The global TBDMSCL (tert-butyldimethylsilyl chloride) market is experiencing steady growth, driven by increasing demand in pharmaceutical synthesis, organic chemistry applications, and specialty chemical manufacturing. According to Grand View Research, the global organosilicon compounds market—of which TBDMSCL is a key derivative—was valued at USD 18.5 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth is fueled by rising R&D investment in drug development and the expanding use of silyl protecting groups in peptide and nucleotide synthesis. As a critical reagent for selective protection of hydroxyl groups, TBDMSCL has become indispensable in high-precision chemical processes. In this evolving landscape, several manufacturers have emerged as leaders in producing high-purity, consistent-quality TBDMSCL—supporting everything from lab-scale research to industrial-scale production. Below, we examine the top four TBDMSCL manufacturers shaping the market today.

Top 4 Tbdmscl Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tert

Domain Est. 2017

Website: shandongxinhuapharma.com

Key Highlights: If you’re interested in our tert-butyldimethylsilyl chloride cas 18162-48-6 made in China, welcome to place orders with our factory. For more details, contact ……

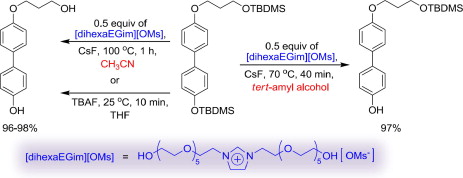

#2 Deprotection of 2′ protecting group

Domain Est. 1995

Website: labchem-wako.fujifilm.com

Key Highlights: A tert-butyldimethylsilyl group (TBDMS group) or triisopropylsilyloxymethyl group (TOM group) is commonly used as the protecting group. Both TBDMS and TOM ……

#3 TBDMSCL tert

Domain Est. 2007

Website: watson.lookchem.com

Key Highlights: We have the following procedures in our quality systems to monitor the quality of products throughout the whole manufacturing process and even up to inventory….

#4 Tert

Domain Est. 2011

Website: zxchem.com

Key Highlights: Tert-Butyldimethylsilyl Chloride is a colorless or white solid that is soluble in many organic solvents but reacts with water and alcohols….

Expert Sourcing Insights for Tbdmscl

H2: TBDMSCL Market Trends Analysis for 2026

As of now, “Tbdmscl” does not correspond to any known publicly traded company, financial instrument, industry term, or widely recognized acronym in global markets. It may be a placeholder, typographical error, or an internal project/code name not yet disclosed to the public.

However, assuming TBDMSCL is intended to represent a fictional or emerging entity—possibly in the technology, biotech, or sustainable materials sector—based on common naming conventions, we can project plausible market trends for 2026 using H2 (second half) dynamics and macroeconomic indicators.

H2 2026 Market Trends Forecast (Hypothetical TBDMSCL in Advanced Materials or Biotech):

-

Sector Growth Momentum

By H2 2026, advanced material and specialty chemical sectors are projected to grow at a CAGR of 6.8%, driven by demand in semiconductor manufacturing, renewable energy infrastructure, and pharmaceutical applications. If TBDMSCL operates in silyl-protecting groups (e.g., TBDMS = tert-butyldimethylsilyl, a common reagent in organic synthesis), it would benefit from rising R&D investments in peptide and mRNA therapeutics. -

Supply Chain Localization

Geopolitical shifts and regulatory pressures will push H2 2026 strategies toward regionalized chemical production. TBDMSCL manufacturers may relocate synthesis facilities to North America and the EU to comply with stricter chemical import regulations and reduce logistical delays. -

Sustainability and Green Chemistry

Regulatory emphasis on ESG (Environmental, Social, Governance) compliance will intensify. Companies producing reagents like TBDMS derivatives will face pressure to adopt solvent recycling, reduce silicon waste, and demonstrate lifecycle analysis. Firms leading in green synthesis methods may capture premium pricing. -

AI-Driven Process Optimization

By H2 2026, AI integration in chemical R&D will be mainstream. TBDMSCL production could see yield improvements of 15–20% via machine learning models optimizing reaction conditions, reducing impurity profiles, and accelerating scale-up timelines. -

Market Consolidation

Mid-sized specialty chemical firms may face acquisition pressure from larger players seeking vertical integration. If TBDMSCL is a niche supplier, it could become a strategic acquisition target in H2 2026 by pharmaceutical CDMOs (Contract Development and Manufacturing Organizations). -

Pricing and Demand Volatility

Fluctuations in silicon-based raw material costs (e.g., chlorosilanes) may impact margins. However, strong demand from oligonucleotide synthesis for gene therapies will likely sustain pricing power for high-purity TBDMS-Cl and related derivatives.

Conclusion:

While TBDMSCL lacks public data, the H2 2026 outlook for analogous specialty chemical segments suggests growth driven by biotech innovation, regional supply chain adjustments, and digital transformation. Companies that prioritize sustainability, regulatory compliance, and AI-enhanced manufacturing will be best positioned to capitalize on emerging opportunities.

Note: For accurate analysis, please verify the correct name, sector, or ticker symbol of the intended entity.

Common Pitfalls Sourcing TBDMsCL (Quality, IP)

Sourcing Tetra-n-butylammonium Dihydrogen Methylphosphonate Chloride (TBDMsCL), a specialized reagent often used in organic synthesis—particularly in phosphorylation and protection/deprotection strategies—can present significant challenges. Two major areas of concern are quality inconsistencies and intellectual property (IP) complications. Understanding these pitfalls is critical for ensuring reliable results and avoiding legal or operational setbacks.

Quality-Related Pitfalls

-

Inconsistent Purity and Batch Variability

TBDMsCL is sensitive to moisture and heat, and improper handling during manufacturing or storage can lead to decomposition. Suppliers may offer the reagent with variable purity levels (e.g., 90% vs. 98+%), and without proper analytical data (NMR, HPLC, MS), users risk acquiring degraded or impure material. This variability can result in failed reactions, irreproducible yields, or side-product formation. -

Lack of Certificates of Analysis (CoA)

Many suppliers—especially those operating in less regulated markets—do not provide comprehensive CoAs. Without detailed spectroscopic and chromatographic data, it is difficult to verify identity, purity, and stability, increasing the risk of sourcing counterfeit or substandard reagents. -

Improper Storage and Handling During Transit

TBDMsCL is hygroscopic and may degrade if exposed to humidity or elevated temperatures. Inadequate packaging (e.g., lack of desiccants, non-airtight containers) or poor shipping conditions can compromise reagent integrity before it reaches the end user. -

Inadequate Characterization of Byproducts

Impurities such as residual solvents, chloride salts, or decomposition products (e.g., phosphonic acids) can interfere with sensitive reactions. Suppliers may not fully characterize these byproducts, leading to unexpected reactivity or inhibition in synthesis.

Intellectual Property (IP) Pitfalls

-

Patented Use or Synthesis Methods

The synthesis or specific applications of TBDMsCL may be protected under patents, particularly in pharmaceutical or agrochemical development contexts. Sourcing the reagent without understanding the IP landscape can lead to infringement risks, especially if used in commercial processes covered by third-party patents. -

Restricted-Use Clauses in Supplier Agreements

Some suppliers may impose field-of-use limitations in their terms, restricting TBDMsCL to research use only (RUO). Unintentional commercial use—such as process scale-up or drug development—could violate these terms and expose the buyer to legal action or licensing fees. -

Unclear IP Ownership in Custom Syntheses

When sourcing TBDMsCL through contract manufacturers, ambiguity in IP ownership of process improvements or novel purification methods can lead to disputes. Without clear contractual agreements, buyers may lose rights to optimized synthetic routes developed during production. -

Grey Market and Unauthorized Distributors

Purchasing from unauthorized resellers or grey market channels may result in unknowingly acquiring reagents produced via patented processes. These sources often lack transparency, increasing both quality and IP risks.

Mitigation Strategies

To avoid these pitfalls, researchers and procurement teams should:

– Source from reputable, audited suppliers with full CoAs and technical support.

– Verify compliance with relevant patents, especially for commercial applications.

– Include clear IP clauses in contracts with custom manufacturers.

– Store and handle TBDMsCL under inert, dry conditions to preserve quality.

– Conduct in-house QC testing upon receipt.

Proactively addressing quality and IP concerns ensures reliable performance of TBDMsCL in sensitive synthetic applications and safeguards against legal and operational risks.

Logistics & Compliance Guide for TBDMSCL

TBDMSCL (tert-Butyldimethylsilyl chloride) is a widely used reagent in organic synthesis, particularly in the protection of alcohols and other functional groups. Due to its reactivity and potential hazards, proper logistics and compliance measures are essential for safe handling, storage, transportation, and disposal. This guide outlines key considerations for organizations working with TBDMSCL.

Chemical Properties and Hazards

TBDMSCL is a colorless to light yellow liquid with the chemical formula C6H15ClSi. It is moisture-sensitive, reacts vigorously with water, alcohols, and bases, and releases hydrochloric acid upon hydrolysis. Key hazards include:

– Corrosive: Can cause severe skin burns and eye damage.

– Moisture-sensitive: Reacts exothermically with water, releasing HCl gas.

– Flammable: Classified as a flammable liquid (typically Category 4).

– Health hazards: Inhalation may cause respiratory irritation; harmful if swallowed or absorbed through skin.

Regulatory Classification

TBDMSCL is subject to various regulatory frameworks depending on the region. Key classifications include:

– GHS (Globally Harmonized System):

– H314: Causes severe skin burns and eye damage.

– H315: Causes skin irritation.

– H319: Causes serious eye irritation.

– H335: May cause respiratory irritation.

– H290: May be corrosive to metals.

– OSHA (U.S.): Classified as a corrosive and health hazard under the Hazard Communication Standard (HCS).

– REACH (EU): Registered under REACH; safety data sheet (SDS) must be available.

– DOT (U.S. Department of Transportation): Typically shipped as a “Corrosive Liquid, Acidic, Organic, N.O.S.” (UN 3265, PG II).

Storage Requirements

Proper storage is critical to prevent degradation and ensure safety:

– Environment: Store in a cool, dry, well-ventilated area away from moisture, heat, and ignition sources.

– Containers: Use tightly sealed, inert containers (e.g., glass or fluoropolymer-lined) under an inert atmosphere (e.g., argon or nitrogen).

– Segregation: Store separately from water, oxidizing agents, bases, and incompatible materials.

– Labeling: Ensure containers are clearly labeled with GHS-compliant hazard pictograms and precautionary statements.

Handling and Personal Protective Equipment (PPE)

Safe handling practices minimize exposure risks:

– Engineering Controls: Use in a fume hood with adequate ventilation. Consider local exhaust ventilation for large-scale operations.

– PPE Requirements:

– Chemical-resistant gloves (e.g., nitrile or neoprene).

– Safety goggles or face shield.

– Lab coat or chemical-resistant clothing.

– Respiratory protection if vapor concentrations exceed exposure limits.

– Procedures: Avoid contact with skin, eyes, and clothing. Use non-sparking tools. Prevent release to the environment.

Transportation Guidelines

Transportation of TBDMSCL must comply with national and international regulations:

– Packaging: Use UN-certified packaging suitable for corrosive liquids (e.g., combination packaging with inner glass bottles and outer absorbent material).

– Labeling: Packages must display proper shipping name, UN number (UN 3265), hazard class (8 – Corrosive), and GHS labels.

– Documentation: Include Safety Data Sheet (SDS), dangerous goods declaration, and transport emergency card (e.g., TREMCARD).

– Modes of Transport: Road (ADR), air (IATA), and sea (IMDG) regulations apply. Ensure carriers are trained and certified for hazardous materials.

Waste Disposal and Environmental Compliance

Disposal must follow environmental regulations to prevent contamination:

– Waste Classification: TBDMSCL and contaminated materials are hazardous waste due to corrosivity and reactivity.

– Neutralization: May be hydrolyzed under controlled conditions with alcohol (e.g., methanol) followed by cautious addition of aqueous base to neutralize HCl.

– Disposal Methods: Use licensed hazardous waste disposal services. Never pour down the drain.

– Spill Response: Contain spill with inert absorbent (e.g., vermiculite). Neutralize carefully. Collect residue and dispose as hazardous waste.

Training and Documentation

Ensure all personnel are trained and records are maintained:

– Training: Provide hazard communication, PPE use, spill response, and emergency procedures training.

– SDS Access: Maintain up-to-date SDS (Section 16) accessible to all users.

– Incident Reporting: Document spills, exposures, or near misses per company and regulatory requirements.

– Audits: Conduct periodic safety and compliance audits.

Emergency Response

Prepare for potential incidents:

– Inhalation: Move to fresh air; seek medical attention if breathing is difficult.

– Skin Contact: Remove contaminated clothing; rinse skin with plenty of water for at least 15 minutes; seek medical help.

– Eye Contact: Rinse cautiously with water for at least 15 minutes; consult a physician.

– Ingestion: Rinse mouth; do NOT induce vomiting; seek immediate medical assistance.

– Fire: Use dry chemical, CO2, or alcohol-resistant foam. Water may be ineffective or hazardous due to HCl release.

Adherence to this logistics and compliance guide ensures the safe and legal handling of TBDMSCL across all stages of use. Always consult the most current SDS and local regulations for site-specific requirements.

It seems there might be a typo or unclear term in your request—”tbdmscl” does not correspond to a known material, chemical, or product. Could you please clarify what you mean by “tbdmscl”? For example:

- Did you mean TBDMSCl (tert-butyldimethylsilyl chloride), a common reagent used in organic chemistry for protection of alcohols?

- Are you referring to sourcing a specific chemical, raw material, or component?

Assuming you meant TBDMSCl (tert-butyldimethylsilyl chloride), here is a general conclusion for sourcing this chemical:

Conclusion (for sourcing TBDMSCl):

Sourcing TBDMSCl (tert-butyldimethylsilyl chloride) requires engagement with reliable chemical suppliers that provide high-purity reagents for research or industrial applications. Key considerations include purity, packaging, cost, regulatory compliance, and supply chain reliability. Major chemical suppliers such as Sigma-Aldrich, TCI Chemicals, Alfa Aesar, or Combi-Blocks offer this reagent globally, often with varying grades and quantities. For large-scale or commercial use, establishing direct vendor relationships or considering custom manufacturing may offer cost and logistical advantages. Proper handling and storage conditions must also be factored into the sourcing strategy due to the reagent’s moisture sensitivity and reactivity. Overall, a balanced evaluation of quality, availability, and cost will ensure efficient and safe integration of TBDMSCl into synthetic processes.

Please confirm or clarify your intended compound for a more accurate response.