The global telecommunication cable market is undergoing robust expansion, driven by escalating demand for high-speed internet, 5G network deployment, and infrastructure modernization worldwide. According to a 2023 report by Mordor Intelligence, the market was valued at USD 24.62 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% over the forecast period (2023–2028). Similarly, Grand View Research estimates the market to exceed USD 37 billion by 2030, fueled by rising data consumption and the proliferation of data centers. As connectivity becomes a cornerstone of digital economies, manufacturers of telecommunication cables—ranging from fiber optic to coaxial solutions—are playing a pivotal role in enabling resilient and scalable networks. Against this backdrop, the following list highlights the top 10 telecommunication cable manufacturers leading innovation, quality, and market share in an increasingly competitive and evolving industry.

Top 10 Telecommunication Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Panduit

Domain Est. 1994

Website: panduit.com

Key Highlights: Panduit develops smarter, scalable network infrastructure and industrial electrical wiring solutions that unlock the full potential of your business….

#2 Belden

Domain Est. 1997

Website: belden.com

Key Highlights: We design, manufacture and market networking, connectivity, cable products and solutions for industrial automation, smart buildings and broadcast markets….

#3 Priority Wire & Cable

Domain Est. 1999

Website: prioritywire.com

Key Highlights: Priority Wire & Cable supplies wire & cable from the largest stock in the U.S. and offers same day shipping. This includes Industrial, Aluminum, and many ……

#4 Prysmian

Domain Est. 2005

Website: prysmian.com

Key Highlights: Welcome to Prysmian: the world leader in cable manufacturer, energy solutions, telecom cables and systems industry. Find out more!…

#5 Southwire

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Southwire for your wire and cable needs – we offer high-performance products that are built to last….

#6 Xtera

Domain Est. 1999

Website: xtera.com

Key Highlights: Xtera offers subsea networks and submarine cable solutions, providing turnkey solutions, project management and industry-leading suppliers….

#7 Nexans leads the way towards sustainable electrification

Domain Est. 2000

Website: nexans.com

Key Highlights: We are a global leader in electrification, driving the energy transition with innovative solutions that power a safer, sustainable, and connected future….

#8 Channell Commercial Corporation

Domain Est. 2003

Website: channell.com

Key Highlights: Channell has established itself as an industry leading full network solutions provider. We are constantly evolving our products to meet the changing needs of ……

#9 AFL

Domain Est. 2008

Website: aflglobal.com

Key Highlights: AFL is a leading provider of fiber optic solutions for broadband networks, data centers, energy infrastructure, and other applications….

#10 CommScope

Website: commscope.com

Key Highlights: Broadband & Access Network Systems; Cable Assemblies; Cable Management; Cables; Connectors; Faceplates & Boxes; Frames, Panels, Cassettes & Modules…

Expert Sourcing Insights for Telecommunication Cable

H2: 2026 Market Trends for Telecommunication Cable

The global telecommunication cable market is poised for significant transformation by 2026, driven by the rapid expansion of digital infrastructure, rising demand for high-speed connectivity, and the ongoing rollout of next-generation communication technologies. As the backbone of modern data transmission, telecommunication cables—including fiber optic, coaxial, and copper cables—are undergoing a strategic shift toward higher performance, scalability, and energy efficiency. Below are the key market trends expected to shape the industry in 2026:

1. Accelerated Adoption of Fiber Optic Cables

Fiber optic cables are expected to dominate the market by 2026, fueled by the global push for 5G deployment, FTTH (Fiber-to-the-Home) initiatives, and increasing demand for low-latency, high-bandwidth networks. Governments and private telecom operators are investing heavily in fiber infrastructure to support smart cities, cloud computing, and IoT ecosystems. According to industry forecasts, fiber optic cable segment growth will outpace other cable types, with a compound annual growth rate (CAGR) exceeding 9% through 2026.

2. 5G Network Expansion Driving Cable Demand

The continued rollout of 5G networks worldwide will necessitate extensive backhaul and fronthaul infrastructure, significantly increasing the demand for high-performance telecommunication cables. Densification of 5G networks requires more cell sites and small cells, which in turn rely on robust fiber connectivity. This trend is particularly strong in regions like North America, Europe, and parts of Asia-Pacific, where 5G adoption is advancing rapidly.

3. Rising Focus on Sustainable and Eco-Friendly Cabling

Environmental sustainability is becoming a key consideration in cable manufacturing and deployment. By 2026, leading manufacturers are expected to prioritize recyclable materials, reduced carbon footprints, and energy-efficient production processes. Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals are pushing the industry toward greener alternatives, including halogen-free and low-smoke cables.

4. Growth in Data Center Interconnectivity

The proliferation of hyperscale data centers and the need for inter-data center connectivity are boosting demand for high-capacity optical cables. As cloud services, AI, and big data analytics expand, data centers require faster and more reliable cabling solutions to handle massive data transfers. This trend supports the growing market for advanced fiber optic systems, including single-mode and multi-mode variants.

5. Increased Regional Investments in Broadband Infrastructure

Government-led broadband expansion programs—such as the U.S. BEAD (Broadband Equity, Access, and Deployment) Program and the European Gigabit Society initiative—are expected to drive telecommunication cable demand through 2026. Emerging markets in Latin America, Africa, and Southeast Asia are also investing in national broadband plans, creating new opportunities for cable suppliers.

6. Advancements in Cable Technology and Materials

Innovation in cable design—including bend-insensitive fibers, lightweight composite cables, and improved shielding—is enhancing performance and ease of installation. These technological improvements reduce deployment costs and increase reliability, making advanced cabling more accessible for both urban and remote deployments.

7. Supply Chain Resilience and Localization

Following recent global disruptions, telecommunication cable manufacturers are focusing on supply chain diversification and regional production. By 2026, localized manufacturing hubs are expected to rise, reducing dependency on single-source suppliers and improving delivery timelines—especially in response to geopolitical tensions and trade regulations.

Conclusion

By 2026, the telecommunication cable market will be characterized by a strong shift toward fiber optics, driven by 5G, digital infrastructure growth, and sustainability imperatives. Companies that invest in innovation, environmental responsibility, and strategic partnerships will be best positioned to capitalize on the expanding global demand for reliable and high-speed connectivity solutions.

Common Pitfalls When Sourcing Telecommunication Cable (Quality, IP)

Sourcing telecommunication cables involves more than just finding the lowest price. Overlooking key factors can lead to performance issues, security vulnerabilities, and costly downtime. Below are common pitfalls related to quality and intellectual property (IP) that procurement teams and network planners should avoid.

Inadequate Quality Assurance and Certification

One of the most frequent pitfalls is procuring cables without proper quality verification. Low-quality or counterfeit cables often fail to meet industry standards (such as ISO/IEC, TIA/EIA, or EN), resulting in poor signal integrity, higher attenuation, and increased network failures. Buyers may be tempted by competitive pricing but risk long-term reliability. Always demand third-party test reports, compliance certificates (e.g., UL, CE, RoHS), and conduct random batch testing to ensure conformity.

Counterfeit or Substandard Materials

Counterfeit cables are prevalent in global supply chains, especially in regions with weak regulatory oversight. These cables may use inferior conductors (e.g., copper-clad aluminum instead of pure copper), subpar insulation, or incorrect cable gauges, leading to overheating, signal loss, and safety hazards. To avoid this, source from reputable manufacturers, verify product markings, and work with trusted distributors who provide traceability.

Lack of IP Compliance and Risk of Infringement

Telecommunication cables, particularly high-performance or specialized types (e.g., fiber optics with proprietary designs or shielding technologies), may be protected by patents or trademarks. Sourcing cables that infringe on intellectual property can expose organizations to legal action, shipment seizures, and reputational damage. Always verify that suppliers have legitimate rights to manufacture and sell the cable technology and request documentation confirming IP clearance.

Insufficient Environmental and Durability Specifications

Cables used in outdoor, industrial, or harsh environments must meet specific IP (Ingress Protection) ratings and environmental standards (e.g., UV resistance, flame retardancy, rodent protection). Selecting generic indoor cables for outdoor deployment—often due to cost-cutting—can result in rapid degradation, water ingress, and network outages. Ensure cables are rated appropriately (e.g., IP67, IP68) for the intended installation environment.

Poor Documentation and Traceability

Lack of detailed product specifications, lot numbers, or manufacturer traceability makes it difficult to address quality issues or conduct recalls. This is especially critical in regulated industries or large infrastructure projects. Insist on comprehensive documentation, including material composition, test results, and country of origin, to support quality audits and compliance.

Overlooking Lifecycle and Future-Proofing

Choosing cables based solely on current needs without considering future bandwidth demands or technology upgrades can lead to premature obsolescence. For example, deploying Category 5e instead of Category 6A may save costs initially but limit scalability. Invest in cables that support evolving standards (e.g., higher frequency ratings, compatibility with PoE++) to extend network lifecycle and reduce replacement costs.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure reliable, secure, and compliant telecommunication infrastructure that supports long-term performance and operational continuity.

Logistics & Compliance Guide for Telecommunication Cable

Overview

Telecommunication cables are critical components in global connectivity infrastructure, used for transmitting data, voice, and video signals across networks. Efficient logistics and strict compliance with international regulations are essential for timely delivery, cost control, and legal operation. This guide outlines key considerations for managing the logistics and regulatory compliance of telecommunication cable shipments.

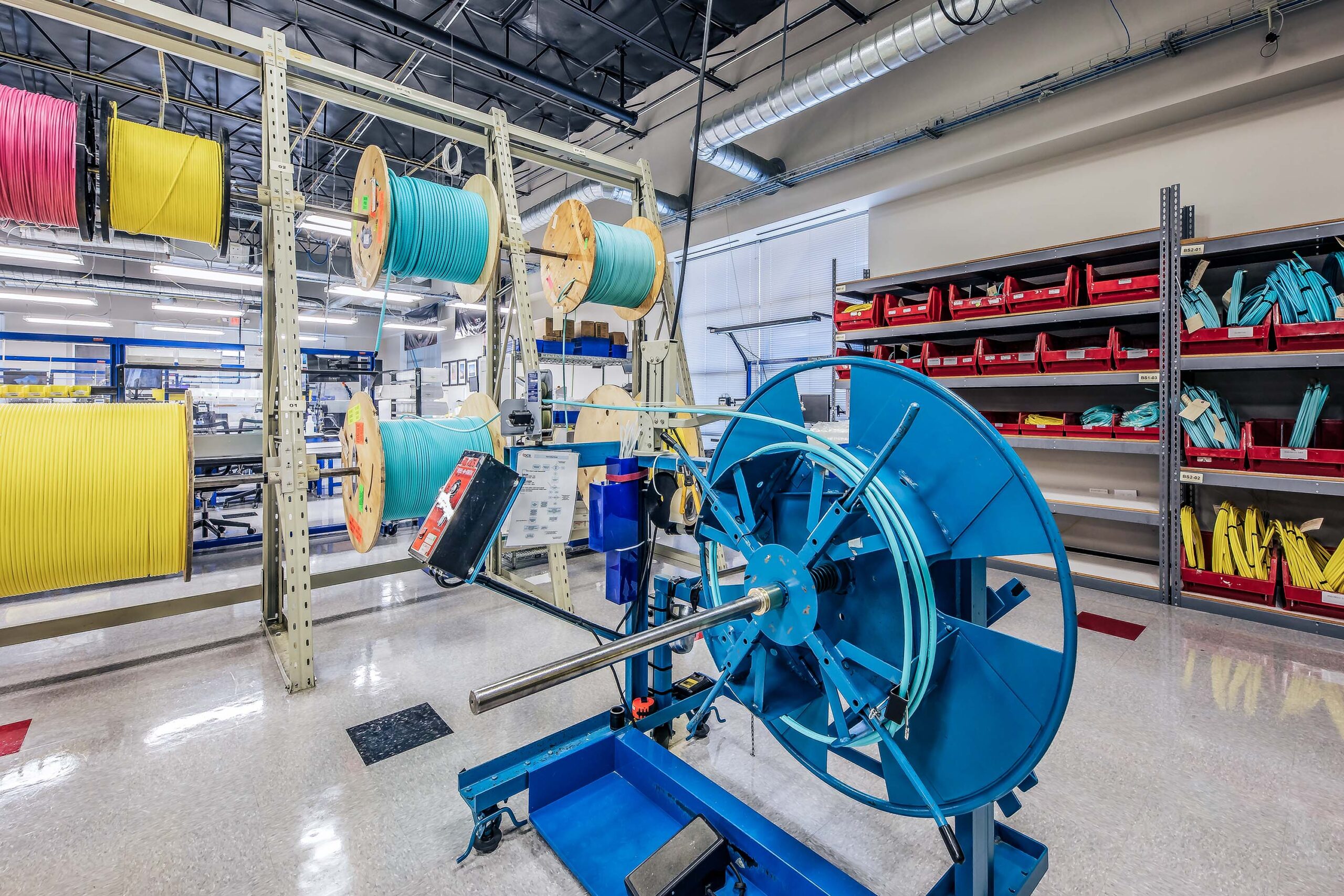

Packaging & Handling Requirements

Telecommunication cables are typically shipped on reels or drums to prevent damage during transit. Proper packaging is vital to maintain cable integrity. Use wooden or steel reels with protective end caps and moisture-resistant wrapping. Clearly label packages with handling instructions such as “This Way Up,” “Fragile,” and “Do Not Roll.” Avoid sharp bending or kinking during loading and unloading.

Transportation Modes

Choose the appropriate mode based on distance, urgency, and cost:

– Road: Ideal for regional or domestic distribution. Ensure vehicles have secure anchoring systems for reels.

– Rail: Cost-effective for long-haul domestic shipments with high volume.

– Sea: Most economical for international bulk shipments. Use ISO containers to protect against moisture and salt exposure.

– Air: Used for urgent deliveries or high-value components. Limited by weight and size restrictions.

Storage Conditions

Store cables in dry, climate-controlled environments away from direct sunlight, chemicals, and extreme temperatures. Reels should be stored vertically on flat surfaces to prevent warping. Avoid stacking unless designed for it. Monitor humidity levels to prevent insulation degradation.

Customs Documentation

Ensure all shipments include accurate and complete documentation:

– Commercial Invoice

– Packing List

– Bill of Lading (or Air Waybill)

– Certificate of Origin

– Import/Export Licenses (if required)

– Product Specifications (cable type, length, materials)

Regulatory Compliance

Compliance with local and international standards is mandatory:

– RoHS (Restriction of Hazardous Substances): Ensure cables are free of lead, mercury, cadmium, and other restricted substances (EU Directive 2011/65/EU).

– REACH: Comply with chemical safety regulations for substances of very high concern (SVHC).

– CE Marking: Required for sale in the European Economic Area, indicating conformity with health, safety, and environmental standards.

– FCC Regulations (USA): Follow Part 68 rules for terminal equipment and Part 15 for electromagnetic interference (EMI) limits.

– UL/CSA Certification: Required in North America for fire safety and electrical performance.

– ITU-T Recommendations: Follow International Telecommunication Union standards for cable performance and interoperability.

Environmental & Safety Regulations

- WEEE (Waste Electrical and Electronic Equipment): Producers may be responsible for recycling end-of-life cables in the EU.

- Conflict Minerals Compliance: Verify sourcing of materials like tantalum, tin, tungsten, and gold (required under U.S. Dodd-Frank Act Section 1502).

- IMDG Code: If transporting hazardous materials (e.g., cables with lead sheathing), comply with International Maritime Dangerous Goods regulations.

Import/Export Controls

Check if telecommunication cables are subject to export controls under:

– Wassenaar Arrangement: Controls on dual-use goods and technologies.

– EAR (Export Administration Regulations, USA): Determine if cables or associated technologies require an export license.

– Sanctions Lists: Screen end-users and destinations against OFAC, EU, and UN sanctions.

Labeling & Traceability

Each reel must include:

– Manufacturer name and logo

– Cable type and specifications (e.g., Cat6, fiber optic type)

– Length and batch/serial number

– Compliance marks (CE, UL, RoHS, etc.)

– Date of manufacture

Maintain traceability through batch tracking systems for quality control and recalls.

Insurance & Risk Management

Insure shipments against risks such as damage, theft, and delay. Specify coverage for high-value consignments and consider cargo insurance tailored for electronics. Conduct regular risk assessments of logistics partners and routes.

Vendor & Carrier Qualification

Select logistics providers with experience in handling heavy, bulky cable reels. Verify their compliance with ISO 9001 (quality management) and ISO 14001 (environmental management). Audit carriers for secure handling practices and regulatory adherence.

Sustainability Considerations

- Use recyclable packaging materials.

- Optimize load planning to reduce carbon footprint.

- Partner with suppliers committed to environmental responsibility.

- Plan reverse logistics for cable reel return or recycling.

Conclusion

Successful logistics and compliance management for telecommunication cables require coordination across packaging, transportation, documentation, and regulatory frameworks. Staying updated on international standards and maintaining strong supplier relationships ensures reliable delivery and legal compliance throughout the supply chain.

Conclusion for Sourcing Telecommunication Cable:

In conclusion, sourcing telecommunication cables requires a strategic approach that balances quality, cost, reliability, and compliance with industry standards. Selecting the right supplier involves evaluating factors such as product specifications (e.g., bandwidth, durability, shielding), certifications (e.g., ISO, RoHS, CPR), lead times, and after-sales support. Partnering with reputable suppliers who demonstrate technical expertise and consistent manufacturing standards ensures the long-term performance and scalability of telecommunications infrastructure. Additionally, considering future-proofing aspects such as fiber optic readiness and evolving industry demands will enhance network resilience. Ultimately, a well-informed sourcing strategy supports seamless connectivity, reduces downtime, and delivers lasting value across telecommunication projects.