The global tensometer market is experiencing steady growth, driven by increasing demand for material testing across industries such as automotive, aerospace, construction, and consumer goods. According to Grand View Research, the global materials testing equipment market was valued at USD 5.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, fueled by stringent quality assurance protocols and regulatory standards. Similarly, Mordor Intelligence forecasts robust expansion in the sector, citing rising R&D investments and the need for high-precision testing instruments in emerging economies. As tensometers—critical for measuring tensile strength, elongation, and compression—become integral to product development and compliance, manufacturers are advancing capabilities in automation, load accuracy, and software integration. In this evolving landscape, nine key players have distinguished themselves through innovation, reliability, and comprehensive testing solutions.

Top 9 Tensometer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tension sensor

Domain Est. 2020

Website: china-tensionmeter.com

Key Highlights: China Shenyang Betten Technology Co., Ltd. provides tension meter, tensiometer, tension sensor, load sensors, winder, unwinder for various industries around ……

#2 Tensile Testing Applications

Domain Est. 1992

Website: mts.com

Key Highlights: Tensile testing with strain measurement techniques that can determine critical material properties including elastic modulus, tensile strength, ……

#3 Instron

Domain Est. 1996

Website: instron.com

Key Highlights: Instron manufactures tensile, compression, fatigue, impact, rheology, and structural testing machines, testing a variety of materials and range of ……

#4 Tinius Olsen

Domain Est. 1996

Website: tiniusolsen.com

Key Highlights: Tinius Olsen offers solutions for testing the strength and performance of plastics, metals, composites and many other materials….

#5 IRROMETER

Domain Est. 1996 | Founded: 1951

Website: irrometer.com

Key Highlights: Since 1951, we have been manufacturing soil water measurement equipment used around the world to improve irrigation. Our IRROMETER tensiometers and WATERMARK ……

#6 Tensitron

Domain Est. 1997

Website: tensitron.com

Key Highlights: Tensitron is recognized as the industry leader for designing and manufacturing precision tension meters, tension transducers, and custom tension measuring ……

#7 ZwickRoell Materials Testing

Domain Est. 2001

Website: zwickroell.com

Key Highlights: ZwickRoell is a worldwide leading supplier of materials testing machines. Our materials testing machines are used in R&D and for quality assurance in more ……

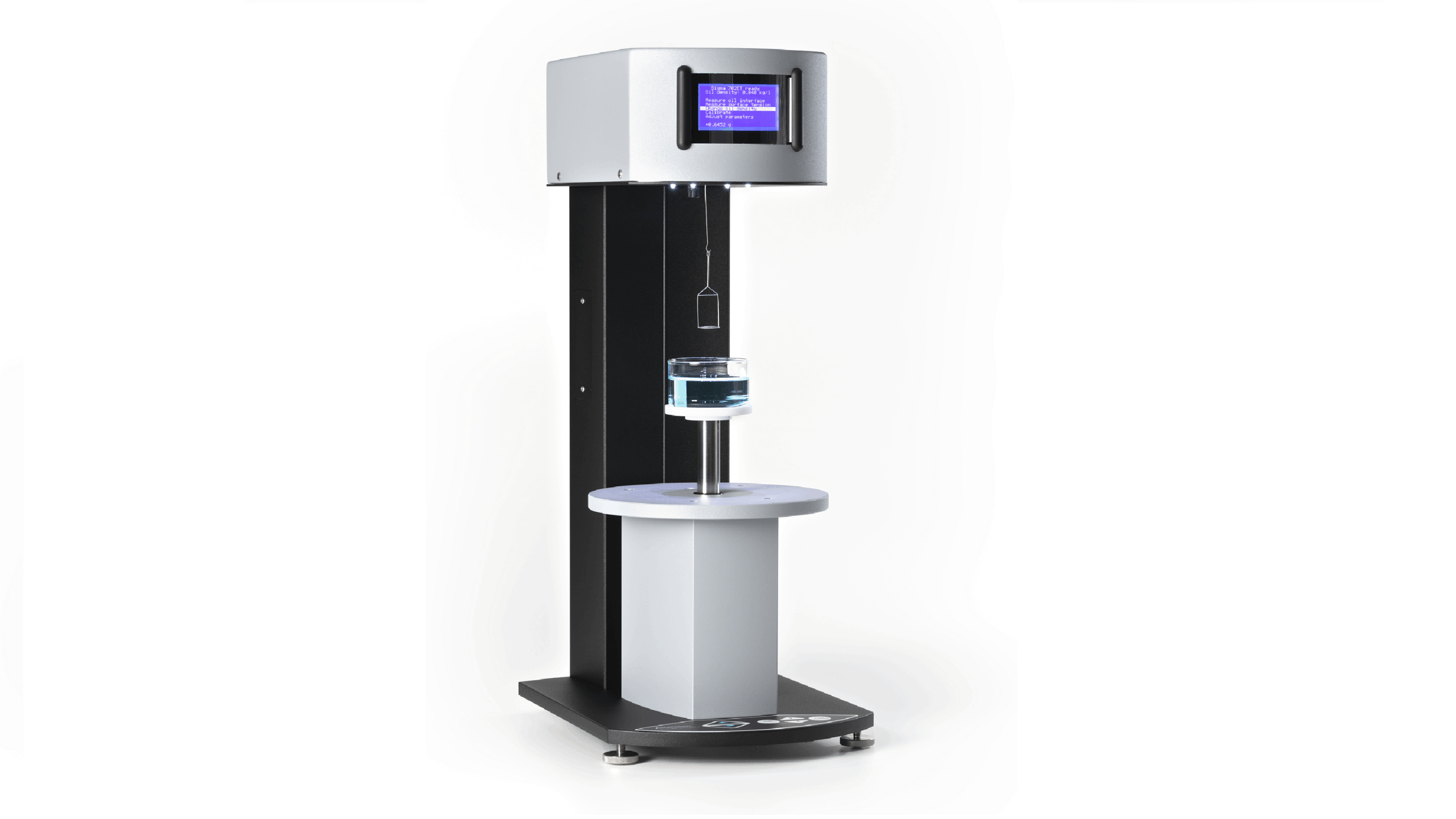

#8 Force Tensiometers

Domain Est. 2012

Website: dynetesting.com

Key Highlights: Sigma Force Tensiometers are precision instruments with unparalleled ease of use. They all feature high precision balances and mechanics, intuitive software ……

#9 Tensometer TS Series

Domain Est. 2017

Website: birdmancpl.com

Key Highlights: The TENSOMETER is very robust and rugged in design and has hardly any component outside the tube casing as a result of which no component can be damaged while ……

Expert Sourcing Insights for Tensometer

H2 2026 Market Trends Analysis for Tensometers

The tensometer market in H2 2026 is expected to be shaped by advanced technological integration, expanding industry demands, and a strong emphasis on automation and precision. Key trends include:

1. Increased Demand from Advanced Materials and R&D Sectors

By H2 2026, the growing development of high-performance materials—such as composites, nanomaterials, and advanced polymers in aerospace, electric vehicles (EVs), and renewable energy—will drive demand for high-precision tensometers. Research institutions and material science labs will require instruments capable of micro- and nano-scale tensile testing, pushing manufacturers to innovate in sensitivity and data resolution.

2. Integration of IoT and Smart Testing Systems

Tensometers will increasingly feature IoT connectivity, enabling real-time data monitoring, predictive maintenance, and cloud-based analytics. Smart tensile testing systems will allow remote operation, centralized quality control across global manufacturing sites, and seamless integration with enterprise resource planning (ERP) and product lifecycle management (PLM) systems—especially in automotive and industrial manufacturing.

3. Automation and AI-Driven Analytics

Automation in tensile testing will accelerate, with robotic sample handling and AI-powered software for data interpretation. In H2 2026, AI algorithms will assist in detecting material anomalies, optimizing test parameters, and improving repeatability. This trend will be particularly strong in high-throughput environments like semiconductor manufacturing and pharmaceutical packaging.

4. Growth in Regulatory and Quality Compliance Needs

Stringent regulatory standards in medical devices, construction, and aerospace will require more frequent and reliable material testing. Tensometers with certified calibration, audit trails, and compliance with ISO 6892, ASTM E8, and other standards will be in higher demand, especially in North America and Europe.

5. Expansion in Emerging Markets

Asia-Pacific—particularly India, Vietnam, and Indonesia—will see rising investments in infrastructure and manufacturing, boosting local demand for tensile testing equipment. Localized production and cost-effective digital tensometers will gain traction, supported by government initiatives promoting quality control.

6. Sustainability and Energy Efficiency in Design

Manufacturers will focus on producing energy-efficient tensometers with reduced environmental impact. Additionally, testing of sustainable and biodegradable materials will increase, requiring adaptation of tensile testing protocols and equipment.

Conclusion

By H2 2026, the tensometer market will be characterized by smarter, more connected, and highly precise testing solutions driven by digital transformation and evolving material science. Companies investing in automation, data intelligence, and global compliance will lead the market, while demand in emerging economies and high-tech industries continues to rise.

Common Pitfalls When Sourcing a Tensometer (Quality, IP)

Sourcing a tensometer (tensile testing machine) involves more than just comparing prices and specifications. Overlooking critical quality and intellectual property (IP) aspects can lead to significant long-term risks, including unreliable test results, regulatory non-compliance, and legal exposure. Below are key pitfalls to avoid:

1. Prioritizing Price Over Calibration and Certification

A common mistake is selecting a tensometer based primarily on cost, ignoring the importance of proper calibration and certification. Low-cost machines may lack traceable calibration to international standards (e.g., ISO 7500-1), leading to inaccurate measurements. Always verify that the supplier provides up-to-date, accredited calibration certificates and supports regular recalibration services.

2. Ignoring Build Quality and Material Specifications

Inferior tensometers often use substandard materials and components (e.g., low-grade load cells, non-precision guides), resulting in poor repeatability and premature wear. Ensure the machine is constructed with high-quality, durable materials suitable for your testing environment. Check for robust frame design, accurate load cell resolution, and compliance with relevant industry standards.

3. Overlooking Intellectual Property (IP) Risks

Sourcing from manufacturers with questionable IP practices—particularly in regions with lax enforcement—can expose your company to legal risks. Be cautious of machines that appear to replicate patented designs or software from established brands. Verify the supplier’s legitimacy, request documentation of IP ownership, and avoid vendors offering “compatible” or “clone” models that may infringe on existing patents.

4. Inadequate Software and Data Compliance

Modern tensometers rely heavily on proprietary software for data acquisition and analysis. Using unlicensed or pirated software not only violates IP rights but also compromises data integrity and auditability. Ensure the supplied software is genuine, regularly updated, and compliant with regulations such as 21 CFR Part 11 (for pharmaceutical applications) or ISO 17025.

5. Lack of Technical Support and Documentation

Poor-quality suppliers may fail to provide comprehensive user manuals, maintenance guides, or responsive technical support. This can hinder proper operation and troubleshooting. Confirm that the supplier offers accessible training, service support, and complete technical documentation—critical for maintaining consistent test quality and compliance.

6. Assuming All “IP-Rated” Claims Are Valid

Some suppliers may misleadingly claim their equipment meets certain IP (Ingress Protection) ratings for dust or moisture resistance without independent verification. If the tensometer will be used in harsh environments, request third-party certification (e.g., IEC 60529) and verify the actual protection level of electrical components and load cells.

By addressing these pitfalls early in the sourcing process, organizations can ensure they procure a reliable, compliant, and legally sound tensometer that delivers accurate and repeatable test results over its lifespan.

Logistics & Compliance Guide for Tensometer

Shipping and Transportation

Ensure the tensometer is securely packed using manufacturer-recommended packaging materials to prevent damage during transit. Utilize double-boxing with shock-absorbing padding, especially for international shipments. Clearly label the package as “Fragile” and “This Side Up.” Use a reputable courier service with tracking capabilities and insurance coverage. For air freight, comply with IATA regulations; for sea freight, adhere to IMDG Code guidelines if applicable. Maintain a chain of custody documentation throughout transit.

Import/Export Compliance

Verify that the tensometer complies with export control regulations such as the Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR), depending on the technical specifications and destination country. Obtain necessary export licenses if the device contains controlled technology. Ensure compliance with Harmonized System (HS) codes and provide accurate commercial invoices, packing lists, and certificates of origin. Screen end-users and destinations against denied party lists (e.g., BIS, EU, UN sanctions lists) prior to shipment.

Regulatory Approvals and Certifications

Confirm that the tensometer meets essential regulatory requirements in the destination market. This includes CE marking for the European Economic Area (under directives such as the Machinery Directive or RED, if applicable), FCC certification for electromagnetic compatibility in the United States, and PSE certification in Japan. Retain technical documentation, Declaration of Conformity, and test reports to demonstrate compliance upon request by customs or regulatory authorities.

Calibration and Documentation

Ship the tensometer with a valid calibration certificate traceable to national or international standards (e.g., NIST, ISO/IEC 17025). Include user manuals, safety data sheets (if applicable), and installation guides in the local language of the destination country. Maintain comprehensive records of calibration dates, service history, and compliance documentation for audit purposes.

Environmental and Disposal Compliance

Adhere to environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) for electronic components. Provide end-of-life disposal guidance in accordance with WEEE (Waste Electrical and Electronic Equipment) directives where applicable. Ensure batteries, if included, comply with UN38.3 testing requirements for safe transport.

Conclusion for Sourcing a Tensometer:

Sourcing a tensometer requires careful consideration of application requirements, accuracy standards, budget constraints, and long-term maintenance needs. After evaluating various suppliers, models, and technical specifications, it is essential to select a tensometer that not only meets current testing demands but also offers scalability for future needs. Factors such as load capacity, precision, software integration, compliance with international standards (e.g., ASTM, ISO), and after-sales support play a critical role in ensuring reliable and repeatable results.

Ultimately, the chosen tensometer should provide a balance between performance and cost-effectiveness while being backed by strong technical support and service. By conducting thorough market research and vendor assessments, the organization can make an informed procurement decision that enhances product quality, supports R&D efforts, and ensures compliance with industry regulations.