The global theatrical rigging market has experienced steady growth, driven by increasing demand for advanced stage technology in live performances, theaters, and large-scale entertainment venues. According to a 2023 report by Mordor Intelligence, the global rigging equipment market—which includes theatrical applications—is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028. This expansion is fueled by rising investments in modernizing performance spaces, the proliferation of multi-purpose event venues, and the growing complexity of stage productions requiring precision-engineered rigging systems. Grand View Research further supports this trajectory, noting that the global entertainment equipment market is expanding due to heightened consumer expectations for immersive experiences, pushing facility operators to adopt reliable, high-performance rigging solutions. As safety, automation, and load capacity become critical in theatrical operations, manufacturers are innovating to meet these demands—setting the stage for a list of the top 10 theatrical rigging manufacturers leading the charge in quality, innovation, and market presence.

Top 10 Theatrical Rigging Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 4Wall

Domain Est. 1999

Website: 4wall.com

Key Highlights: We offer the best rental equipment in the industry. By regularly selling our rental gear, we are able to invest in the latest technology from top manufacturers….

#2 PRG

Domain Est. 1995

Website: prg.com

Key Highlights: PRG is the world’s leading production & AV company in entertainment & live events, working across every technical & production specialty….

#3 ETC

Domain Est. 1995

Website: etcconnect.com

Key Highlights: Electronic Theatre Controls, Inc. Lighting solutions, control equipment for Theater, Film & TV studios, Architectural spaces and entertainment industries….

#4 Tru

Domain Est. 1996

Website: truroll.com

Key Highlights: Tru-Roll has been a full service manufacturer of stage rigging equipment, curtain track and draperies for over 70 years….

#5

Domain Est. 1997

Website: atlantarigging.com

Key Highlights: ARS is recognized as a world class provider of rigging, automation and production services exclusively tailored to the entertainment industry….

#6 City Theatrical Homepage

Domain Est. 1997

Website: citytheatrical.com

Key Highlights: Welcome to City Theatrical, LLC! We invent, manufacture, and customize unique lighting accessories for the film and video, live entertainment, and architectural ……

#7 Texas Scenic Company

Domain Est. 1997

Website: texasscenic.com

Key Highlights: From stage curtains & rigging systems to theatrical lighting & more, trust Texas Scenic with the design, manufacturing & installation of theatre equipment….

#8 JR Clancy

Domain Est. 1998

Website: jrclancy.com

Key Highlights: At J.R. Clancy, we’ve partnered on rigging systems for thousands of venues worldwide since 1885. So whether your facility is a grand opera house or a local high ……

#9 IWEISS

Domain Est. 1999

Website: iweiss.com

Key Highlights: Discover IWEISS, your one-stop destination for premium fabric, drapery, curtain tracks, and rigging systems. 120 years of excellence, serving customers ……

#10 Gallagher Staging and Manufacturing

Domain Est. 2011

Website: gallagherstaging.com

Key Highlights: Gallagher Staging and Manufacturing is your foundation for premier events. Creating a safe and reliable experience for audiences is our number one priority….

Expert Sourcing Insights for Theatrical Rigging

H2: 2026 Market Trends in Theatrical Rigging

The theatrical rigging industry is poised for notable transformation by 2026, driven by technological innovation, evolving performance demands, and increased emphasis on safety and sustainability. As live entertainment continues to rebound and adapt post-pandemic, venues are investing in modernization, creating new opportunities and challenges for rigging systems. Below are key market trends shaping the theatrical rigging landscape in 2026.

1. Digital Integration and Smart Rigging Systems

By 2026, smart rigging systems incorporating Internet of Things (IoT) sensors and real-time monitoring are becoming standard in professional theaters and touring productions. These systems allow for remote diagnostics, predictive maintenance, and automated load balancing, reducing downtime and enhancing operational safety. Integration with Building Information Modeling (BIM) and show control software enables seamless coordination between lighting, stage mechanics, and rigging, improving precision during complex performances.

2. Demand for Modular and Portable Solutions

The rise of pop-up theaters, immersive experiences, and outdoor performances is fueling demand for modular and portable rigging systems. Lightweight, easy-to-assemble components made from advanced composite materials are increasingly popular, particularly for event production companies and cultural festivals. These systems offer flexibility without compromising load capacity or safety standards.

3. Heightened Focus on Safety and Compliance

Regulatory scrutiny and industry standards—such as those from ESTA (Entertainment Services and Technology Association) and OSHA—are driving stricter compliance in rigging installations. By 2026, certification requirements for rigging technicians and mandatory periodic inspections are becoming more widespread. Automated safety features, such as overload protection and emergency stop integration, are now expected components in new rigging systems.

4. Sustainability and Energy Efficiency

Environmental concerns are influencing design choices in theatrical rigging. Manufacturers are shifting toward energy-efficient electric hoists and recyclable materials to reduce the carbon footprint of production. Additionally, longer product lifecycles and serviceability are becoming key selling points as theaters aim to reduce waste and operational costs.

5. Growth in Emerging Markets

While North America and Western Europe remain dominant markets, regions such as Southeast Asia, the Middle East, and Latin America are seeing increased investment in cultural infrastructure. New performing arts centers and upgraded venues in countries like India, UAE, and Brazil are expanding the global footprint of theatrical rigging demand, encouraging international vendors to localize support and training.

6. Labor Shortages and Automation

A persistent shortage of skilled rigging technicians is pushing venues toward automated solutions that require less manual intervention. Automated flying systems and pre-programmed cue-based operations are reducing reliance on large crews, making productions more efficient and cost-effective—especially for small to mid-sized theaters with limited technical staff.

7. Hybrid Performances and Technological Blending

As hybrid (in-person and virtual) performances continue beyond the pandemic era, rigging systems are being designed to accommodate augmented reality (AR), projection mapping, and drone integration. These technologies require precise spatial coordination, pushing rigging systems to evolve into multi-functional platforms that support both physical and digital stagecraft.

In conclusion, the 2026 theatrical rigging market reflects a fusion of tradition and innovation. While the core principles of safety and reliability remain unchanged, advancements in technology, expanding markets, and shifting audience expectations are driving a more dynamic, intelligent, and sustainable future for stage rigging systems. Companies that adapt to these trends will lead the industry in performance, efficiency, and creative possibility.

Common Pitfalls When Sourcing Theatrical Rigging (Quality and Intellectual Property)

Sourcing theatrical rigging requires careful attention to safety, performance, and legal compliance. Overlooking key factors related to quality and intellectual property (IP) can lead to equipment failure, legal disputes, and costly downtime. Below are common pitfalls to avoid.

Overlooking Certification and Compliance Standards

One of the most critical mistakes is failing to verify that rigging components meet recognized safety and performance standards. Theatrical rigging must comply with regulations such as OSHA guidelines in the U.S., EN standards in Europe (e.g., EN 1808), or other local codes. Sourcing equipment without proper certification—such as Load Testing Certificates, CE marking, or UL listing—can result in unsafe installations and liability in the event of failure.

Prioritizing Cost Over Quality

Choosing lower-cost rigging solutions to save money often leads to compromised materials, poor workmanship, and reduced lifespan. Inadequate load ratings, substandard steel, or inferior motors can result in catastrophic failures during performances. Investing in high-quality, purpose-built rigging from reputable manufacturers ensures long-term reliability and performer safety.

Ignoring Manufacturer Reputation and Track Record

Sourcing from unknown or unproven suppliers increases the risk of receiving counterfeit or poorly engineered products. Established manufacturers typically offer warranties, technical support, and documented testing. Skipping due diligence on vendor reputation may result in receiving equipment that fails under real-world conditions or lacks traceability for maintenance and inspections.

Failing to Verify Load Ratings and Safety Factors

Theatrical rigging systems must support dynamic loads, often with safety factors of 10:1 or higher. A common pitfall is accepting nominal load ratings without independent verification or understanding the context in which they were tested. Using equipment with inflated or unverified load claims can endanger cast, crew, and audience members.

Neglecting Intellectual Property Rights

Using or replicating rigging designs, control systems, or proprietary hardware without proper licensing infringes on intellectual property rights. Many manufacturers hold patents on motor designs, control algorithms, or structural innovations. Sourcing counterfeit or reverse-engineered products not only violates IP laws but can also void insurance and lead to legal penalties.

Assuming Compatibility Without Testing

Integrating rigging components from multiple vendors without thorough testing can lead to interoperability issues. Control protocols (e.g., DMX, RDM, sACN), mechanical interfaces, and software compatibility must be validated. Assuming plug-and-play functionality often results in system failures or costly retrofitting.

Skipping Site-Specific Engineering and Documentation

Rigging systems must be engineered for the specific venue, including structural load capacity, headroom, and environmental conditions. Sourcing generic systems without site-specific engineering oversight can lead to improper installation, overloading, or code violations. Additionally, lacking proper documentation (e.g., as-built drawings, maintenance logs) compromises accountability and future upgrades.

Overlooking Maintenance and Support Requirements

High-performance rigging demands regular maintenance, software updates, and trained technicians. Sourcing equipment from suppliers who don’t provide adequate support or training leads to increased downtime and safety risks. Ensure that service manuals, spare parts, and technical assistance are available before purchase.

Using Second-Hand or Decommissioned Equipment Without Certification

While cost-effective, used rigging equipment may lack current certification, have undocumented wear, or contain obsolete parts. Purchasing without full inspection and recertification by a qualified engineer poses serious safety risks. Always require up-to-date inspection reports and load test documentation.

Underestimating the Need for Training and Certification

Even the highest-quality rigging is unsafe in untrained hands. Sourcing equipment without ensuring access to certified training programs for operators and riggers leads to misuse and accidents. Verify that suppliers offer or partner with training institutions to certify personnel.

By avoiding these common pitfalls, organizations can ensure they source theatrical rigging that is safe, reliable, and compliant with both quality standards and intellectual property laws.

Logistics & Compliance Guide for Theatrical Rigging

Theatrical rigging is a critical component of live performance production, requiring meticulous planning, precise execution, and strict adherence to safety and regulatory standards. This guide outlines key logistics considerations and compliance requirements essential for the safe and efficient operation of rigging systems in theatrical environments.

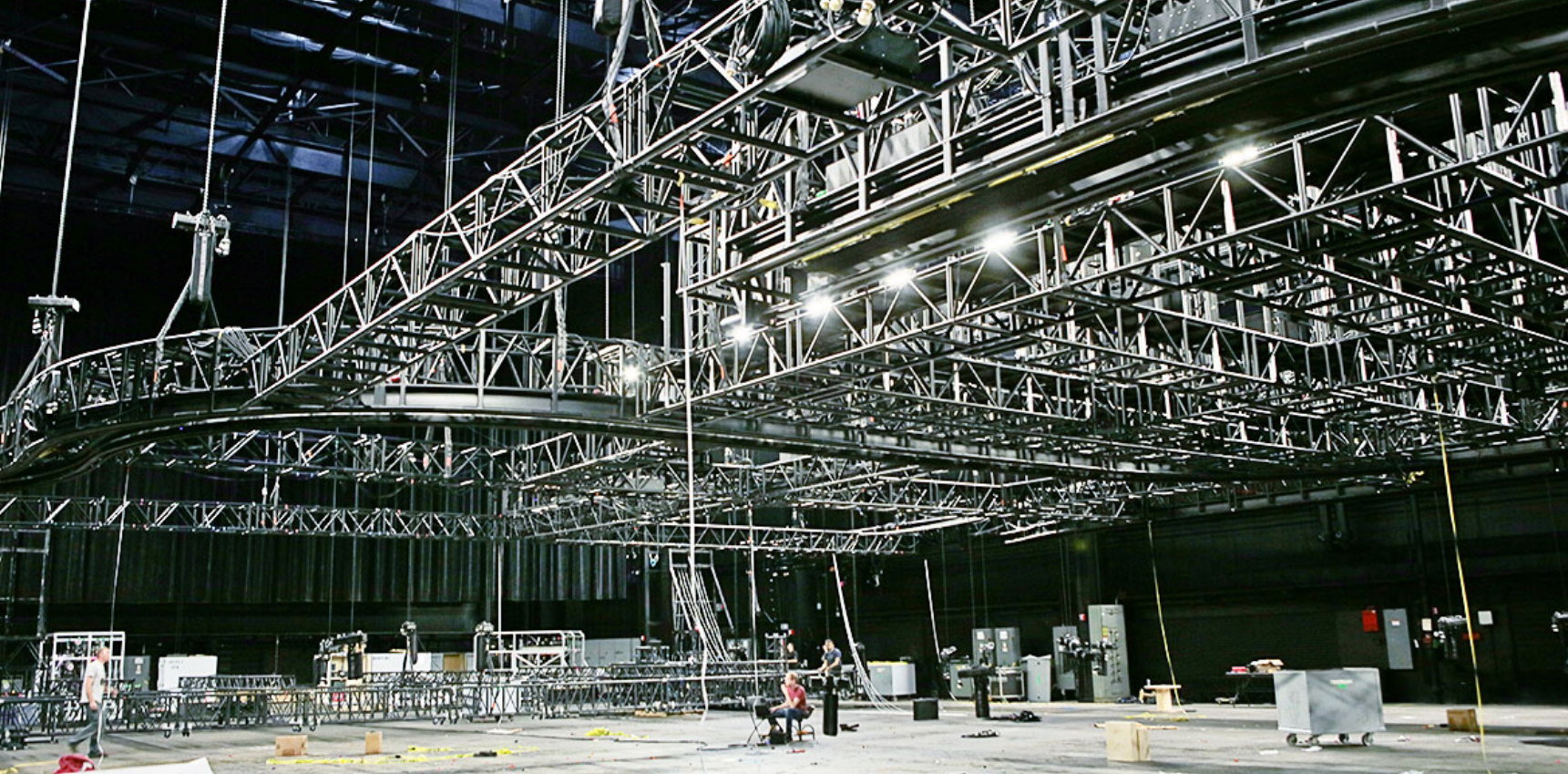

Understanding Theatrical Rigging Systems

Theatrical rigging systems are categorized into two main types: manual and motorized. Manual systems include counterweight and hemp (rope line) systems, while motorized systems use electric hoists and automated controls. Each system type has specific operational, maintenance, and safety requirements. Proper identification and documentation of the rigging system in use are foundational to ensuring compliance and safety.

Regulatory and Industry Standards

Compliance begins with adherence to relevant standards and regulations. Key governing documents include:

– ANSI E1.4 – Entertainment Technology – Design, Manufacture, and Use of Electrically Powered Hoists

– ANSI E1.6 – Entertainment Technology – Theatrical Fly Systems

– OSHA Regulations (29 CFR 1910) – Particularly those related to fall protection and machine guarding

– NFPA 70 (National Electrical Code) – For electrical installations powering motorized rigging

– Local building and fire codes – Which may impose additional load, access, or emergency egress requirements

Facilities must ensure that all rigging equipment and practices meet or exceed these standards.

Load Capacity and Load Testing

All rigging components must be clearly rated for specific load capacities. Overloading is a leading cause of rigging failure. Best practices include:

– Clearly labeling all pipes, battens, and hoists with their maximum safe working load (SWL)

– Performing regular load testing (typically every 12 months) in accordance with ANSI E1.6

– Maintaining detailed records of load tests, inspections, and maintenance

– Accounting for dynamic loads and safety factors (typically 8:1 for manual systems, 5:1 for motorized)

Only certified personnel should conduct load testing, and all tests must be documented.

Inspection and Maintenance Protocols

Routine inspection and preventive maintenance are mandatory for safe operation:

– Daily Operational Checks: Visual inspection for frayed cables, damaged sheaves, loose bolts, or abnormal wear before each use

– Monthly Visual Inspections: More detailed examination by qualified technicians

– Annual Thorough Inspections: Comprehensive assessment by a certified rigging inspector, including non-destructive testing (e.g., magnetic particle inspection) as needed

– Maintenance logs must be kept on-site and available for audit

Any identified defects must be addressed before further use.

Personnel Qualifications and Training

Only trained and authorized personnel should operate or maintain rigging systems. Compliance requires:

– Rigging operators to be trained in system-specific procedures, emergency protocols, and load management

– Certification programs such as ESTA’s Rigging Certification or ETCP (Entertainment Technician Certification Program) are strongly recommended

– Documentation of training and competency assessments

– Clear chain of command and communication protocols during rigging operations

Untrained individuals must not be permitted to operate rigging equipment.

Installation and Transportation Logistics

For touring productions or temporary installations:

– Rigging equipment must be packed and transported securely to prevent damage

– Reinstallation must follow manufacturer specifications and venue requirements

– A full inspection and load test must be performed after reassembly

– Temporary rigging must comply with the same standards as permanent installations

Coordination with venue technical staff is essential for integration with existing systems.

Emergency Procedures and Fall Protection

Emergency preparedness is critical:

– Clearly posted emergency stop procedures and contact information

– Functional emergency stop buttons on all motorized systems

– Fall protection measures for personnel working at height (e.g., harnesses, guardrails)

– Evacuation plans for performers and crew in case of rigging failure

All staff must be trained in emergency response.

Documentation and Recordkeeping

Maintaining comprehensive records ensures compliance and accountability:

– Equipment inventory with serial numbers and SWL ratings

– Inspection and maintenance logs

– Load test results

– Personnel training and certification records

– As-built rigging plots and system diagrams

Records should be retained for a minimum of five years or as required by local regulations.

Conclusion

Theatrical rigging demands rigorous attention to logistics and compliance to ensure the safety of performers, crew, and audiences. By adhering to industry standards, implementing regular inspections, training qualified personnel, and maintaining thorough documentation, venues and production companies can mitigate risks and support the successful execution of theatrical productions. Safety is not optional—it is the foundation of every rigging operation.

In conclusion, sourcing theatrical rigging requires careful consideration of safety, quality, compliance, and technical specifications to ensure the reliable and secure operation of equipment in performance spaces. It is essential to partner with reputable suppliers who adhere to industry standards such as ETCP, OSHA, and local regulations, and who provide certified, well-documented rigging systems. A thorough evaluation of venue requirements—including load capacities, system type (manual, motorized, or counterweight), and maintenance support—will guide effective decision-making. Additionally, investing in professional installation, staff training, and routine inspections enhances long-term safety and performance. Ultimately, a strategic and informed approach to sourcing theatrical rigging not only protects performers and audiences but also ensures the longevity and operational efficiency of the venue’s technical infrastructure.