The global tenting materials market has experienced robust growth, driven by rising demand across outdoor recreation, defense, emergency relief, and event management sectors. According to a 2023 report by Mordor Intelligence, the global camping and outdoor shelters market was valued at USD 6.8 billion in 2022 and is projected to grow at a CAGR of 6.5% from 2023 to 2028. This expansion is fueled by increasing consumer interest in outdoor activities, technological advancements in fabric durability and weather resistance, and the growing need for temporary shelter solutions in disaster-prone regions. Additionally, Grand View Research notes that innovations in lightweight, UV-resistant, and eco-friendly materials are reshaping sourcing priorities for manufacturers and brand partners alike. As competition intensifies and sustainability becomes a key differentiator, identifying top-tier tenting material manufacturers with strong R&D, scalable production, and compliance with international standards is critical for stakeholders across the value chain. The following analysis highlights the top 10 manufacturers leading this dynamic and evolving landscape.

Top 10 Tenting Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

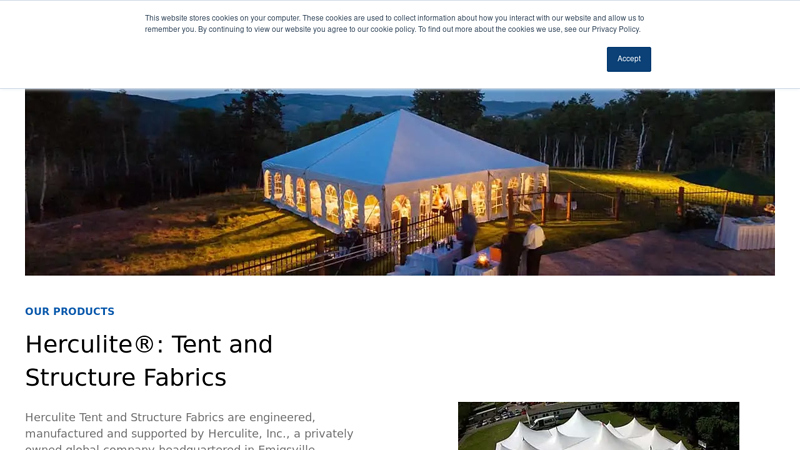

#1 American-Made Tent & Structure Fabrics

Domain Est. 1996

Website: herculite.com

Key Highlights: Herculite has been an innovative leader in flexible composite textiles for demanding applications that range from solar protection to healthcare….

#2 CampTec

Domain Est. 1996

Website: camptec.com

Key Highlights: We are very good at OEM process, like designing, developing, and manufacturing tents. We honor our customers by perfect executions….

#3 Aztec Tents

Domain Est. 1997

Website: aztectent.com

Key Highlights: Aztec Tents is your leading manufacturer of party tents and event tents distributed globally from Torrance, California….

#4 Fabric Tent Wholesale: Fabrictent Homepage

Domain Est. 2002

Website: fabrictent.com

Key Highlights: We are a leading producer and distributor with an offering of over 500 patterns ranging from trims to jacquards….

#5 Anchor has you covered: American

Domain Est. 1995

Website: anchorinc.com

Key Highlights: Explore Anchor’s full line of American-made fabric & frame structures: tents, pool covers, shade, fire shelters, pergolas and awnings….

#6 Tent Fabrics

Domain Est. 1997

Website: snyderman.com

Key Highlights: Snyder Manufacturing is the industry leader in providing laminated vinyl fabric and PVC coated mesh products for the tent and structural fabric market….

#7 Davis Tent: Canvas Wall Tents

Domain Est. 1999

Website: davistent.com

Key Highlights: Davis Tent manufactures top quality handmade canvas tents and wall tents. Shop online for a wide selection of durable, affordable canvas tents!…

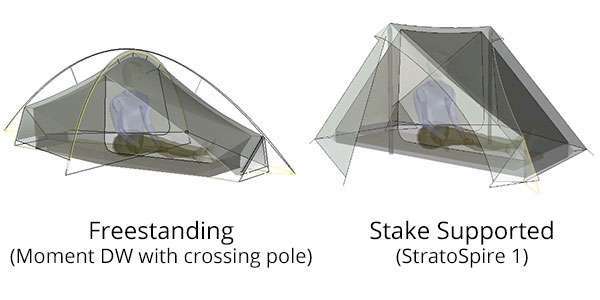

#8 Tents, packs, and bags

Domain Est. 1999

Website: dyneema.com

Key Highlights: The ultimate tents are made with Dyneema® composites. Lighter and stronger than other materials, they are rainproof and resist sagging even during wet weather….

#9 Tarptent

Domain Est. 2001

Website: tarptent.com

Key Highlights: Tarptent is a premium collection of ultralight, mobile shelters that shed everything from flying bugs to summer snow….

#10 American

Domain Est. 2015

Website: diamondbrandgear.com

Key Highlights: Hand-sewn canvas wall tents for all of life’s adventures: outdoor hospitality, glamping, camping, scouting, festivals, catering and beyond….

Expert Sourcing Insights for Tenting Material

2026 Market Trends for Tenting Material

The global tenting material market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and growing demand across diverse sectors. Key trends shaping the landscape include:

Sustainable and Eco-Friendly Materials Take Center Stage

Environmental consciousness will be a primary driver, pushing manufacturers towards recycled, bio-based, and biodegradable fabrics. Expect increased use of recycled polyester (rPET) from plastic bottles, bio-nylon, and plant-derived coatings. Demand for materials with lower carbon footprints and reduced reliance on perfluorinated compounds (PFCs) will intensify, particularly in consumer markets and corporate event sectors responding to ESG mandates.

Performance Enhancement through Advanced Coatings and Laminates

Innovation in coatings (e.g., silicone, polyurethane, and eco-PFC-free DWRs) and lamination techniques will focus on improving durability, weather resistance (UV, rain, wind), breathability, and fire retardancy. Smart coatings offering self-cleaning, antimicrobial, or temperature-regulating properties may gain traction, especially in high-end and specialty applications like medical or military shelters.

Lightweight, High-Strength Fabrics for Portability and Efficiency

Demand for ultralight yet robust materials will grow, fueled by the outdoor recreation sector (backpacking, ultralight camping) and rapid-deployment needs in disaster relief and military operations. Advanced fibers like Dyneema® Composite Fabrics (DCF), high-tenacity nylon, and innovative weaves will enable lighter structures without sacrificing strength or longevity.

Circular Economy and End-of-Life Management

By 2026, pressure to address textile waste will lead to greater investment in take-back programs, recyclability, and material traceability. Standards for recyclable tent materials and clearer labeling (e.g., mono-material construction) will emerge, supported by regulations in regions like the EU. Design for disassembly will become a key consideration.

Customization and Aesthetic Innovation

The events and luxury glamping markets will drive demand for customizable materials in diverse colors, textures, and translucency levels. Digitally printable high-performance fabrics will allow for branded or artistic designs without compromising functionality, enabling unique experiential spaces.

Rise of Smart and Multifunctional Textiles

Integration of technology into tent fabrics—such as embedded solar panels, sensors for environmental monitoring (humidity, temperature), or conductive threads for power delivery—will begin to move from concept to commercial application, particularly in expedition, defense, and temporary infrastructure uses.

Regional Growth and Supply Chain Resilience

Asia-Pacific will remain a key manufacturing hub, but nearshoring and regional supply chain diversification will gain importance due to geopolitical and logistical risks. North America and Europe will see growth in high-performance and sustainable materials, driven by outdoor recreation and climate adaptation needs.

In summary, the 2026 tenting material market will be defined by sustainability, performance innovation, and technological integration. Leading players will differentiate through eco-certifications, advanced material science, and solutions that balance environmental responsibility with functional excellence.

Common Pitfalls When Sourcing Tenting Material (Quality, IP)

Sourcing tenting materials involves more than just selecting fabric and poles—overlooking key quality and intellectual property (IP) concerns can lead to product failures, legal issues, and reputational damage. Below are common pitfalls to avoid.

Poor Material Quality and Performance

One of the most frequent issues is selecting materials that fail under real-world conditions. Sourcing low-grade polyester or nylon without adequate UV resistance, waterproofing, or tear strength results in tents that degrade quickly, leak, or collapse in wind. Always verify technical specifications such as denier count, hydrostatic head rating, and UV protection factor. Relying solely on supplier claims without third-party testing can lead to substandard products.

Inadequate Weather Resistance

Tents must withstand environmental stressors like rain, wind, and prolonged sun exposure. A common mistake is sourcing materials with insufficient coatings or laminates for waterproofing. Over time, poor-quality PU or silicone coatings may delaminate or crack. Ensure materials meet recognized standards (e.g., ISO 4916 for water resistance) and request accelerated weathering test results before bulk ordering.

Lack of Fire Retardancy Compliance

Many regions require tenting materials to meet fire safety standards (e.g., CPAI-84, NFPA 701). Sourcing non-compliant fabrics can result in legal liability and market rejection. Verify that materials have valid fire retardant (FR) certifications and that treatments are durable through repeated use and cleaning.

Ignoring Intellectual Property Rights

Using patented fabric technologies (e.g., ripstop weaves, breathable membranes, or branded coatings like Gore-Tex or Dyneema) without proper licensing is a significant IP risk. Even if the material is sourced from a third-party supplier, the end manufacturer may be held liable for infringement. Conduct due diligence on fabric origins and ensure suppliers provide IP indemnification.

Counterfeit or Misrepresented Materials

Some suppliers may misrepresent material composition or origin, selling counterfeit or downgraded versions of high-performance fabrics. This is especially common with well-known branded textiles. Always require mill certificates, batch testing, and, if possible, conduct independent lab analysis to confirm material authenticity.

Inconsistent Batch-to-Batch Quality

Variations in color, coating thickness, or tensile strength between production batches can affect product consistency and brand reliability. Establish clear quality control protocols with suppliers, including pre-shipment inspections and sample approvals, to minimize variability.

Overlooking Environmental and Sustainability Claims

Greenwashing—making false or exaggerated environmental claims—is a growing concern. Sourcing “eco-friendly” materials without verifying certifications (e.g., OEKO-TEX, GRS) can damage brand integrity. Ensure suppliers provide transparency on sourcing, dyes, and manufacturing processes.

Failure to Secure Long-Term Supply Agreements

Relying on short-term or spot purchases can lead to supply chain disruptions, especially for specialized or patented materials. Establish long-term contracts with reputable suppliers to ensure continuity and protect against price volatility.

By addressing these pitfalls proactively—through rigorous vetting, testing, and legal review—companies can ensure the quality, compliance, and IP safety of their tenting materials.

Logistics & Compliance Guide for Tenting Material

Tenting materials—such as tarps, coverings, and temporary shelter fabrics used in construction, events, or transportation—are subject to specific logistics and regulatory requirements. Proper handling, transportation, and compliance with safety and environmental standards are essential to ensure operational efficiency and legal adherence. This guide outlines key considerations for managing tenting material throughout the supply chain.

Regulatory Compliance

Tenting materials may be subject to national and international regulations depending on their composition, usage, and destination. Key compliance areas include:

- Flammability Standards: Materials used in public spaces or construction must often meet fire resistance requirements (e.g., NFPA 701 in the U.S., EN 13501-1 in the EU).

- REACH & RoHS Compliance: If tenting materials contain chemicals or treated fabrics, they may fall under EU REACH or RoHS regulations restricting hazardous substances.

- Import/Export Documentation: When shipping across borders, ensure proper classification under HS codes (e.g., 6306.22 or 6306.32 for textile tarpaulins), and provide required certificates of origin, conformity, or test reports.

- Environmental Regulations: Disposal or recycling of used tenting materials may be governed by local waste management laws, especially if materials contain PVC, coatings, or flame retardants.

Packaging and Handling

Proper packaging safeguards tenting material during transit and storage:

- Roll or fold materials uniformly to prevent creasing and damage.

- Use moisture-resistant wrapping (e.g., plastic sleeves or shrink wrap) to protect against humidity and weather.

- Label packages clearly with product details, batch numbers, handling instructions (e.g., “Do Not Fold,” “Keep Dry”), and safety symbols as needed.

- Use durable outer packaging such as cardboard tubes or crates for rolled materials to prevent deformation.

Transportation Requirements

Transporting tenting materials requires attention to size, weight, and environmental conditions:

- Secure loads properly to prevent shifting during transit, especially for oversized rolls or folded tarps.

- Use enclosed trucks or containers to protect from rain, UV exposure, and contamination.

- For air freight, comply with IATA regulations—verify weight and dimensional restrictions.

- Avoid exposure to extreme temperatures that may degrade coatings or adhesives during transit.

Storage Guidelines

Appropriate storage preserves material integrity:

- Store in a dry, well-ventilated area away from direct sunlight to prevent UV degradation.

- Keep materials off the floor using pallets to avoid moisture absorption and pest infestation.

- Maintain stable temperatures; avoid freezing or excessive heat that could compromise fabric integrity.

- Rotate stock using the First Expired, First Out (FEFO) or First In, First Out (FIFO) method to reduce aging risks.

Safety and Worker Compliance

Ensure personnel handling tenting materials follow safety protocols:

- Provide training on safe lifting techniques, especially for heavy rolls.

- Use PPE (gloves, safety shoes) when handling sharp or abrasive materials.

- Follow site-specific safety rules when installing or removing tenting in construction or event settings.

- Comply with OSHA (or local equivalent) standards for working at heights or in confined spaces if applicable.

Documentation and Traceability

Maintain accurate records to support compliance and quality control:

- Keep material safety data sheets (MSDS/SDS) for treated or chemical-impregnated fabrics.

- Retain test certifications for fire, UV, and tear resistance as proof of compliance.

- Log batch numbers, shipment dates, and storage locations for traceability in case of recalls or audits.

By following these logistics and compliance guidelines, organizations can ensure the safe, legal, and efficient handling of tenting materials throughout their lifecycle—from procurement to end use or disposal.

Conclusion on Sourcing Tenting Material

In conclusion, sourcing tenting material requires a strategic balance between quality, durability, cost-efficiency, and sustainability. After evaluating various suppliers, material types (such as polyester, nylon, and PVC-coated fabrics), and performance factors like UV resistance, waterproofing, and tensile strength, it is evident that selecting the right material is critical to ensuring product reliability and customer satisfaction. Partnering with reputable suppliers who adhere to industry standards and offer consistent quality control will support long-term project success. Additionally, considering eco-friendly materials and ethical sourcing practices aligns with growing environmental and social responsibilities. Ultimately, a well-informed decision based on thorough research, sample testing, and supplier evaluations will ensure the optimal performance and value of the sourced tenting materials.