The global construction and DIY sectors are driving strong demand for fasteners, with the tek screw market—known for its self-drilling capabilities in metal and wood—experiencing steady expansion. According to Grand View Research, the global screws market was valued at USD 100.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. A key contributor to this growth is the increasing use of structural screws in metal framing, roofing, and HVAC applications, where tek screws offer superior speed and efficiency. Mordor Intelligence also projects robust growth in the fasteners market, citing rising infrastructure development and industrial automation as key drivers. With demand escalating, especially in North America and Asia-Pacific, identifying the top-performing tek screw manufacturers has become critical for contractors, distributors, and procurement teams aiming to balance performance, reliability, and cost-effectiveness.

Top 5 Tek Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#2 Specialty Fastening Solutions for the Commercial Construction …

Domain Est. 1996

Website: itwbuildex.com

Key Highlights: We manufacture self-drilling and tapping screws, anchors, toggles, and other fastening systems under the Teks, Sammys, Dec-King, EZ Ancor, and Rock-On-brands….

#3 Tek Screws

Domain Est. 1996

Website: teksupply.com

Key Highlights: Self drilling screw for fastening to aluminum and steel. No pre-drilling, cuts its own threads. Unslotted hex washer heads….

#4 Self Drilling (Tek) Screws

Domain Est. 1996

#5 Teks Screws

Domain Est. 2018

Website: teksscrews.com

Key Highlights: Drill, Tap, Fasten in One Motion. Teks® Metal Fasteners are the original self-drilling screws developed to drill, tap, and fasten metal in one motion….

Expert Sourcing Insights for Tek Screws

H2: Market Trends for Tek Screws in 2026

As we approach 2026, the global market for Tek Screws—high-performance, self-drilling and self-tapping fasteners widely used in metal, construction, and industrial applications—is undergoing significant transformation driven by macroeconomic shifts, technological innovation, sustainability demands, and evolving end-user industries. Below is an analysis of key market trends shaping the Tek Screws sector in 2026:

-

Growth in Construction and Infrastructure Sectors

Global infrastructure investments, particularly in emerging economies and North America’s rebuild initiatives, are driving demand for efficient fastening solutions. Tek Screws, known for their speed and reliability in structural steel and metal roofing applications, are benefiting from the rise in commercial, industrial, and residential construction projects. Public-private partnerships in infrastructure are further accelerating adoption, especially in regions like Southeast Asia, the Middle East, and Eastern Europe. -

Expansion in Renewable Energy Applications

The surge in solar panel installations and wind turbine construction is a major growth vector for Tek Screws. These fasteners are critical in mounting systems due to their corrosion resistance and ability to secure materials without pre-drilling. In 2026, with renewable energy capacity expanding under global decarbonization goals, demand for high-grade, weather-resistant Tek Screws with specialized coatings (e.g., zinc-aluminum or ceramic) is at an all-time high. -

Technological Advancements and Smart Fastening Systems

Tek Screw manufacturers are integrating advanced materials and precision engineering to improve performance. Innovations include enhanced thread designs for better torque control, improved drill points for faster penetration, and compatibility with automated installation tools. In 2026, smart fastening systems—where Tek Screws are used in conjunction with IoT-enabled power tools for real-time installation tracking—are gaining traction in industrial automation and large-scale construction. -

Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG commitments are pushing manufacturers to adopt sustainable production practices. Tek Screw producers are increasingly using recycled steel and eco-friendly coating technologies. Additionally, product longevity and recyclability are becoming key selling points. In 2026, leading brands are marketing “green” Tek Screw lines certified by environmental standards (e.g., EPD, Cradle to Cradle), appealing to environmentally conscious contractors and OEMs. -

Supply Chain Localization and Resilience

Following disruptions in recent years, companies are reshoring or nearshoring production. In 2026, many Tek Screw manufacturers are establishing regional production facilities in North America, India, and Eastern Europe to reduce dependency on Asian imports and improve delivery times. This trend supports just-in-time construction schedules and mitigates geopolitical and logistics risks. -

Increased Competition and Price Sensitivity

While demand is rising, the market is becoming more competitive, especially with low-cost producers from Asia. In response, premium Tek Screw brands are differentiating through quality, technical support, and application-specific solutions. Value-added services such as engineering consultations and digital product catalogs are becoming standard to maintain margins in a price-sensitive environment. -

Digitalization and E-Commerce Adoption

Distribution channels are shifting rapidly. By 2026, B2B e-commerce platforms dominate procurement for fasteners, enabling contractors and distributors to access product specs, inventory, and technical data instantly. Augmented reality (AR) tools for product visualization and AI-driven inventory forecasting are being integrated into major platforms, enhancing customer experience and operational efficiency.

Conclusion

The Tek Screws market in 2026 is defined by innovation, sustainability, and digital transformation. Companies that invest in R&D, adopt circular economy principles, and leverage digital tools will gain a competitive edge. With strong tailwinds from construction, renewables, and industrial automation, the Tek Screw industry is poised for steady growth—provided it adapts to evolving customer needs and global challenges.

Common Pitfalls When Sourcing Tek Screws (Quality, IP)

Sourcing Tek Screws—self-drilling, high-strength fasteners commonly used in structural steel and metal roofing applications—requires careful attention to detail. Overlooking key factors can lead to compromised performance, safety risks, and project delays. Below are common pitfalls related to quality and intellectual property (IP) concerns.

Poor Quality Control and Material Substitution

One of the most frequent issues when sourcing Tek Screws is receiving products that do not meet specified strength, durability, or dimensional standards. Many suppliers, especially low-cost offshore manufacturers, may substitute lower-grade materials (e.g., substandard steel or inadequate coatings) to cut costs. This results in screws that strip easily, fail under load, or corrode prematurely—particularly in harsh environments.

Signs of poor quality:

– Inconsistent thread formation or head geometry

– Flaking or uneven coating (e.g., zinc or Geomet®)

– Screws that break during installation

– Lack of traceability or material certifications

Always request certified mill test reports (MTRs) and verify compliance with ASTM or ISO standards (e.g., ASTM C1513 for structural screws).

Misrepresentation of Intellectual Property and Brand Authenticity

“Tek Screw” is a registered trademark of Illinois Tool Works Inc. (ITW), specifically associated with their popular product line. A common pitfall is sourcing counterfeit or imitation screws labeled as “Tek” or “TEK®” without authorization. These knock-offs may mimic the appearance but lack the rigorous testing, heat treatment, and quality control of genuine ITW products.

IP-related risks include:

– Purchasing unauthorized clones marketed as “equivalent” or “compatible”

– Legal exposure for using counterfeit branded products in commercial projects

– Voided warranties and liability if fastener failure causes damage

To avoid IP issues, clearly specify whether you require genuine ITW Tek Screws or certified equivalents compliant with the same technical standards.

Inadequate Corrosion Protection for Intended Environment

Many low-quality or misrepresented Tek Screws use inferior corrosion-resistant coatings that fail to meet IP (Ingress Protection) or environmental exposure requirements. For example, using standard zinc-coated screws in coastal or high-humidity areas can lead to rapid rusting.

Best practice: Match the coating type (e.g., hot-dip galvanized, stainless steel, or proprietary coatings like Dura Screw® or Geomet®) to the project’s environmental conditions and longevity requirements. Verify coating thickness and salt spray test results (e.g., ASTM B117).

Lack of Technical Documentation and Compliance

Reputable suppliers provide comprehensive technical data sheets, load ratings, and installation guidelines. Sourcing from vendors who cannot supply such documentation increases the risk of using screws unsuitable for structural applications.

Always confirm:

– Compliance with building codes (e.g., IBC, AISI)

– Load testing data for specific materials and thicknesses

– Proper certification for use in seismic or high-wind zones

Conclusion

To avoid quality and IP pitfalls when sourcing Tek Screws, work with reputable, authorized distributors, insist on full documentation, and clearly define technical and compliance requirements in procurement contracts. When in doubt, opt for genuine branded products or certified equivalents from trusted manufacturers.

Logistics & Compliance Guide for Tek Screws

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence related to Tek Screws—a high-performance fastening solution commonly used in construction, manufacturing, and metal-to-metal applications.

Product Classification and Specifications

Tek Screws (also known as self-drilling or self-piercing screws) are typically made from hardened steel with a drill-point tip, allowing them to penetrate metal without pre-drilling. They are often coated (e.g., zinc, ceramic, or corrosion-resistant finishes) to meet environmental durability standards. Proper classification under international trade codes (e.g., HS Code 7318.15 for threaded screws) is critical for customs clearance and tariff assessment.

Packaging and Labeling Requirements

- Packaging: Tek Screws should be packed in moisture-resistant containers (e.g., sealed polybags inside sturdy cardboard boxes or steel drums for bulk shipments) to prevent corrosion during transit.

- Labeling: Each package must include:

- Product name and part number

- Quantity and weight (net/gross)

- Material specification (e.g., Grade 4.8, 8.8)

- Coating type (e.g., Zn-plated, HDG)

- Manufacturer name and country of origin

- Batch/lot number for traceability

- Handling symbols (e.g., “Fragile,” “Keep Dry”)

Transportation and Handling

- Mode of Transport: Tek Screws can be shipped via road, rail, sea, or air. For international shipments, containerized ocean freight is most cost-effective.

- Storage Conditions: Store in a dry, temperature-controlled environment to prevent rust. Avoid direct contact with concrete floors or outdoor exposure.

- Handling: Use appropriate lifting equipment for palletized loads. Avoid dropping or impact, which may damage screw tips or coatings.

Customs and Import Compliance

- Documentation: Ensure all shipments include:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (required for preferential tariffs under trade agreements)

- Material Test Reports (if requested)

- Duties and Tariffs: Verify applicable import duties based on destination country and HS code. Some regions may impose anti-dumping duties on fasteners from certain countries.

- Import Restrictions: Confirm that product coatings (e.g., hexavalent chromium) comply with local environmental regulations such as REACH (EU) or TSCA (USA).

Regulatory and Safety Compliance

- REACH (EU): Ensure no restricted substances (e.g., lead, cadmium) exceed allowable limits in coatings or base materials.

- RoHS (EU): Applies if screws are used in electrical/electronic equipment.

- OSHA (USA): Provide safe handling guidelines to prevent injury during use; Material Safety Data Sheets (MSDS) are not typically required for metal fasteners but may be provided upon request.

- ISO Standards: Tek Screws should comply with relevant ISO standards (e.g., ISO 10666 for self-drilling screws).

Environmental and Sustainability Considerations

- Recyclability: Steel screws are 100% recyclable. Include end-of-life recycling guidance in product literature.

- Packaging Waste: Use recyclable or reusable packaging materials where possible to meet environmental regulations and customer sustainability goals.

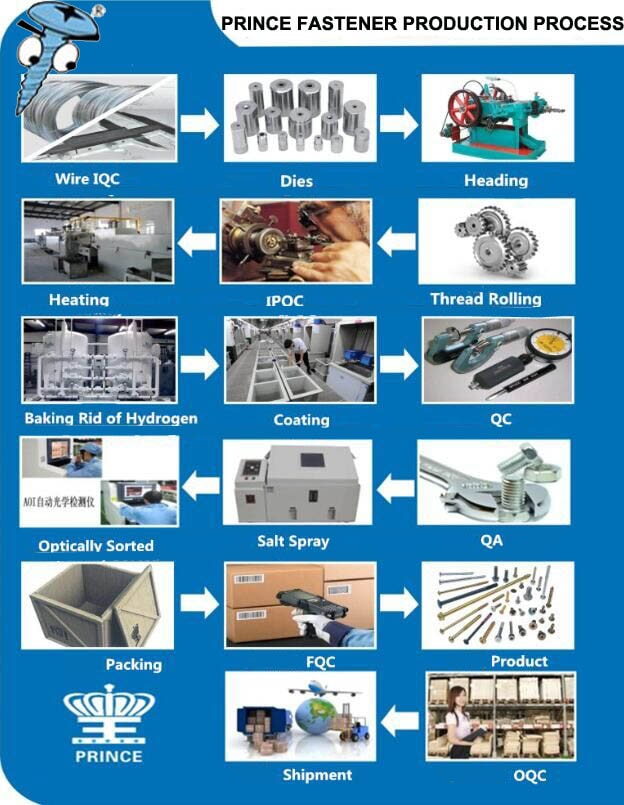

Quality Assurance and Traceability

- Maintain batch-level traceability from raw material sourcing through production and shipping.

- Implement a quality control process that includes:

- Dimensional inspection

- Torque and drive testing

- Salt spray testing for coating durability

- Provide test certificates upon request (e.g., EN 14592 for construction fasteners).

Returns and Non-Conformance Handling

- Establish a clear returns process for damaged or non-compliant shipments.

- Investigate root causes of non-conformance and document corrective actions.

- Coordinate with logistics partners for reverse logistics, ensuring returned goods are quarantined and assessed.

By adhering to this logistics and compliance guide, distributors, importers, and users of Tek Screws can ensure smooth operations, regulatory compliance, and product integrity across the supply chain.

Conclusion for Sourcing TEK Screws:

In conclusion, sourcing TEK screws requires a strategic approach that balances quality, cost, reliability, and compliance with project-specific requirements. By evaluating suppliers based on material quality (typically carbon steel, stainless steel, or coated variants), thread design, drive type, corrosion resistance, and adherence to industry standards (such as ASTM or ISO), organizations can ensure optimal performance in applications like metal-to-metal fastening, construction, and HVAC systems.

Establishing partnerships with reputable suppliers, conducting sample testing, and considering long-term logistics—such as lead times and minimum order quantities—further enhances supply chain efficiency. Additionally, prioritizing sustainability and supplier certifications can support corporate responsibility goals.

Ultimately, a well-informed sourcing decision ensures the durability, safety, and cost-effectiveness of TEK screw applications, contributing to overall project success and operational reliability.