The global tent fabric manufacturing industry has experienced steady expansion, driven by rising demand from outdoor recreation, military, emergency relief, and event management sectors. According to Grand View Research, the global outdoor gear market was valued at USD 46.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with tent textiles representing a critical segment of this industry. Additionally, Mordor Intelligence forecasts the technical textiles market—encompassing high-performance tent materials such as ripstop nylon, polyester, and silicone-coated fabrics—to reach USD 236 billion by 2028, expanding at a CAGR of 5.3%. This growth is fueled by advancements in material durability, waterproofing, UV resistance, and lightweight engineering. As sustainability and performance become key purchasing drivers, leading manufacturers are investing in eco-friendly coatings, recyclable fibers, and innovative weaves. Against this backdrop, the following list highlights the top 10 tent material fabric manufacturers shaping the industry through scale, innovation, and technical excellence.

Top 10 Tent Material Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

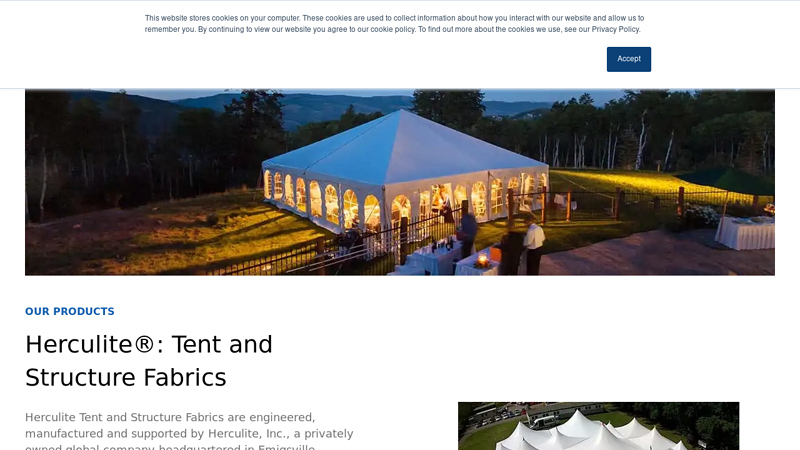

#1 American-Made Tent & Structure Fabrics

Domain Est. 1996

Website: herculite.com

Key Highlights: Herculite Tent and Structure Fabrics are engineered, manufactured and supported by Herculite, Inc., a privately owned global company headquartered in Emigsville ……

#2 Sattler PRO

Domain Est. 1996

Website: protex.sattler.com

Key Highlights: The SATTLER GROUP is one of the world’s leading manufacturers of special textiles for outdoor use and in the planning and realization of membrane constructions….

#3 Fabric Tent Wholesale: Fabrictent Homepage

Domain Est. 2002

Website: fabrictent.com

Key Highlights: We are a leading producer and distributor with an offering of over 500 patterns ranging from trims to jacquards….

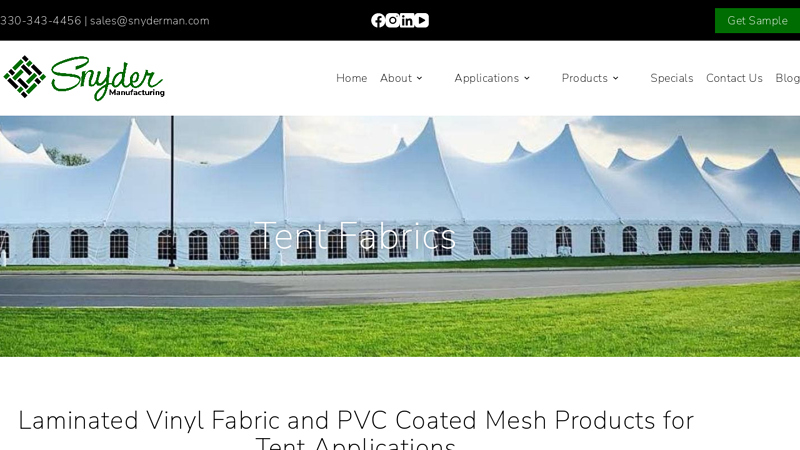

#4 Tent Fabrics

Domain Est. 1997

Website: snyderman.com

Key Highlights: Snyder Manufacturing is the industry leader in providing laminated vinyl fabric and PVC coated mesh products for the tent and structural fabric market….

#5 Royal TenCate

Domain Est. 1997

Website: tencate.com

Key Highlights: Royal TenCate used to be one company with multiple divisions in technical textiles, serving a wide range of applications areas….

#6 Davis Tent: Canvas Wall Tents

Domain Est. 1999

Website: davistent.com

Key Highlights: Davis Tent manufactures top quality handmade canvas tents and wall tents. Shop online for a wide selection of durable, affordable canvas tents!…

#7 Heytex technical textiles

Domain Est. 2001

Website: heytex.com

Key Highlights: Technical textiles made by Heytex can be used in virtually every field of application: as boat cover, pool cover, machine protection, oil barrier or roll-up ……

#8 Tent fabric

Domain Est. 2007

Website: tencateoutdoorfabrics.com

Key Highlights: TenCate offers a range of specialised fabrics, which are ideally suited for all areas of the camping and outdoor market….

#9 American

Domain Est. 2015

Website: diamondbrandgear.com

Key Highlights: Hand-sewn canvas wall tents for all of life’s adventures: outdoor hospitality, glamping, camping, scouting, festivals, catering and beyond….

#10 Temporary buildings & tents

Website: verseidag.de

Key Highlights: Verseidag has a selection of opaque, translucent and highly translucent materials for aluminium, steel and wooden structures. Airdomes, marquees, VIP tents, ……

Expert Sourcing Insights for Tent Material Fabric

H2: 2026 Market Trends for Tent Material Fabric

The global tent material fabric market is poised for significant transformation by 2026, driven by technological innovation, sustainability demands, and evolving consumer preferences across recreational, military, and emergency response sectors. Key trends shaping the market include:

1. Rising Demand for Lightweight and High-Performance Materials

Consumers and organizations increasingly prioritize portability and durability. Fabrics made from advanced synthetics such as silicone-coated nylon, high-tenacity polyester, and Dyneema composites are gaining traction due to their superior strength-to-weight ratios. These materials enhance ease of transport while maintaining resilience against UV exposure, abrasion, and extreme weather conditions—critical for outdoor enthusiasts and disaster relief operations.

2. Sustainability and Eco-Friendly Fabric Development

Environmental consciousness is reshaping material choices. By 2026, a growing number of manufacturers are expected to adopt recyclable, biodegradable, or bio-based tent fabrics. Water-based PU coatings and PFC-free DWR (durable water repellent) finishes are being integrated to reduce ecological footprints. Brands promoting circular economy principles—such as take-back programs and recyclable tent systems—are likely to gain competitive advantages.

3. Technological Integration and Smart Textiles

Smart tent fabrics embedded with solar-reactive coatings, temperature-regulating layers, or integrated sensors are emerging. These innovations cater to the growing demand for off-grid living, expedition-grade gear, and emergency shelters with self-sustaining capabilities. For example, photovoltaic-integrated canopies could power small electronics, enhancing functionality in remote areas.

4. Expansion in Emerging Markets and Humanitarian Applications

Rapid urbanization and increased awareness of disaster preparedness in Asia-Pacific, Africa, and Latin America are driving demand for affordable, durable tent fabrics. Governments and NGOs are investing in large-scale emergency shelter solutions, favoring materials that are quick to deploy, mold-resistant, and thermally efficient. This trend supports market growth in regions vulnerable to climate-related disasters.

5. Shift Toward Multi-Use and Modular Shelter Systems

The boundary between tents, temporary housing, and event structures is blurring. Consumers seek modular, reconfigurable designs adaptable for camping, glamping, and disaster relief. Fabric suppliers are responding with versatile textiles that support aesthetic appeal, structural integrity, and ease of assembly—often using modular pole systems and interlocking fabric panels.

6. Supply Chain Resilience and Regional Manufacturing

Post-pandemic, companies are diversifying supply chains and investing in localized production to mitigate disruptions. Nearshoring in North America and Europe, coupled with automation in fabric coating and laminating processes, is expected to improve lead times and reduce dependency on single-source suppliers—particularly those in Southeast Asia.

Conclusion

By 2026, the tent material fabric market will be characterized by innovation, sustainability, and adaptability. Key players who invest in R&D for high-performance, eco-conscious materials and respond to regional needs will lead the market. As outdoor recreation, climate challenges, and technological advancements converge, tent fabrics will evolve beyond mere shelter—they will become intelligent, sustainable, and integral components of modern living solutions.

Common Pitfalls When Sourcing Tent Material Fabric (Quality, IP)

Sourcing tent material fabric involves critical decisions that impact product performance, durability, and legal compliance. Overlooking key quality and intellectual property (IP) aspects can lead to product failure, customer dissatisfaction, or legal disputes. Below are common pitfalls to avoid:

Poor Fabric Quality and Performance

Inadequate Durability and Weather Resistance

Choosing fabrics without sufficient UV resistance, waterproofing, or tear strength can result in rapid degradation under outdoor conditions. Low-quality coatings or laminates may peel or delaminate, compromising the tent’s integrity.

Misaligned Fabric Specifications

Using incorrect denier, thread count, or coating weight for the intended application (e.g., using lightweight fabric for expedition tents) leads to structural failure or reduced lifespan.

Inconsistent Batch Quality

Sourcing from suppliers with poor quality control can result in variations in color, thickness, or performance between production batches, affecting brand consistency.

Lack of Environmental and Safety Compliance

Failing to verify compliance with REACH, RoHS, or Prop 65 regulations can lead to market access issues or recalls, especially when hazardous chemicals are present in dyes or coatings.

Intellectual Property Risks

Inadvertent Use of Patented Technologies

Some high-performance fabrics (e.g., ripstop weaves, specific silicone or PU coatings) may be protected by patents. Using them without authorization exposes the buyer to infringement claims.

Copying Branded or Proprietary Fabrics

Mimicking well-known branded materials (e.g., rip-offs of Cuben Fiber, Dyneema Composite Fabrics, or Gore-Tex) can result in trademark or design patent violations, even if the fabric is sourced from a third-party mill.

Supplier Misrepresentation of IP Status

Suppliers may claim their fabric is “equivalent” to a patented material, but such claims do not eliminate legal risk. Buyers remain liable if the product infringes on existing IP.

Unsecured Custom Fabric Development

When co-developing a custom fabric, failing to establish clear IP ownership in contracts can result in loss of rights or unexpected licensing fees if the supplier retains rights to the innovation.

Mitigation Strategies

- Conduct thorough due diligence on fabric performance specs and certifications.

- Request sample testing under real-world conditions (e.g., hydrostatic head, UV exposure).

- Verify IP status through patent searches and legal consultation.

- Include clear IP clauses in supplier agreements, especially for custom developments.

- Work with reputable, transparent suppliers who provide full material traceability and compliance documentation.

Avoiding these pitfalls ensures reliable product performance and protects your brand from legal and reputational risks.

Logistics & Compliance Guide for Tent Material Fabric

Overview

Tent material fabric, typically composed of synthetic textiles like polyester, nylon, or polyethylene with coatings such as PVC or PU, requires careful handling throughout the supply chain to ensure product integrity, regulatory compliance, and timely delivery. This guide outlines best practices and compliance considerations for the logistics of tent fabric materials.

Packaging Requirements

Proper packaging is essential to prevent damage during transit and storage.

– Roll Packaging: Fabric should be wound tightly on robust cardboard or plastic cores (typically 3” or 6” diameter) and wrapped with protective polyethylene film to guard against moisture and dust.

– Labeling: Each roll must be clearly labeled with product name, weight, width, length, batch/lot number, care instructions, and handling symbols (e.g., “Fragile,” “This Side Up”).

– Palletization: Rolls should be secured on wooden or plastic pallets using stretch wrap or strapping. Overhang should be minimized to prevent edge damage.

Storage Conditions

Maintain optimal environmental conditions to preserve fabric quality.

– Temperature & Humidity: Store in a dry, well-ventilated area with temperatures between 10°C and 30°C (50°F–86°F) and relative humidity under 65%.

– Light Exposure: Avoid prolonged exposure to direct sunlight or UV light to prevent degradation of coatings and color fading.

– Stacking: Limit stack height to prevent bottom rolls from being crushed. Use pallets and avoid floor storage to reduce moisture absorption.

Transportation Guidelines

Ensure safe and compliant transit across all modes.

– Containerized Shipping (Maritime/Intermodal):

– Use dry, clean, and pest-free containers.

– Place desiccant packs inside packaging or container to mitigate moisture.

– Secure loads with load bars or air bags to prevent shifting.

– Over-the-Road (Truck):

– Cover loads with waterproof tarps if transported on open trailers.

– Use edge protectors for banded loads.

– Air Freight:

– Required for time-sensitive shipments; ensure packaging meets IATA standards.

– Declare weight and dimensions accurately for cost and handling purposes.

Regulatory & Compliance Considerations

Adhere to international and regional standards based on destination.

– REACH (EU): Ensure no restricted substances (e.g., certain phthalates, heavy metals) exceed allowable thresholds in coated fabrics.

– RoHS (EU/UK): Apply if electronic components (e.g., conductive threads) are integrated.

– Flammability Standards:

– CPAI-84 (USA): Required for camping tents sold in North America; fabric must pass flame propagation tests.

– DIN 4102 (Germany): Classification for building materials; relevant if used in temporary structures.

– Customs Documentation:

– Provide accurate HS codes (e.g., 5903.90 for plastic-coated textile fabrics).

– Include commercial invoice, packing list, certificate of origin, and test reports (e.g., fire safety).

– EPA & TSCA (USA): Comply with chemical reporting requirements if importing synthetic fabrics with chemical treatments.

Quality Assurance & Traceability

Maintain consistency and accountability across the supply chain.

– Batch Tracking: Implement a system to trace raw materials, production batches, and shipping records.

– Pre-Shipment Inspection: Conduct quality checks for color consistency, coating adhesion, and dimensional accuracy.

– Certificates: Provide mill test certificates, fire retardancy certifications, and compliance declarations upon request.

Sustainability & Disposal

Address environmental impact and end-of-life considerations.

– Recycling: Advise customers on recyclability; PVC-coated fabrics may require specialized recycling.

– Packaging Materials: Use recyclable or biodegradable materials where possible.

– Waste Management: Follow local regulations for disposal of off-cuts or contaminated materials.

Emergency Response

Prepare for potential incidents during logistics.

– Spill or Contamination: In case of coating chemical leakage, follow local hazardous material protocols.

– Fire Risk: Store away from ignition sources; coated fabrics may emit toxic fumes when burned. Keep fire extinguishers (Class A/B) accessible.

Conclusion

Efficient logistics and strict compliance are critical for tent material fabric to ensure product performance and market access. By following these guidelines—from secure packaging and climate-controlled storage to regulatory documentation—suppliers and distributors can minimize risks and deliver high-quality materials globally.

Conclusion: Sourcing Tent Material Fabric

In conclusion, sourcing the right fabric for tent manufacturing is a critical decision that directly impacts the performance, durability, and overall value of the final product. After evaluating various materials such as polyester, nylon, polyethylene, and specialized fabrics like silicone-coated or PU-coated textiles, it is evident that the choice depends on the intended use—whether for recreational camping, commercial events, emergency shelter, or extreme weather conditions.

Key factors such as water resistance, UV stability, tear strength, weight, breathability, and ease of maintenance must be balanced against cost and sustainability goals. Additionally, partnering with reliable suppliers who adhere to quality standards and ethical production practices ensures long-term success and brand credibility.

Ultimately, investing time and resources in thorough material evaluation and supplier vetting leads to superior tent performance, customer satisfaction, and a competitive edge in the market. A well-informed sourcing strategy not only meets technical requirements but also supports environmental responsibility and innovation in outdoor and shelter solutions.