The global textured soy protein (TSP) market is experiencing robust growth, driven by rising consumer demand for plant-based protein alternatives and increasing adoption in meat substitute products. According to Grand View Research, the global meat substitutes market was valued at USD 5.09 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, with textured soy protein being one of the most widely used ingredients due to its high protein content, functional properties, and cost efficiency. Similarly, Mordor Intelligence reports that the soy protein market is expected to grow at a CAGR of approximately 5.2% over the forecast period (2023–2028), fueled by expanding vegetarian and flexitarian populations, as well as advancements in food processing technologies. As bulk demand for TSP rises across foodservice, retail, and industrial applications, a select group of manufacturers have emerged as key suppliers, leveraging scale, quality control, and global distribution networks to lead the market.

Top 8 Textured Soy Protein Bulk Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Organic Textured Soy Protein Suppliers, Manufacturers, Factory

Domain Est. 2016

Website: biowayorganicinc.com

Key Highlights: Xi’an Bioway Organic Ingredients Co., Ltd. is one of the most reliable manufacturers and suppliers of organic textured soy protein in China….

#2 Wholesale Textured Vegetable Protein Supplier

Domain Est. 2000

Website: benfurney.com

Key Highlights: We are Australia’s leading manufacturer of Textured Vegetable Protein (TVP). Our product is made from Defatted Soy and is a stable textured Soy protein….

#3 Textured Vegetable Protein

Domain Est. 2004

Website: americaninternationalfoods.com

Key Highlights: AIFI is a leading textured vegetable protein supplier & distributor offering high quality wholesale vegetable proteins at competitive prices….

#4 Soy Protein

Domain Est. 1994

Website: adm.com

Key Highlights: ADM’s world-class textured soy proteins are versatile, economical, and help to enhance your finished product quality across a multitude of applications. Learn ……

#5 Textured Protein – Wholesale Ingredients

Domain Est. 1996

Website: bulkfoods.com

Key Highlights: Textured Proteins in Bulk. Great for Vegan & Vegetarian Food Applications. Wholesale TVP and Textured Soy Proteins. Bulkfoods is a leading Distributor of TVP….

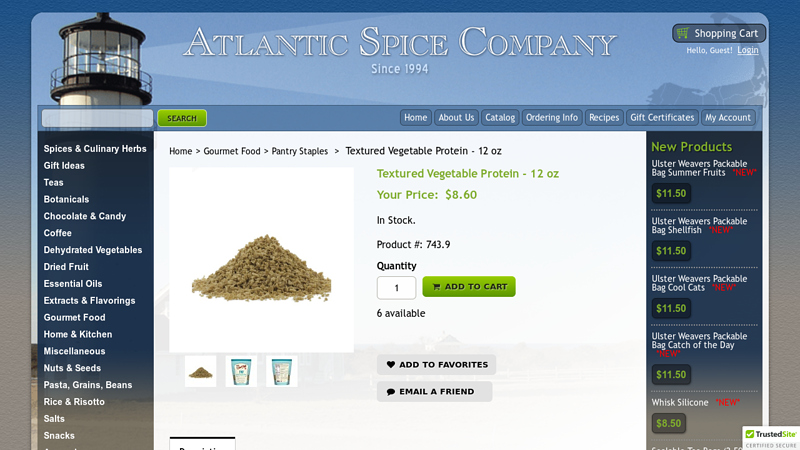

#6 Textured Vegetable Protein

Domain Est. 1996

#7 Textured Vegetable Proteins TVP

Domain Est. 2019

Website: gerickegroup.com

Key Highlights: High moisture meat analogues (HMMA) and textured vegetable proteins (TVP, also textured soy protein or soy meat) have become a widely accepted and tasty ……

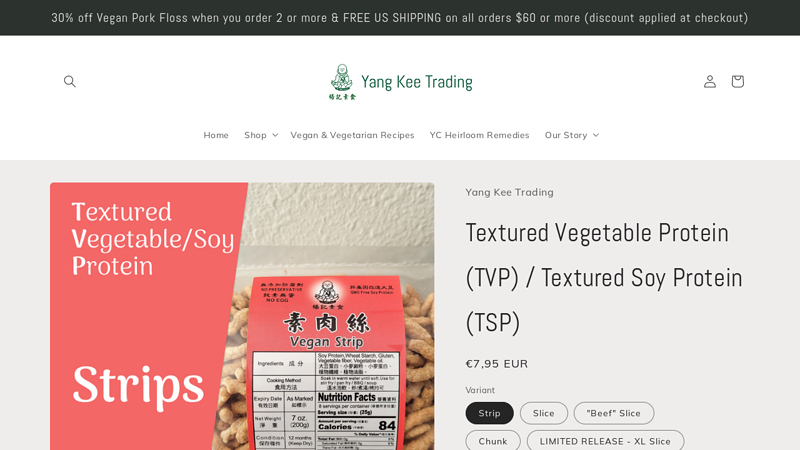

#8 Textured Vegetable Protein (TVP) / Textured Soy Protein (TSP)

Domain Est. 2022

Expert Sourcing Insights for Textured Soy Protein Bulk

H2: 2026 Market Trends for Textured Soy Protein (TSP) Bulk

The global market for Textured Soy Protein (TSP) in bulk is poised for substantial transformation by 2026, driven by shifting consumer preferences, sustainability imperatives, and advancements in food technology. As a high-protein, plant-based ingredient, TSP continues to gain prominence across food manufacturing, meat alternatives, and ready-to-eat sectors. Below is an analysis of key trends expected to shape the TSP bulk market in 2026:

1. Rising Demand for Plant-Based Proteins

By 2026, the global shift toward plant-based diets is expected to accelerate, fueled by health consciousness, ethical concerns, and environmental awareness. Textured Soy Protein, as a cost-effective and nutritionally rich alternative to animal protein, is projected to see increased adoption in meat substitutes, vegetarian meals, and functional foods. Market research suggests the plant-based protein market will surpass $20 billion by 2026, with TSP playing a pivotal role due to its scalability and versatility.

2. Expansion in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are anticipated to become high-growth regions for bulk TSP. Rising urbanization, increasing disposable incomes, and government support for sustainable agriculture are driving investments in plant-based food infrastructure. Countries like China, India, and Brazil are expected to boost domestic production and consumption of TSP, particularly in school feeding programs and affordable protein supplements.

3. Sustainability and Climate-Driven Procurement

Food manufacturers and retailers are increasingly prioritizing low-carbon, resource-efficient ingredients. TSP offers a significantly lower environmental footprint compared to animal-based proteins—requiring less water, land, and generating fewer greenhouse gas emissions. By 2026, corporate sustainability commitments and ESG (Environmental, Social, and Governance) reporting will push more companies to source bulk TSP from certified sustainable and non-GMO suppliers.

4. Innovation in Product Formulation and Applications

Advancements in extrusion and texturization technologies will enable the production of TSP with improved sensory profiles—better texture, flavor absorption, and cooking performance. Manufacturers are focusing on developing non-beany, allergen-reduced, and high-fiber variants to appeal to a broader consumer base. In 2026, expect to see TSP integrated into new product categories such as plant-based seafood, dairy alternatives, and sports nutrition products.

5. Price Volatility and Supply Chain Resilience

While demand grows, the TSP market may face challenges related to soybean price fluctuations, geopolitical trade tensions, and climate-related crop disruptions. By 2026, major buyers are expected to adopt long-term contracts, regional sourcing strategies, and investment in vertical integration to stabilize supply. Traceability and blockchain-enabled transparency will become standard for bulk procurement.

6. Regulatory and Labeling Developments

Regulatory scrutiny on health claims and labeling of plant-based products will intensify. In 2026, clearer guidelines around terms like “meat,” “protein content,” and “source transparency” are expected in key markets such as the EU and North America. This will influence how bulk TSP is marketed and used in final products, pushing manufacturers toward clean-label, non-GMO, and organic certification.

7. Strategic Partnerships and Market Consolidation

The TSP bulk sector is likely to witness increased consolidation, with large food conglomerates acquiring or partnering with specialty soy processors. These alliances will focus on scaling production, improving R&D capabilities, and expanding distribution networks—particularly in response to growing demand from plant-based meat brands and foodservice providers.

Conclusion

By 2026, the bulk Textured Soy Protein market will be shaped by a confluence of health, environmental, and technological trends. With growing adoption across diverse geographies and applications, TSP is set to remain a cornerstone ingredient in the future of sustainable protein. Stakeholders who invest in innovation, supply chain resilience, and sustainable sourcing will be best positioned to capitalize on this expanding market.

Common Pitfalls When Sourcing Textured Soy Protein in Bulk (Quality & Intellectual Property)

Sourcing Textured Soy Protein (TSP) in bulk offers cost advantages, but it comes with significant risks related to both quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can lead to product failures, brand damage, legal disputes, and financial losses.

Quality Inconsistencies and Specifications

One of the biggest challenges in bulk TSP sourcing is ensuring consistent product quality across batches and suppliers. Without strict controls, variations can undermine your final product.

-

Inconsistent Protein Content and Functional Properties

TSP sourced from different suppliers—or even different batches from the same supplier—may vary in protein concentration, hydration capacity, texture, color, and flavor. These inconsistencies can affect the mouthfeel, cooking performance, and nutritional labeling of your end product, especially in meat alternatives where texture is critical. -

Contamination and Purity Issues

Bulk TSP may be exposed to cross-contamination with allergens (e.g., gluten, nuts), pesticides, or mycotoxins if the supplier lacks rigorous quality control or shared production lines. Poor storage or transportation practices can also introduce moisture, leading to microbial growth or spoilage. -

Lack of Traceability and Certifications

Without clear documentation on sourcing (e.g., non-GMO, organic, origin of soybeans), manufacturers risk non-compliance with food safety regulations or failing to meet consumer expectations. Absence of third-party certifications (like ISO, FSSC 22000, or organic standards) increases vulnerability to quality lapses.

Intellectual Property Exposure and Misuse

When developing proprietary formulations or products using TSP, protecting your IP is essential—especially when working with external suppliers or co-manufacturers.

-

Formula Disclosure Without Legal Safeguards

Sharing your unique blend or processing methods with a TSP supplier or co-packer without a robust Non-Disclosure Agreement (NDA) or IP clause risks reverse engineering or unauthorized use. Suppliers may leverage your formulation to serve competitors. -

Unclear Ownership of Developed Products

If a supplier assists in customizing TSP (e.g., flavor integration, particle size modification), the absence of a clear IP assignment agreement can lead to disputes over who owns the resulting product or process improvements. -

Risk of Counterfeiting or Diversion

In global supply chains, especially with offshore suppliers, there’s a risk that your custom-formulated TSP could be diverted or replicated and sold to third parties without authorization. Weak contractual terms and lack of audit rights increase this exposure.

Mitigation Strategies

To avoid these pitfalls:

– Enforce detailed specifications (including protein %, moisture, color, texture metrics) and require COAs (Certificates of Analysis) with every shipment.

– Audit suppliers regularly for quality systems, sanitation, and traceability.

– Secure IP with strong legal agreements, including NDAs, IP ownership clauses, and restrictions on subcontracting.

– Consider dual sourcing or vertical integration to reduce dependency and protect formulation secrecy.

Proactively addressing these quality and IP concerns ensures both product integrity and long-term competitive advantage in the plant-based protein market.

Logistics & Compliance Guide for Textured Soy Protein (TSP) in Bulk

Product Overview and Specifications

Textured Soy Protein (TSP), also known as Textured Vegetable Protein (TVP), is a plant-based protein derived from defatted soy flour. In bulk form, it is typically supplied as dried granules, chunks, or flakes, used widely in food manufacturing, meat alternatives, and institutional food service. Key specifications include protein content (usually 50–70%), moisture level (typically <10%), and absence of pathogens and contaminants. Ensure supplier documentation includes a Certificate of Analysis (CoA) verifying compliance with food safety and quality standards.

Packaging and Handling Requirements

Bulk TSP is commonly transported in multi-wall paper bags with polyethylene liners (e.g., 20–25 kg bags), FIBCs (Flexible Intermediate Bulk Containers, e.g., 500–1,000 kg), or in bulk tanker containers for pneumatic delivery. Packaging must be food-grade, moisture-resistant, and sealed to prevent contamination and spoilage. During handling, avoid exposure to moisture, direct sunlight, and extreme temperatures. Use clean, dedicated equipment for loading and unloading to prevent cross-contamination with allergens or non-food materials.

Storage Conditions and Shelf Life

Store bulk TSP in a cool, dry, and well-ventilated area with temperatures between 15–25°C (59–77°F) and relative humidity below 65%. Keep product off the floor on pallets and away from walls to allow air circulation. Protect from pests and ensure the storage area is clean and sanitized. When stored properly, bulk TSP typically has a shelf life of 12–24 months. Implement a FIFO (First-In, First-Out) inventory system to minimize spoilage and ensure freshness.

Transportation and Freight Considerations

Transport TSP in dry, clean, and enclosed vehicles (e.g., food-grade bulk trailers, containers) to prevent moisture ingress and contamination. If using containers, ensure they are inspected for cleanliness and lined with food-grade polyliners if necessary. Avoid co-loading with hazardous materials, strong-smelling goods, or allergens (e.g., nuts, gluten). For international shipments, verify that transport complies with ISPM 15 for wooden pallets and use temperature-controlled logistics if required by climate conditions.

Regulatory Compliance and Documentation

TSP must comply with food safety regulations in the destination market. In the U.S., it is regulated by the FDA under the Food Safety Modernization Act (FSMA); in the EU, by EFSA and Regulation (EC) No 178/2002. Required documentation includes:

– Certificate of Analysis (CoA)

– Certificate of Origin

– Bill of Lading

– Commercial Invoice

– Sanitary or Phytosanitary Certificate (if required)

Ensure TSP is labeled as “Textured Soy Protein” and includes allergen declarations (soy is a major allergen). Verify non-GMO or organic status if applicable, and maintain records for traceability.

Allergen and Food Safety Management

Soy is a recognized allergen in most jurisdictions. Implement strict allergen control protocols throughout logistics, including cleaning procedures between loads, dedicated storage zones, and clear labeling. Prevent cross-contact with other allergens during transport and handling. Adhere to HACCP and GMP (Good Manufacturing Practices) standards. Suppliers should provide allergen statements and confirm absence of undeclared allergens in CoAs.

Import and Export Requirements

For international trade, verify import permits and customs requirements in the destination country. Some countries may require pre-shipment inspection, registration of foreign food facilities, or compliance with local labeling laws. Ensure Harmonized System (HS) code 2304.00 (for soybean meal and residues) or 1904.00 (for food preparations of plant origin) is correctly applied. Check for SPS (Sanitary and Phytosanitary) measures and any import bans or restrictions related to soy products.

Sustainability and Traceability

Source TSP from suppliers committed to sustainable soy production (e.g., ProTerra, Roundtable on Responsible Soy – RTRS certified). Maintain full traceability from origin to delivery using batch/lot tracking. Document supplier sustainability practices and ensure deforestation-free supply chains where required by regulation (e.g., EU Deforestation Regulation). Report sustainability metrics if part of corporate ESG goals.

Emergency Response and Recalls

Develop a recall plan aligned with regulatory requirements (e.g., FDA’s 3rd Party Audit Rule). In case of contamination, spoilage, or mislabeling, immediately isolate affected batches and notify authorities and customers. Maintain contact lists for suppliers, regulators, and logistics partners. Conduct mock recalls annually to test traceability and response efficiency.

In conclusion, sourcing textured soy protein (TSP) in bulk offers a cost-effective, sustainable, and efficient solution for food manufacturers, plant-based product developers, and suppliers in the alternative protein market. By leveraging bulk procurement, businesses can benefit from reduced per-unit costs, consistent product quality, and improved supply chain efficiency. Key factors to consider when sourcing TSP in bulk include supplier reliability, product specifications (such as protein content, texture, and hydration capacity), certifications (non-GMO, organic, allergen-free, etc.), and logistical capabilities. Establishing strong relationships with reputable suppliers—whether domestic or international—ensures long-term supply security and supports scalability. As global demand for plant-based proteins continues to grow, strategic sourcing of bulk TSP positions companies to meet consumer needs for nutritious, sustainable, and affordable protein alternatives while maintaining operational excellence.