicat.com

Key Highlights: MEMS-Thermal Mass Flow Meters & Controllers … Alicat Scientific’s smallest BASIS 2 mass flow instrument line uses MEMS thermal technology to measure mass flow….

#4 Mass Flow Controllers

Domain Est. 1989

Website: mks.com

Key Highlights: Find the Perfect Mass Flow Controller with MKS. Wide range of MFCs for diverse flow rates and gases. Reliable flow measurement & control….

#5 Mass Flow Controller and Module

Domain Est. 1994

Website: horiba.com

Key Highlights: HORIBA is the recognised leader of high performance mass flow meters, mass flow controllers, automatic pressure controllers and liquid vaporization systems….

#6 GFC Mass Flow Controller

Domain Est. 1996

Website: aalborg.com

Key Highlights: GFC Mass Flow Controller. GFC low cost aluminum or stainless steel thermal mass flow controllers. Displaying 1 to 10 (of 11913 products)….

#7 Sierra Instruments

Domain Est. 1997

Website: sierrainstruments.com

Key Highlights: We design and manufacture high-performance thermal mass flow controllers, immersible thermal mass flowmeters, vortex flow meters and transit-time ultrasonic ……

#8 Our mass flow controllers

Domain Est. 1998

Website: bronkhorst.com

Key Highlights: A mass flow controller precisely controls the flow rate of gas or liquid within a system. Acting as a regulator, an MFC ensures that the correct amount of gas ……

#9 Thermal Mass Flow Products

Domain Est. 2002

Website: teledyne-hi.com

Key Highlights: Teledyne Hastings Instruments brings decades of experience to offer a full line of thermal mass flow meters and controllers….

#10 Thermal Mass & Vortex Shedding Flow Meters

Domain Est. 2006

Website: foxthermal.com

Key Highlights: We manufacture reliable thermal gas mass flow meters and vortex shedding meters for gas, steam, and liquid applications. Get a quote today….

Expert Sourcing Insights for Thermal Mass Flow Controller

H2: 2026 Market Trends for Thermal Mass Flow Controllers

The global market for Thermal Mass Flow Controllers (TMFCs) is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and increasing demand across high-growth sectors. Key trends shaping the TMFC market include rising adoption in semiconductor manufacturing, stringent environmental regulations, integration with Industry 4.0 technologies, and regional shifts in manufacturing hubs.

-

Growth in Semiconductor and Electronics Manufacturing

By 2026, the semiconductor industry will remain a primary driver for TMFC demand. With the global push for advanced microelectronics, electric vehicles, and 5G infrastructure, precise gas flow control in fabrication processes—such as chemical vapor deposition (CVD) and etching—is critical. TMFCs offer high accuracy and repeatability in controlling process gases like nitrogen, oxygen, and specialty gases, making them indispensable in cleanroom environments. Asia-Pacific, particularly South Korea, Taiwan, and China, will continue to expand semiconductor production, boosting regional TMFC consumption. -

Integration with Smart Manufacturing and IoT

The evolution toward Industry 4.0 is accelerating the integration of smart sensors and digital communication protocols in TMFCs. By 2026, an increasing number of TMFCs will support Fieldbus, Modbus, and Ethernet/IP, enabling real-time monitoring, predictive maintenance, and remote diagnostics. Cloud-based platforms and AI-driven analytics will enhance process optimization, reducing downtime and improving yield rates. Manufacturers are expected to offer TMFCs with embedded diagnostics and self-calibration features to meet the demands of smart factories. -

Environmental and Energy Efficiency Regulations

Stringent emissions standards and sustainability goals are pushing industries to adopt more efficient and accurate flow measurement technologies. TMFCs, which measure mass flow directly without the need for pressure and temperature compensation, offer energy-efficient performance in applications such as biogas monitoring, carbon capture, and fuel cell development. Regulatory mandates in North America and Europe for greenhouse gas reporting will drive TMFC use in environmental monitoring and emissions control systems. -

Expansion in Renewable Energy and Hydrogen Economy

The global shift toward clean energy is creating new opportunities for TMFCs, particularly in hydrogen production and fuel cell technologies. Electrolysis systems for green hydrogen require precise gas flow control during hydrogen and oxygen separation. By 2026, increased investments in hydrogen infrastructure—especially in Germany, Japan, and the U.S.—will elevate demand for TMFCs capable of handling hydrogen with high safety and accuracy standards. -

Regional Market Dynamics

While North America and Europe maintain strong demand due to advanced industrial infrastructure and R&D investments, the Asia-Pacific region is expected to witness the highest compound annual growth rate (CAGR) through 2026. China’s emphasis on self-reliance in semiconductor and clean energy technologies, along with India’s expanding manufacturing base, will fuel regional TMFC adoption. Local production and partnerships with global TMFC suppliers will intensify competition and drive innovation. -

Technological Advancements and Miniaturization

Ongoing R&D efforts are leading to the development of compact, low-power TMFCs suitable for portable and medical applications, such as respiratory devices and lab-on-a-chip systems. MEMS (Micro-Electro-Mechanical Systems)-based TMFCs are gaining traction for their small footprint and cost-effectiveness. By 2026, these miniaturized sensors are expected to open new markets in healthcare, environmental sensing, and consumer electronics.

In conclusion, the 2026 outlook for Thermal Mass Flow Controllers is highly positive, characterized by technological innovation, sectoral expansion, and global demand diversification. Companies that invest in smart, sustainable, and application-specific TMFC solutions will be best positioned to capitalize on emerging opportunities.

H2: Common Pitfalls When Sourcing Thermal Mass Flow Controllers for Hydrogen (H2) Applications

Sourcing Thermal Mass Flow Controllers (TMFCs) for hydrogen (H₂) service involves unique challenges due to hydrogen’s physical and chemical properties. Selecting the wrong device or overlooking key technical and intellectual property (IP) considerations can lead to safety risks, poor performance, and legal complications. Below are critical pitfalls to avoid:

1. Inadequate Material Compatibility with Hydrogen

- Pitfall: Using wetted materials not certified for H₂ service can lead to hydrogen embrittlement, seal degradation, or catastrophic failure.

- Solution: Ensure all wetted parts (e.g., stainless steel 316L, specific elastomers like Kalrez or Chemraz) are rated for hydrogen. Avoid materials prone to embrittlement, such as standard carbon steels or certain aluminum alloys.

2. Poor Accuracy and Calibration for Low-Density Gases

- Pitfall: TMFCs calibrated for heavier gases (e.g., N₂, CO₂) may perform inaccurately with low-density H₂ due to differences in thermal conductivity and specific heat.

- Solution: Source TMFCs specifically calibrated for hydrogen. Verify NIST-traceable calibration and ensure the device covers the required flow range for H₂.

3. Ignoring Safety and Certification Requirements

- Pitfall: Deploying non-certified devices in hazardous areas (e.g., ATEX, IECEx, FM) increases explosion risks.

- Solution: Choose TMFCs with appropriate safety certifications for hydrogen environments, especially in fuel cell, electrolyzer, or refueling applications.

4. Overlooking Response Time and Dynamic Performance

- Pitfall: Slow response times can compromise process control in dynamic H₂ systems (e.g., fuel cell load-following).

- Solution: Select TMFCs with fast response times (<1 second) and verify performance under actual operating pressure and temperature conditions.

5. Intellectual Property (IP) and Counterfeit Risk

- Pitfall: Sourcing from unauthorized distributors or low-cost suppliers may result in counterfeit or reverse-engineered TMFCs infringing on patents.

- Solution: Purchase only from authorized distributors or OEMs. Verify product authenticity and check for IP protection (e.g., patented sensor designs, firmware algorithms). Avoid suppliers offering “compatible” models that may violate patents.

6. Lack of H₂-Specific Software and Communication Protocols

- Pitfall: Generic controllers may lack proper gas selectability or fail to compensate for H₂-specific thermal properties in firmware.

- Solution: Ensure firmware supports hydrogen as a selectable gas with proper compensation algorithms. Confirm compatibility with fieldbus protocols (e.g., Modbus, Profibus, Foundation Fieldbus) if needed.

7. Insufficient Pressure and Temperature Rating

- Pitfall: H₂ systems often operate at high pressures (350–700 bar in mobility applications), exceeding standard TMFC limits.

- Solution: Verify that the TMFC is rated for maximum operating pressure and temperature of your system. Use pressure-reducing stages if necessary.

8. Poor Long-Term Stability and Maintenance Support

- Pitfall: Low-quality TMFCs may drift over time, especially in cyclic H₂ applications, leading to inaccurate dosing.

- Solution: Choose suppliers offering recalibration services, long-term support, and proven field reliability in hydrogen applications.

Conclusion

Sourcing TMFCs for hydrogen demands attention to material science, calibration specificity, safety compliance, and IP legitimacy. Avoiding these common pitfalls ensures reliable, safe, and legally compliant operation in hydrogen energy systems. Always prioritize supplier reputation, technical validation, and proper certification when selecting TMFCs for H₂ service.

H2: Logistics & Compliance Guide for Thermal Mass Flow Controller (Using Hydrogen – H₂)

1. Overview

This guide outlines the logistics, handling, transportation, and regulatory compliance considerations specific to Thermal Mass Flow Controllers (TMFCs) when used with hydrogen (H₂) gas. Hydrogen’s unique physical and chemical properties require special attention to ensure safe and compliant operations throughout the supply chain and operational lifecycle.

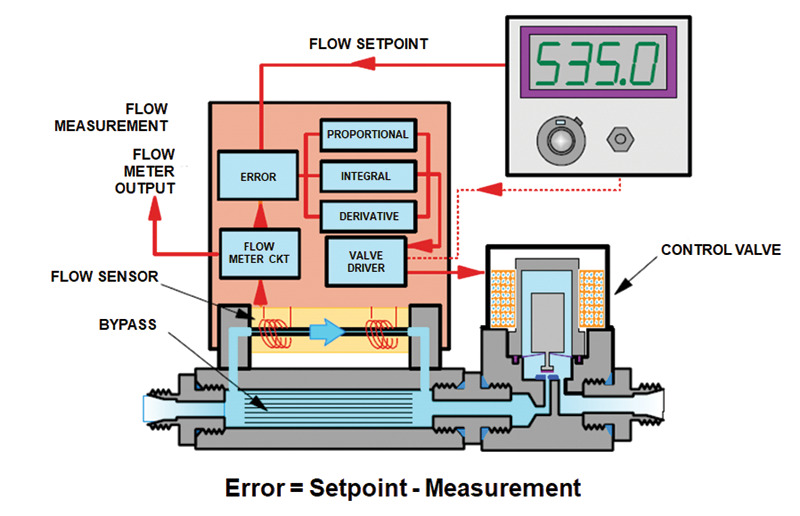

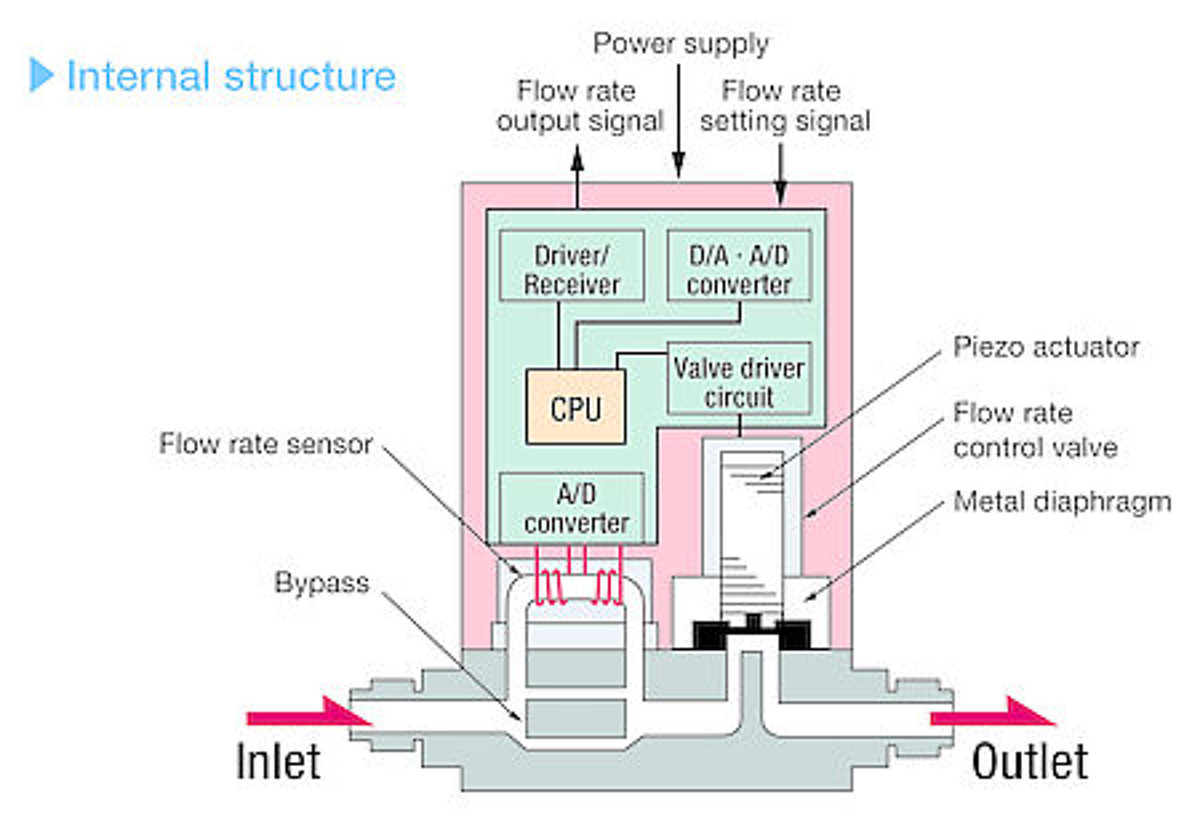

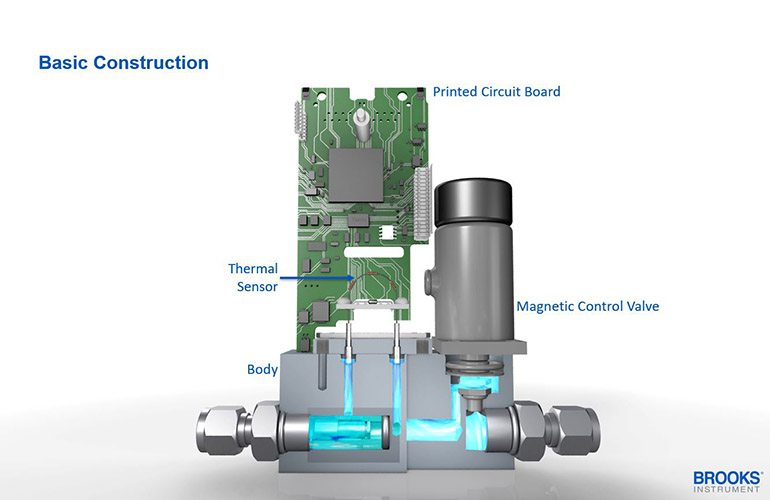

2. Product Description – Thermal Mass Flow Controller (TMFC)

A Thermal Mass Flow Controller (TMFC) is a precision instrument used to measure and control the mass flow rate of gases. When configured for hydrogen (H₂), the TMFC must be compatible with H₂’s properties, including low molecular weight, high diffusivity, flammability, and embrittlement potential.

Key Features:

– Designed for accurate H₂ flow measurement (e.g., 0–100 sccm to 0–50 slpm)

– Materials compatible with hydrogen (e.g., 316L stainless steel, metal seals)

– Leak-tight construction (helium leak tested)

– Certifications: ATEX, IECEx, UL, or CSA (if used in hazardous areas)

3. Hydrogen (H₂) Safety Considerations

Hydrogen is a highly flammable gas (flammability range: 4–75% in air) with a low ignition energy. It is colorless, odorless, and lighter than air, which affects leak behavior and detection.

Critical Safety Attributes:

– Flammability: Wide explosive range; requires strict leak prevention.

– Embrittlement: Can cause hydrogen embrittlement in certain metals—TMFCs must use H₂-compatible materials.

– Diffusivity: Rapidly disperses; requires tight seals and proper ventilation in storage and use areas.

– Detection: Use hydrogen gas detectors in operational environments.

4. Packaging & Storage

Packaging Requirements:

– TMFCs must be sealed with protective end caps to prevent contamination.

– Desiccant included to prevent internal moisture.

– Anti-static and shock-absorbent materials used for sensitive electronics.

– Clearly labeled: “Fragile,” “This Side Up,” and “Hydrogen Compatible – Do Not Expose to Air/Contaminants.”

Storage Conditions:

– Temperature: 5°C to 40°C (41°F to 104°F)

– Humidity: < 80% RH, non-condensing

– Ventilated, non-hazardous indoor area (away from oxidizers and ignition sources)

– Isolated from corrosive chemicals and direct sunlight

5. Transportation & Shipping

Regulatory Framework:

– International Air Transport Association (IATA): For air freight (if TMFCs contain residual H₂ or are classified as hazardous)

– ADR (Europe): For road transport of dangerous goods

– 49 CFR (USA): U.S. Department of Transportation (DOT) regulations

– IMDG Code: For maritime shipping

Classification:

– TMFCs themselves are typically non-hazardous if depressurized and purged.

– If shipped with H₂ or pressurized: Classified as UN1049, Hydrogen, compressed, Hazard Class 2.1 (Flammable Gas).

Shipping Guidelines:

– Empty & Purged: TMFCs must be depressurized and purged with inert gas (e.g., N₂) before shipment.

– Documentation: Include Safety Data Sheet (SDS), packing declaration (if hazardous), and certificate of purge.

– Labeling:

– “Clean, Dry, Inerted” label if purged.

– Hazard labels (Class 2.1) if pressurized with H₂.

– Carrier Coordination: Notify carrier of H₂ compatibility and any residual risks.

6. Import/Export Compliance

Export Controls:

– EAR (Export Administration Regulations – USA): TMFCs used in hydrogen applications may be subject to EAR99 or listed under ECCN 3A230 (flow controllers for gases used in nuclear, chemical, or energy applications).

– Dual-Use Items: Assess if TMFC could be used in sensitive applications (e.g., fuel cells, hydrogen production).

– Documentation: Commercial invoice, packing list, export declaration, and license (if required).

Import Requirements:

– Country-specific certifications (e.g., CE for EU, CRN for Canada, PSE for Japan).

– Customs may require proof of H₂ compatibility and safety testing.

7. Installation & Operational Compliance

Installation Best Practices:

– Use H₂-rated tubing (e.g., 316L stainless steel, welded or VCR fittings).

– Leak test with helium or H₂ sensor after installation.

– Install in ventilated area; avoid confined spaces.

– Ground all components to prevent static discharge.

Regulatory Standards:

– ISO 16111: Transportable gas storage devices – High-pressure hydrogen.

– NFPA 2: Hydrogen Technologies Code (USA).

– ISO 22734: Hydrogen generators for fuel cell applications.

– ATEX Directive 2014/34/EU: For use in explosive atmospheres (if applicable).

8. Maintenance & Leak Management

- Perform periodic leak checks using hydrogen-specific detectors or soap solution.

- Use only H₂-compatible lubricants and seals during servicing.

- Record maintenance logs for compliance audits.

9. Disposal & End-of-Life

- TMFCs are not classified as hazardous waste unless contaminated.

- Recycle metals and electronics per local e-waste regulations (e.g., WEEE in EU).

- Depressurize and purge before disposal.

10. Documentation & Training

Required Documentation:

– User Manual (H₂-specific operation)

– Certificate of Conformity (CE, UL, etc.)

– Calibration Certificate

– Material Compatibility Report

– SDS for Hydrogen (if applicable)

Personnel Training:

– Hydrogen safety (handling, storage, emergency response)

– TMFC operation and leak detection

– Emergency shutdown procedures

11. Emergency Response

In case of H₂ leak:

1. Evacuate area and eliminate ignition sources.

2. Ventilate the area.

3. Use combustible gas indicator to assess risk.

4. Isolate gas supply.

5. Contact emergency services if large leak or fire.

Fire involving H₂:

– Use dry chemical or CO₂ extinguishers.

– Cool surrounding equipment with water (do not apply directly to H₂ flame).

12. Contact Information

For technical support, compliance queries, or emergency assistance:

– Manufacturer: [Insert Company Name]

– Phone: [Insert Contact]

– Email: [Insert Support Email]

– Website: [Insert URL]

Revision Date: [Insert Date] Author: [Insert Name/Department] Approved By: [Insert Name/Title]

Disclaimer: This guide is for informational purposes. Always consult applicable local, national, and international regulations and the manufacturer’s specifications before handling, transporting, or operating TMFCs with hydrogen.

Conclusion for Sourcing a Thermal Mass Flow Controller

Sourcing a suitable thermal mass flow controller (MFC) requires careful evaluation of application-specific parameters such as flow range, accuracy, gas compatibility, response time, and environmental conditions. It is essential to select a reputable supplier offering high-quality, calibrated devices with reliable technical support and certification traceable to recognized standards (e.g., NIST). Consideration of communication interfaces, integration capabilities, and long-term maintenance requirements further ensures optimal performance and cost-efficiency. By prioritizing precision, durability, and supplier reliability, organizations can secure a thermal mass flow controller that enhances process control, improves repeatability, and supports operational excellence across industries such as semiconductor manufacturing, chemical processing, and environmental monitoring.